All-plastic miniature one-way valve and machining method thereof

A processing method and one-way valve technology, which can be applied to control valves, valve devices, functional valve types, etc., can solve the problems of low processing rate, unsuitable for mass production, complex process, etc., and achieve high production efficiency and are conducive to etching. The effect of simple processing and craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

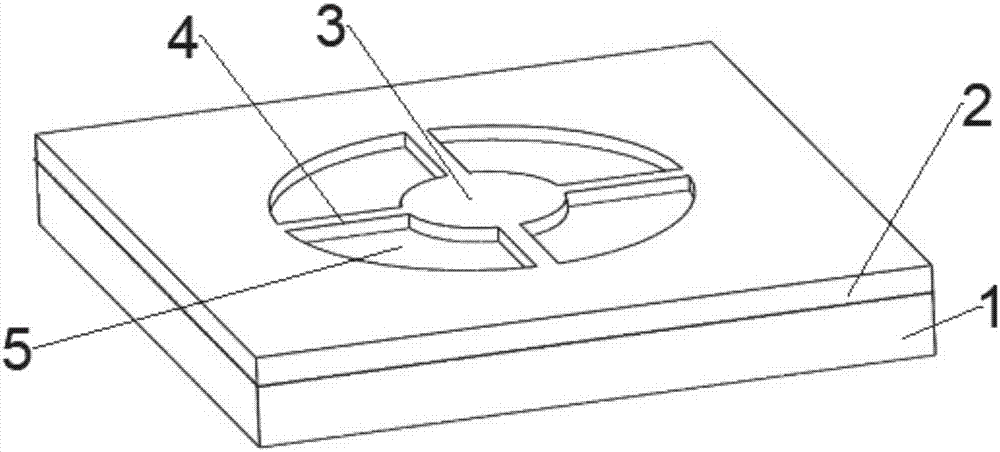

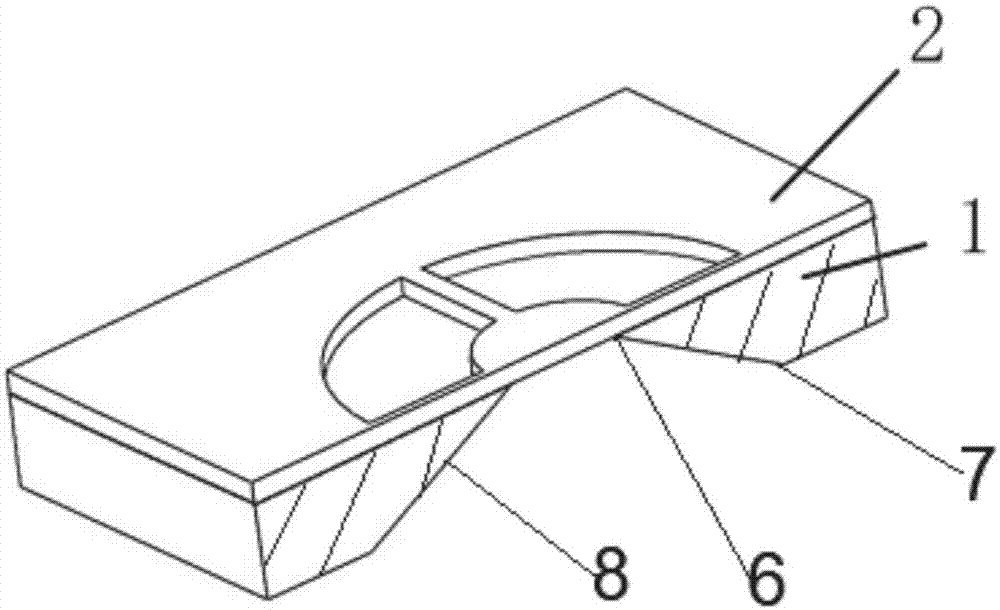

[0037] Such as figure 1 and 2 Shown are the structural schematic diagram and the cross-sectional structural schematic diagram of an all-plastic miniature one-way valve provided by the present invention, respectively. Comprising a PMMA substrate 1 and a PDMS valve membrane 2, the PMMA substrate 1 is provided with a conical through hole 8, the PDMS valve membrane 2 covers the substrate side of the conical through hole narrow end 6, the PDMS valve membrane 2 is provided with four fan-shaped through-holes 5 arranged in a ring around a circular diaphragm 3 in the middle. The area of the circular diaphragm 3 is larger than the narrow end 6 of the conical through-hole, and completely covers the narrow end 6 of the conical through-hole. The fluid flow path of the miniature one-way valve is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com