Toilet cleaning brush with integral toilet plunger

a technology of toilet plunger and toilet cleaning brush, which is applied in the direction of brushes, hollow-piece cleaning, mechanical equipment, etc., can solve the problems of inferior substitute for diaphragm, poor support of sponge collar, and inability to unclog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

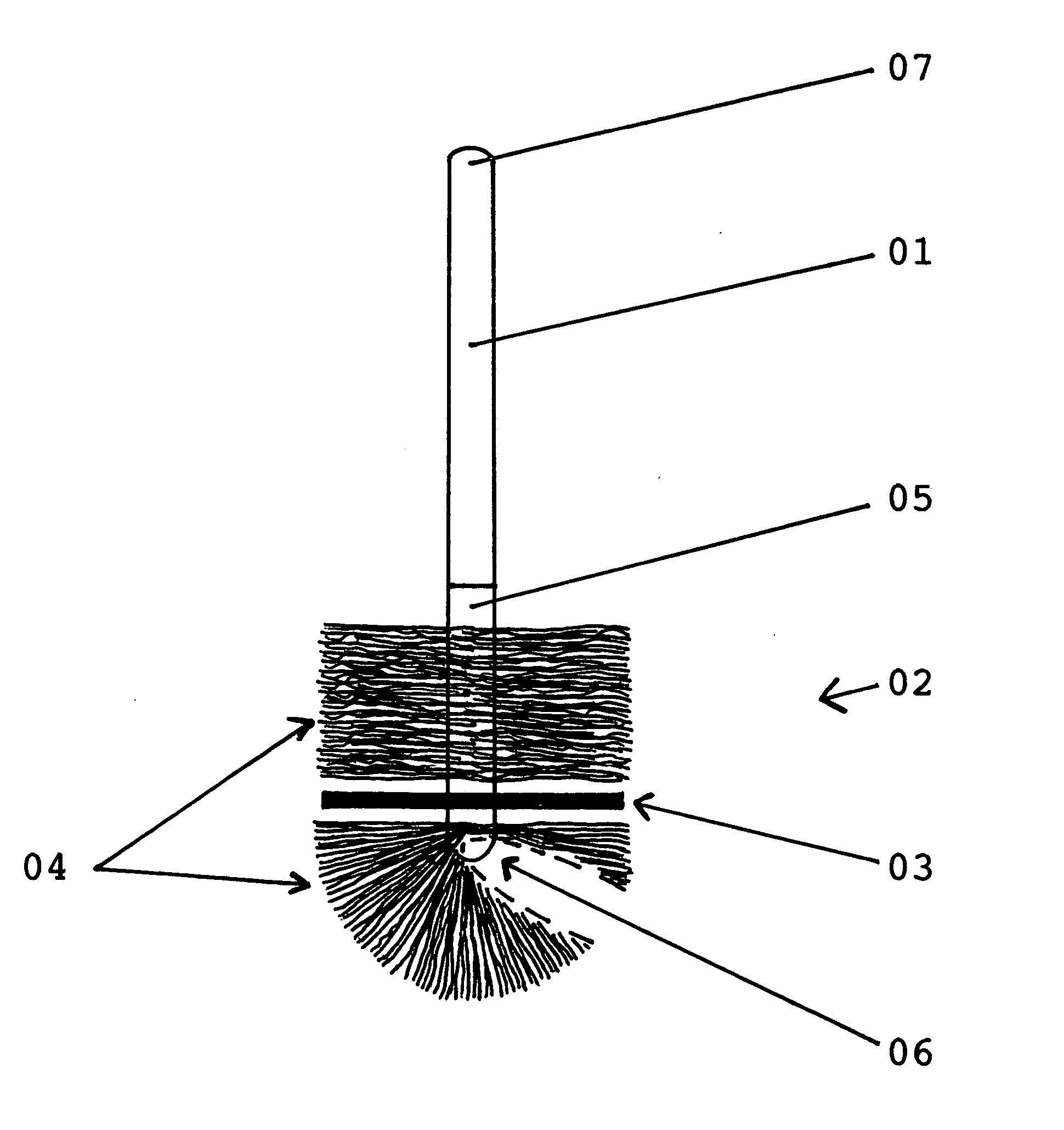

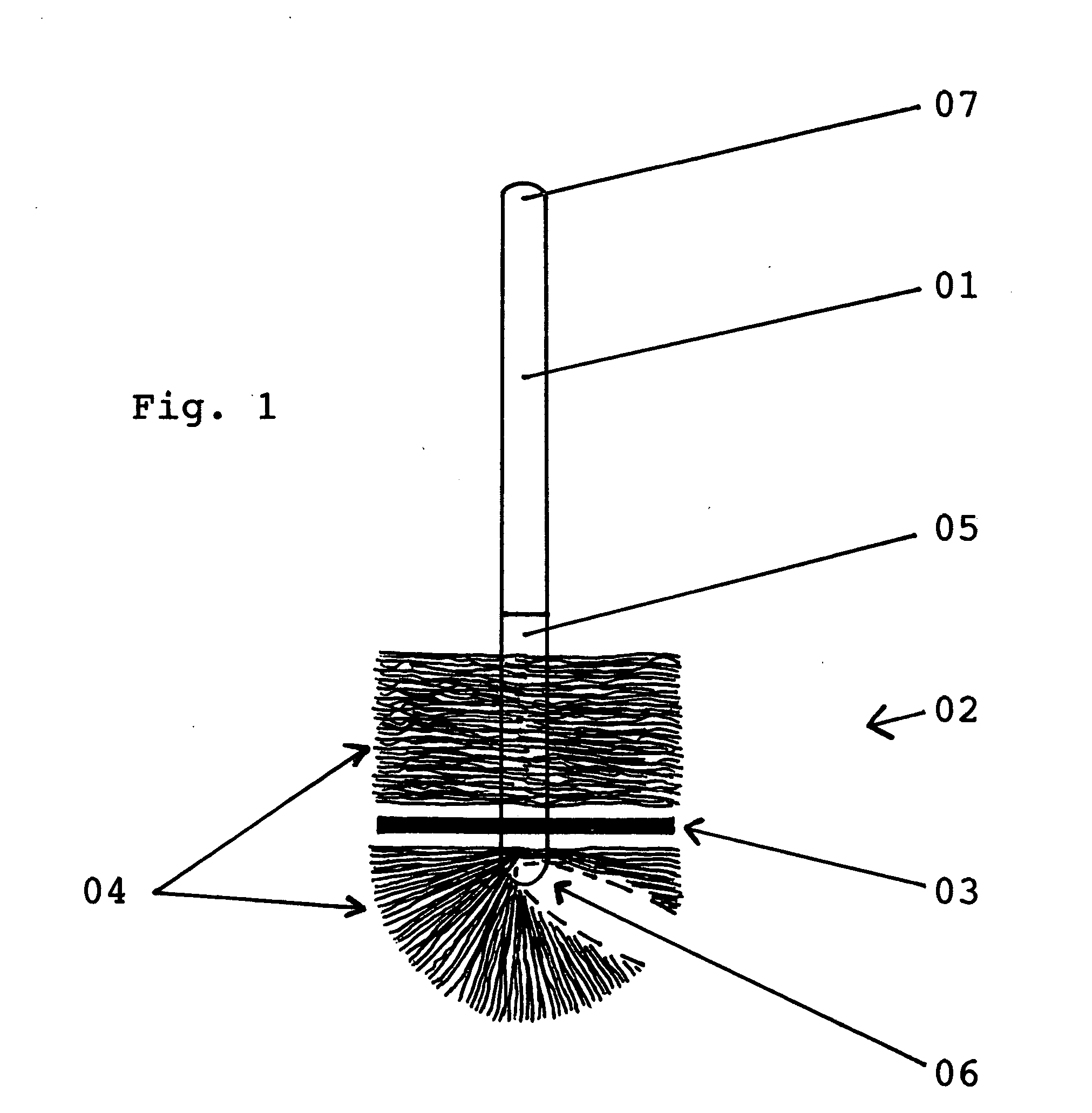

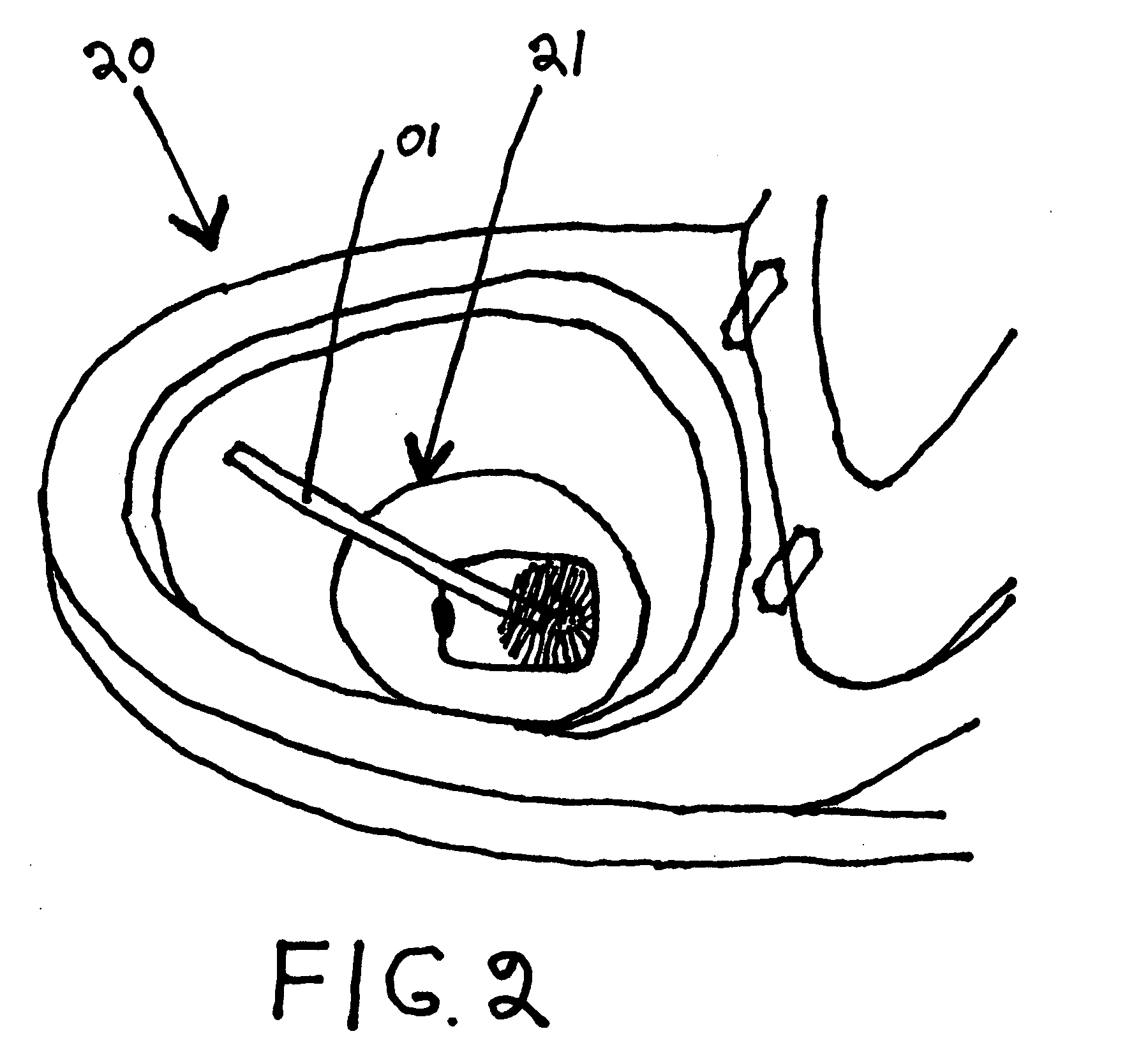

[0109] The current invention is shown in FIG. 1. Handle 01 connects to head 02. Head 02 includes diaphragm 03 and scrubber 04 and shaft 05. The end of shaft 05 is identified as tip 06. The end of handle 01 opposite head 02 is top 07.

[0110] The current invention performs two functions: (1) it operates as a conventional cylindrical toilet cleaning brush for toilet-surface-cleaning, and (2) it operates as a toilet plunger for toilet-trap-unclogging.

[0111] To make the current invention: first build or obtain an ordinary cylindrical toilet cleaning brush. Those skilled in the art will readily understand how to make a standard toilet cleaning brush; that detail will be skipped here. Refer to FIG. 1 for the style of brush referred to herein. Then, make diaphragm 03: cut a circle of 40 mil PVC sheet to the diameter of scrubber 04; cut a round hole in the center of the PVC circle to match the diameter of shaft 05. Finally, install the PVC circle on shaft 05, near tip 06, leaving a ring of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com