Patents

Literature

966results about "Pipe units with cleaning apertures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

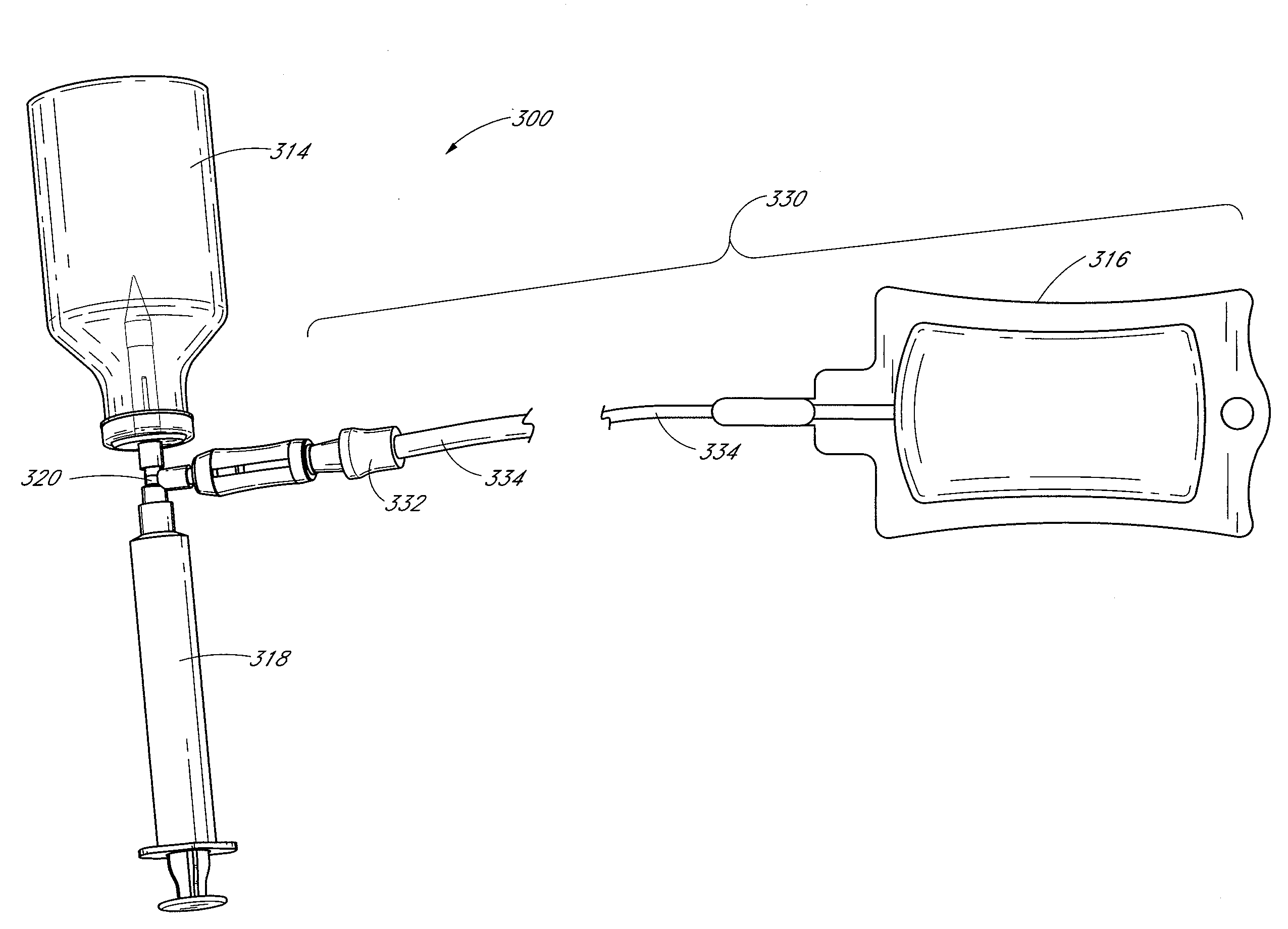

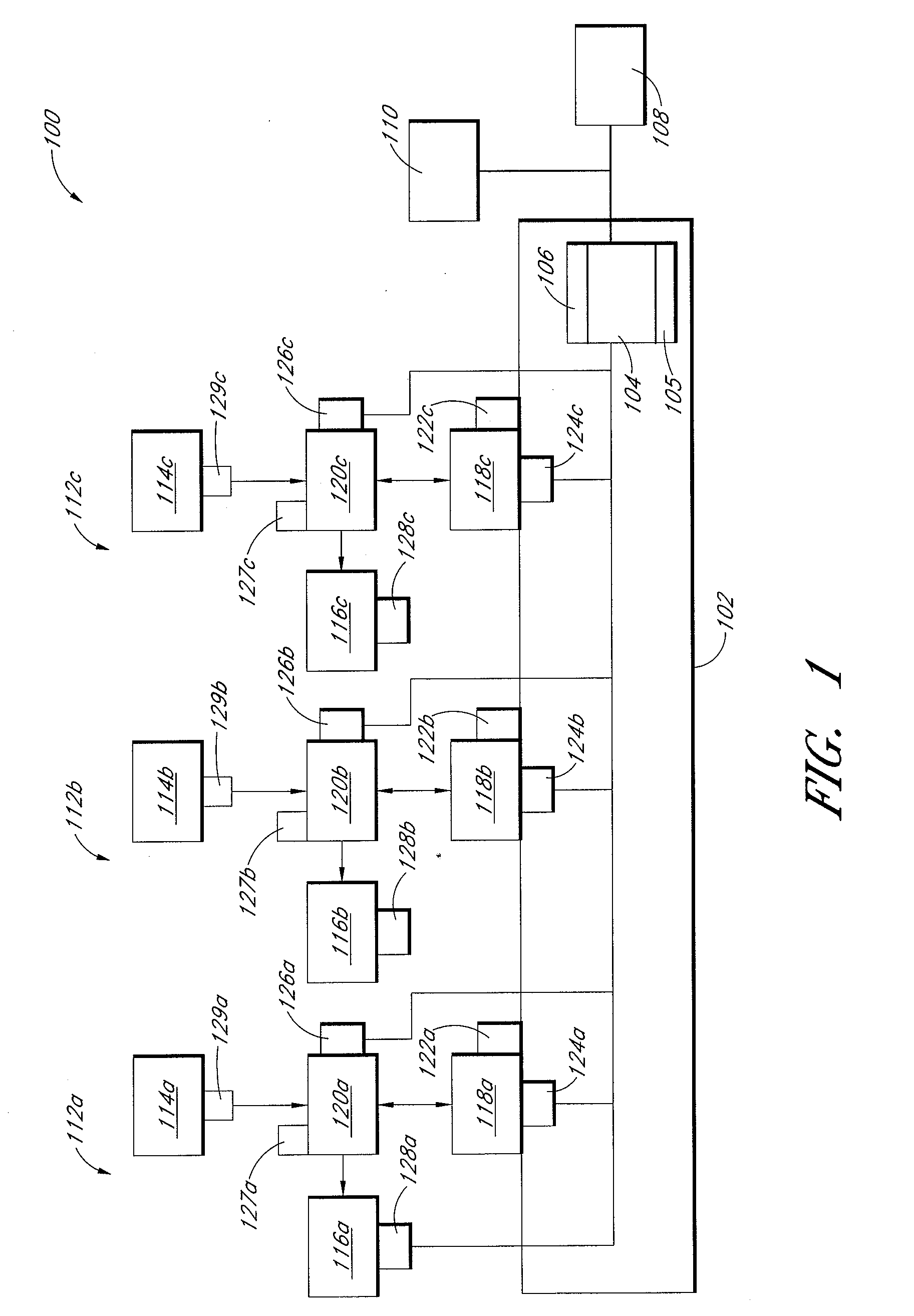

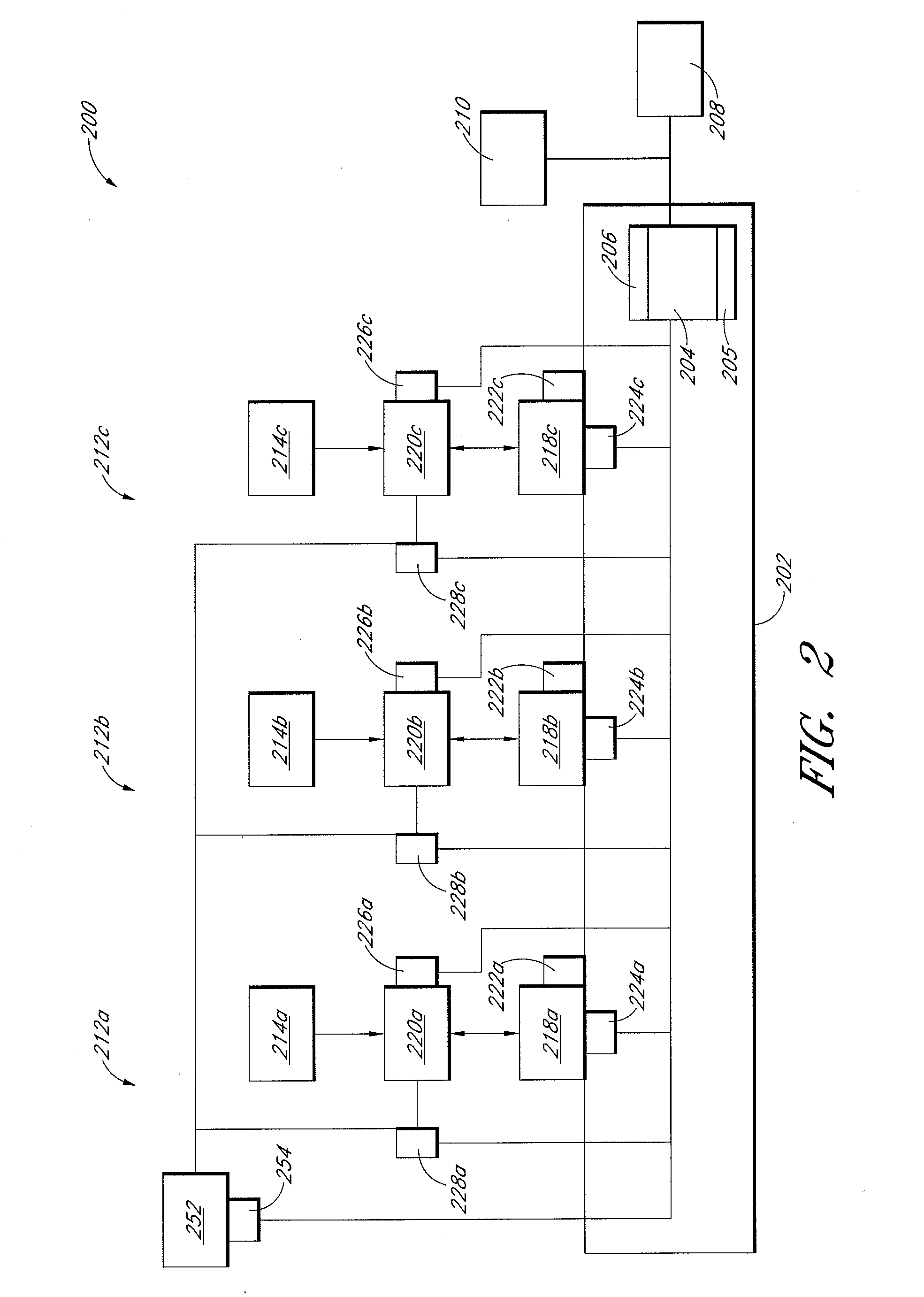

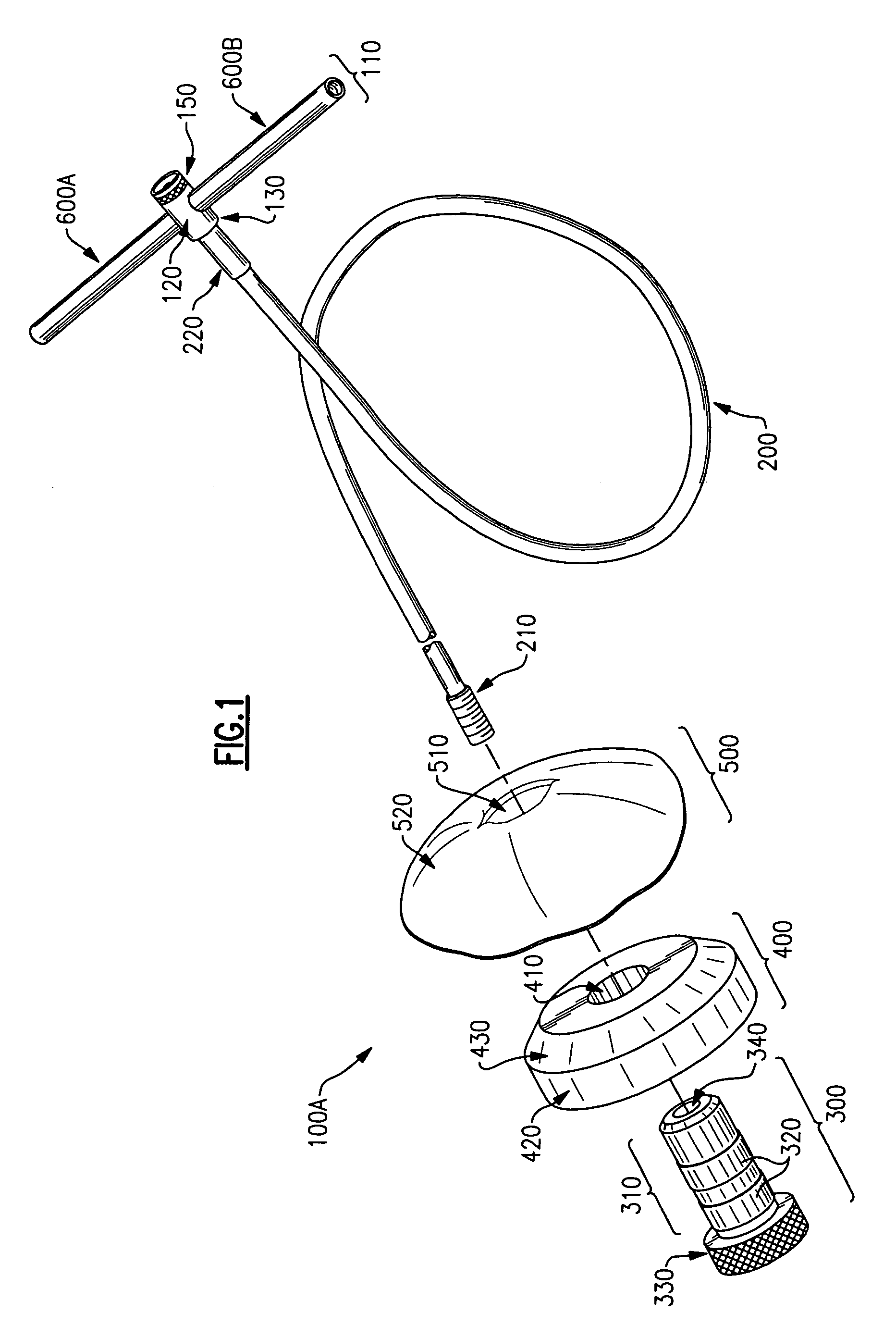

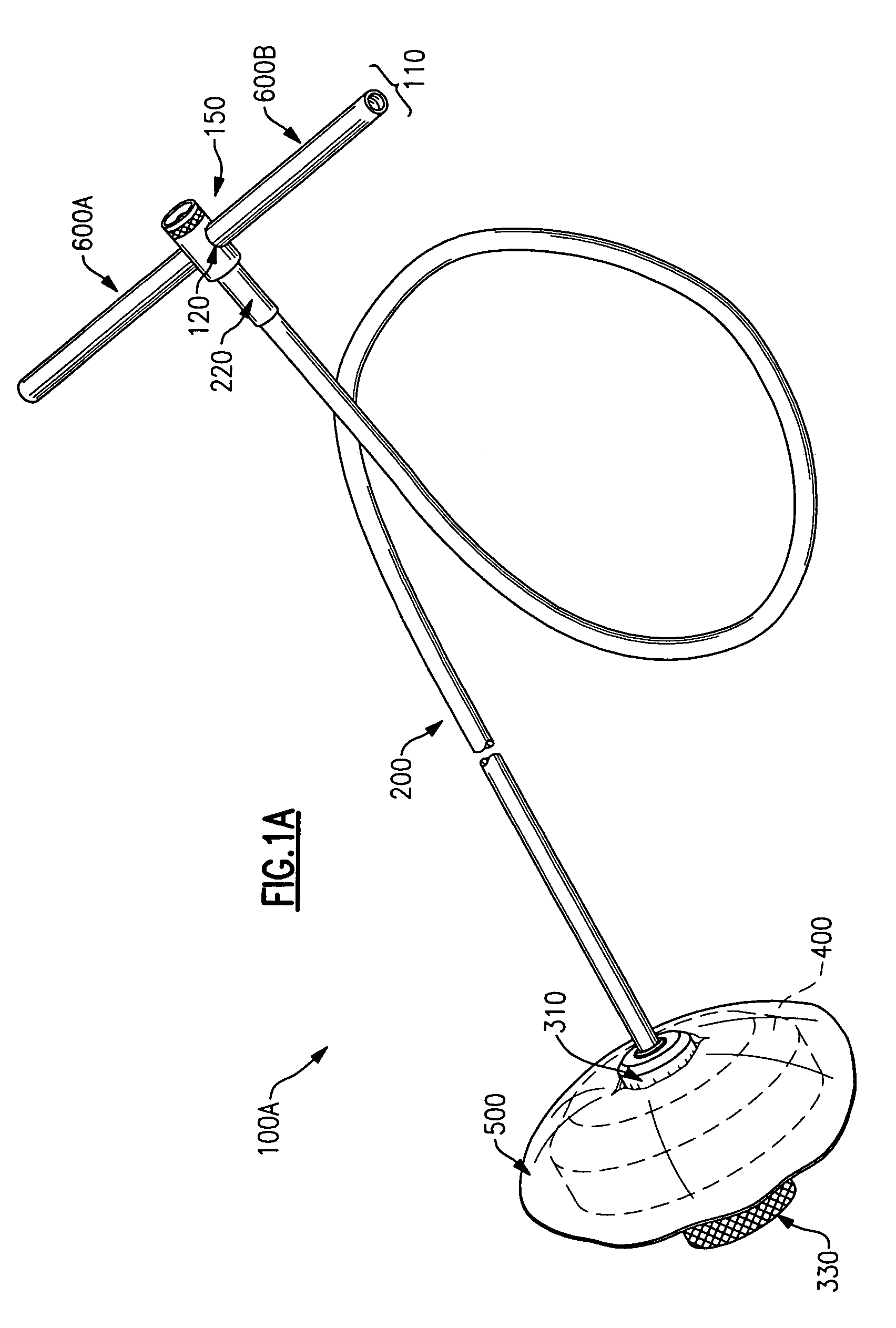

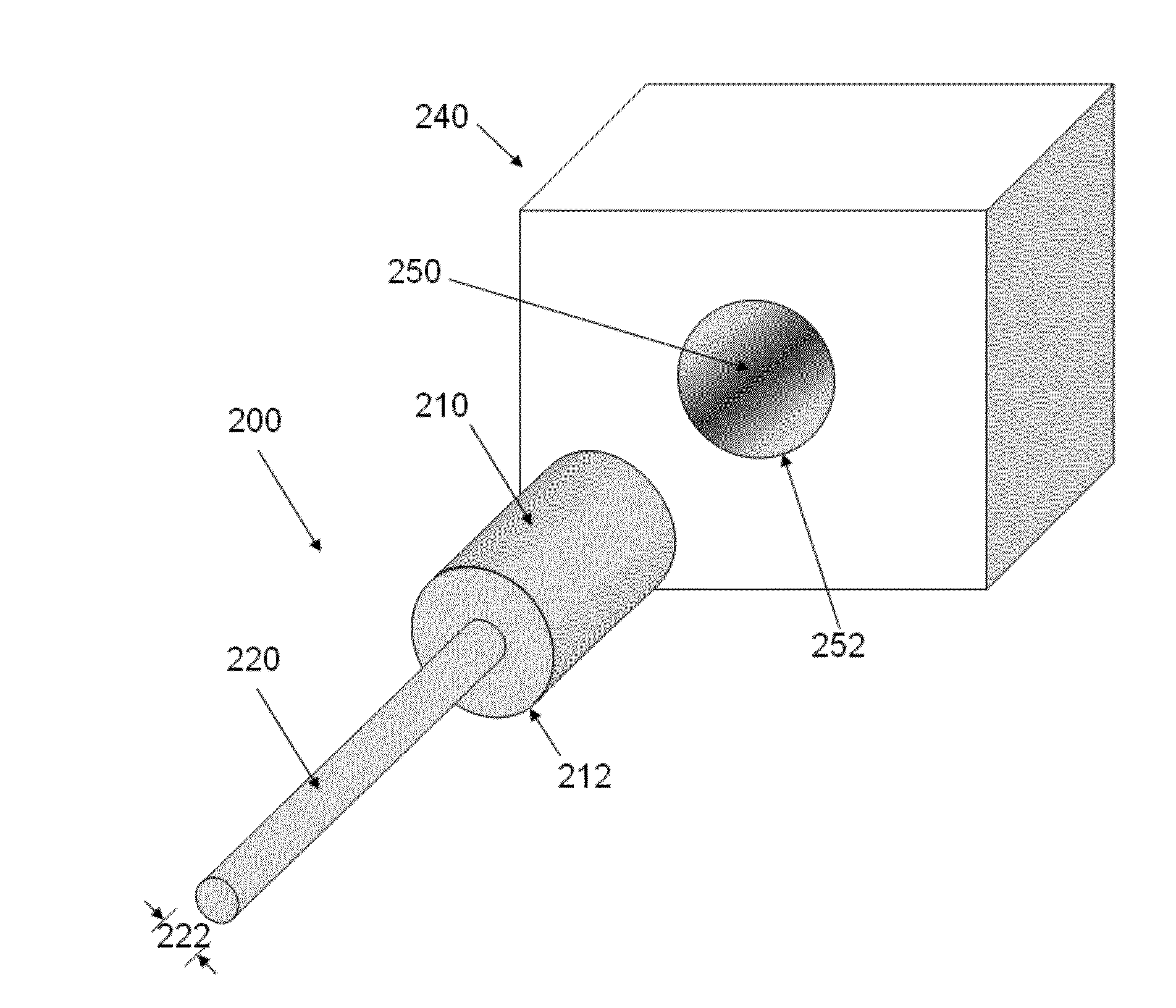

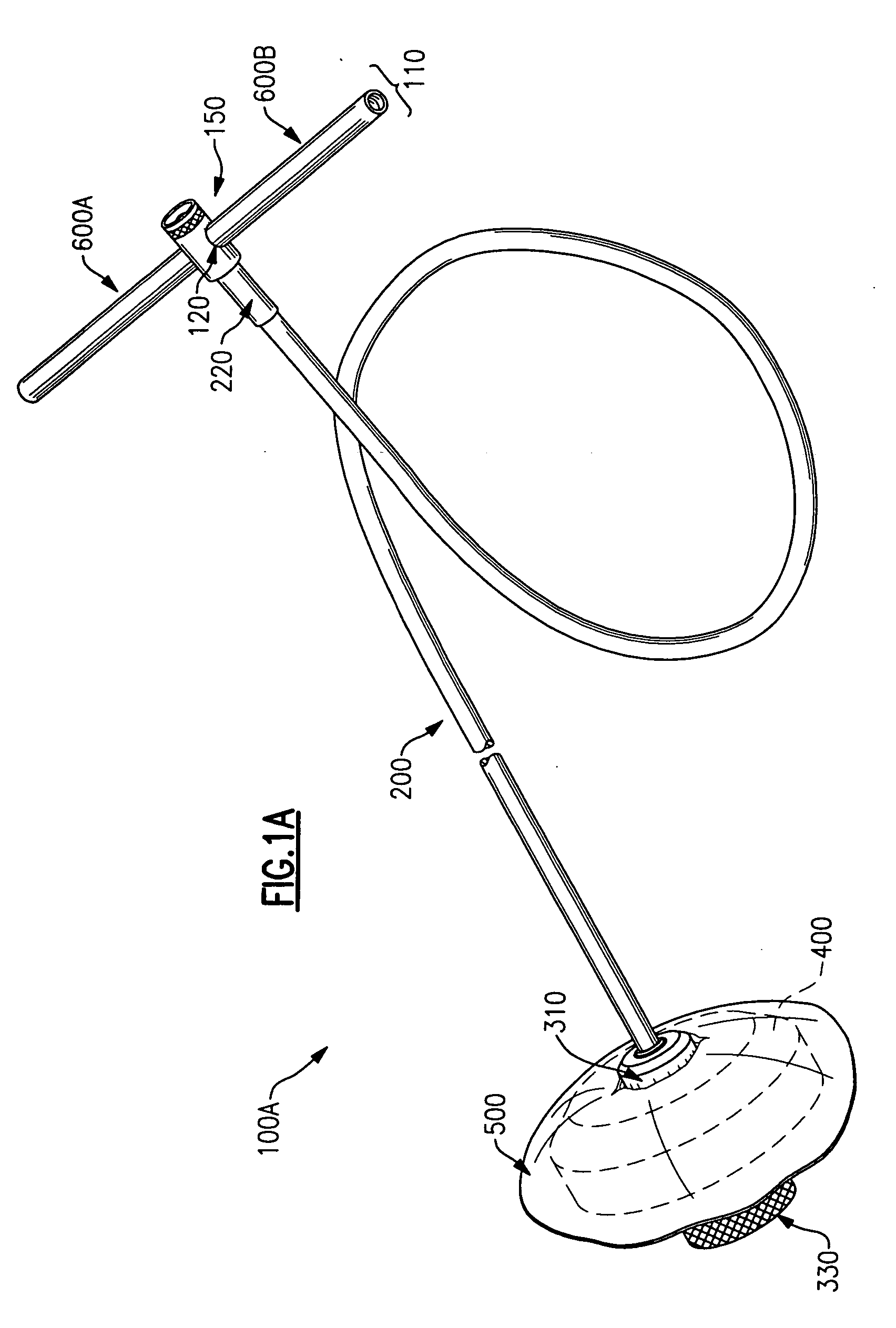

Fluid transfer devices and methods of use

Some embodiments disclosed herein related to a device for transferring precise amounts of fluid from at least one source container to a at least one target container. In some embodiments, the fluid is first transferred from the source container (e.g., a vial) through a connector to an intermediate measuring container (e.g., a syringe). In some embodiments air can pass through an air inlet and enter the vial to compensate for the volume of fluid withdrawn from the vial. An air check valve or a bag or a filter can prevent the fluid from escaping through the air inlet. The precisely measured amount of fluid can then be transferred from the intermediate measuring container to the target container (e.g., an IV bag). In some embodiments the connector can include a source check valve and a target check valve to direct fluid first from the source container to the intermediate measuring container and then from the intermediate measuring container to the target container. Some embodiments of the device can include a motor and a controller for automatically actuating a plunger of the syringe to transfer the desired amount of fluid.

Owner:ICU MEDICAL INC

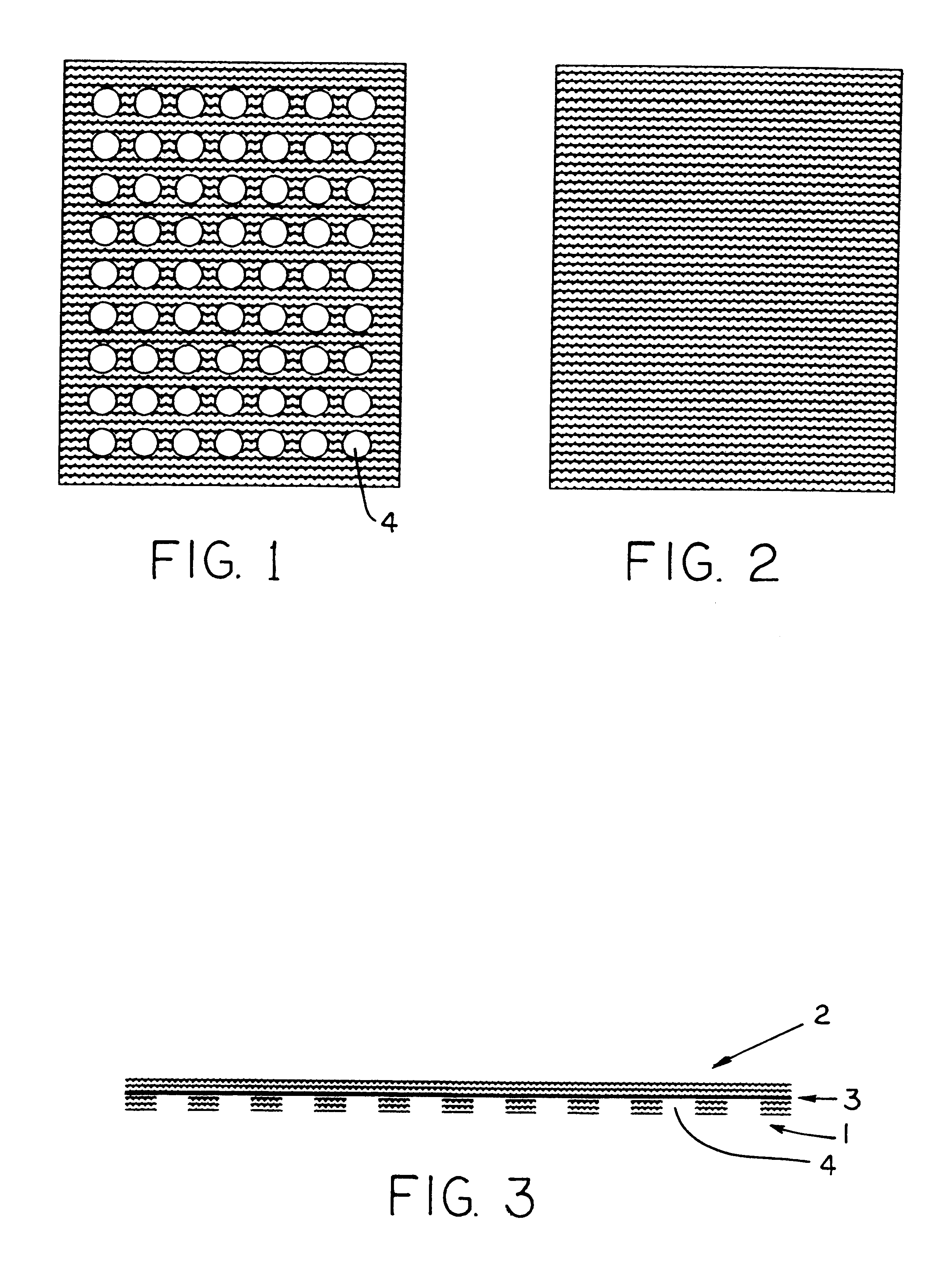

Cleaning sheet with particle retaining cavities

Owner:SC JOHNSON & SON INC

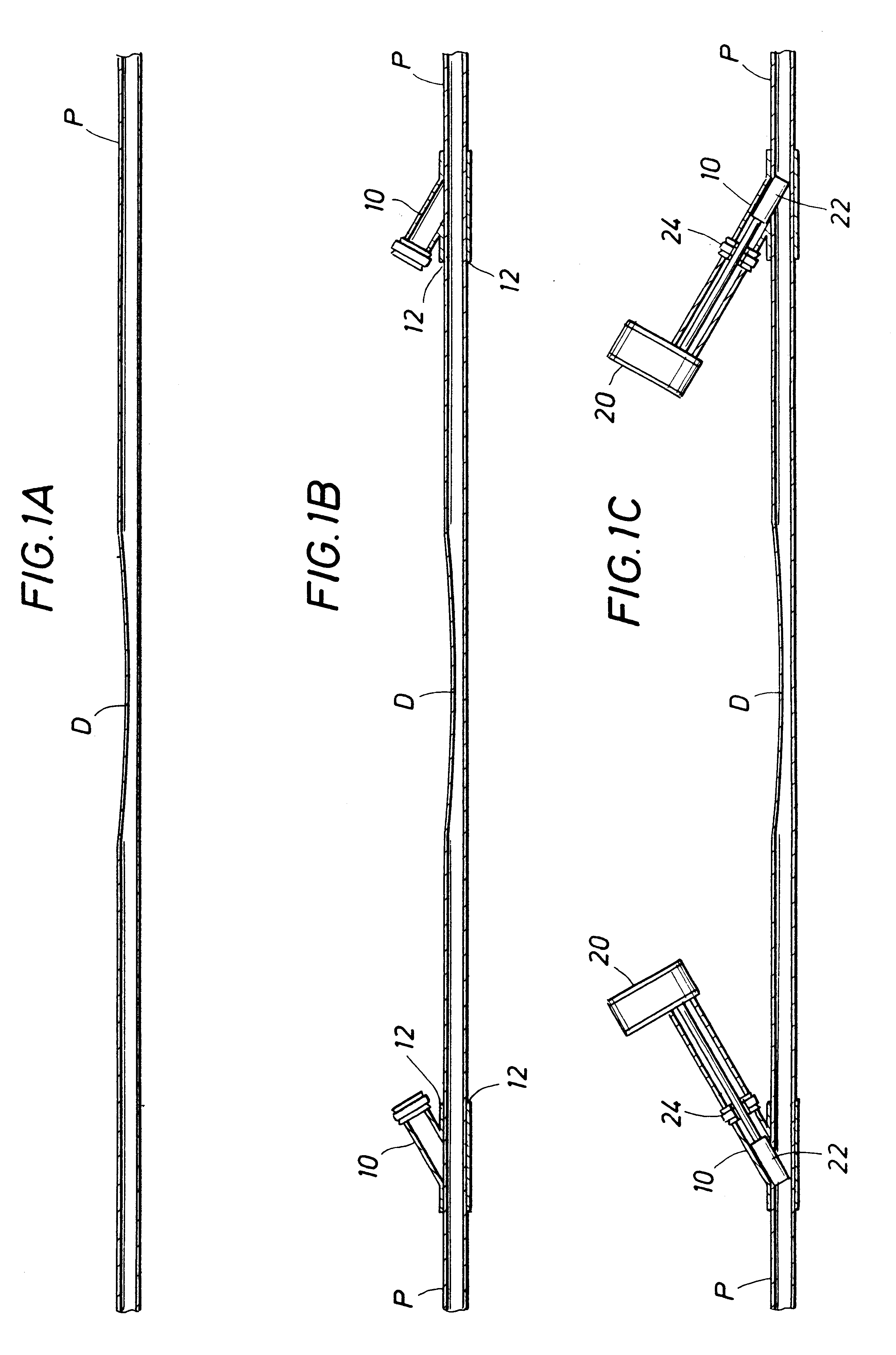

Method for remotely launching subsea pigs in response to wellhead pressure change

A method for sensing and launching pipeline pigs into a pipeline. The method includes pressurizing a pressure accumulator in a pig launching system that includes a pig chamber, a plurality of pigs, a launch tube, and the pressure accumulator. The method further includes sensing a pressure within the pipeline and applying pressure from the pressure accumulator to force a pig through the launch tube and into the pipeline.

Owner:SAIPEM AMERICA

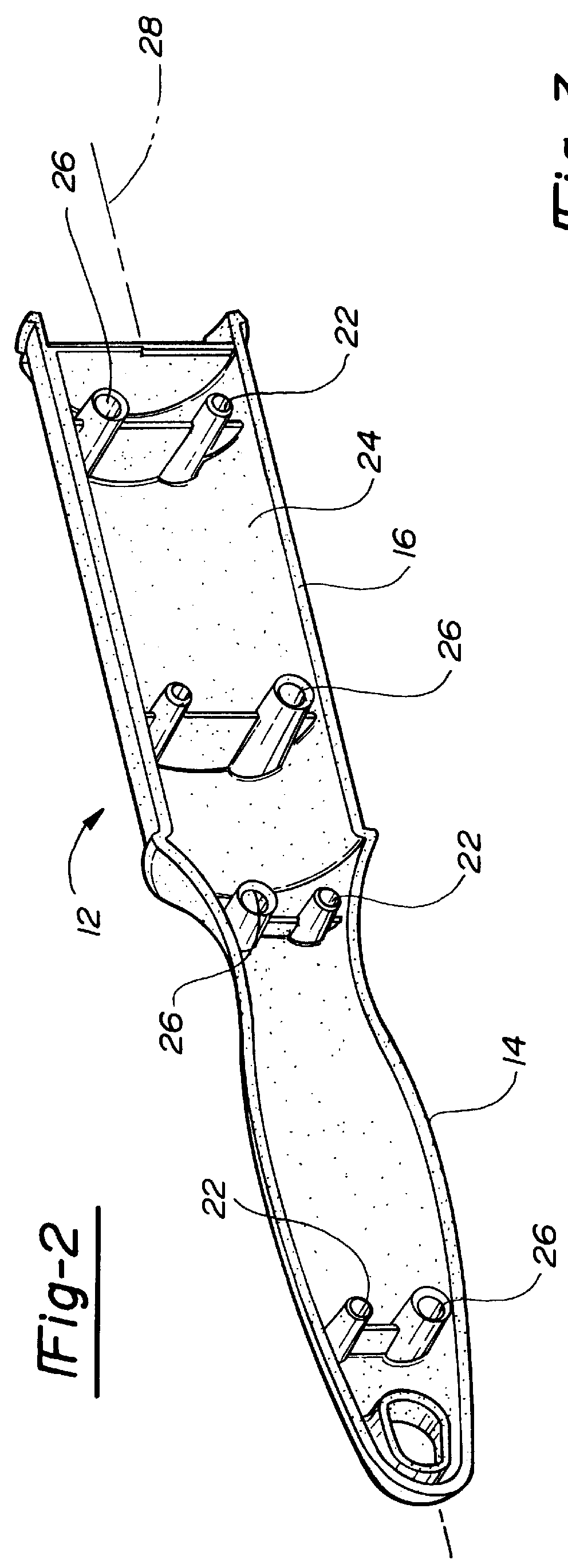

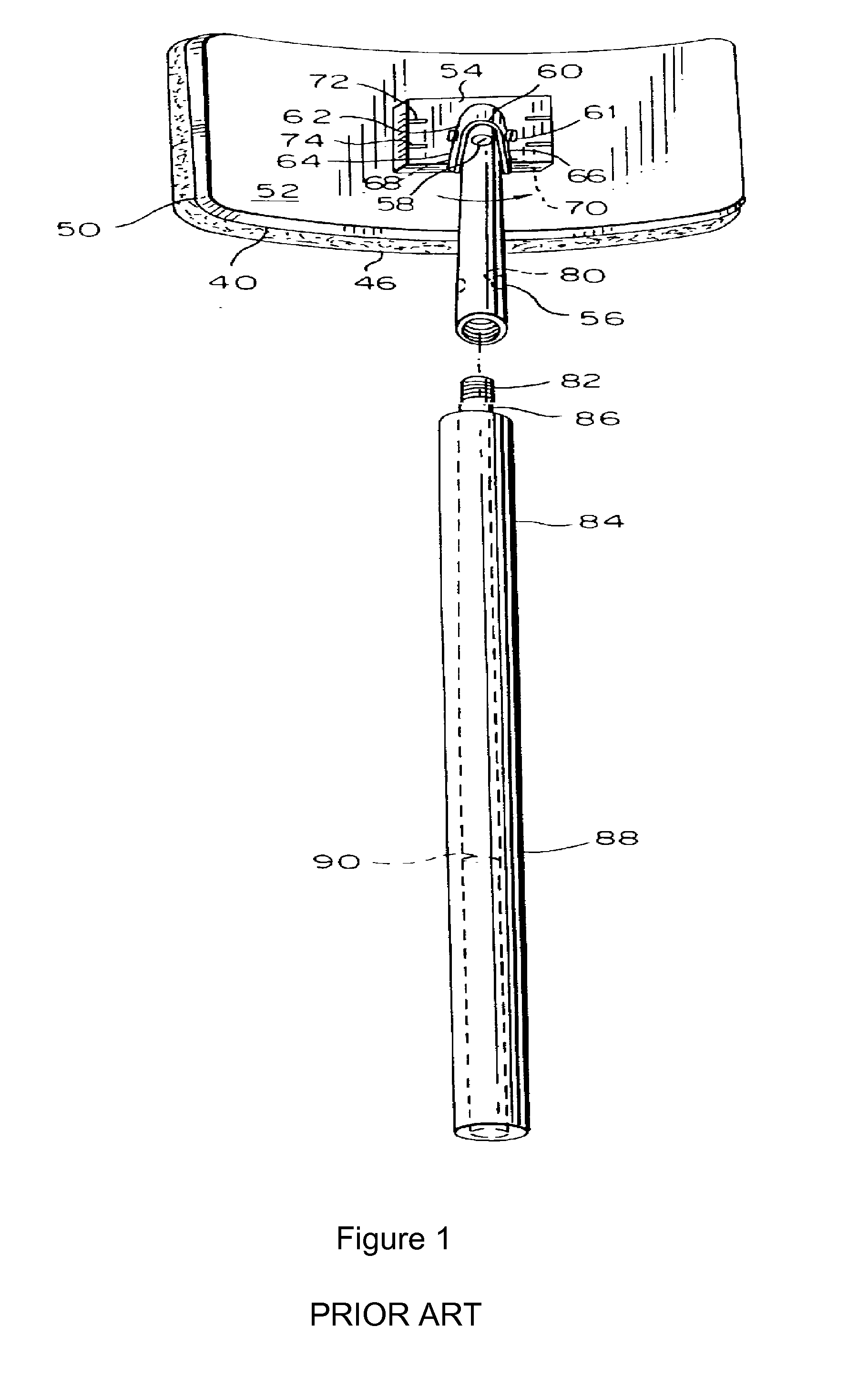

Lint roller assembly

InactiveUS6055695AMinimize frictional contactFacilitate free rotationLiquid surface applicatorsHousehold cleanersEngineeringMechanical engineering

A lint roller assembly is disclosed for rotatably supporting a tubular and cylindrical adhesive lint remover roller. The assembly includes a pair of elongated housing parts which are substantially identical to each other. Each housing part includes an elongated handle section and a semi-cylindrical lint roller support section longitudinally adjacent the handle section. The lint roller support section has an outer diameter less than the diameter of the adhesive roller. The housing parts are secured together in a facing relationship by registering pins and sockets formed on the housing parts. In doing so, the lint roller support sections form a cylindrical lint roller support for the adhesive roller while the handle sections abut against each other to form a handle.

Owner:THE EVERCARE

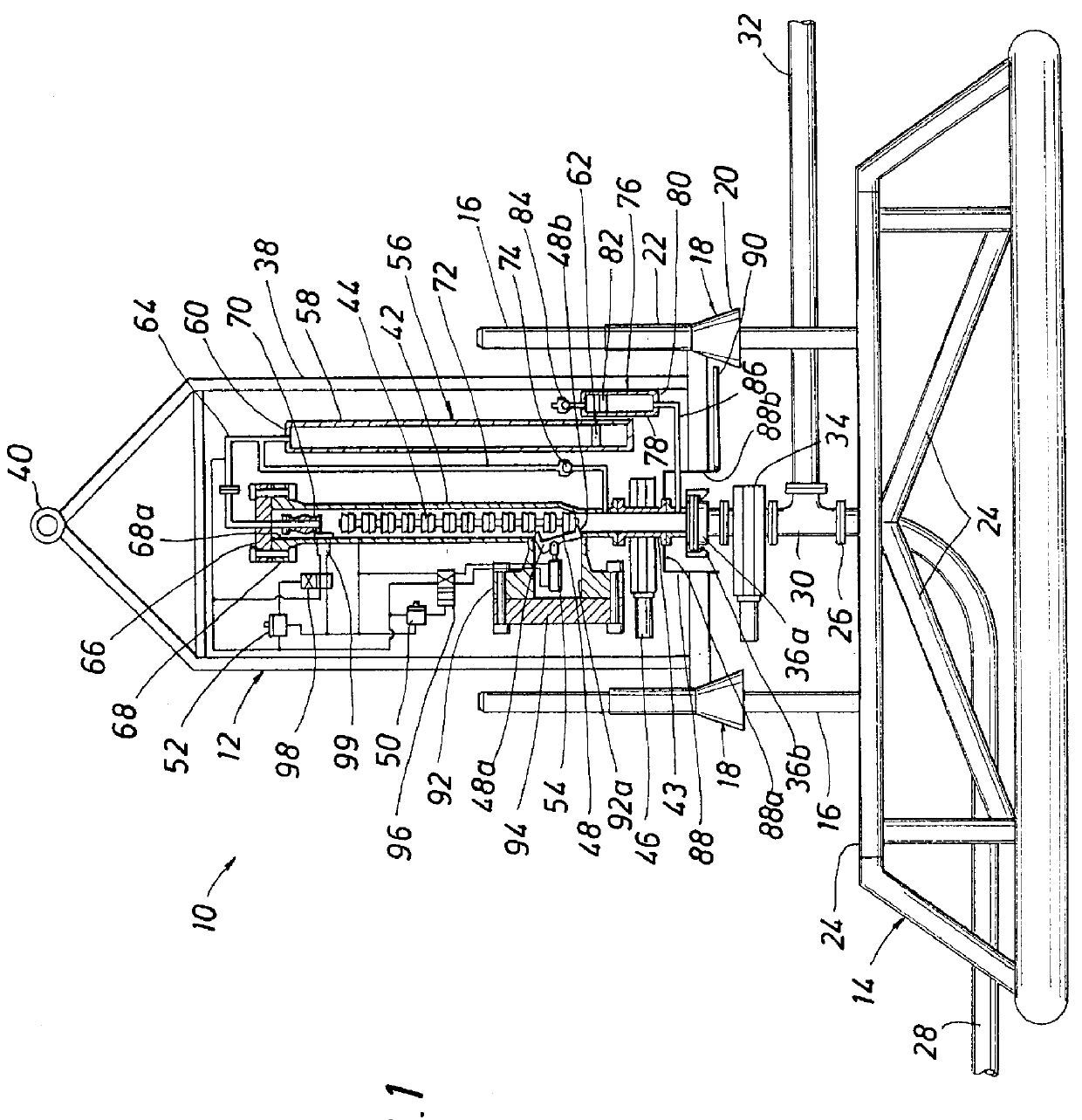

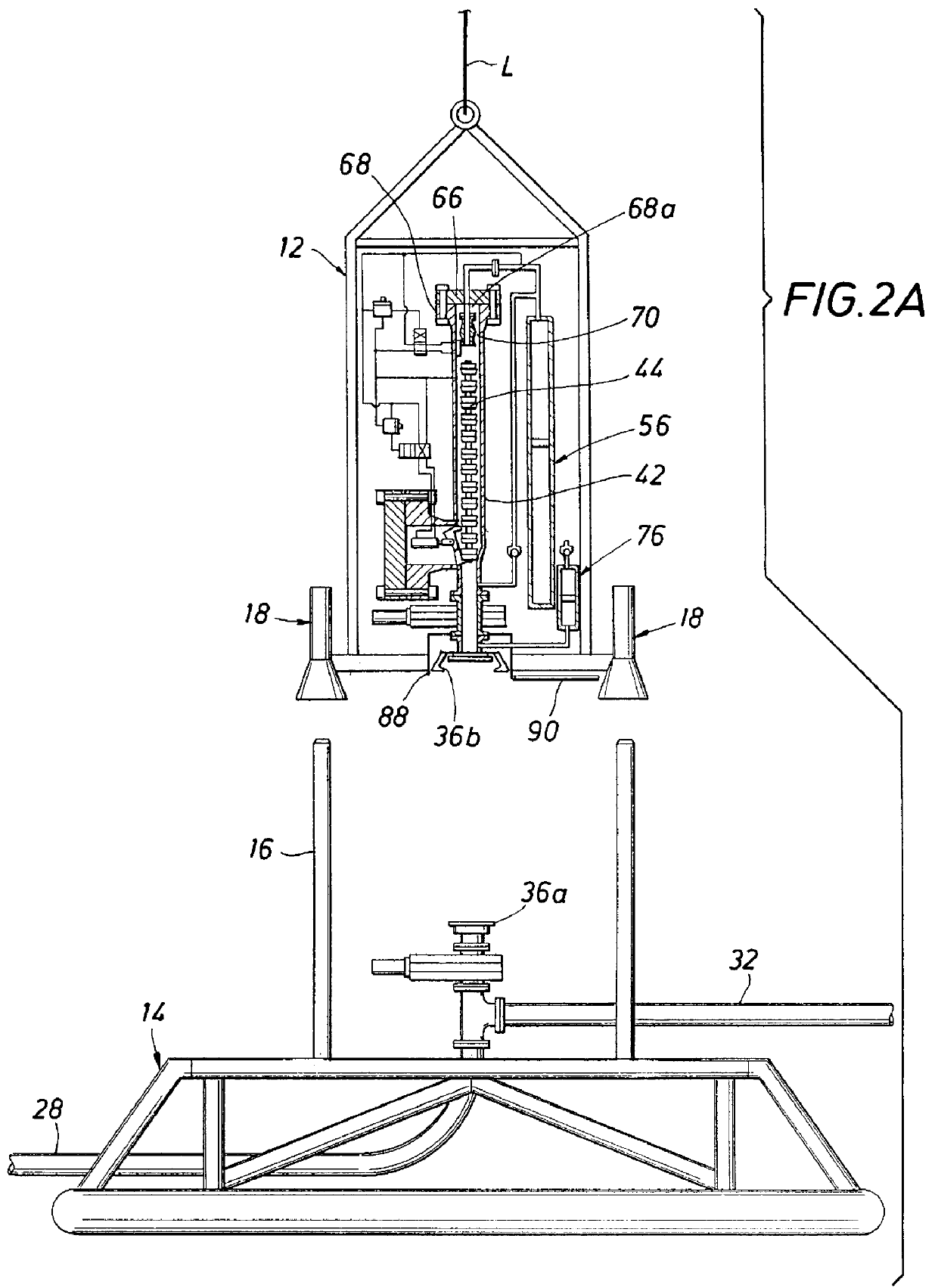

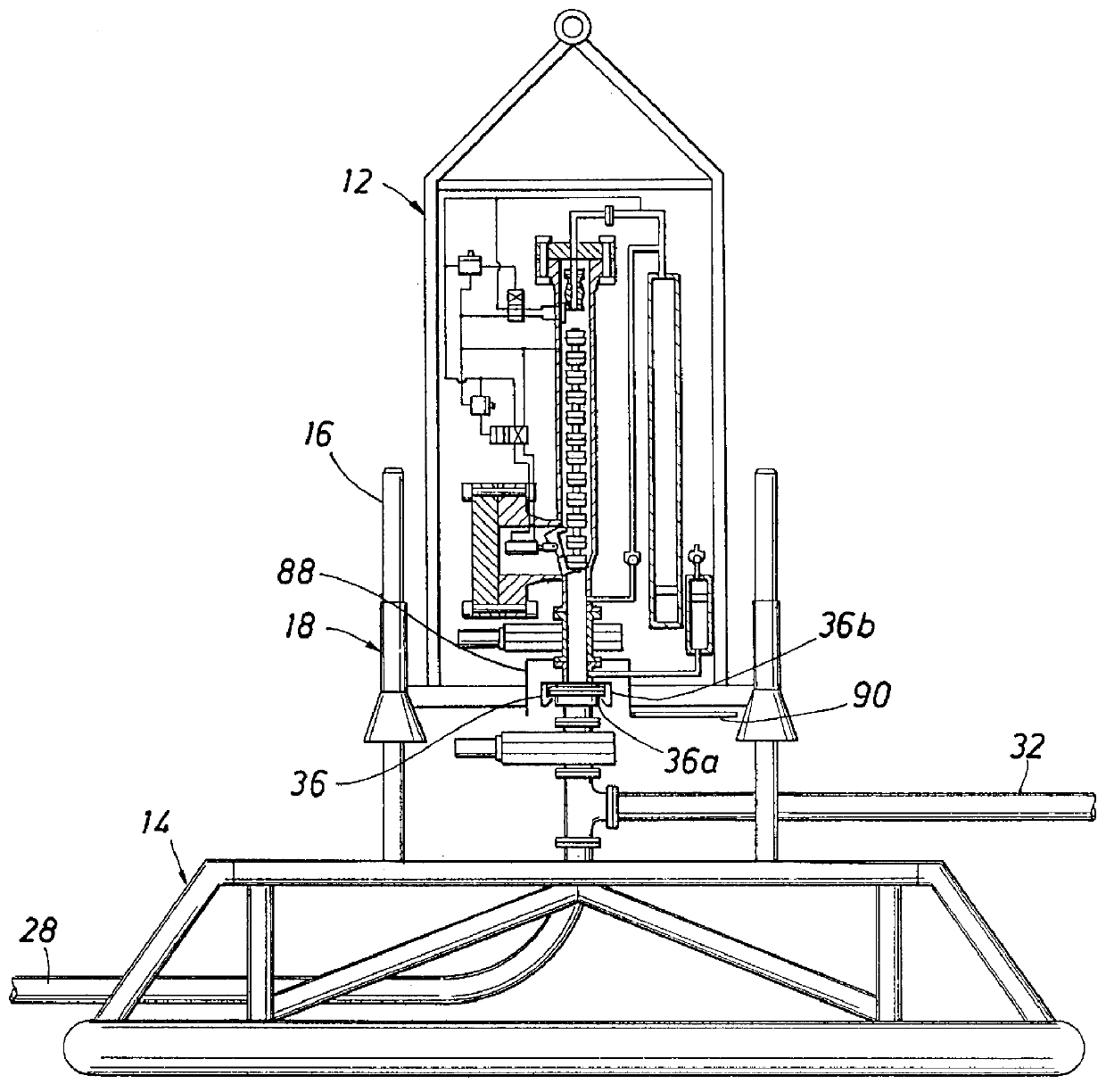

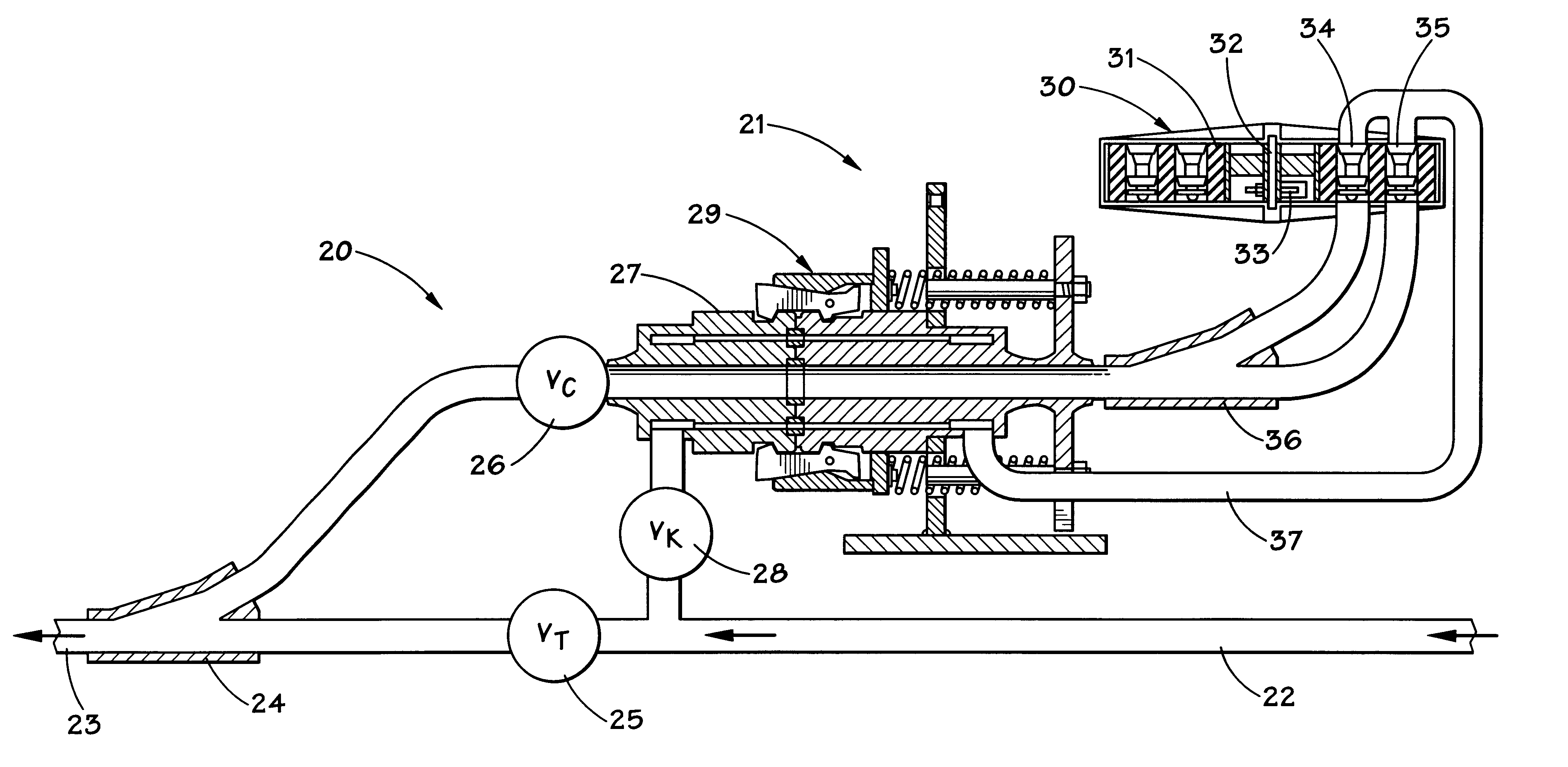

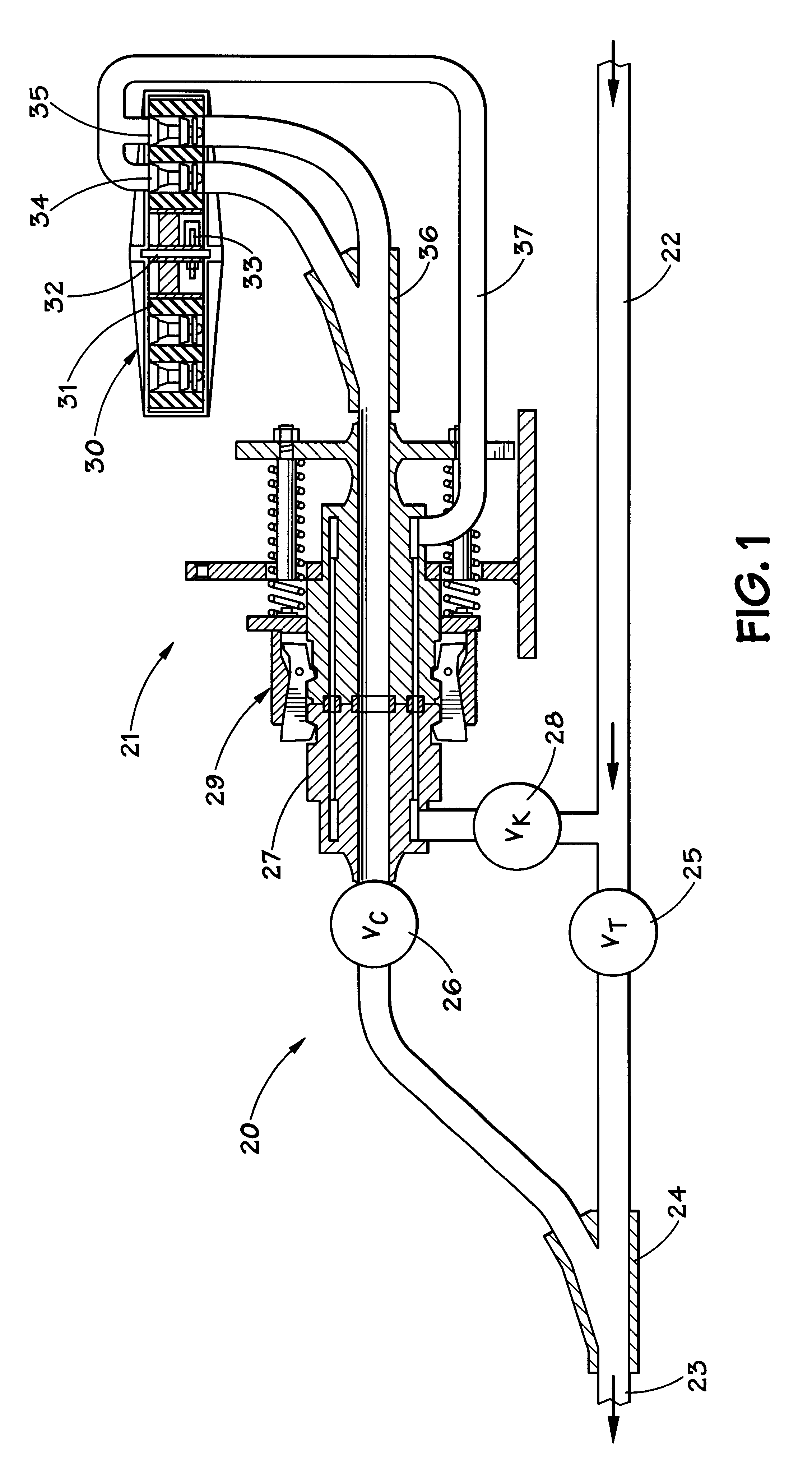

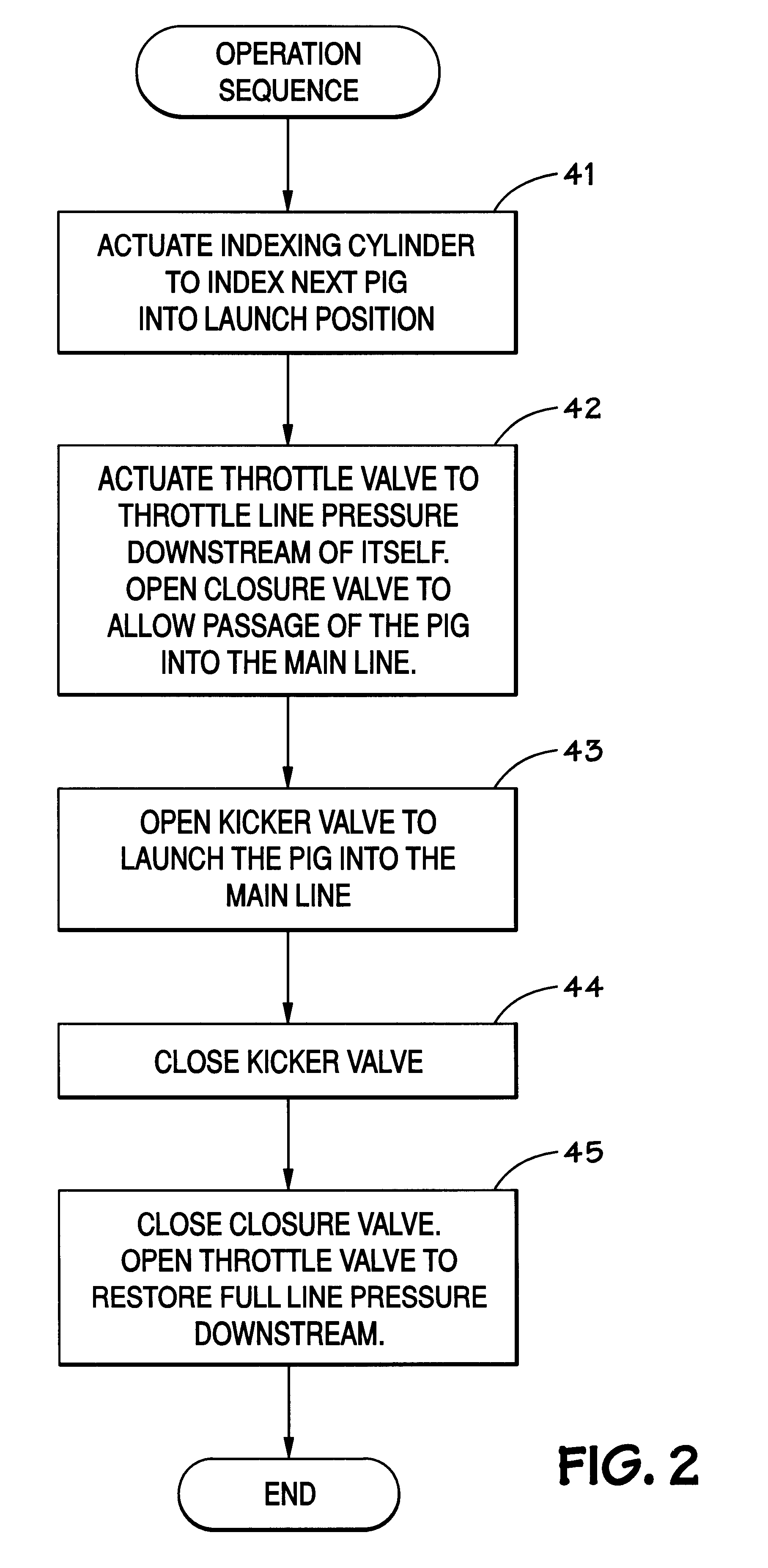

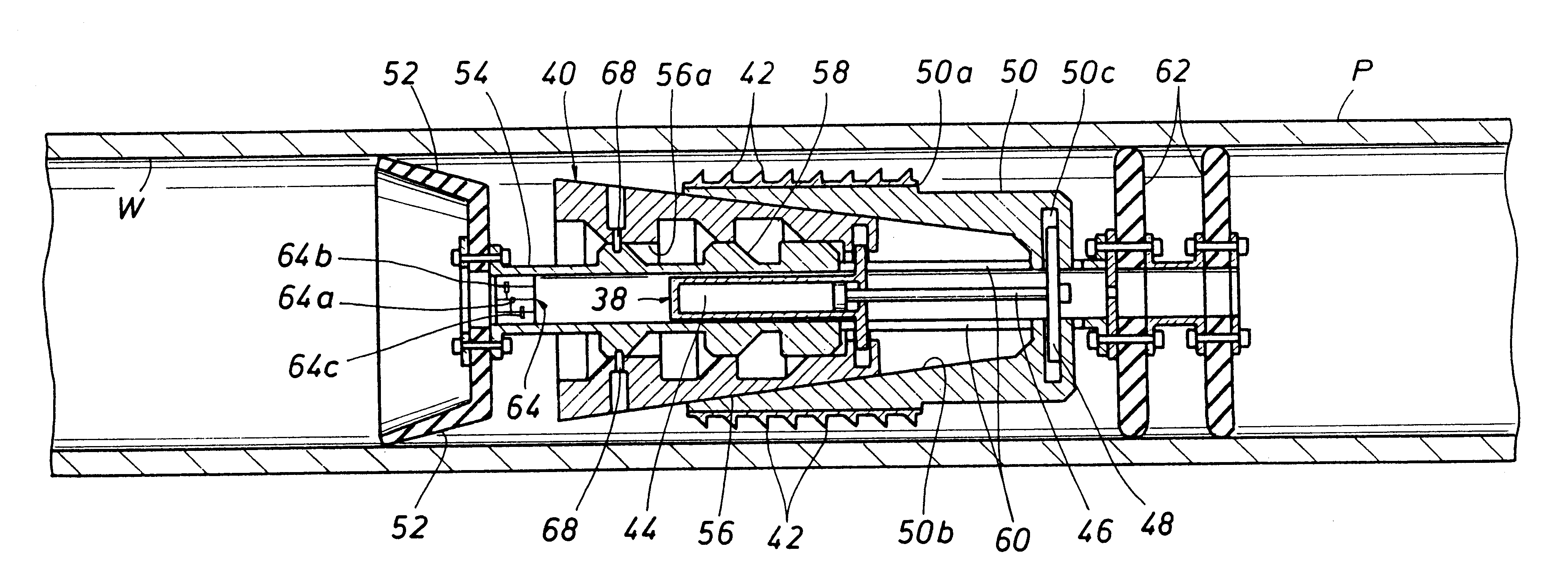

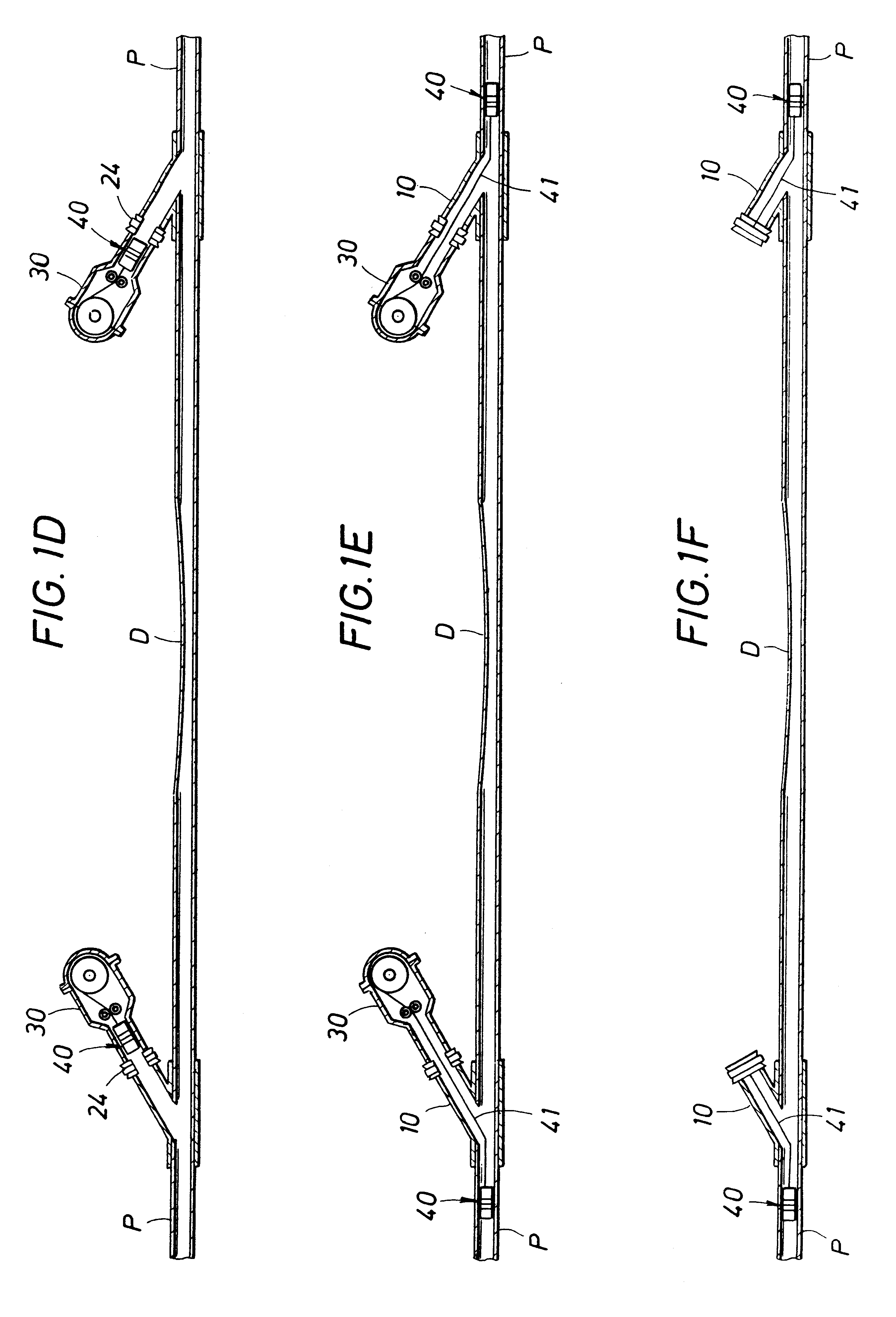

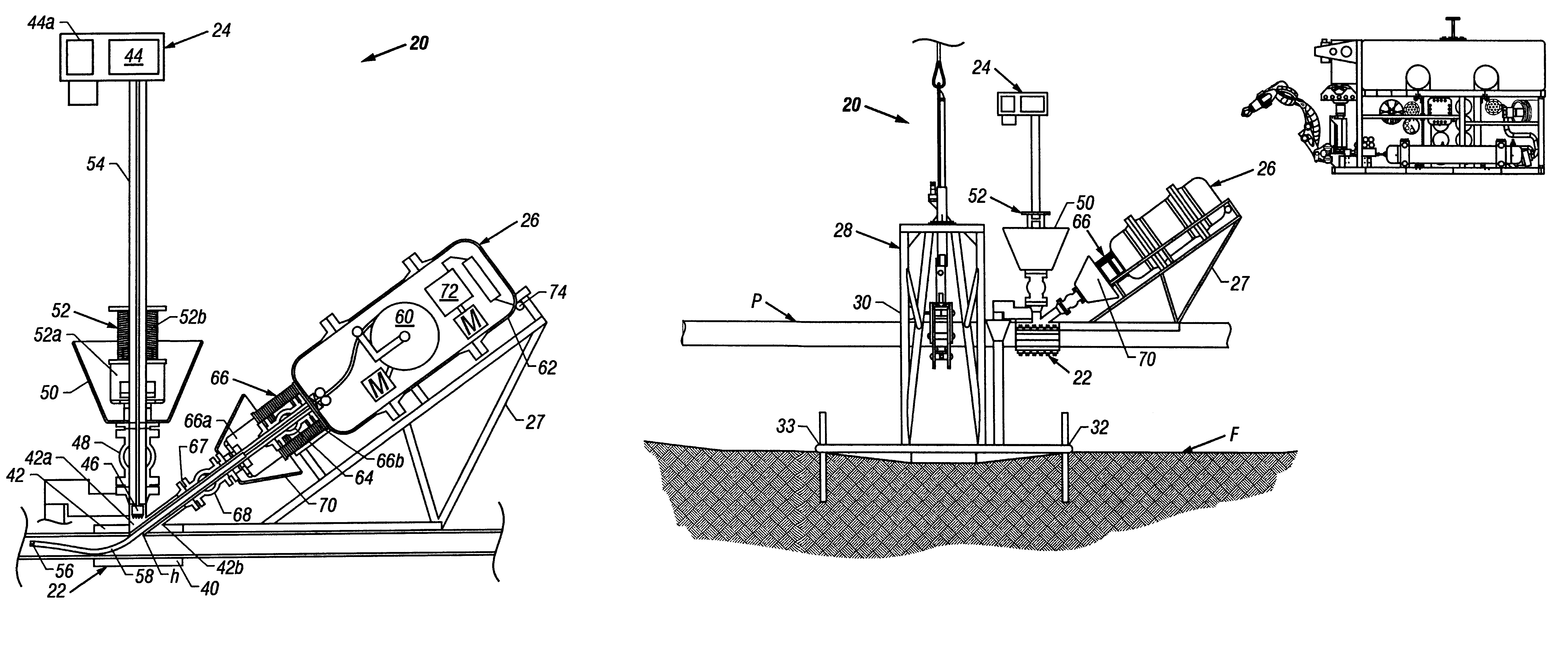

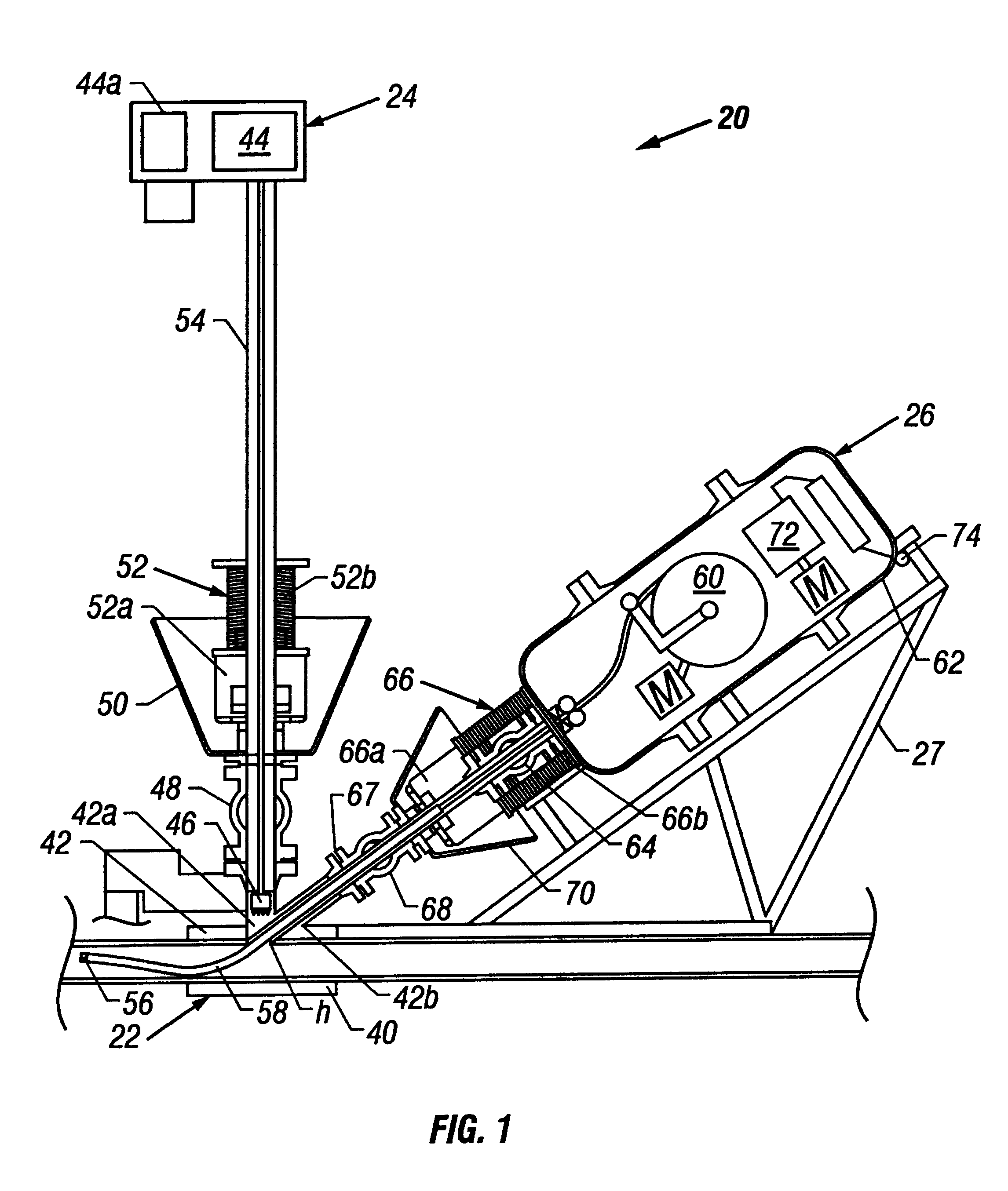

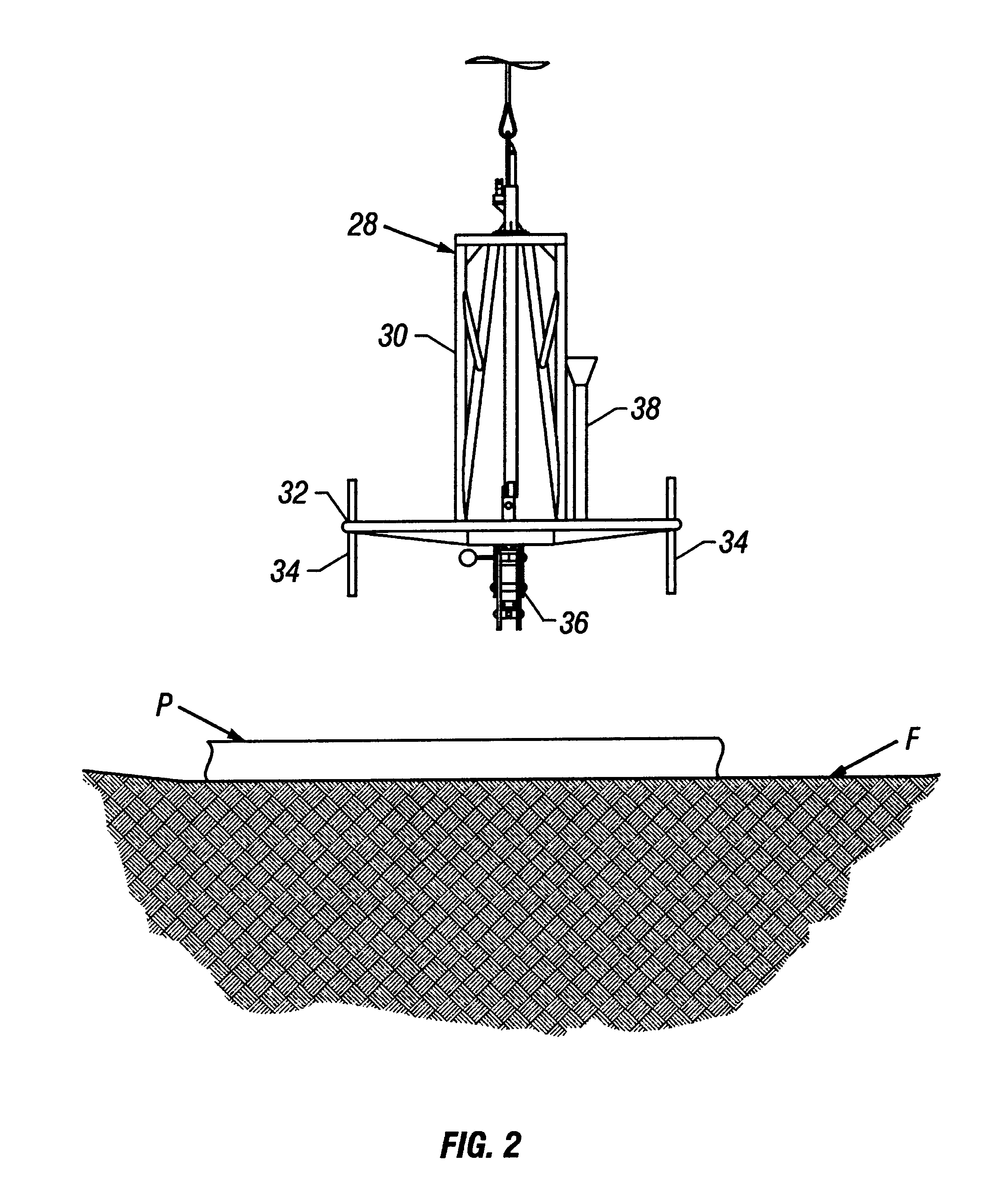

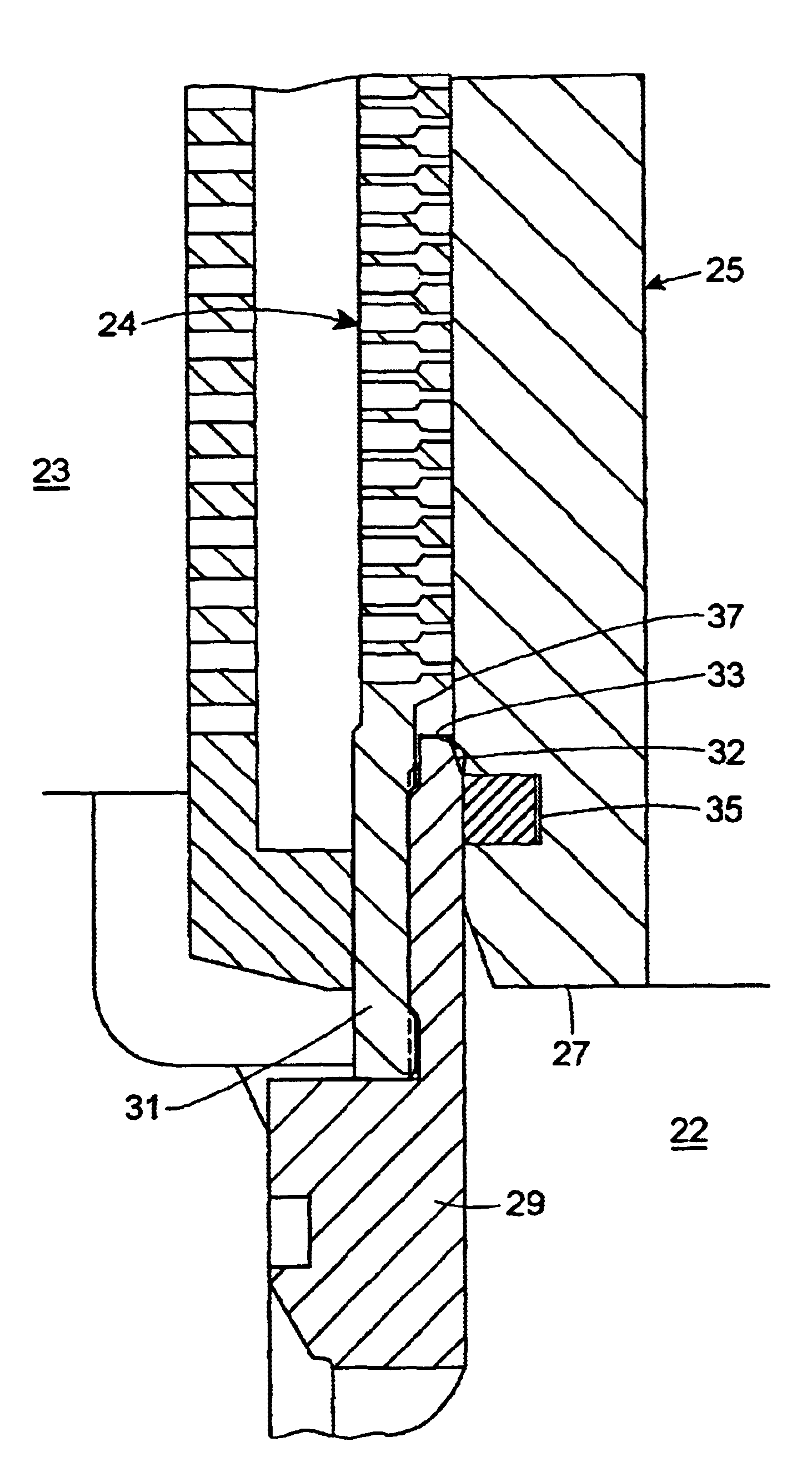

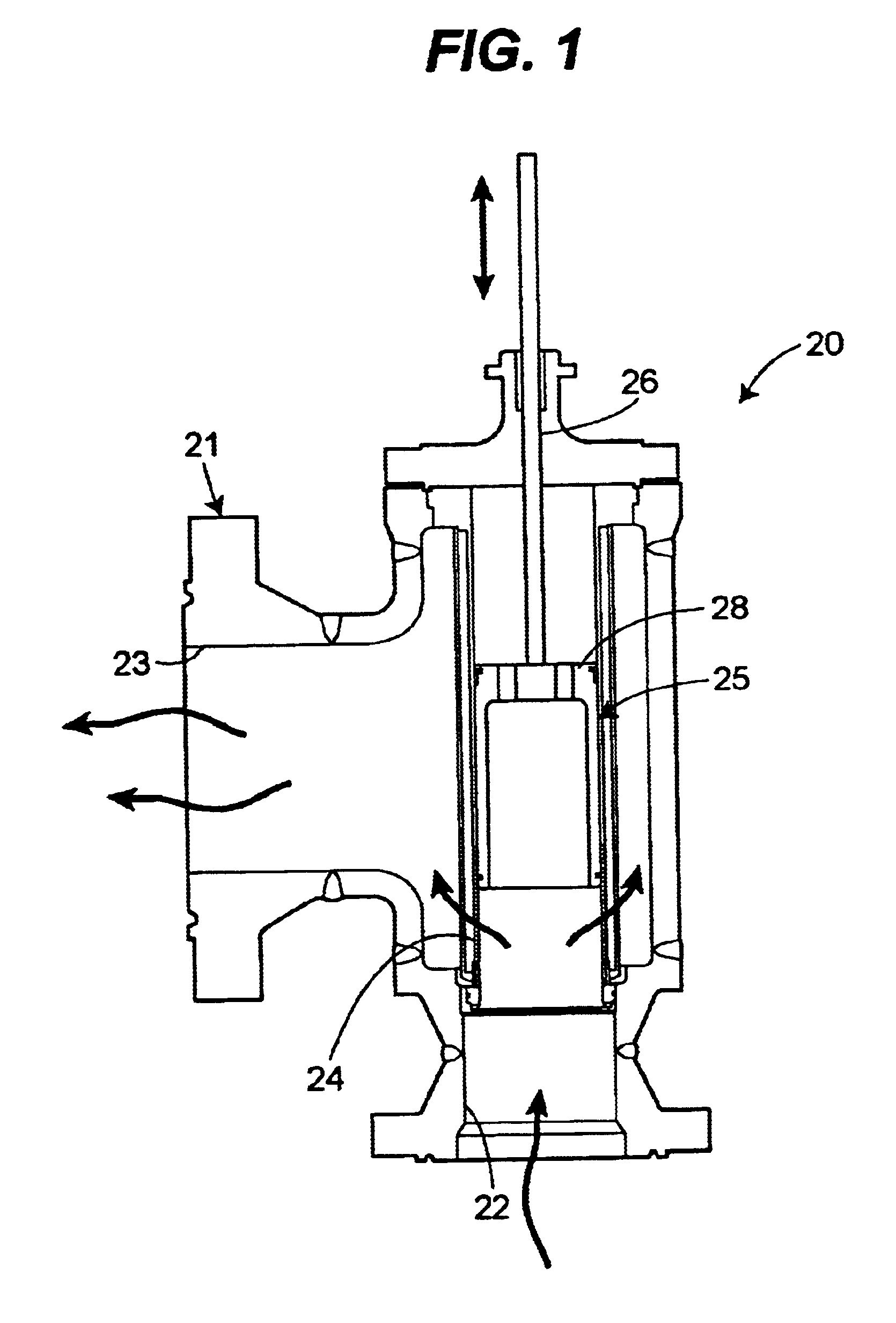

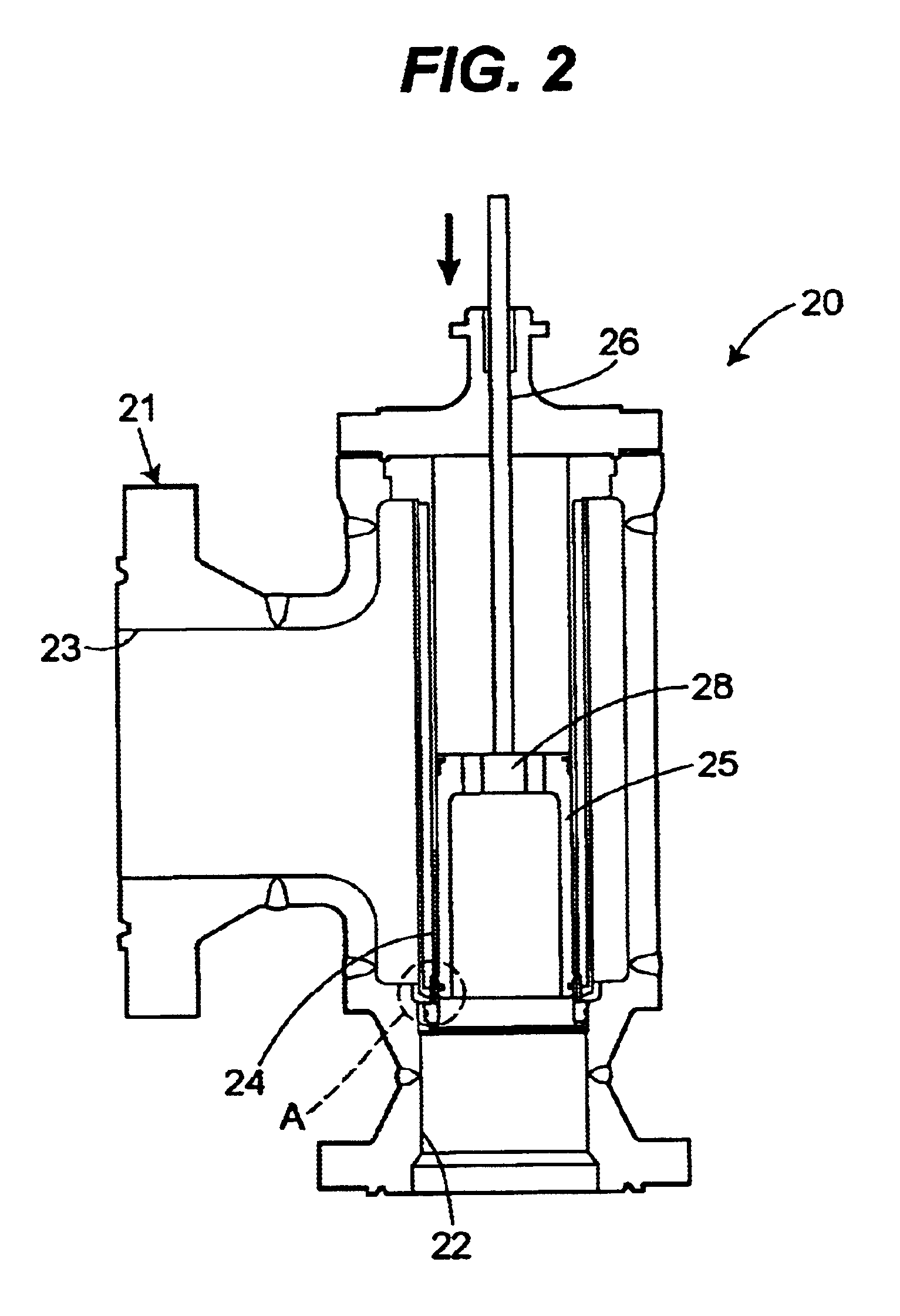

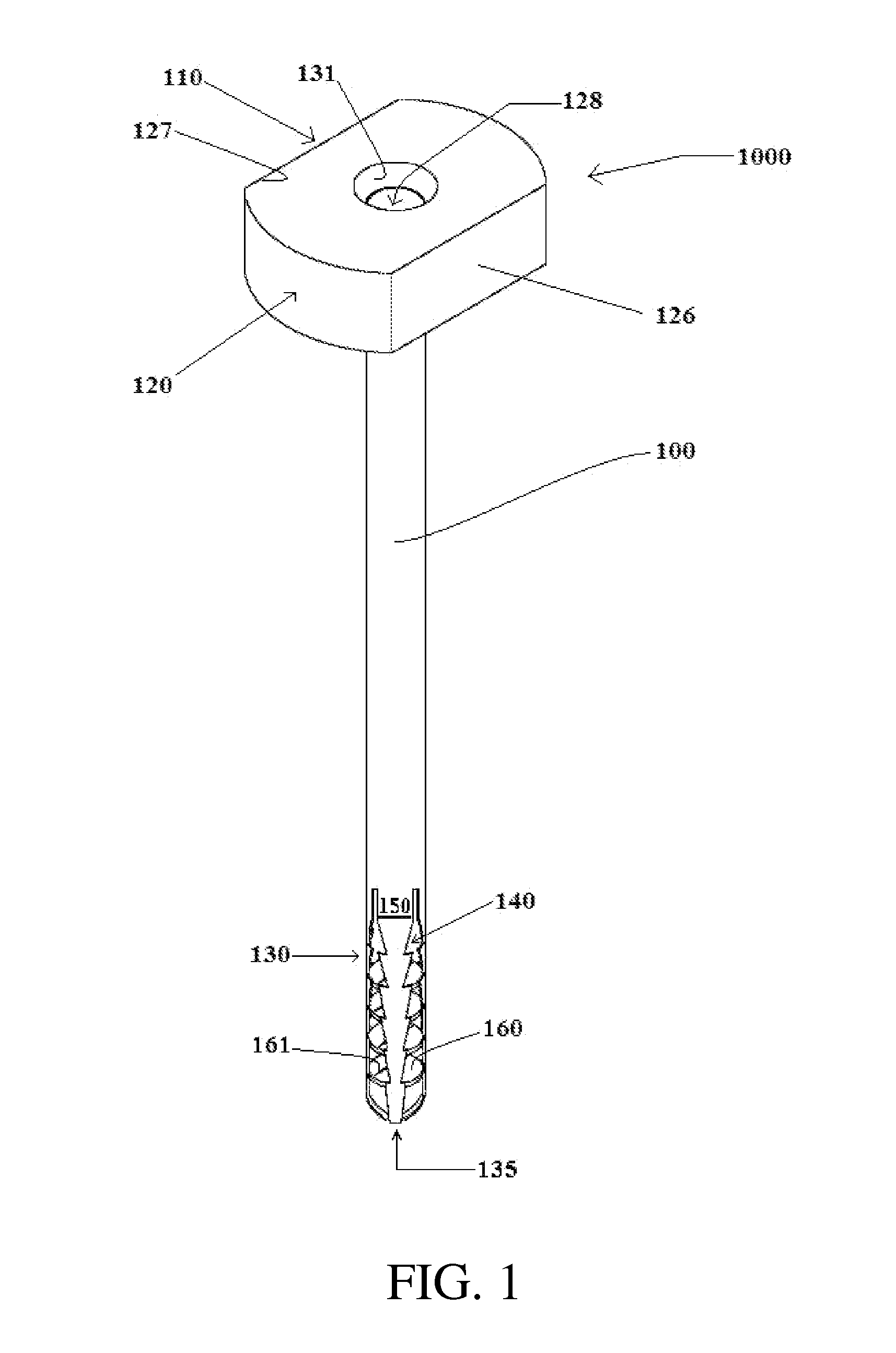

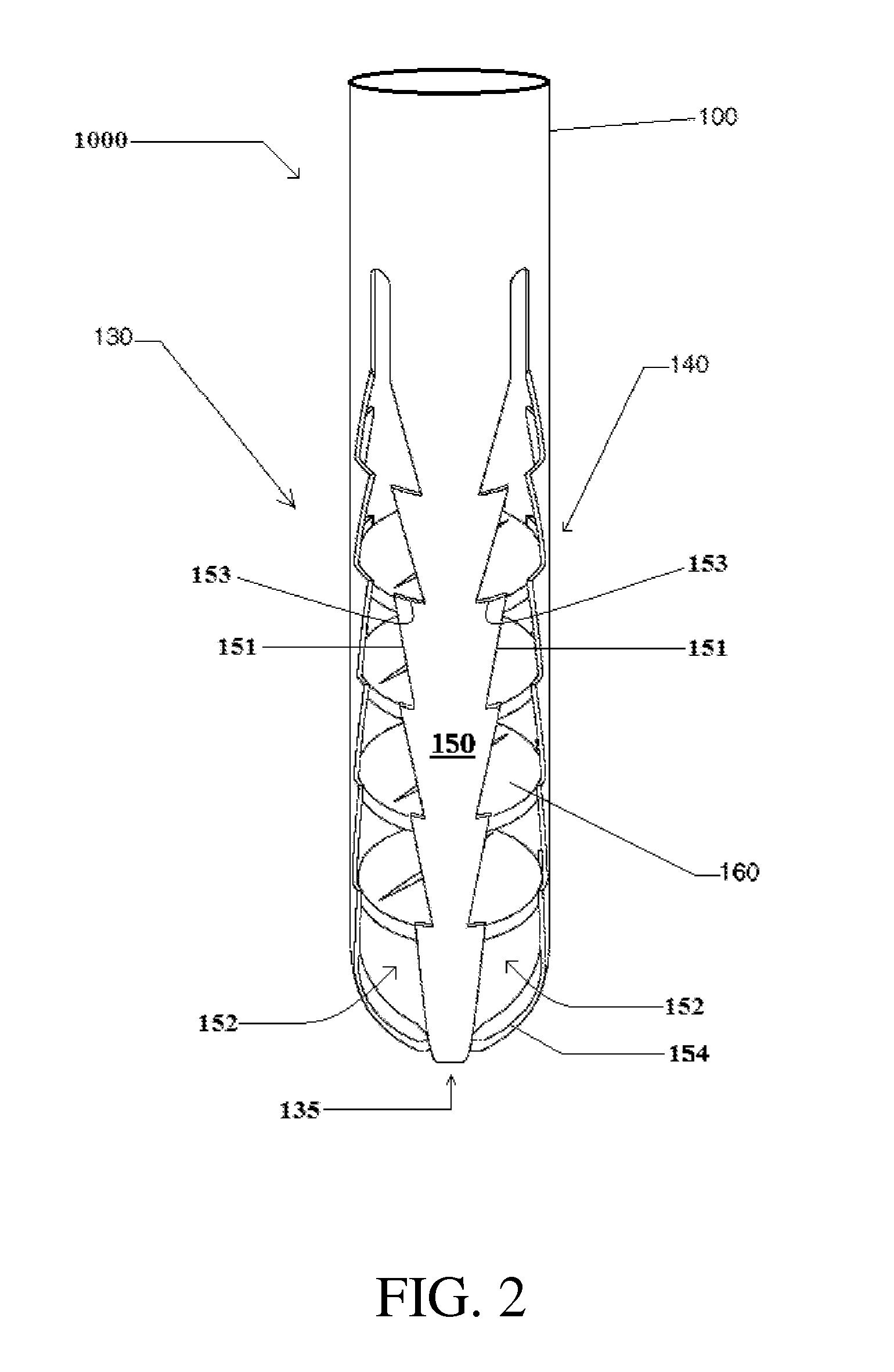

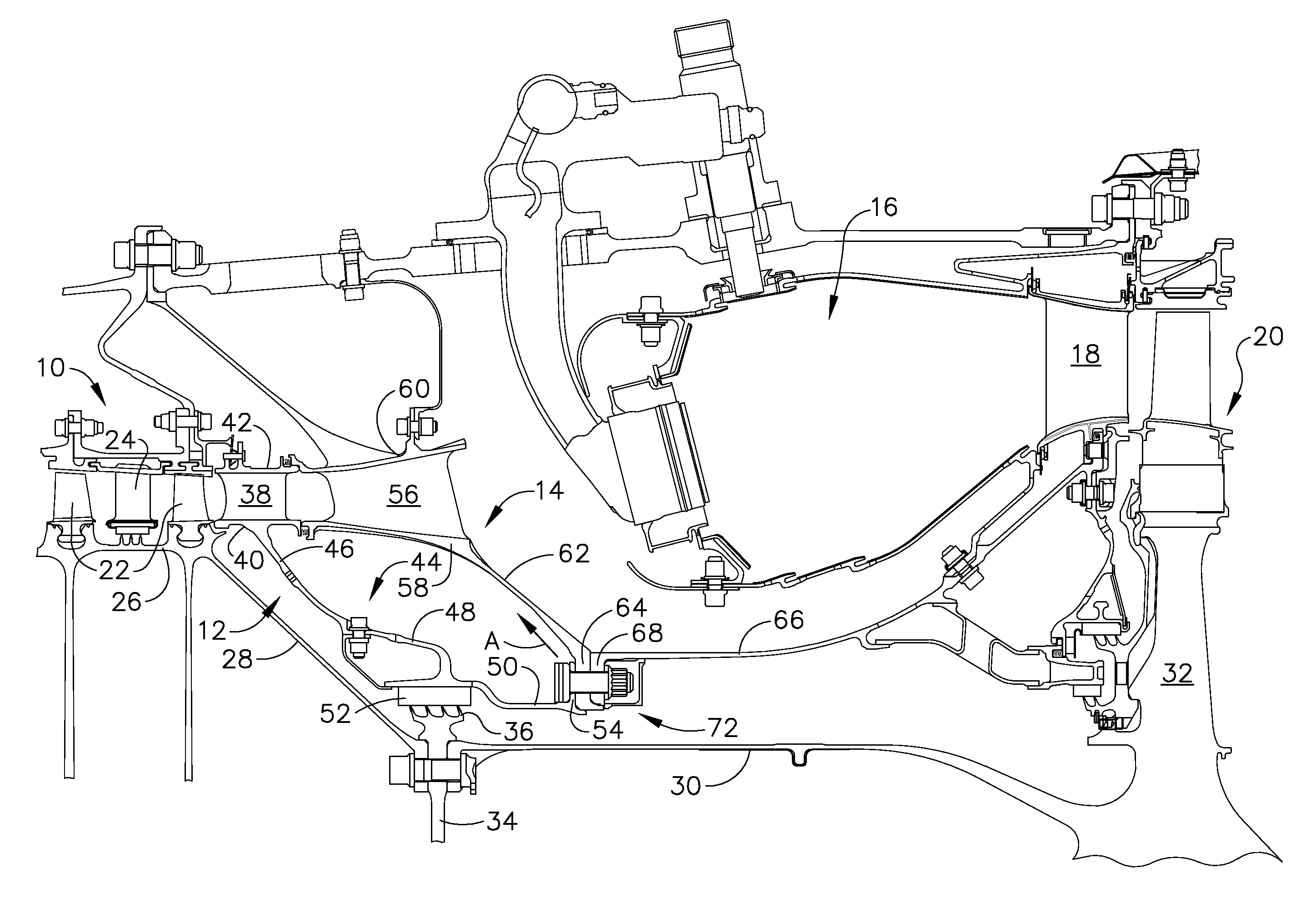

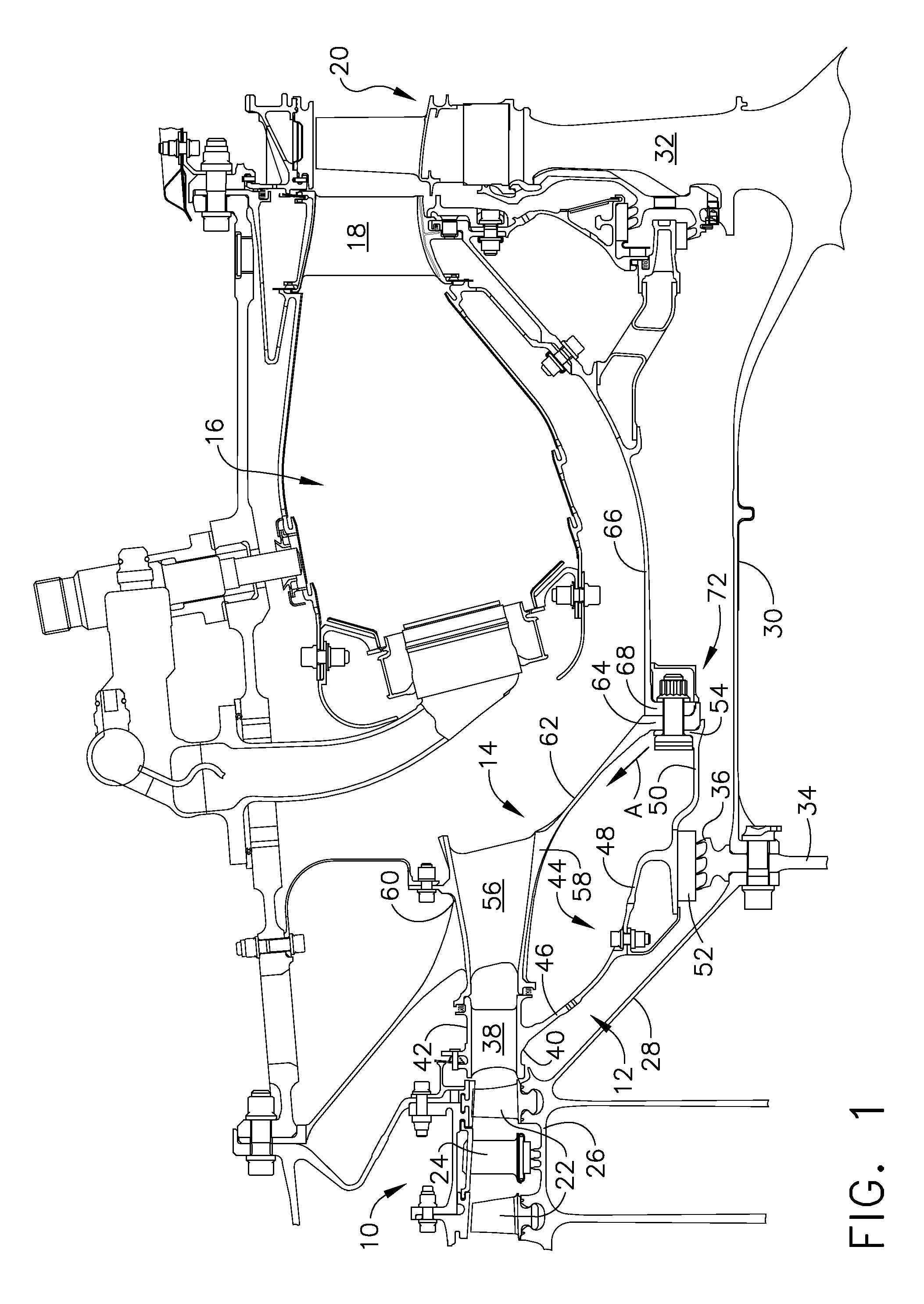

Multiple pig subsea pig launcher

The pig launcher is installed subsea by coupling it to a launcher manifold. The launcher manifold is installed substantially permanently subsea as a part of a pipeline. The pig launcher includes a dual bore collet connector for coupling to the launcher manifold, and a rotary storage magazine for storing the pigs. The launcher manifold can be manufactured, for example, as part of an inline lateral tie-in sled or as part of a pipeline end manifold (PLEM). A branch connection from the pipeline to the pig launcher is provided in the launcher manifold via a piggable Y connection to a dual bore collet connector male hub. The pig launcher is landed and latched to the launcher manifold to complete the pig launching system. A closure valve between the Y connection and the hub prevents a pressure loss when the pig launcher is not installed, and the closure valve is opened to permit passage of the pigs during launching. A throttle valve upstream of the Y connection allows the pipeline pressure to be dropped downstream so that a pig can be launched using upstream pressure. During launching, a kicker valve is opened to bypass the throttle valve and direct the higher upstream pressure through the secondary bore of the dual bore collet connector and into the rotary magazine.

Owner:OIL STATES INDS UK

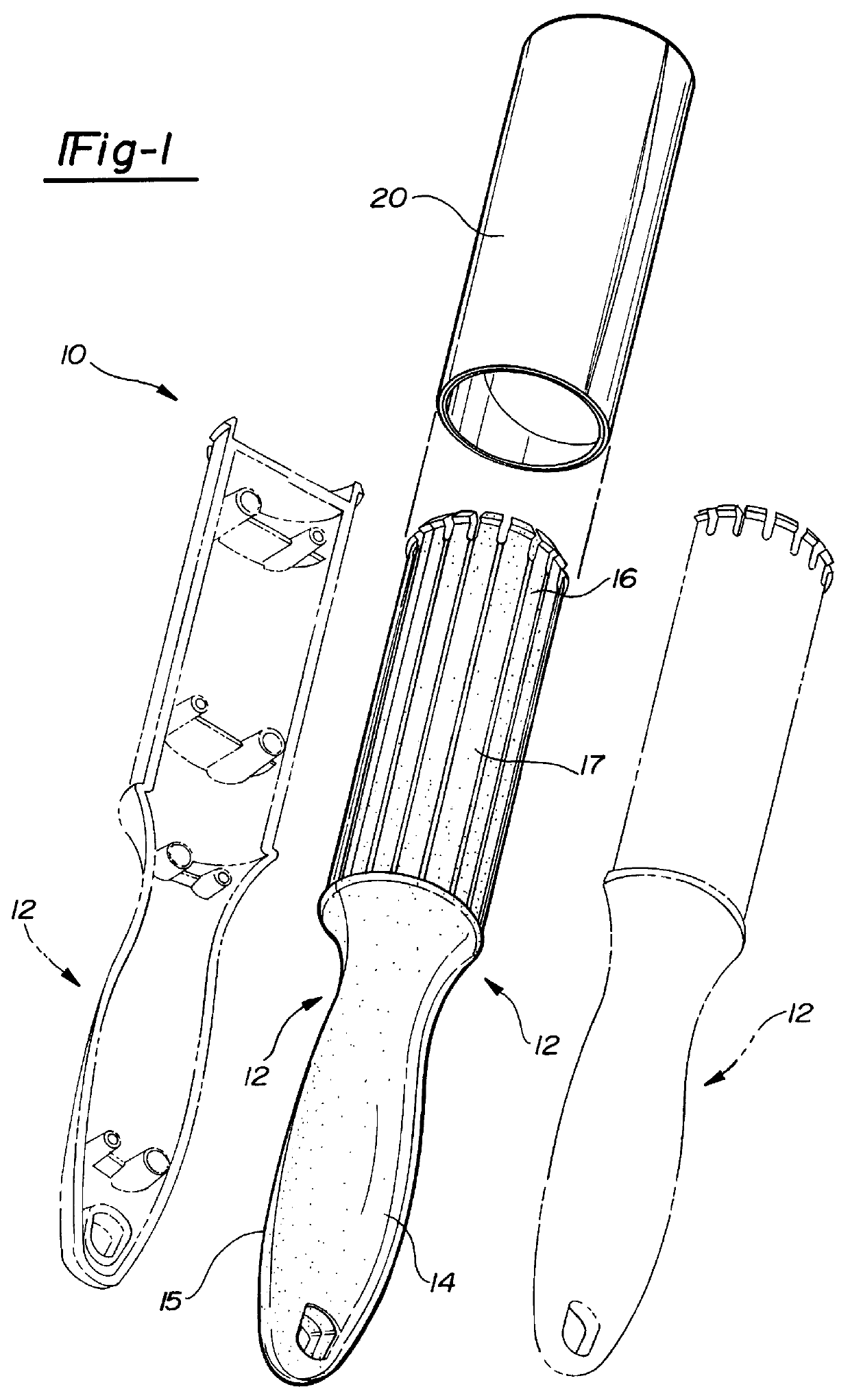

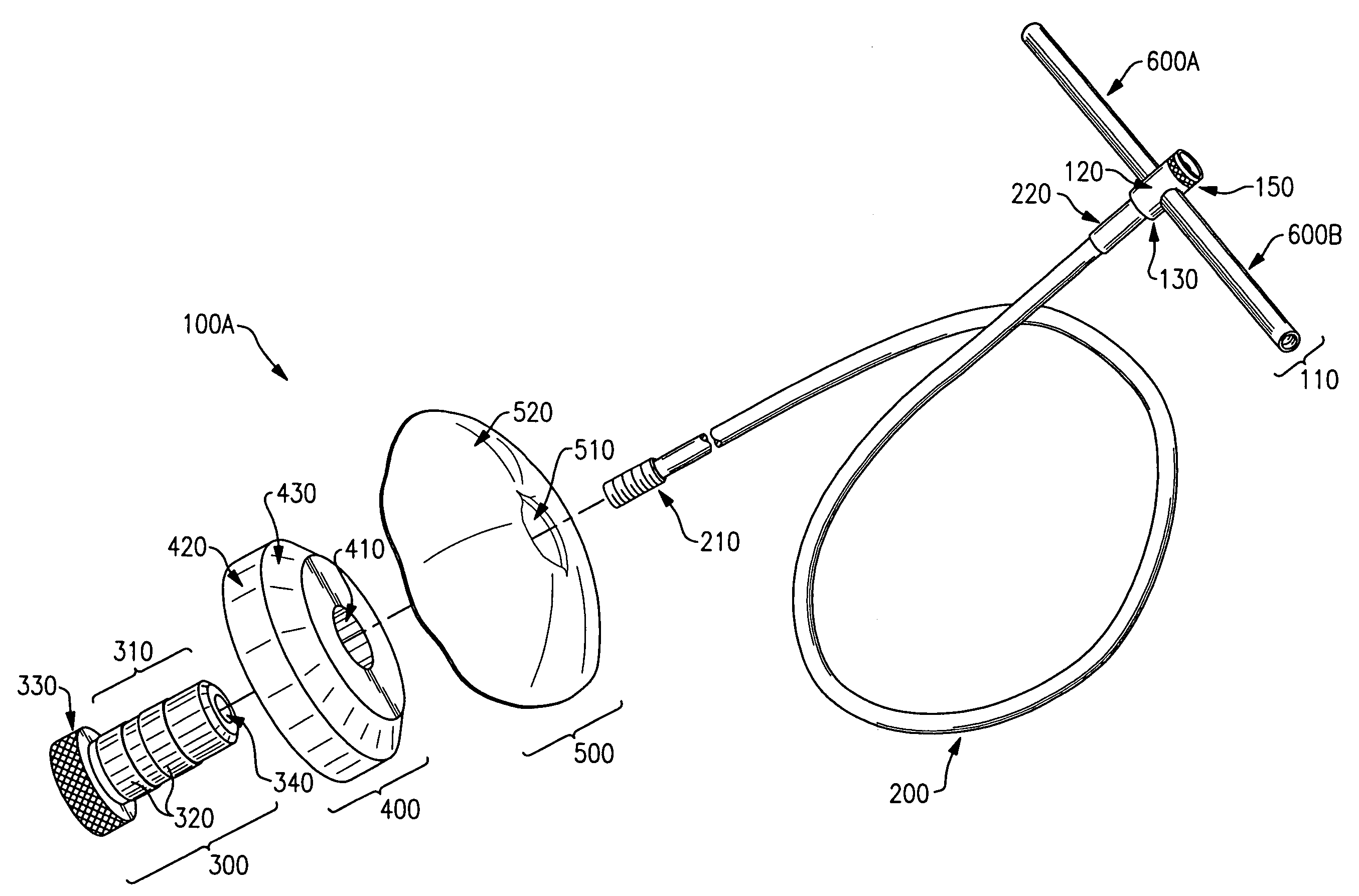

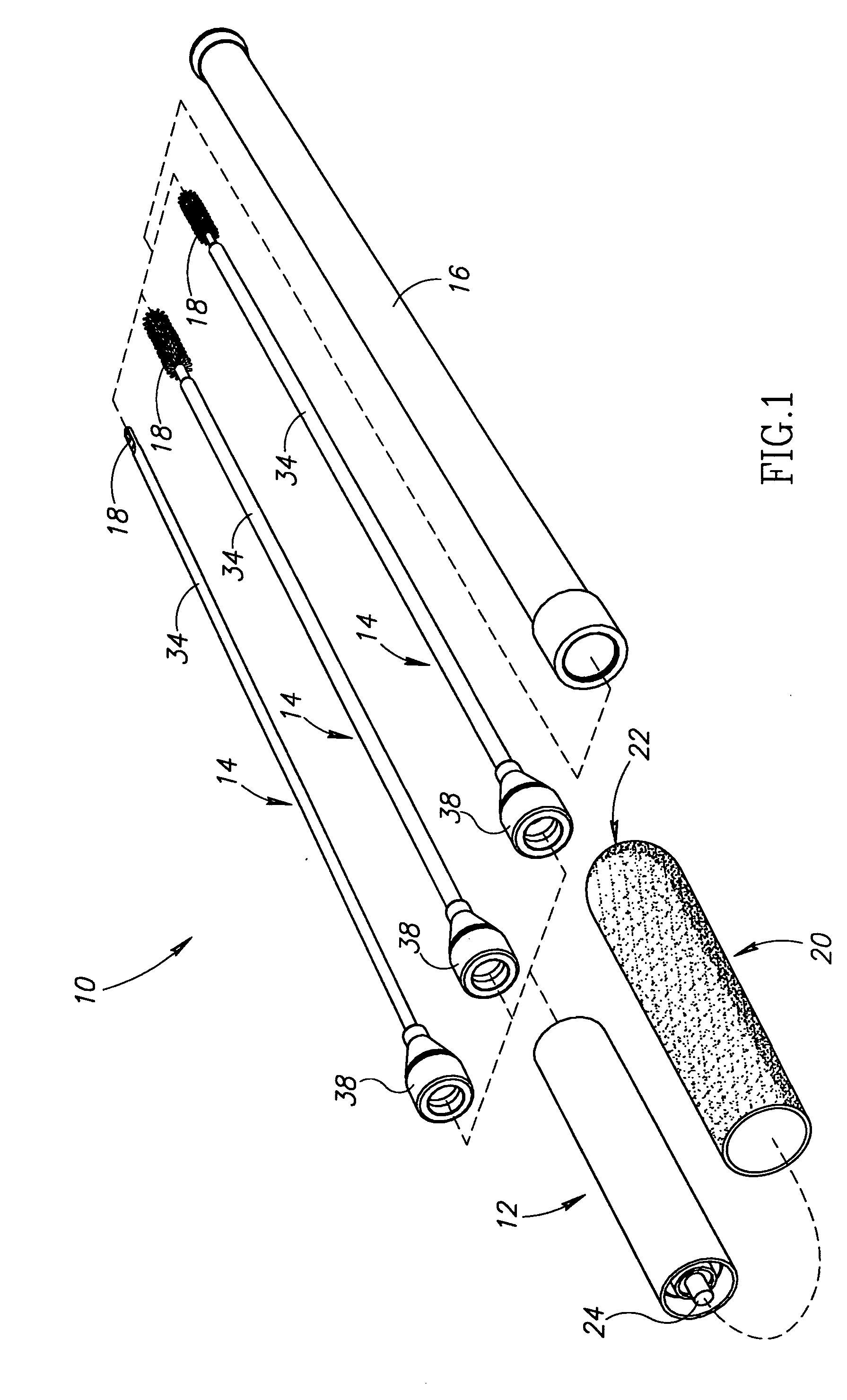

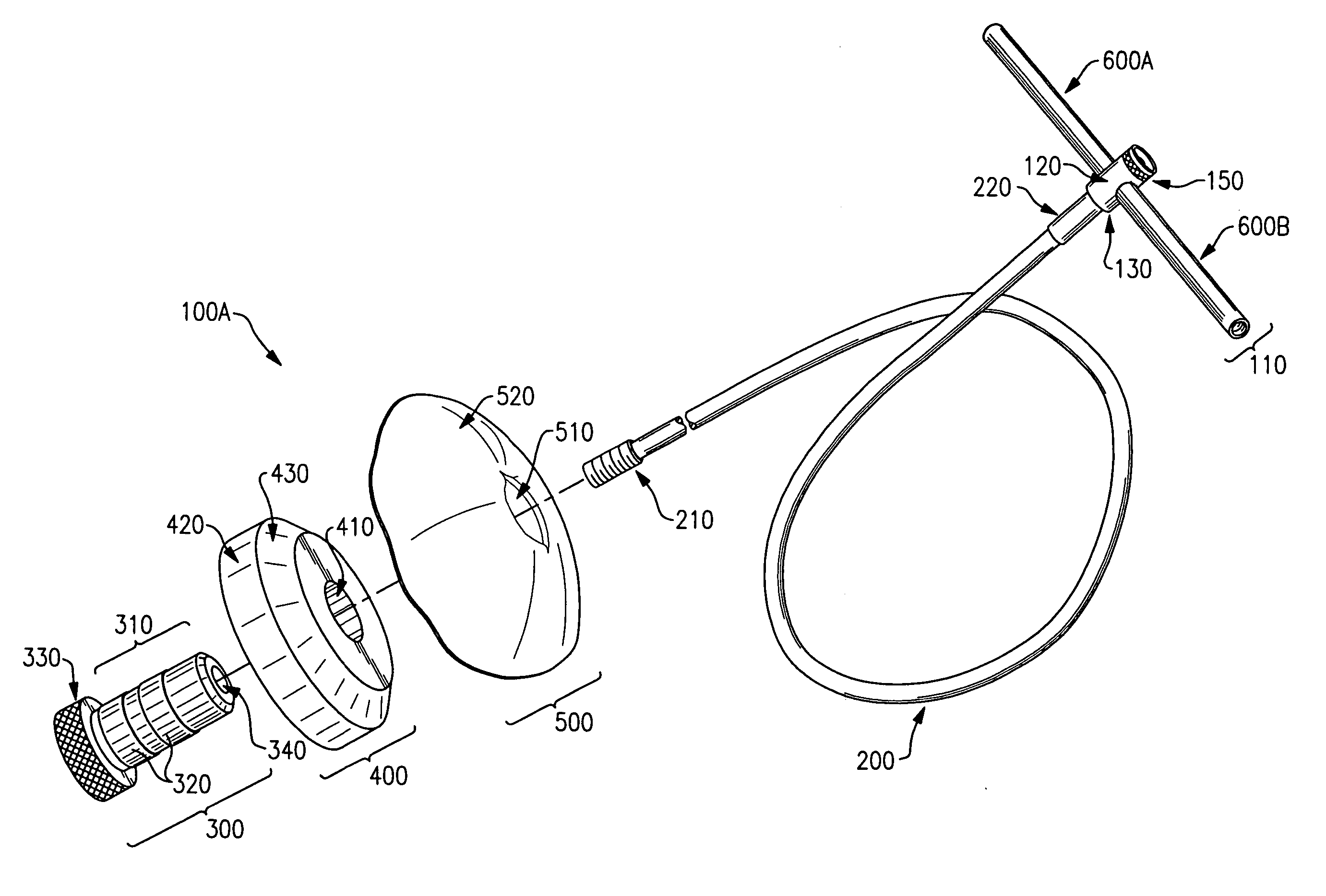

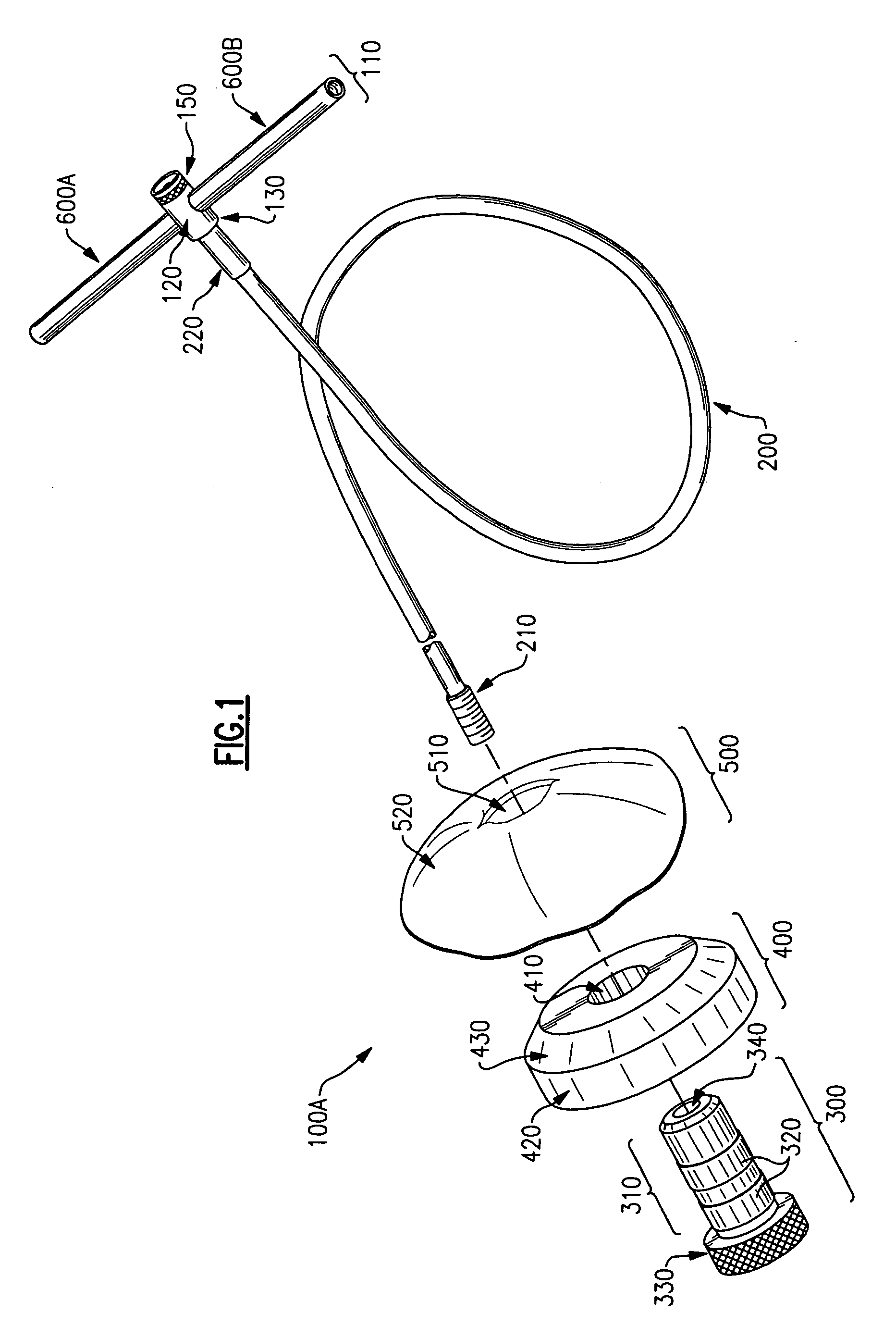

Configurable device for cleaning the barrel of a firearm, and firearm cleaning kit containing components of device

ActiveUS7356961B2Easy to carryReliably and effectively clean a wide variety of firearmsHollow article cleaningCleaning using toolsEngineering

Methods and devices are provided for cleaning firearm barrels, including those of military issue firearms, wherein the methods include a step for removing loose materials from within the barrel, a step for dislodging materials not removed during the first removal step, and a step for removing the materials dislodged during the dislodging step, as well as one or more optional cleaning steps to be performed in addition to or in lieu of the other cleaning steps, and wherein the firearm barrel cleaning device can be adapted to have different configurations for use during one or more of the various cleaning steps.

Owner:THE OTIS PATENT TRUST

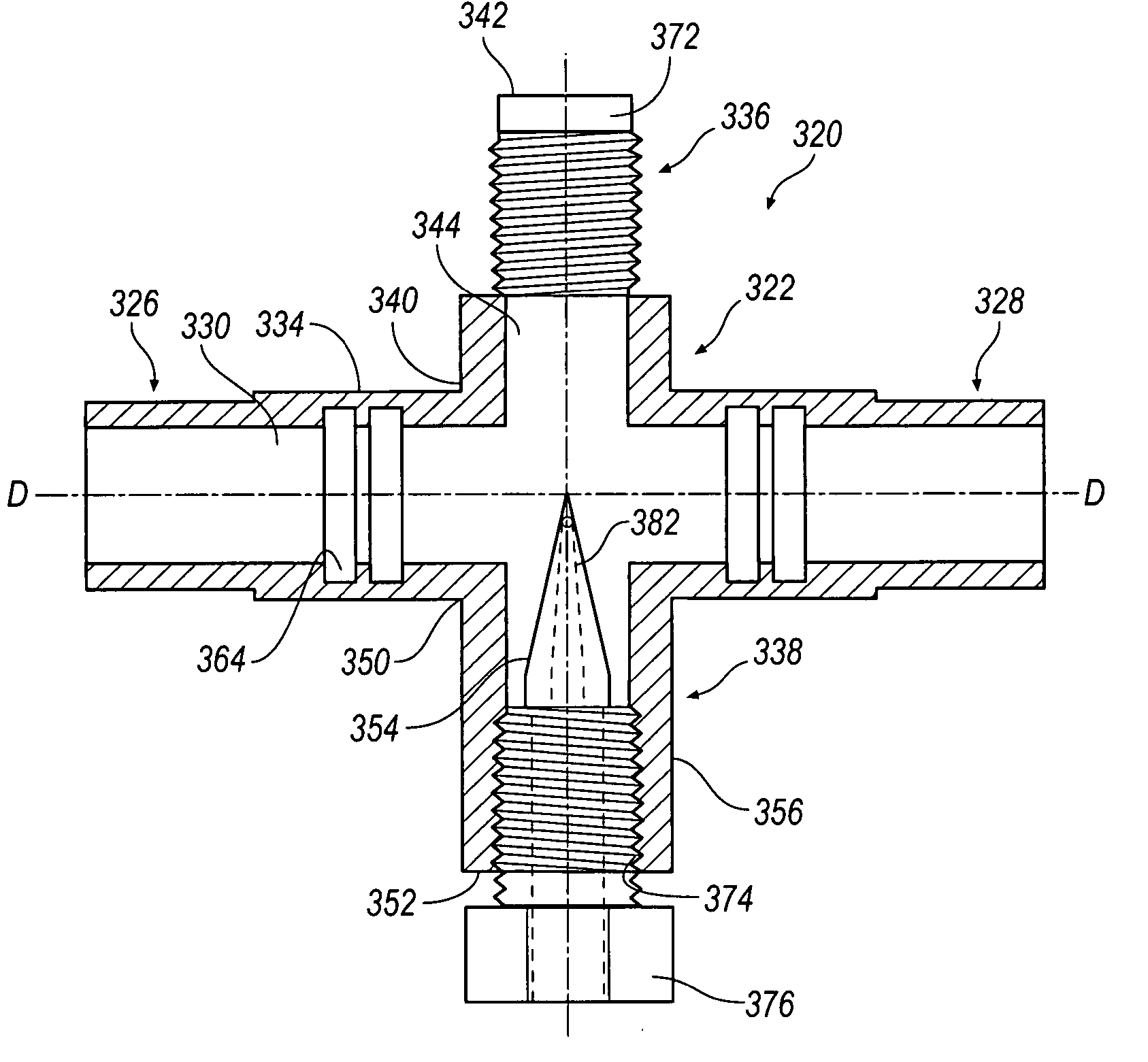

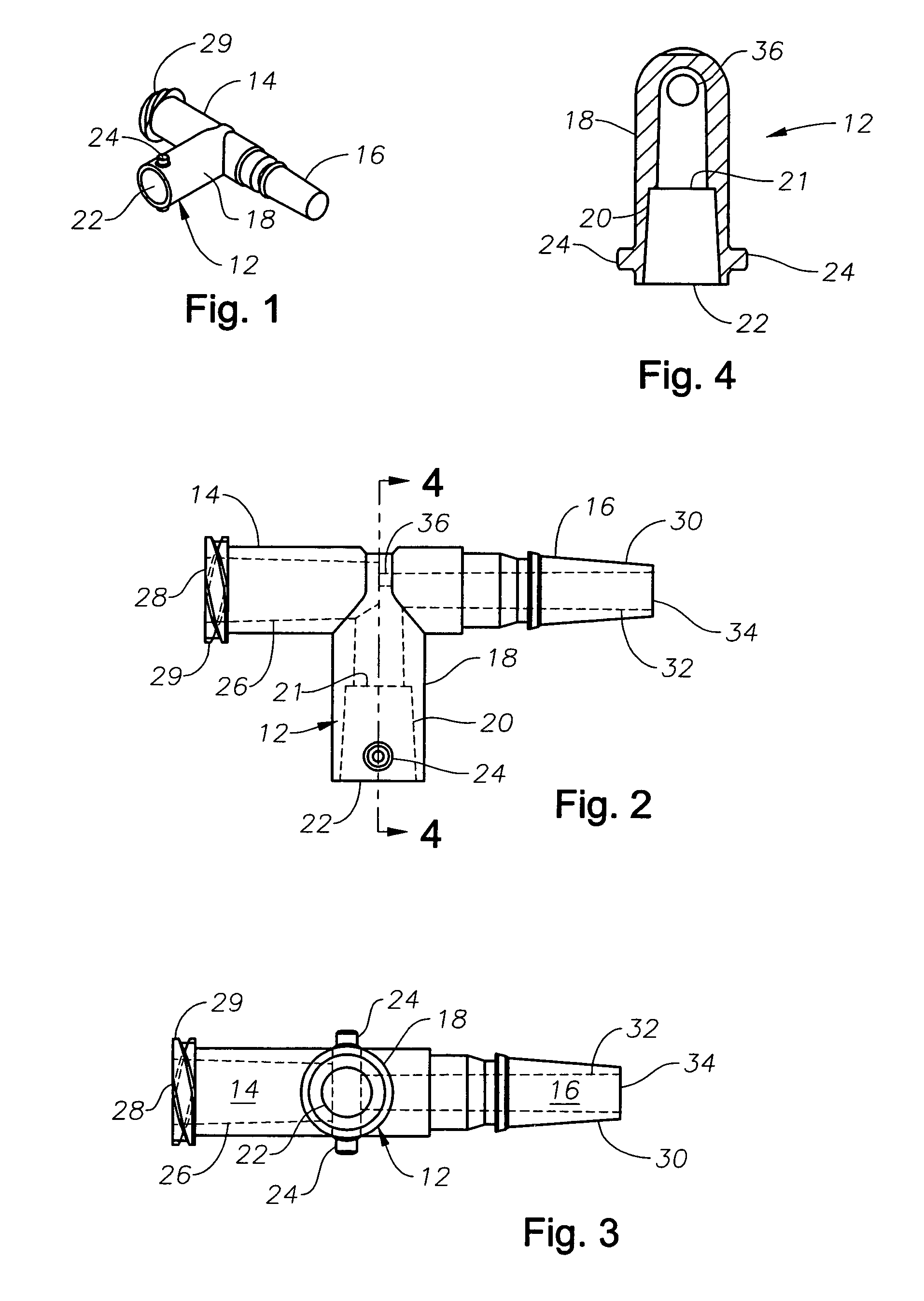

Fitting for fluid conveyance

InactiveUS20050134038A1Takes number of stepLow costPipeline expansion-compensationBranching pipesEngineering

Owner:EATON CORP

Method and apparatus for replacing damaged section of a subsea pipeline without loss of product or entry of seawater

A method and apparatus for repairing a submerged pipeline. The method comprises installing a pair of hot tap tees on either side of the damaged section of pipeline, cutting a hole in the pipeline through each hot tap tee, inserting and securing plugging pigs into the pipeline, cutting and removing the damaged section of pipeline, and installing a new section of pipeline. The apparatus includes a plugging pig for use during repair of a damaged pipeline comprising a body shaft, a cup seal secured to the body shaft for engaging an interior wall of the pipeline, a cam attached to the exterior of the body shaft, a slip assembly for sliding on the cam and engaging a slip against the pipeline wall, and a control mechanism for engaging and releasing the slip from the wall.

Owner:VALMET OY +1

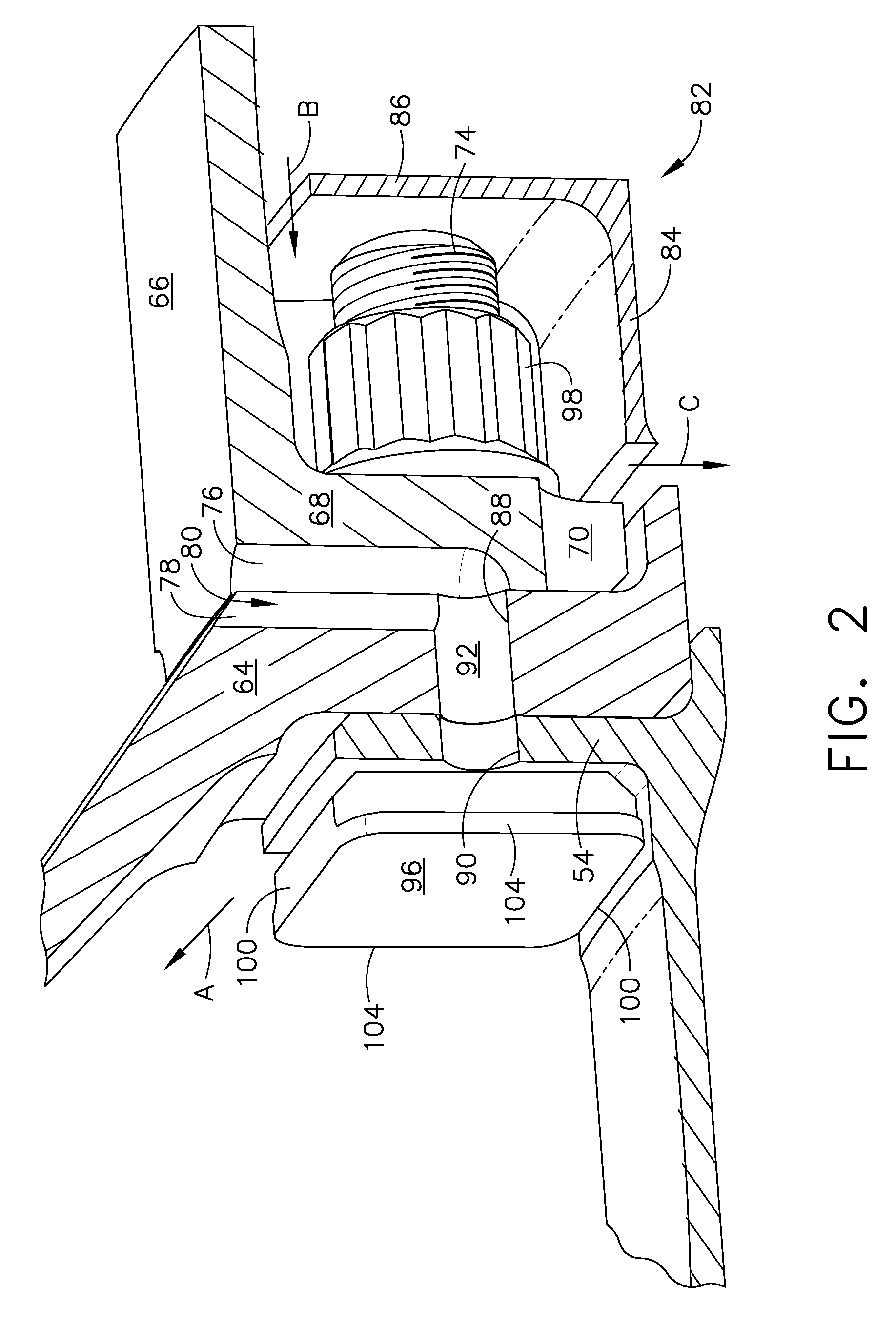

Hot tap fluid blaster apparatus and method of using same

A apparatus and method of using the apparatus for removing a blockage in a subsea pipeline without retrieval of the pipeline to the surface. The apparatus components include a hot tap saddle, a drill assembly, a fluid blaster assembly and a support frame. The hot tap saddle component has a first portion and a second portion, with the first and second portions being configured to clampingly engage in a sealing relationship to the subsea pipeline. The first portion of the saddle includes a first and second opening with the first opening extending generally upwardly and configured for connecting to a drill assembly and the second opening being positioned generally at an angle to the first opening and configured for connecting to a fluid blaster assembly. The fluid blaster assembly including a nozzle, a hose and a high pressure pump with the fluid blaster assembly being contained within a pressure vessel. The fluid blaster assembly is configured for mounting to the second opening of the hot tap saddle component. The support frame assembly is configured for gripping and supporting the subsea pipeline on the sea floor while the fluid blaster assembly operates to remove a blockage in the subsea pipeline with the pipeline being under pressure and without severing the pipeline.

Owner:SAIPEM AMERICA

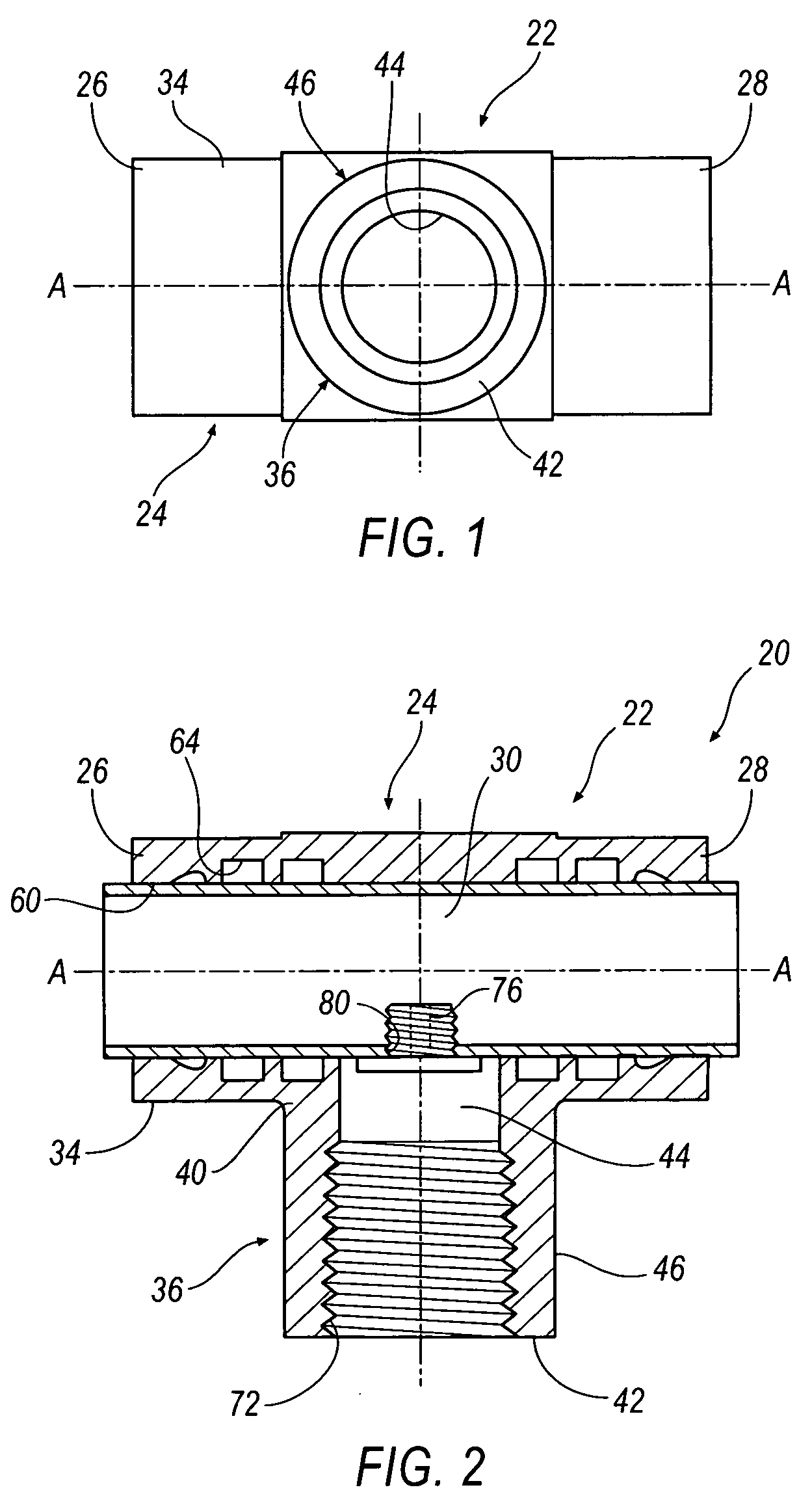

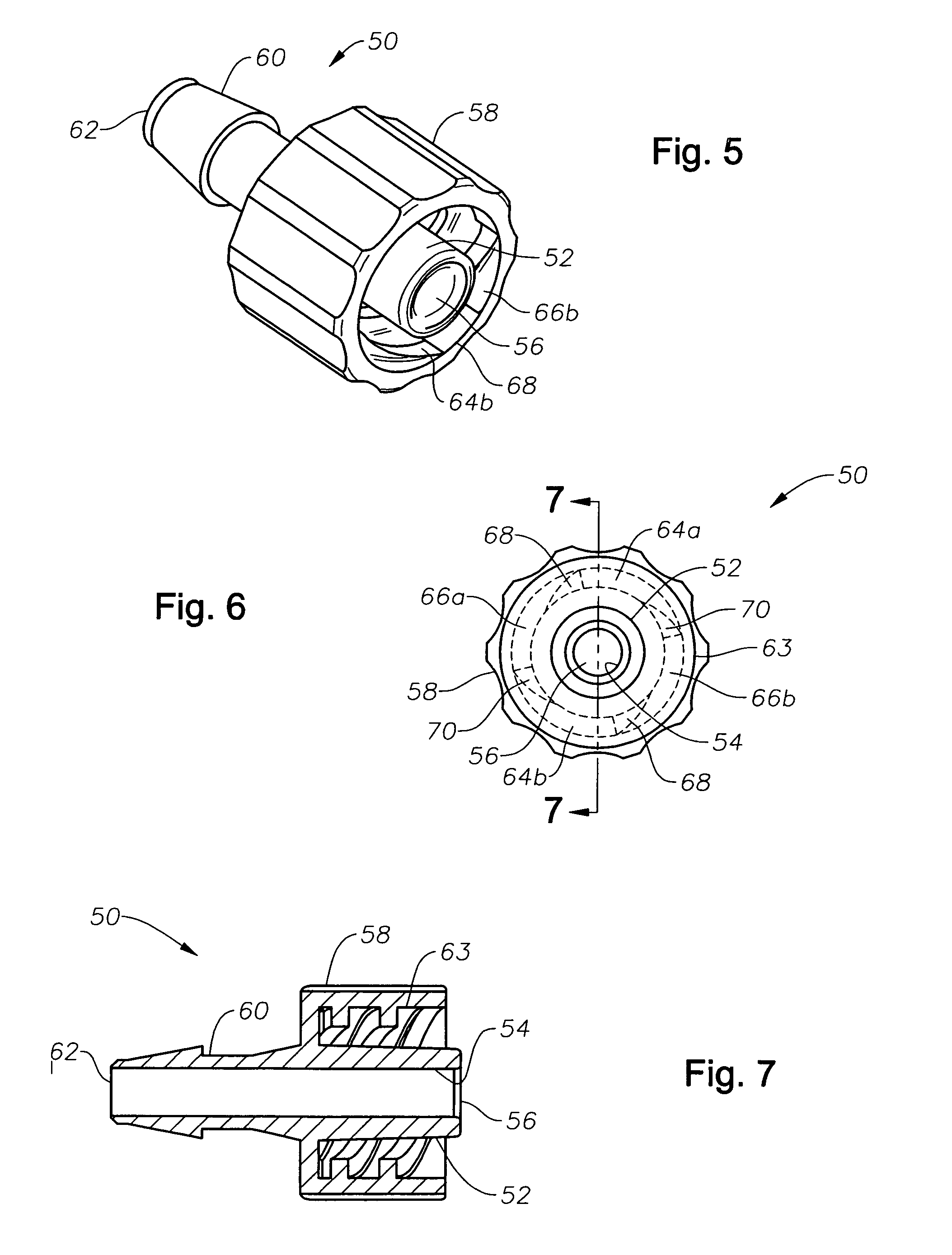

Tubing fitting

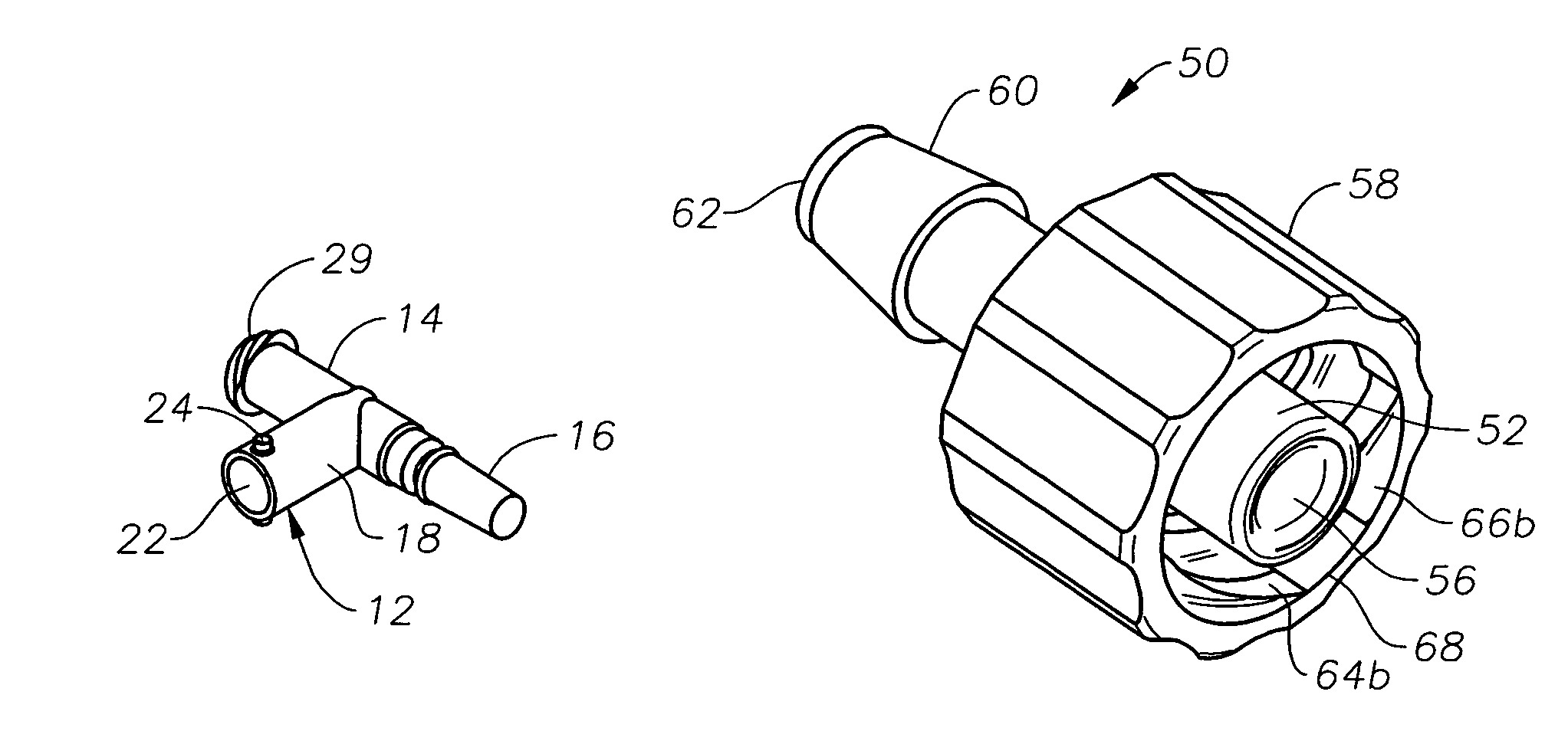

ActiveUS7523967B2Engage with obstructionSleeve/socket jointsPipeline expansion-compensationShaft collarBiomedical engineering

A tubing fitting for use in microsurgery including a female tubing fitting and a male tubing fitting. The female tubing fitting has an external surface with a pair of opposing projections disposed thereon and an internal bore. The male tubing fitting has a second internal bore and a collar at least partially surrounding the second internal bore. The collar has an internal surface with two pairs of opposing sloping ramps disposed thereon. The pairs of opposing sloping ramps are arranged so as to create a pair of opposing spaces for removably receiving the pair of opposing projections.

Owner:ALCON INC

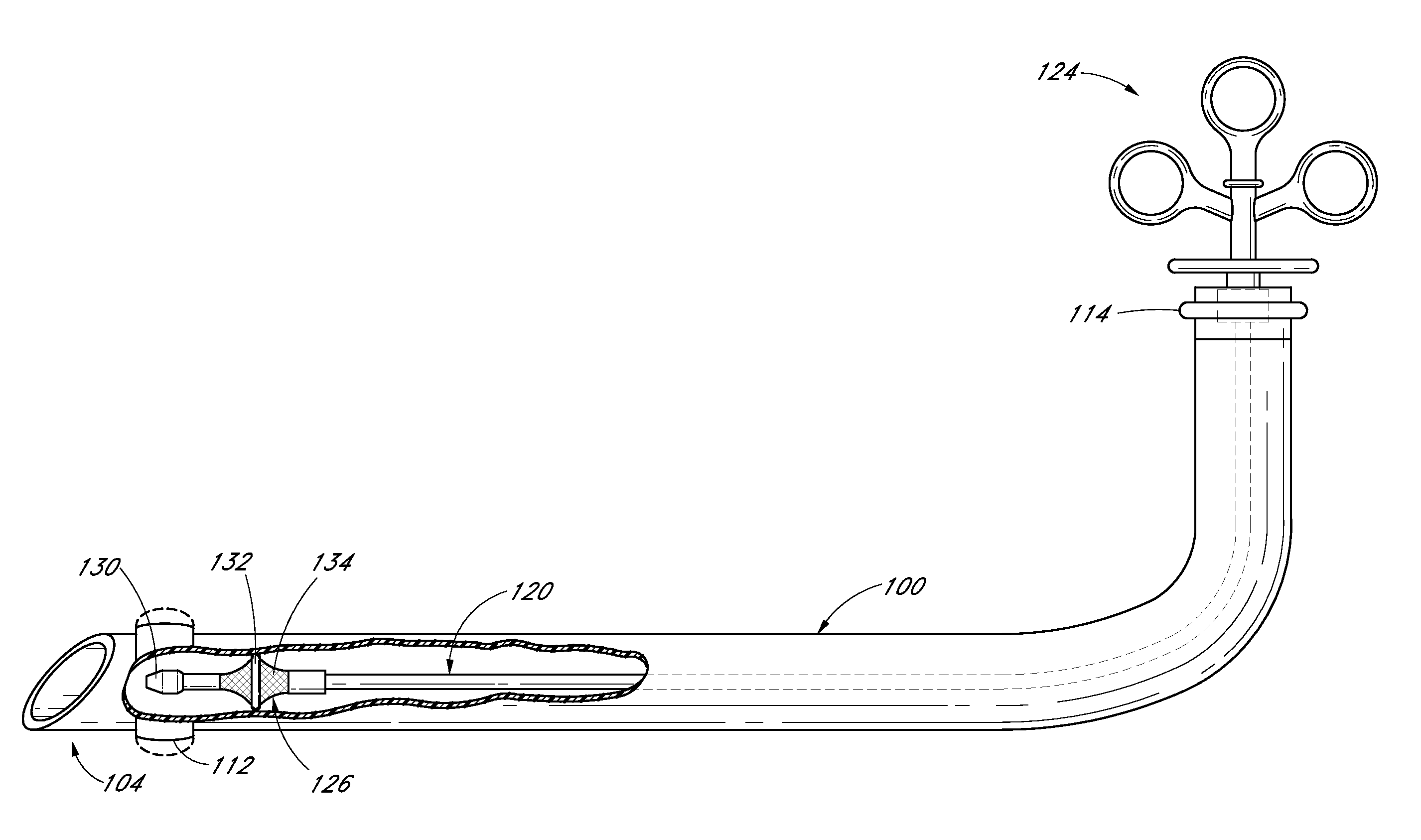

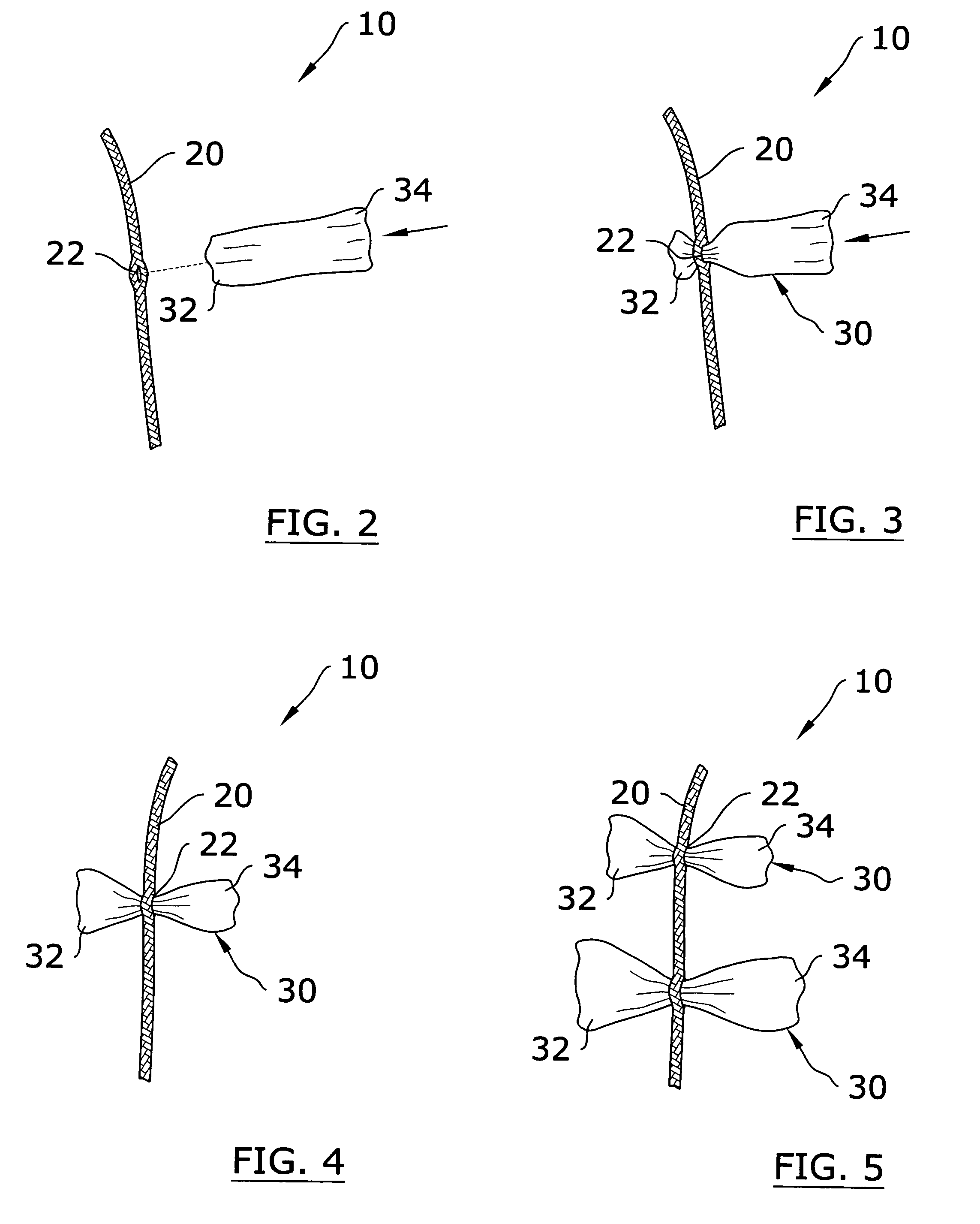

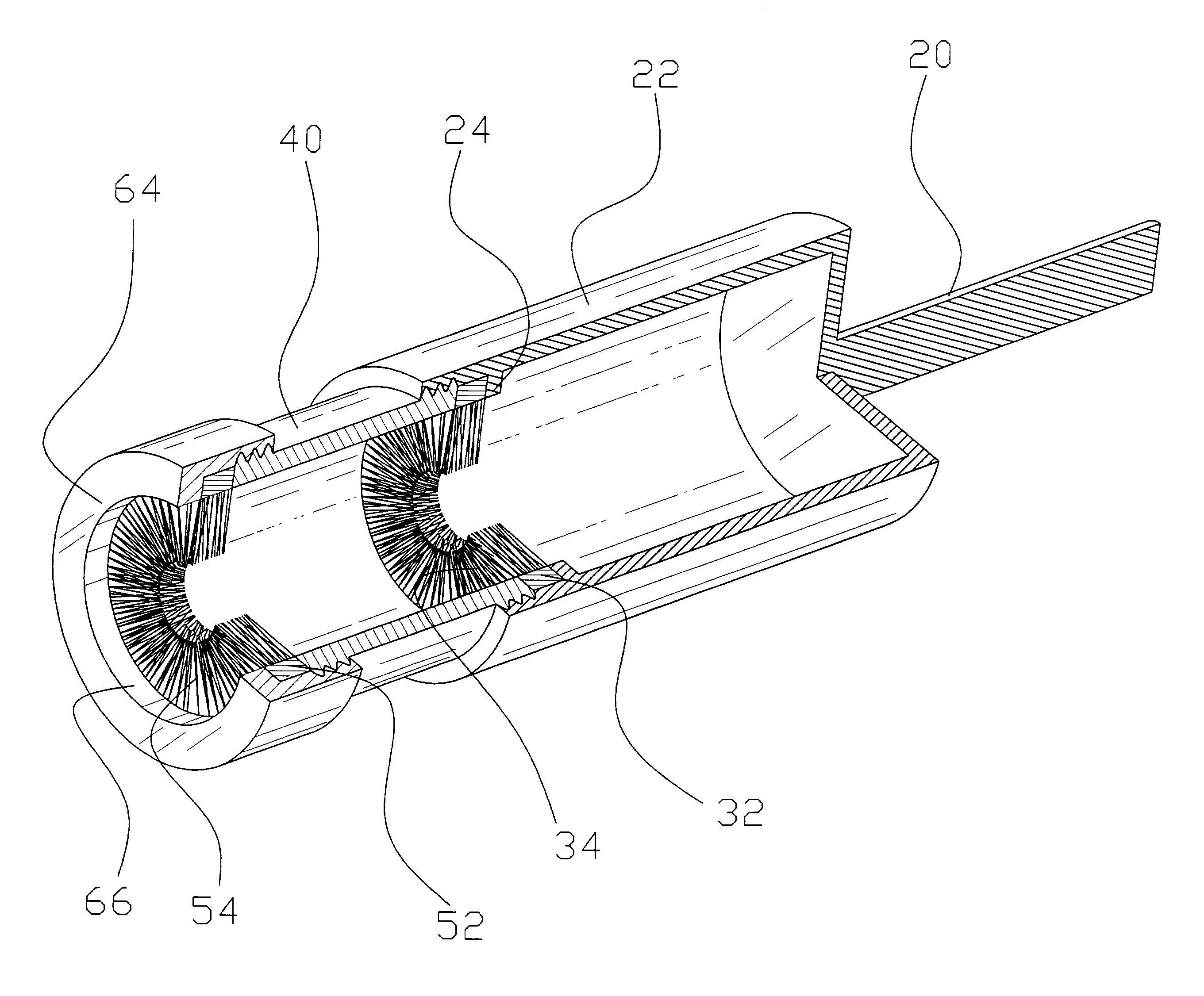

Devices for cleaning endotracheal tubes

ActiveUS20100199448A1Adequate airflowPrevent buildupBronchoscopesLaryngoscopesTracheal tubeEndotracheal tube

Systems, devices, and methods are disclosed for the cleaning of an endotracheal tube while a patient is being supported by a ventilator connected to the endotracheal tube. According to some embodiments, a mechanically-actuated non-inflatable cleaning device for scraping debris (e.g., biofilm) from an interior wall of an endotracheal tube is provided. In one embodiment, the cleaning device comprises an elongated member having a proximal end and a distal end and a mechanically-expandable scaffold positioned along the distal end of the elongated member. In one embodiment, the mechanically-expandable scaffold comprises one or more removal members configured to engage an interior surface of an endotracheal tube when the scaffold is in a radially-expanded position and to remove debris from the interior surface of the endotracheal tube when the device is withdrawn from the endotracheal tube.

Owner:AVENT INC

Valve with self-cleaning trim

The seal assembly is disclosed for use with a valve having a trim cage with an inner surface extending along in axis and a plug sized to fit inside the trim cage inner surface, wherein the plug is adapted to move along the axis thereof. A seal ring is attached to an upstream portion of the cage to effectuate a seal with the plug. The plug is equipped with a wiper seal that cleans or otherwise removes debris from the seating surface of the seal ring, an interior surface of the seal ring and an interior surface of the cage during both the opening and the closing of the valve. Thus, the valve is self-cleaning. Further, the wiper seal delays throttling action through the valve until the plug has moved a substantial distance away from the seating surface of the seal ring which reduces high pressure abrasive flow against the seating surface of the seal ring to reduce wear on the trim set.

Owner:FISHER CONTROLS INT LLC

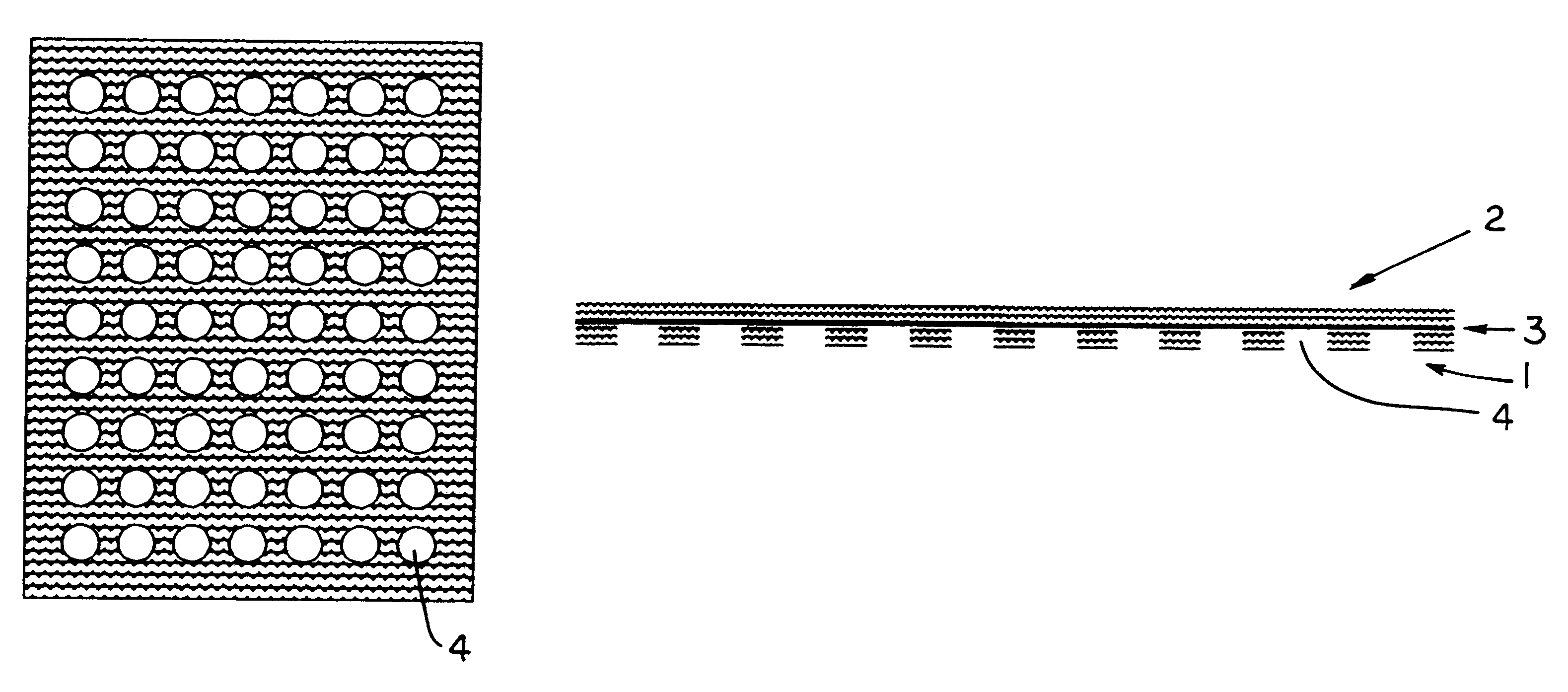

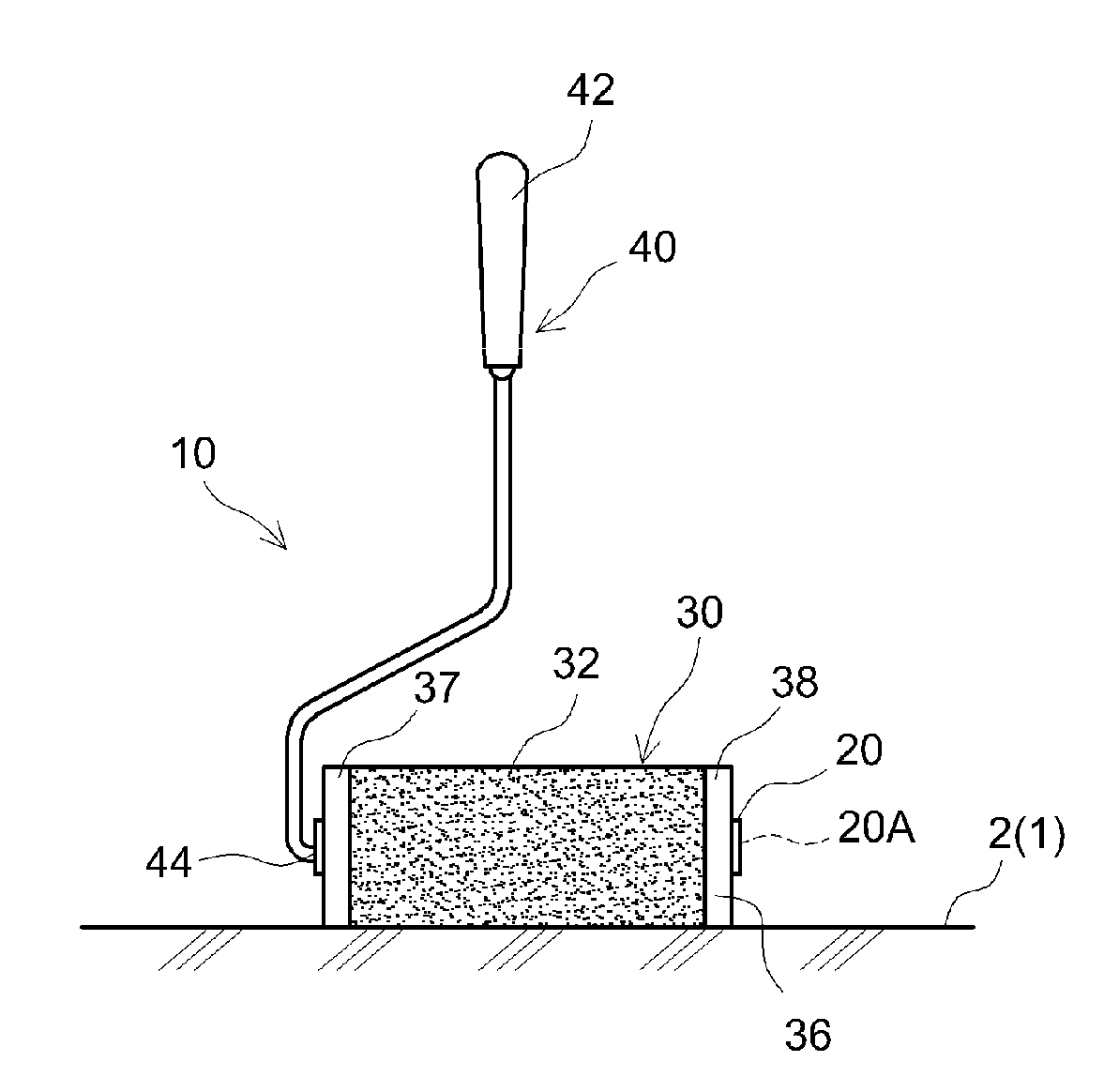

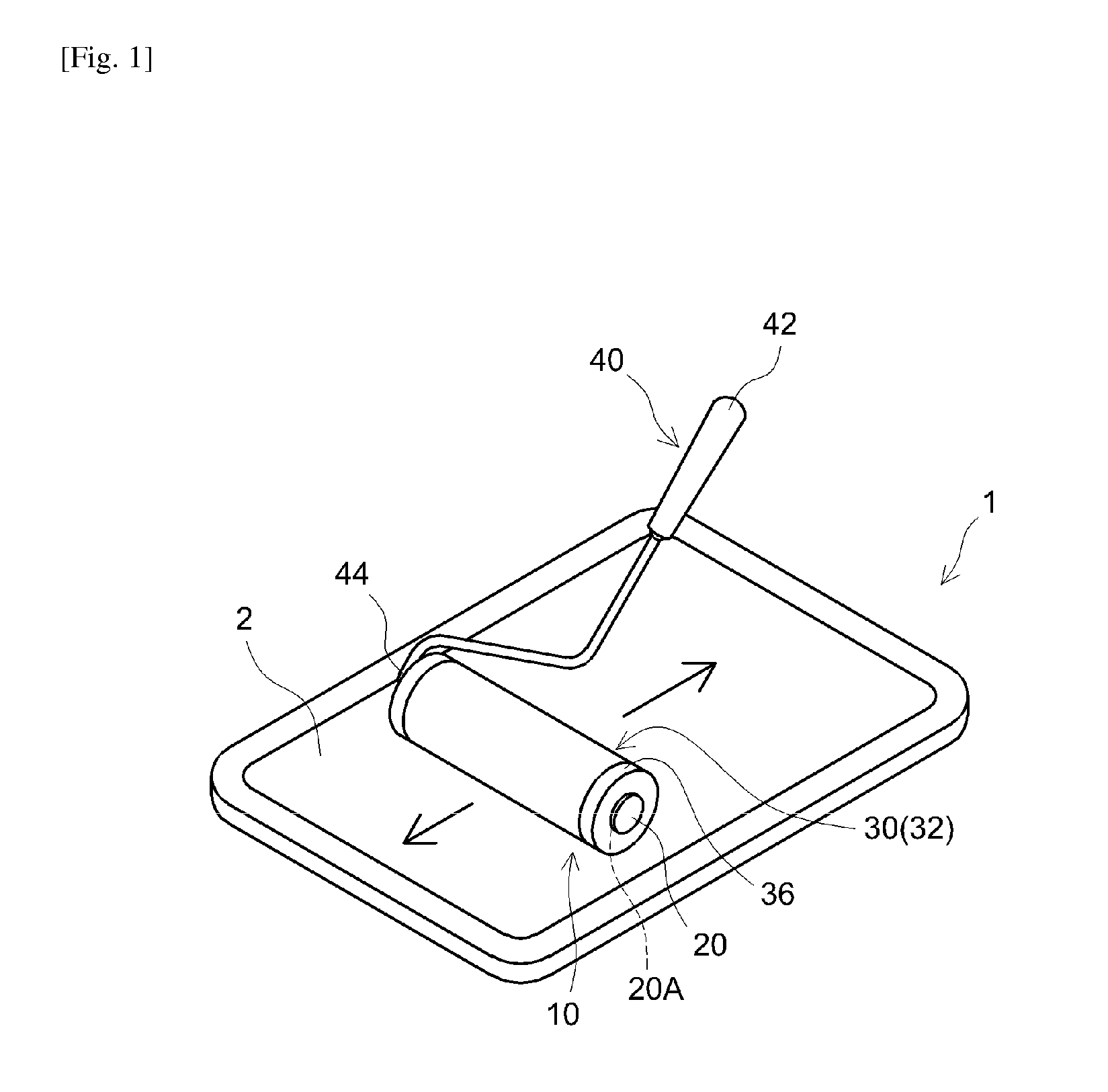

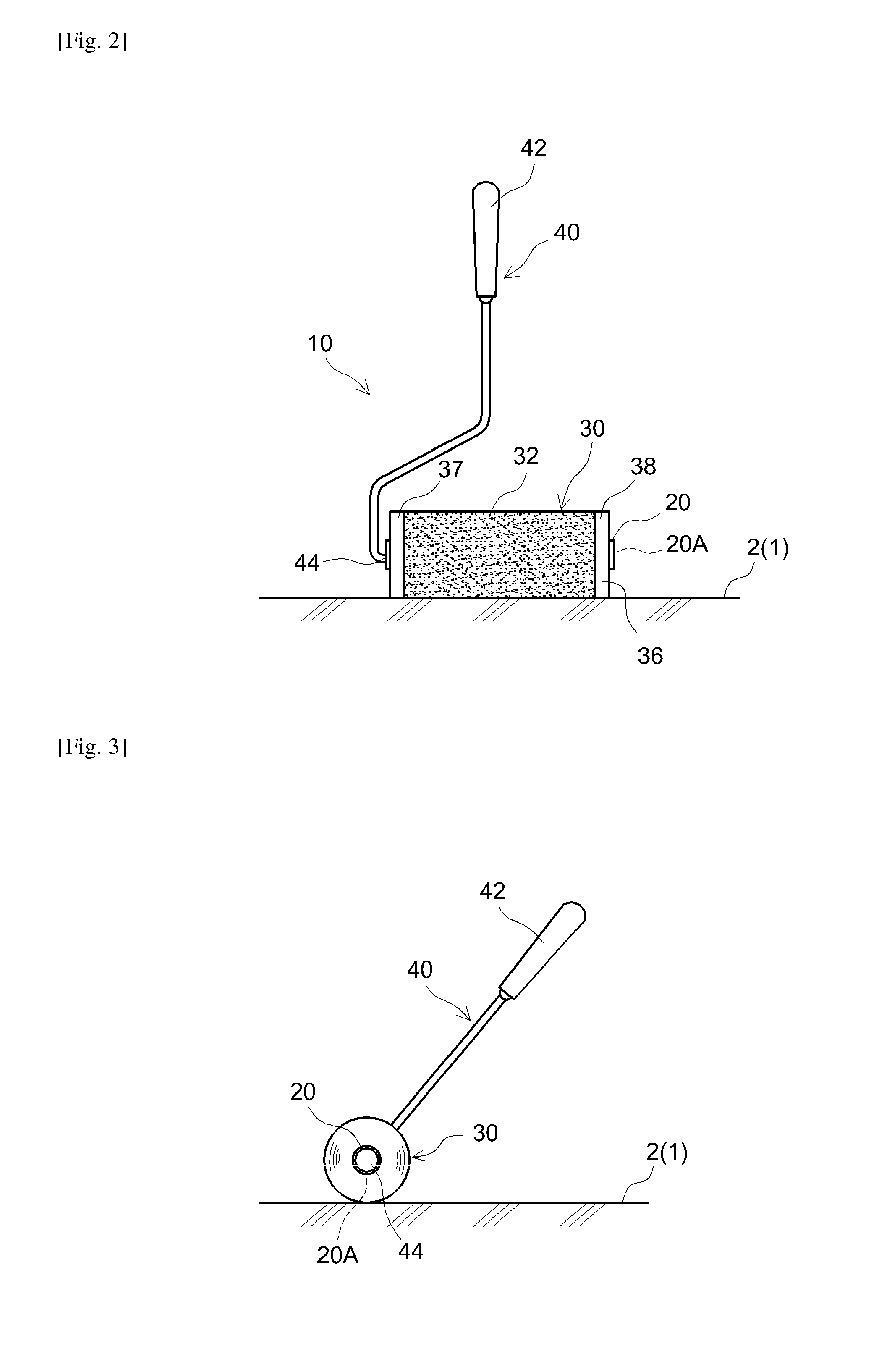

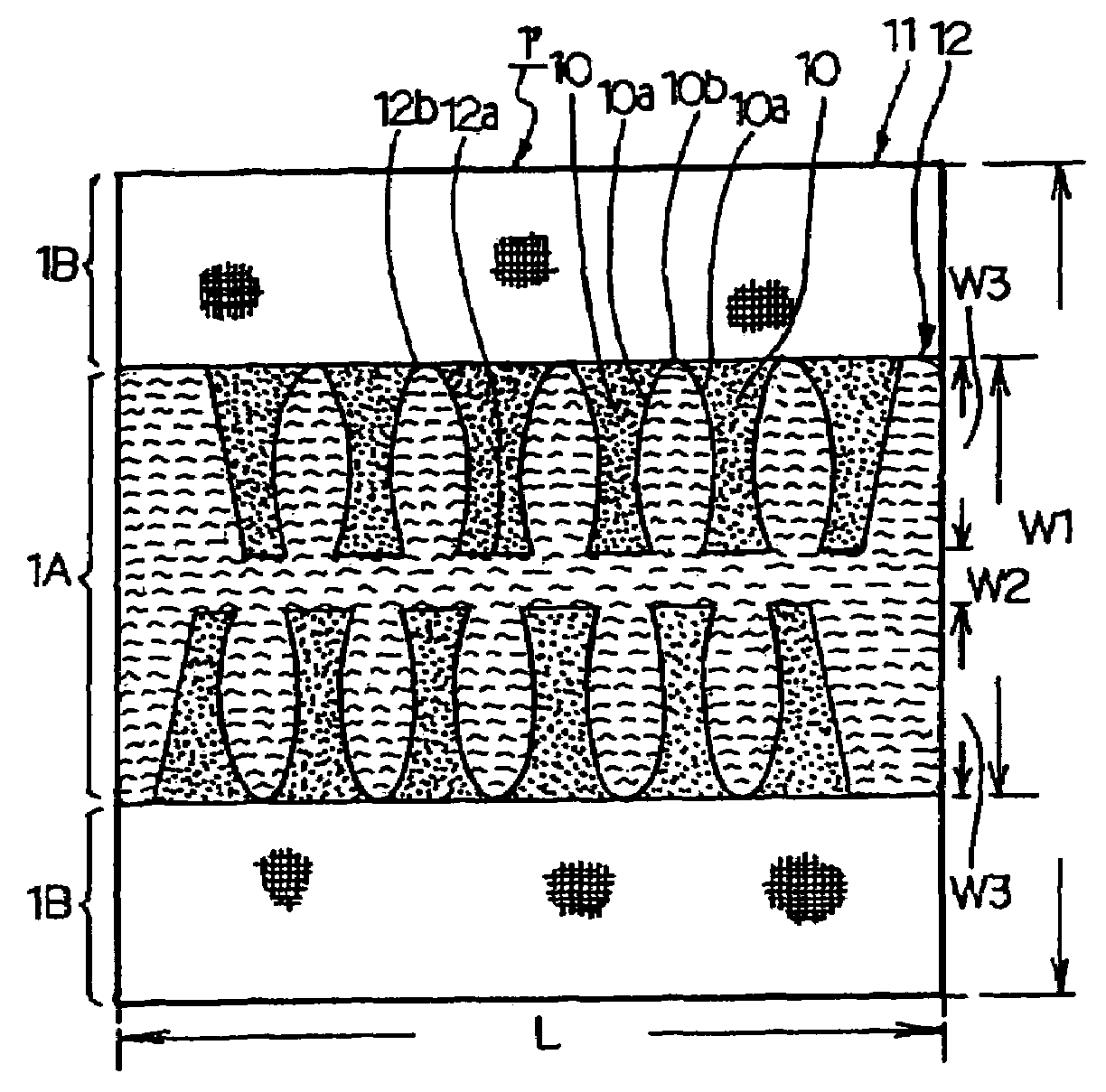

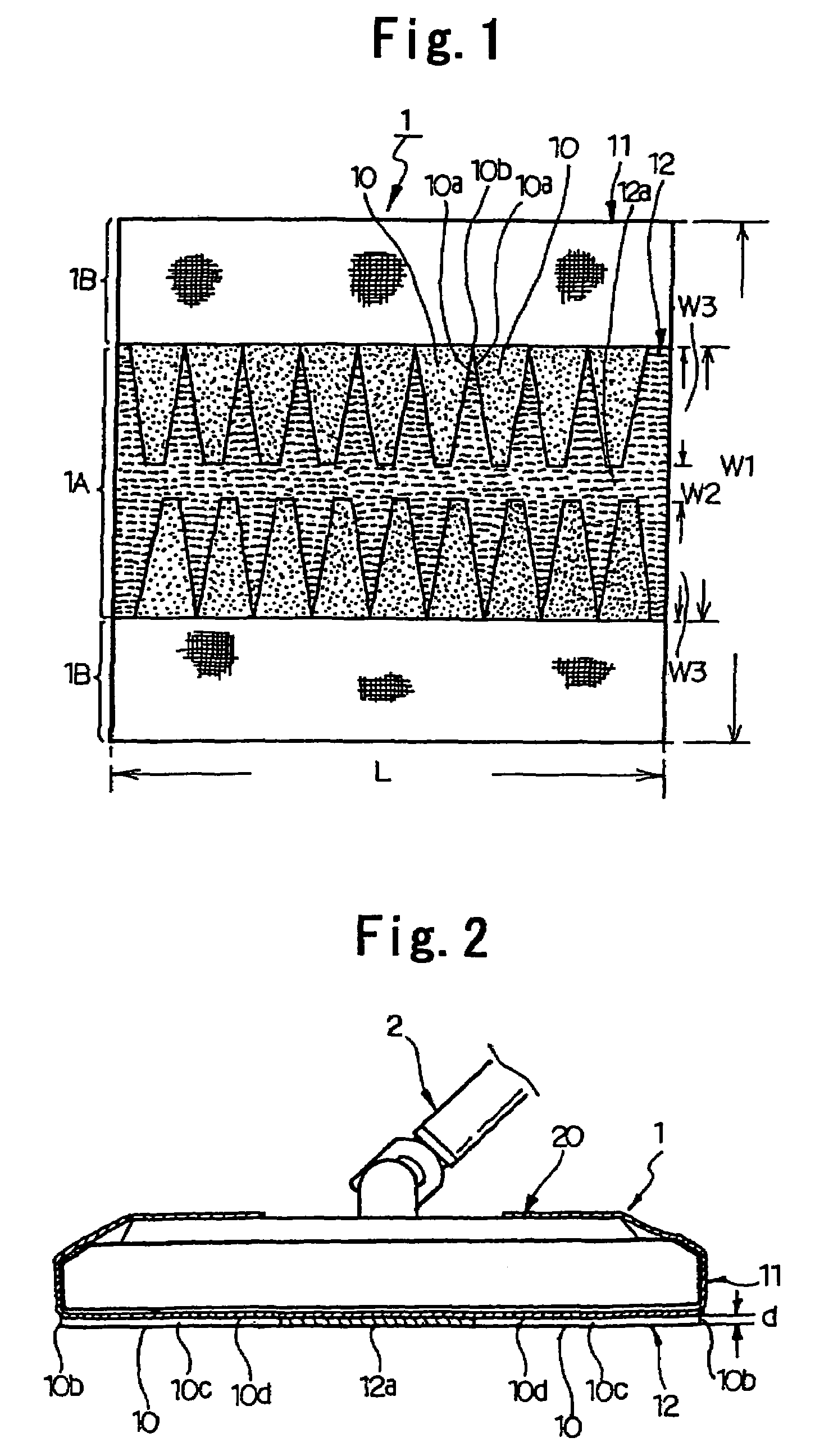

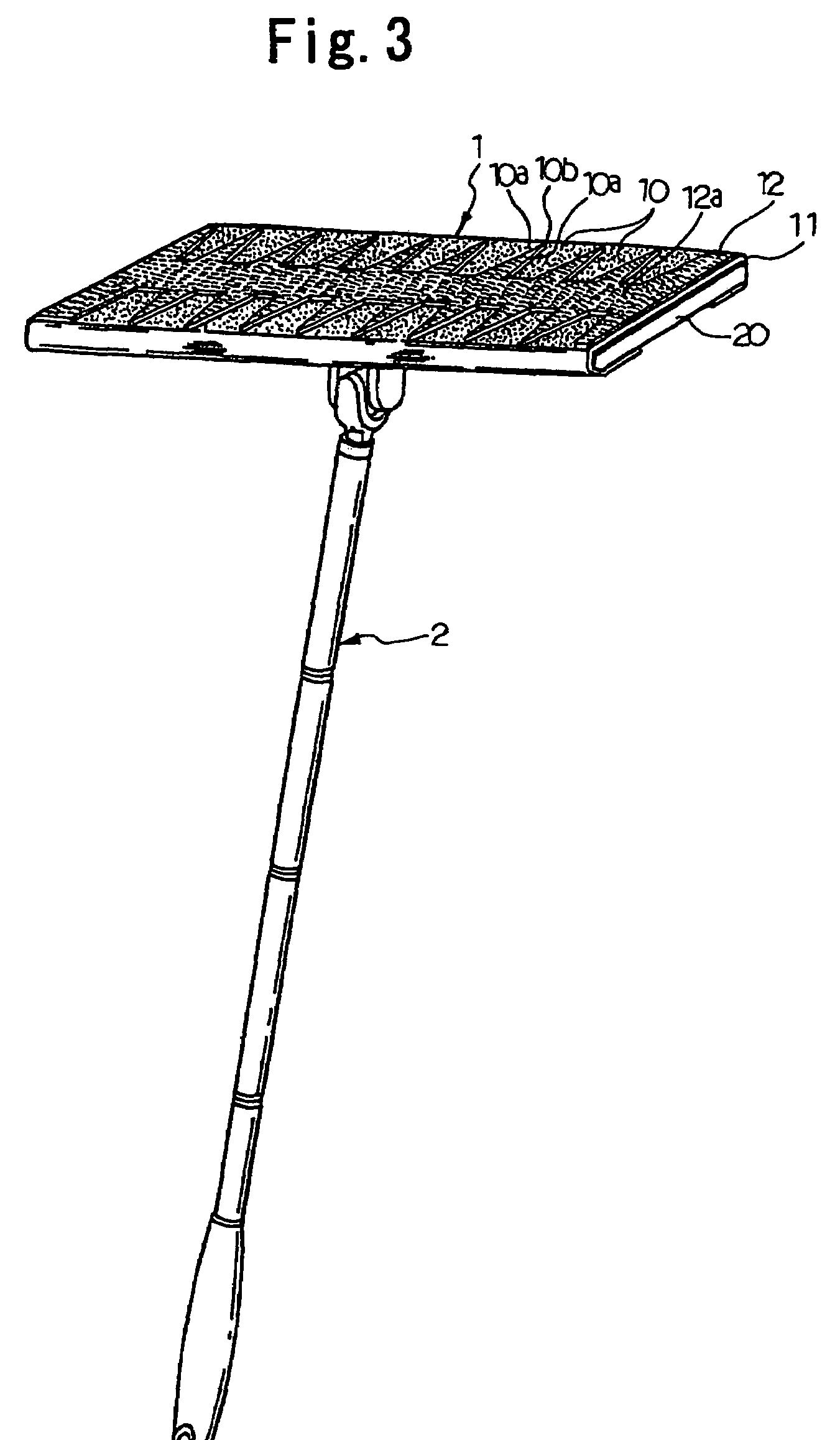

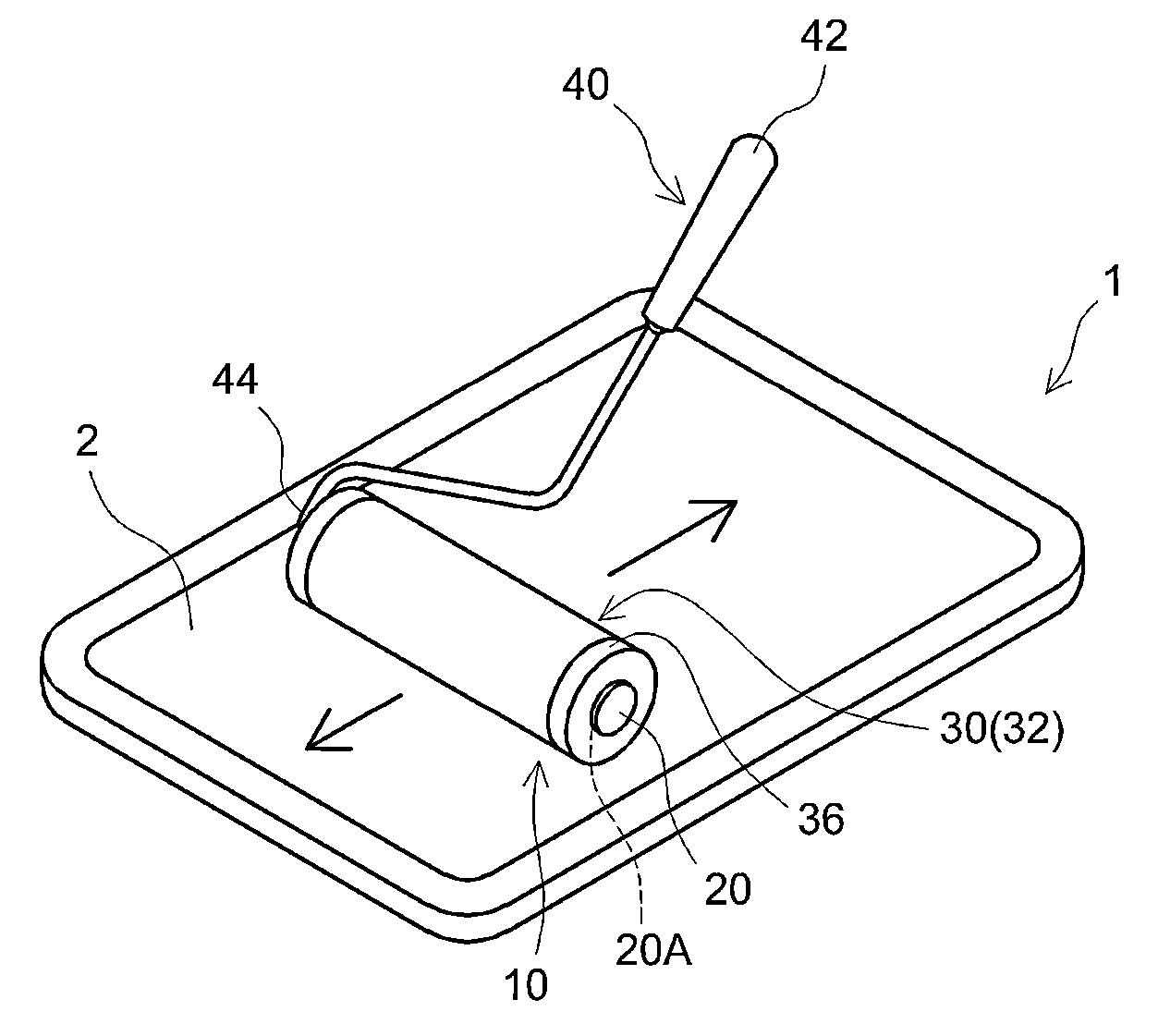

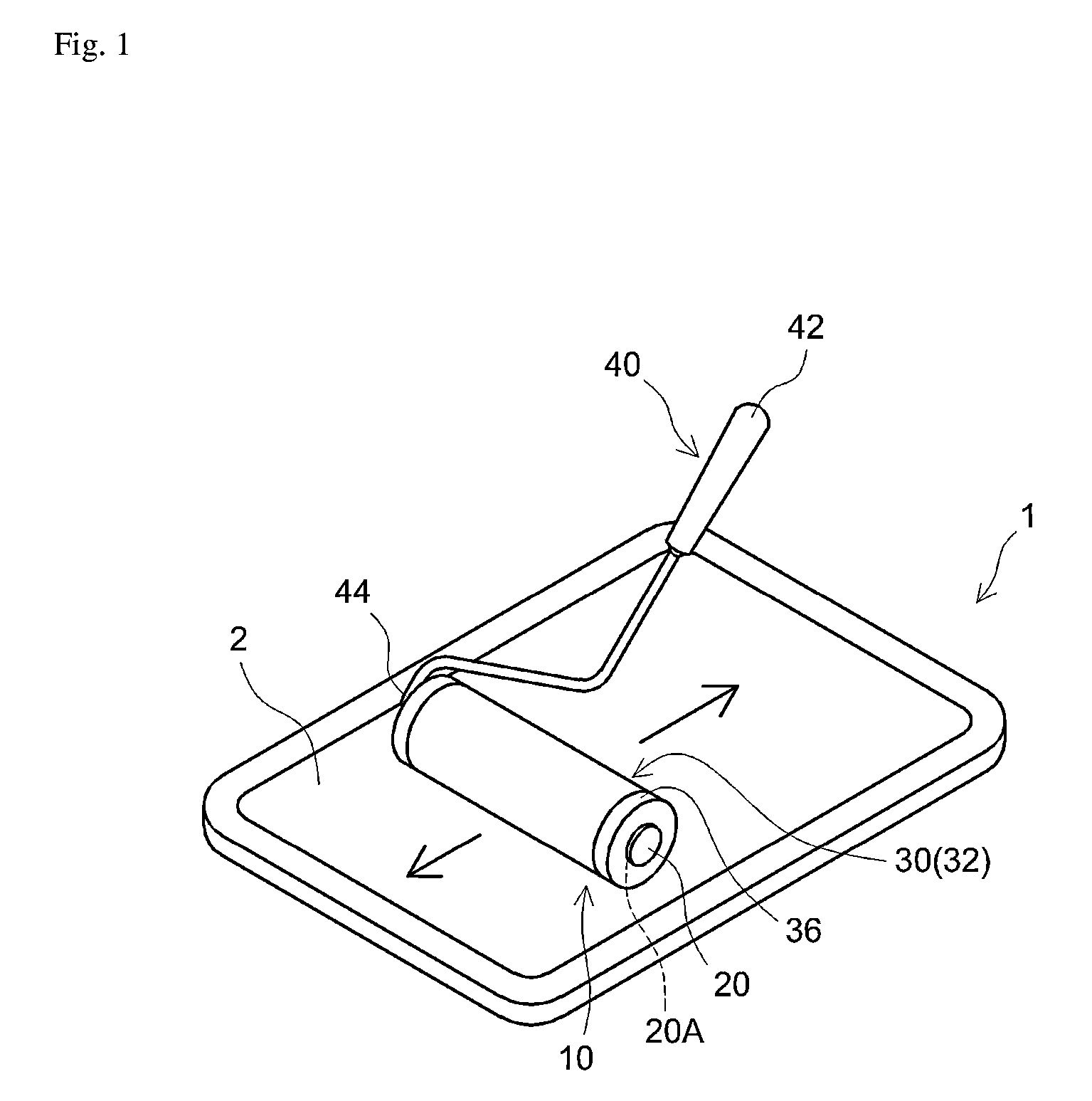

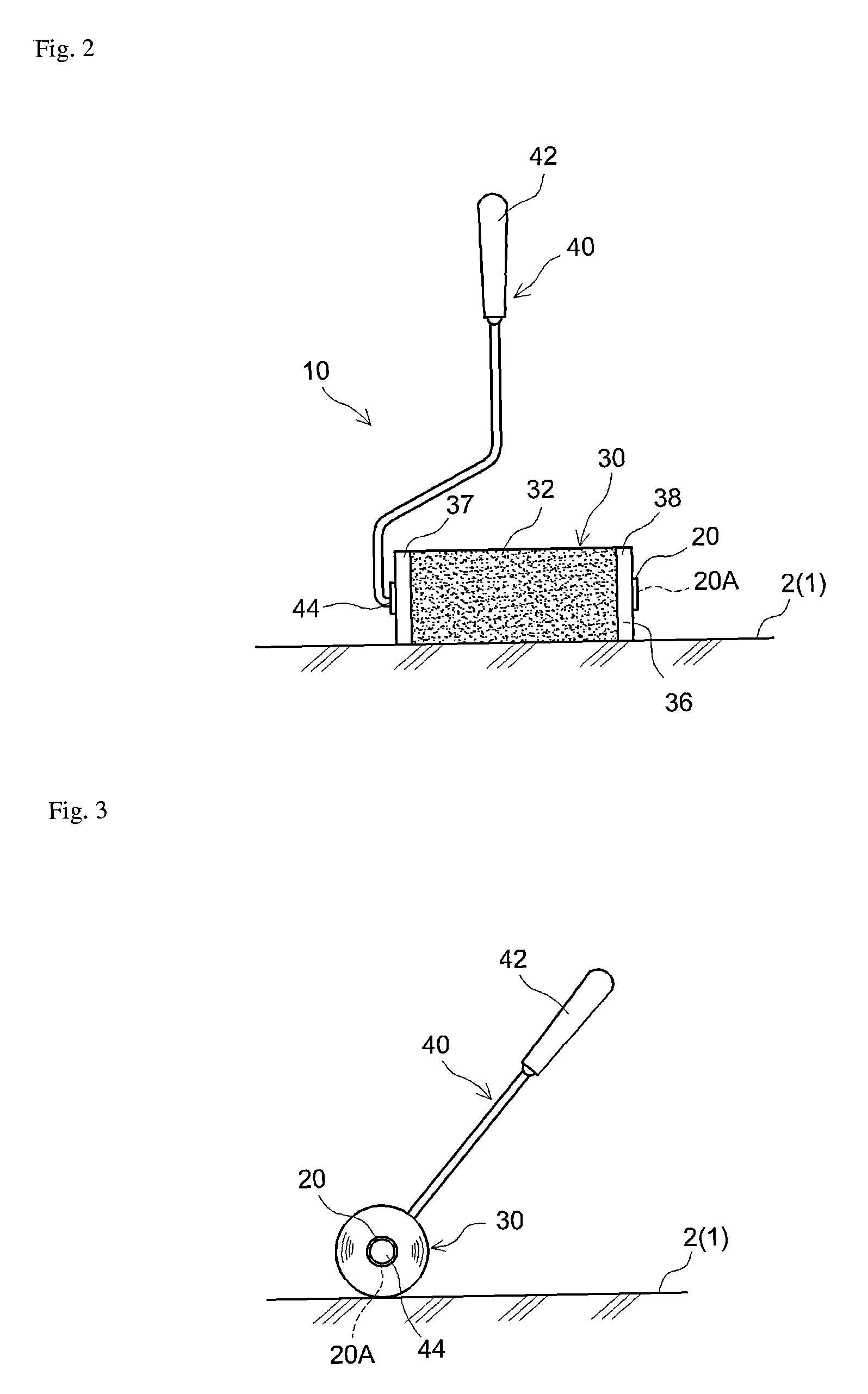

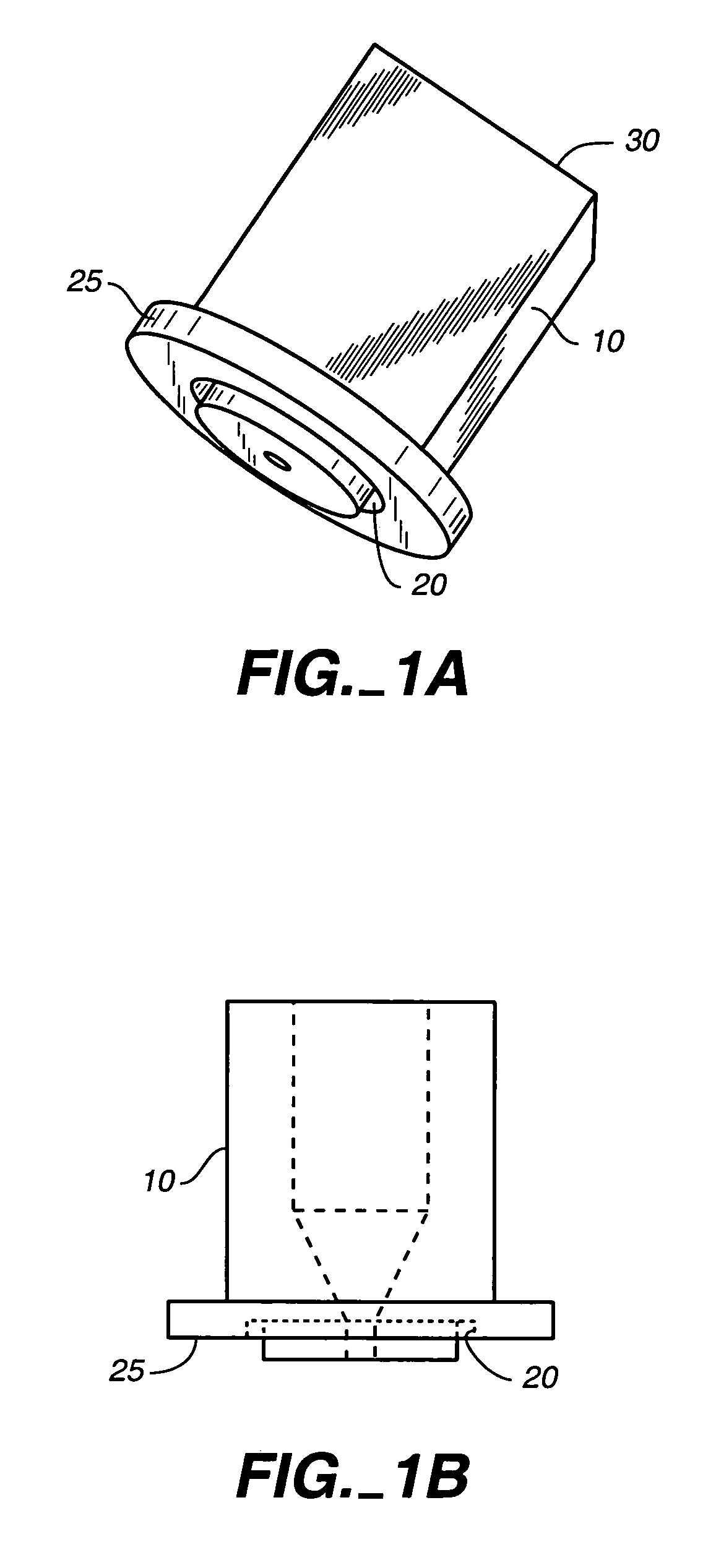

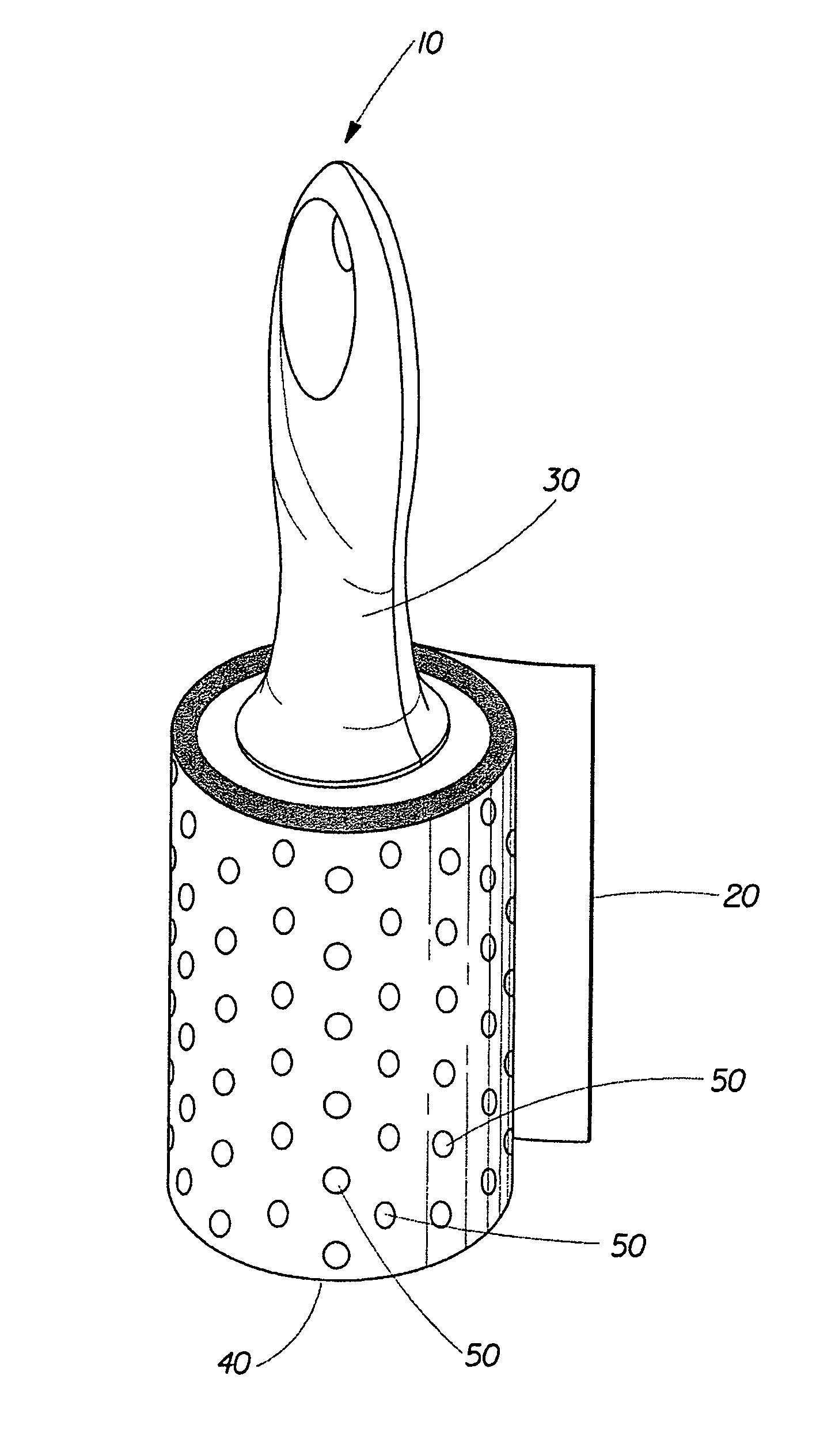

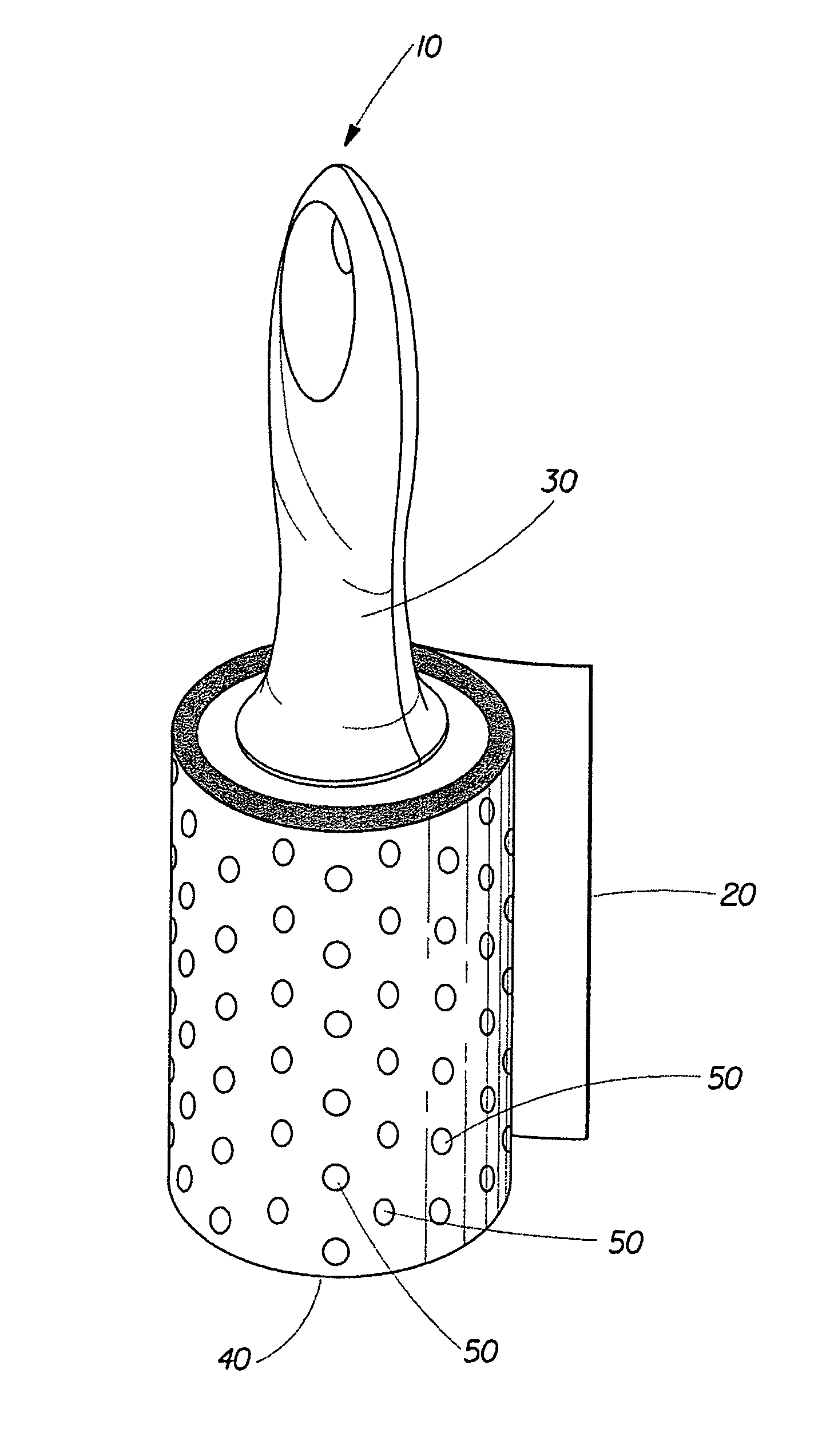

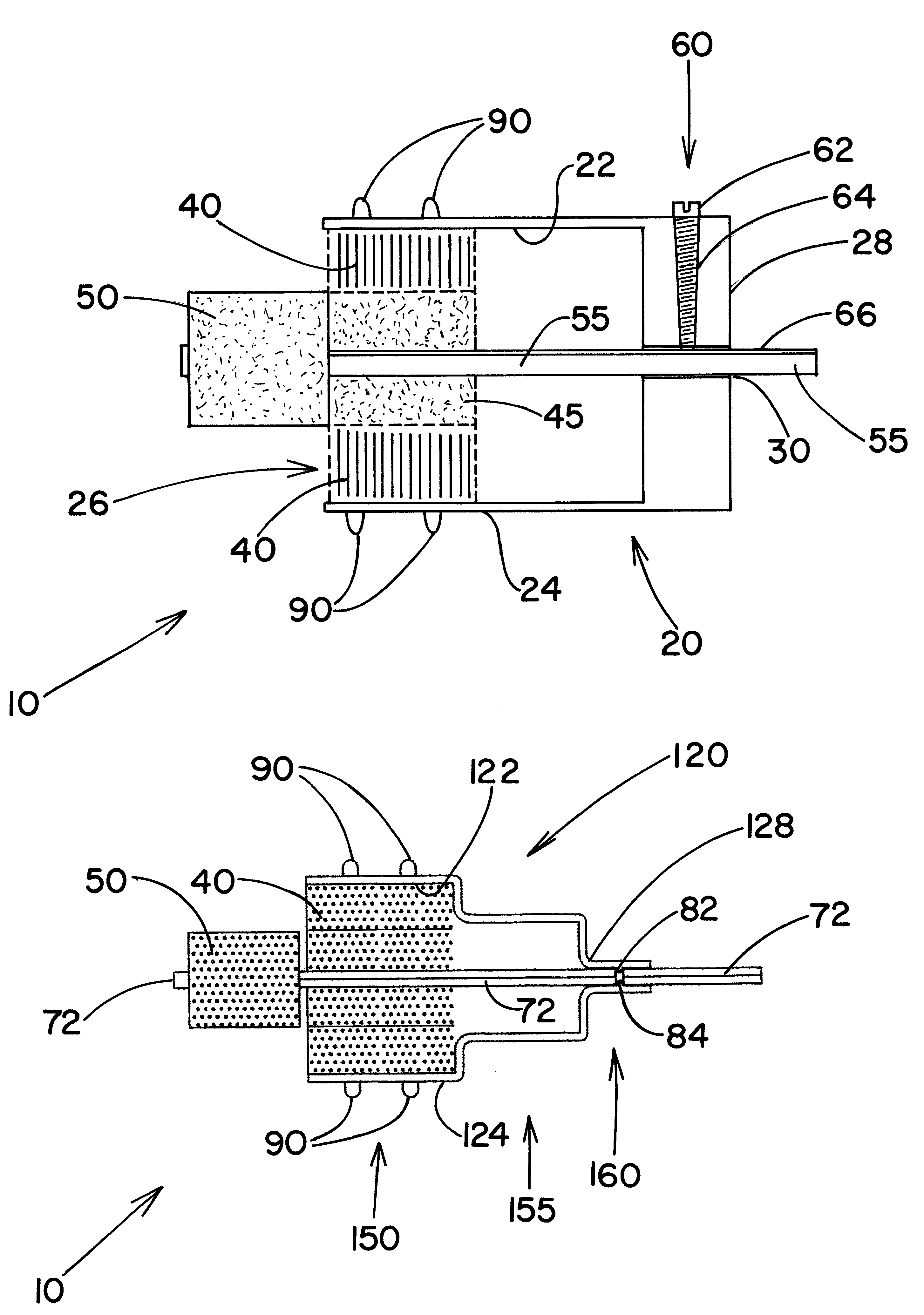

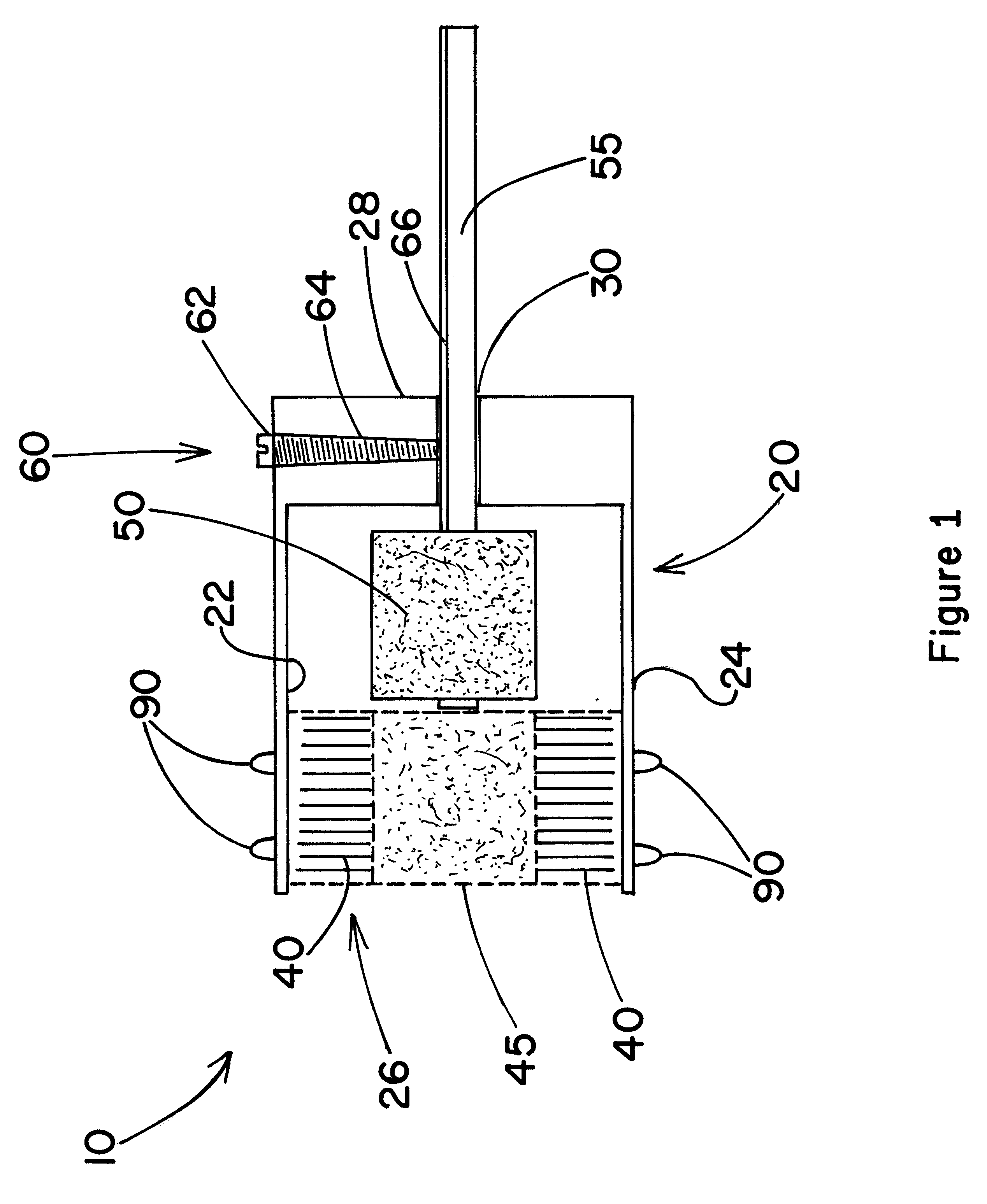

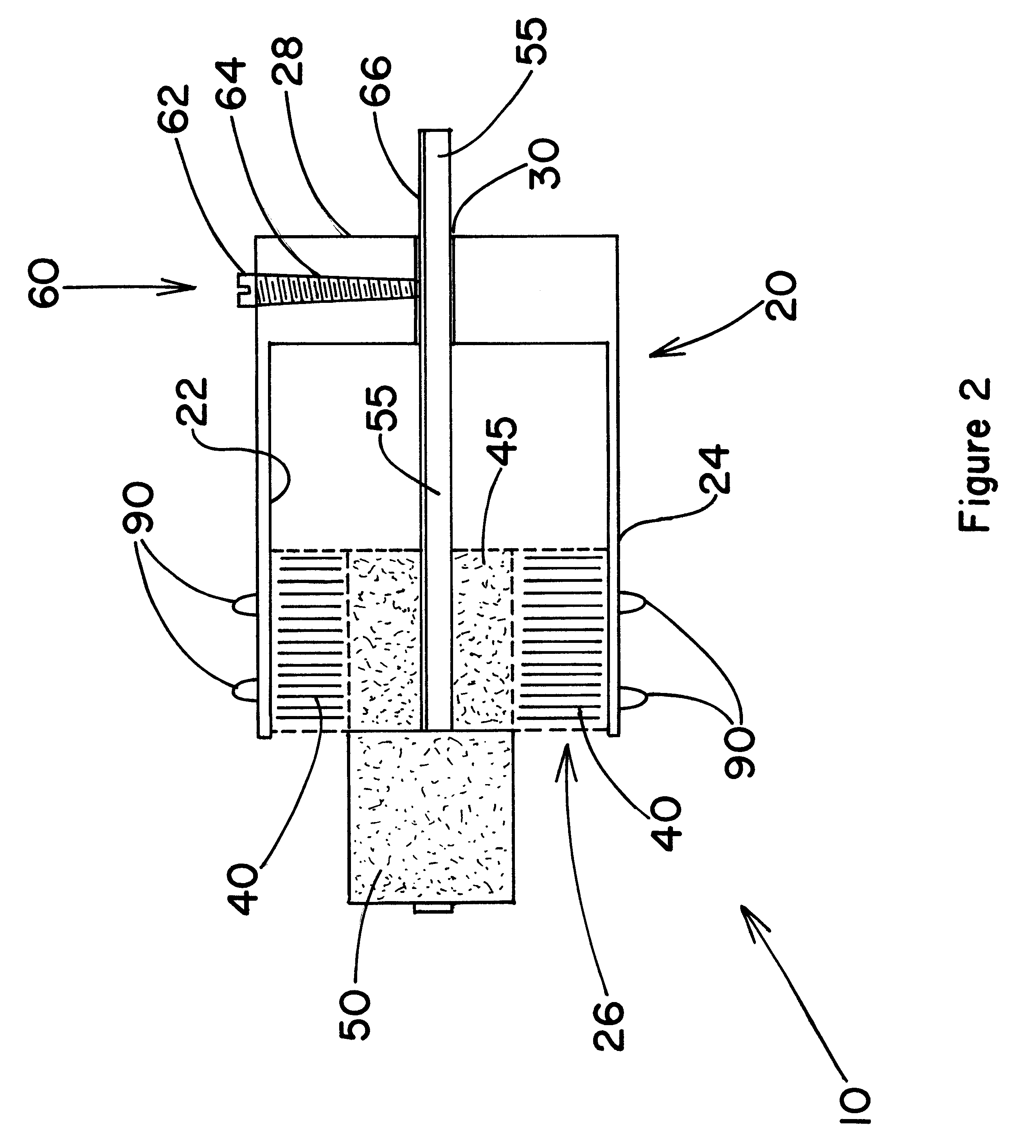

Pressure-sensitive adhesive cleaner for plate surfaces

InactiveUS20130125322A1Efficient removalEasy to disassembleHousehold cleanersCleaning processes and apparatusEngineeringTouch panel

Provided is a cleaner that can easily and efficiently remove organic dirt accumulated on a flat plate surface such as a display-input member (touch panel member) in a portable device. The cleaner (10) provided by the present invention is a pressure-sensitive adhesive plate surface cleaner (10) that comprises a pressure-sensitive adhesive body (30) having a removable pressure-sensitive adhesive and is used so as to allow the pressure-sensitive adhesive body (30) to contact a flat plate surface (2) of a plate such as a portable device (1) having a flat surface in order to remove organic dirt accumulated on the plate surface (2).

Owner:NITOMS INC +1

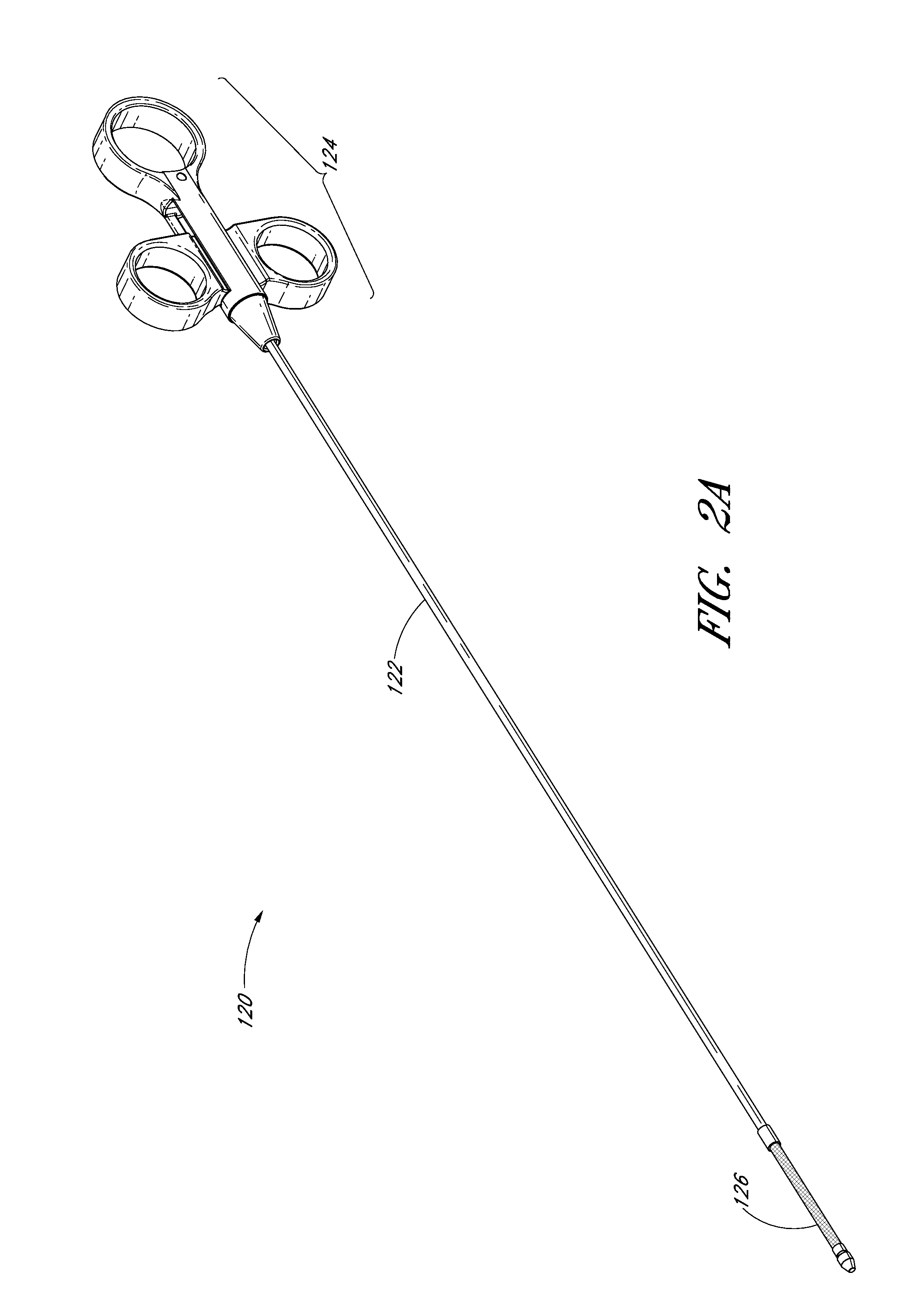

Minimally invasive apparatus and method for cleaning endoscope lenses

InactiveUS20140215736A1Time-consume and cumbersomeKeep sizeHollow article cleaningEndoscopesEndoscopeBiomedical engineering

The disposable apparatus for cleaning a distal lens of an endoscope comprises a hollow tube having an open proximal end and an openable distal end and is sized and configured to receive an endoscope therethrough, the apparatus including a plurality of lens cleaning members disposed across an inner diameter of the hollow tube, the cleaning members each including a slit through which the distal lens passes with the lint-free material of the cleaning members wiping across the lens as it passes therethrough.

Owner:TYCO HEALTHCARE GRP LP

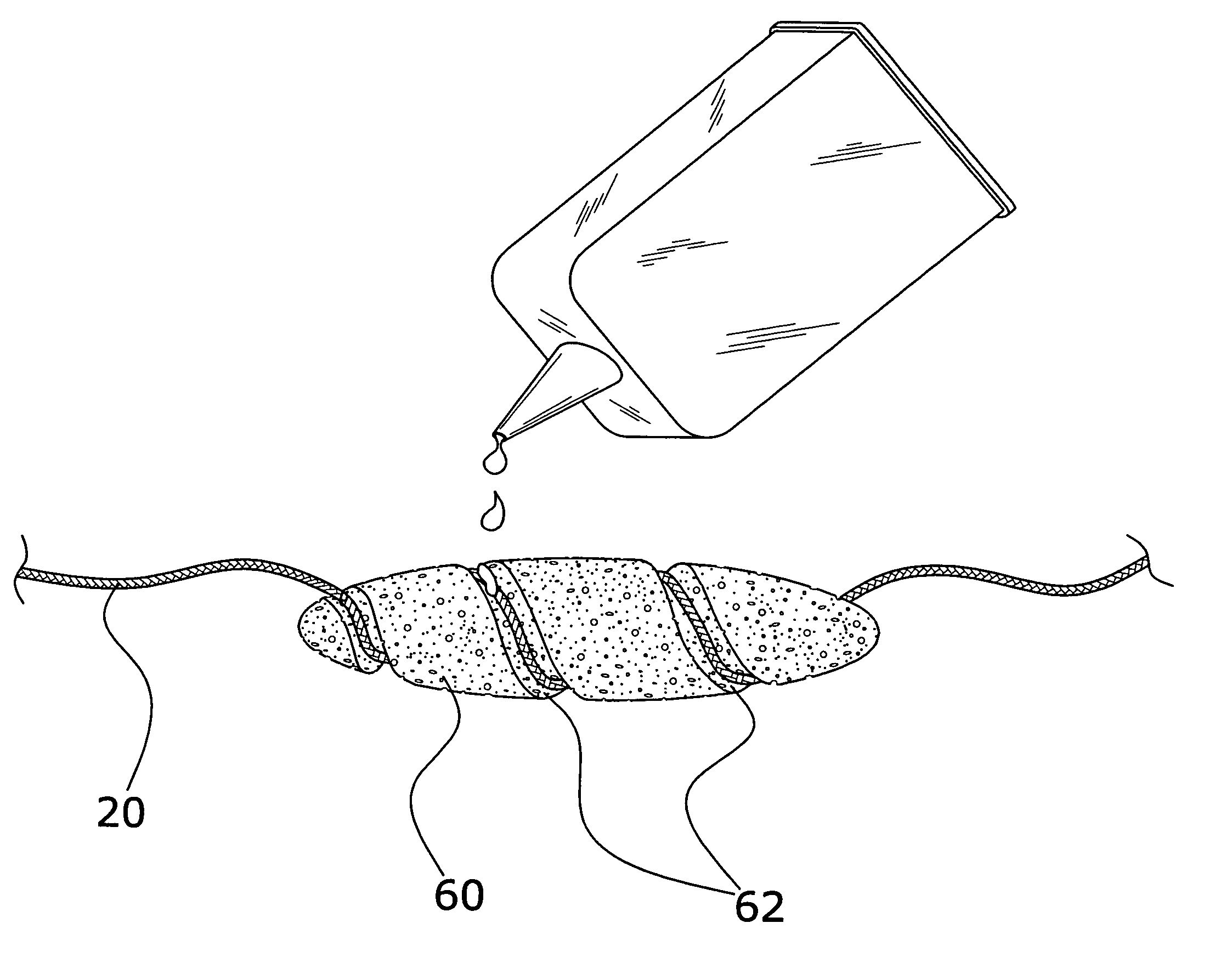

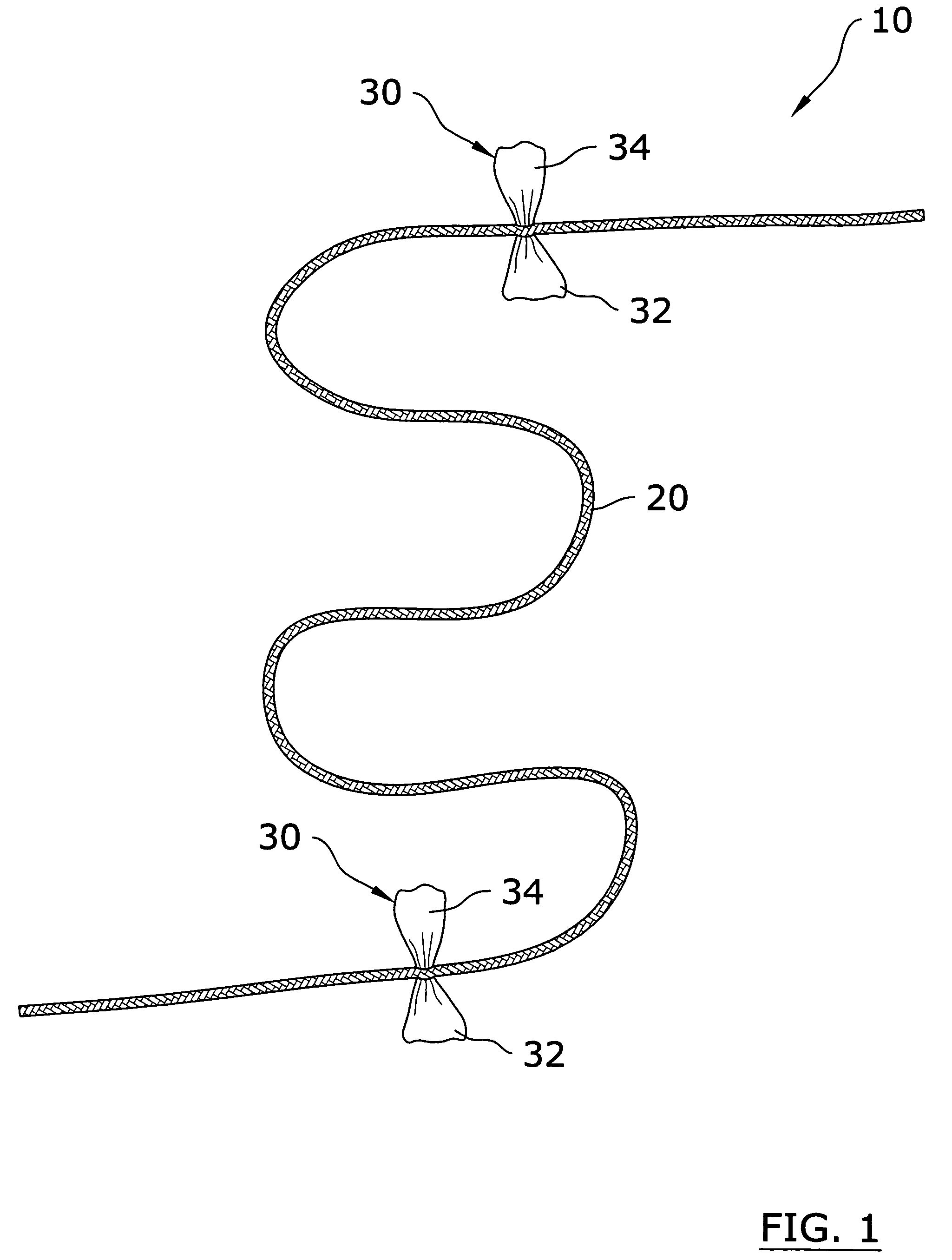

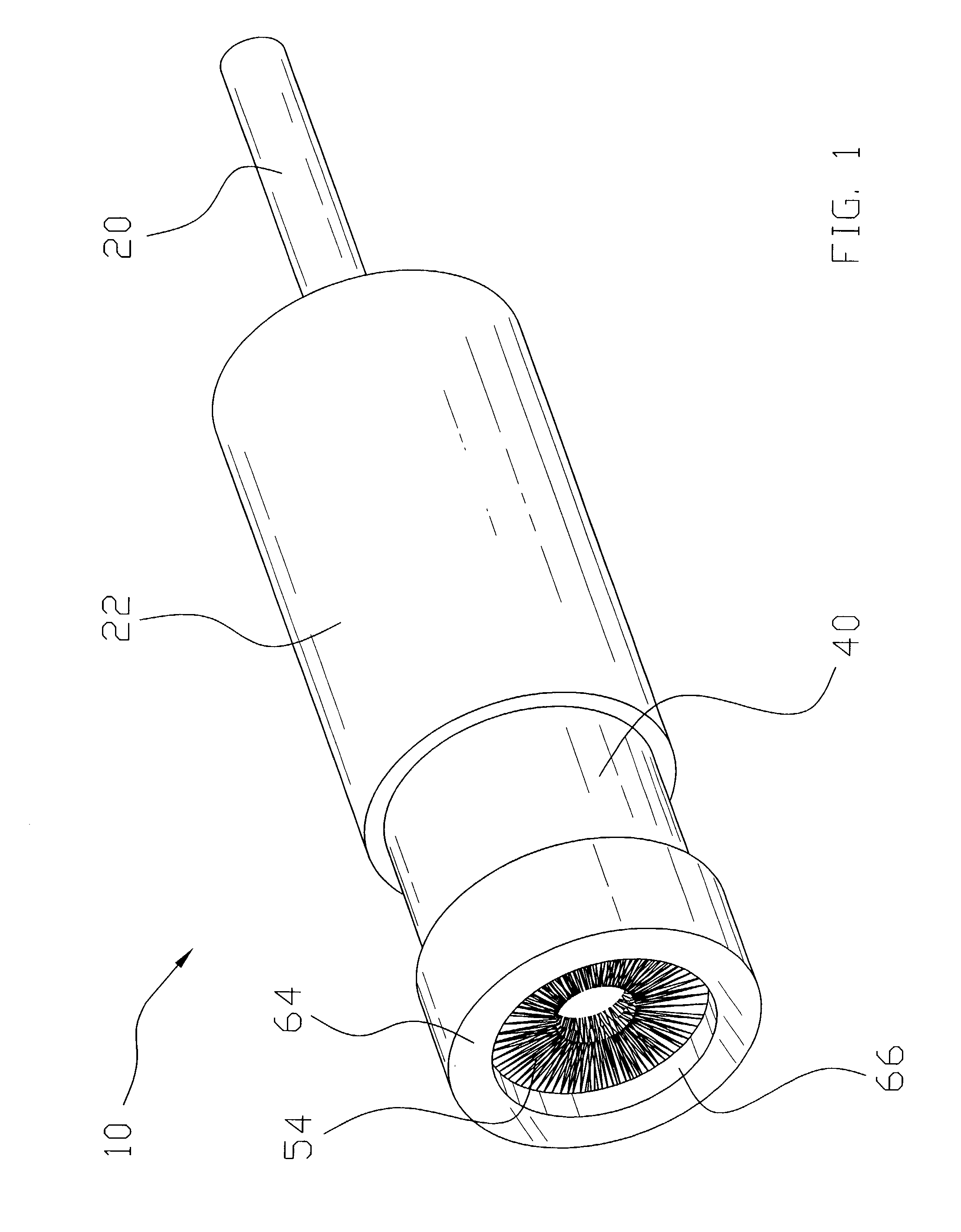

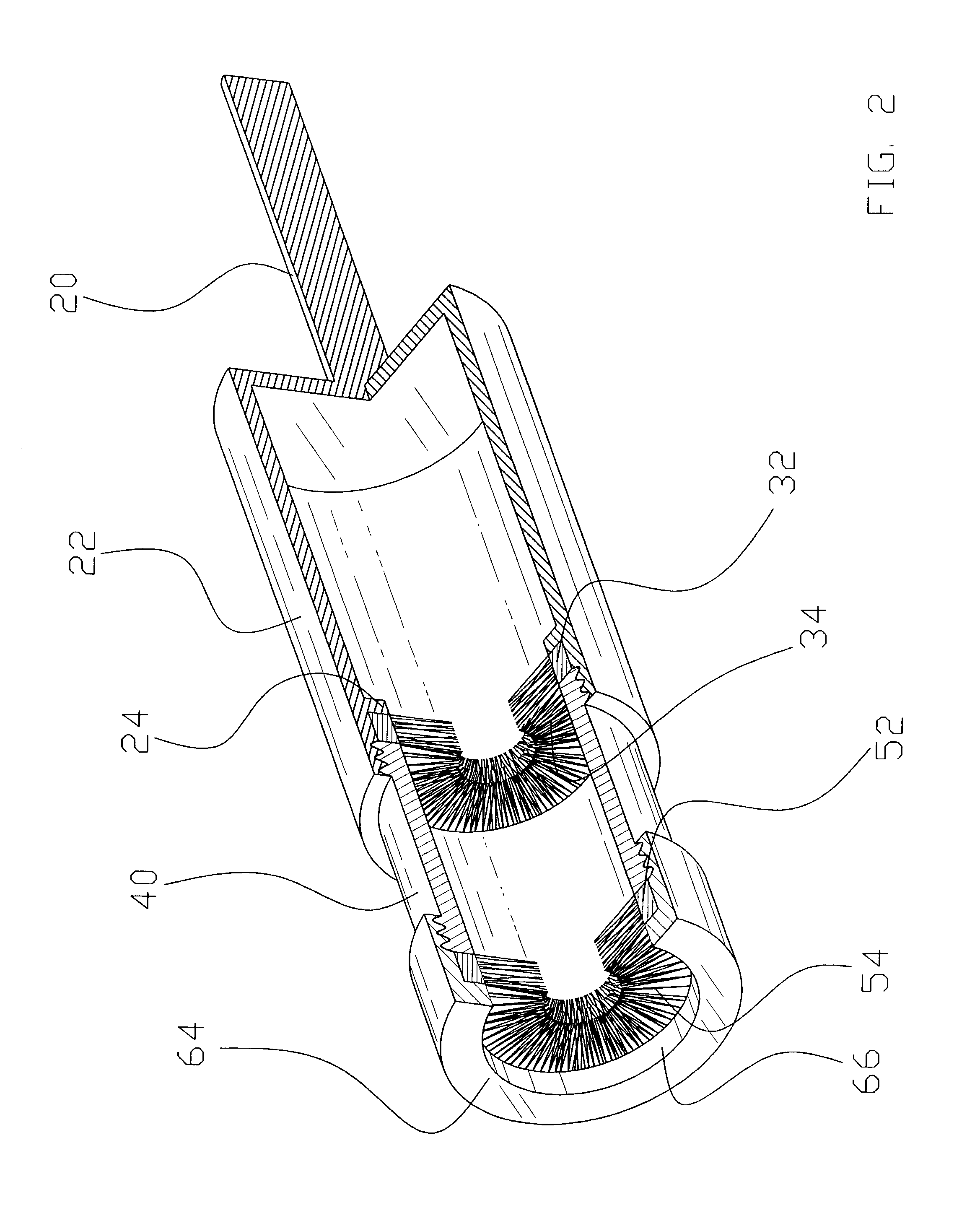

Gun bore cleaning system

InactiveUS7367151B1Easy to storeReduce areaCartridge extractorsHollow article cleaningEngineeringMechanical engineering

A gun bore cleaning system for efficiently cleaning a bore of a gun. The gun bore cleaning system includes a cleaning member having a spiral groove and a length of cord positionable within the spiral groove. The cord is extended through a bore of a gun with the cleaning member cleaning the bore of the gun.

Owner:NEW PRODS MARKETING

Cleaning sheet

Owner:KAO CORP

Pressure-sensitive adhesive cleaner for plate surfaces

InactiveUS9003591B2Efficient removalHousehold cleanersCleaning processes and apparatusSurface cleaningEngineering

Provided is a cleaner that can easily and efficiently remove organic dirt accumulated on a flat plate surface such as a display-input member (touch panel member) in a portable device. The cleaner (10) provided by the present invention is a pressure-sensitive adhesive plate surface cleaner (10) that comprises a pressure-sensitive adhesive body (30) having a removable pressure-sensitive adhesive and is used so as to allow the pressure-sensitive adhesive body (30) to contact a flat plate surface (2) of a plate such as a portable device (1) having a flat surface in order to remove organic dirt accumulated on the plate surface (2).

Owner:NITOMS INC +1

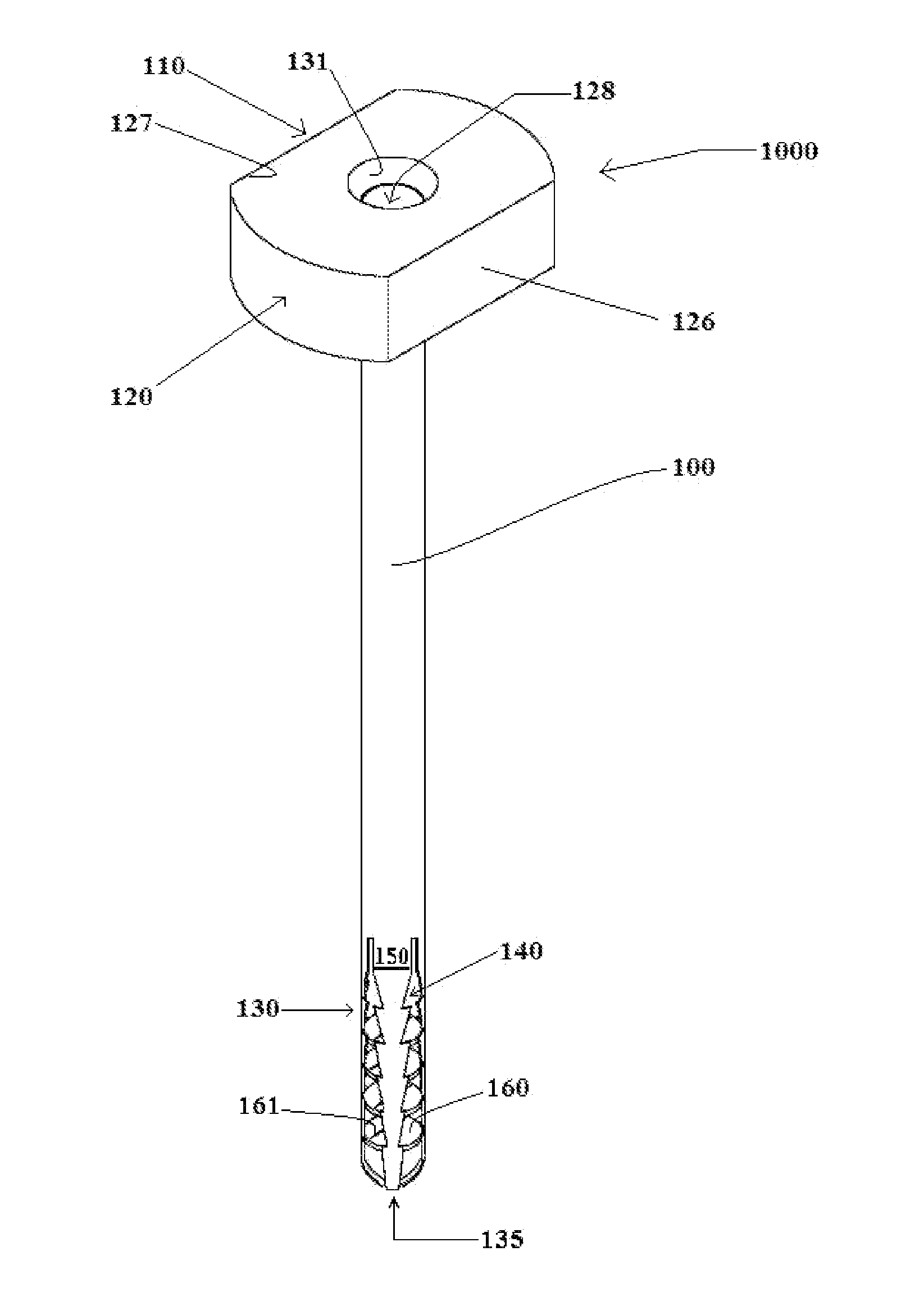

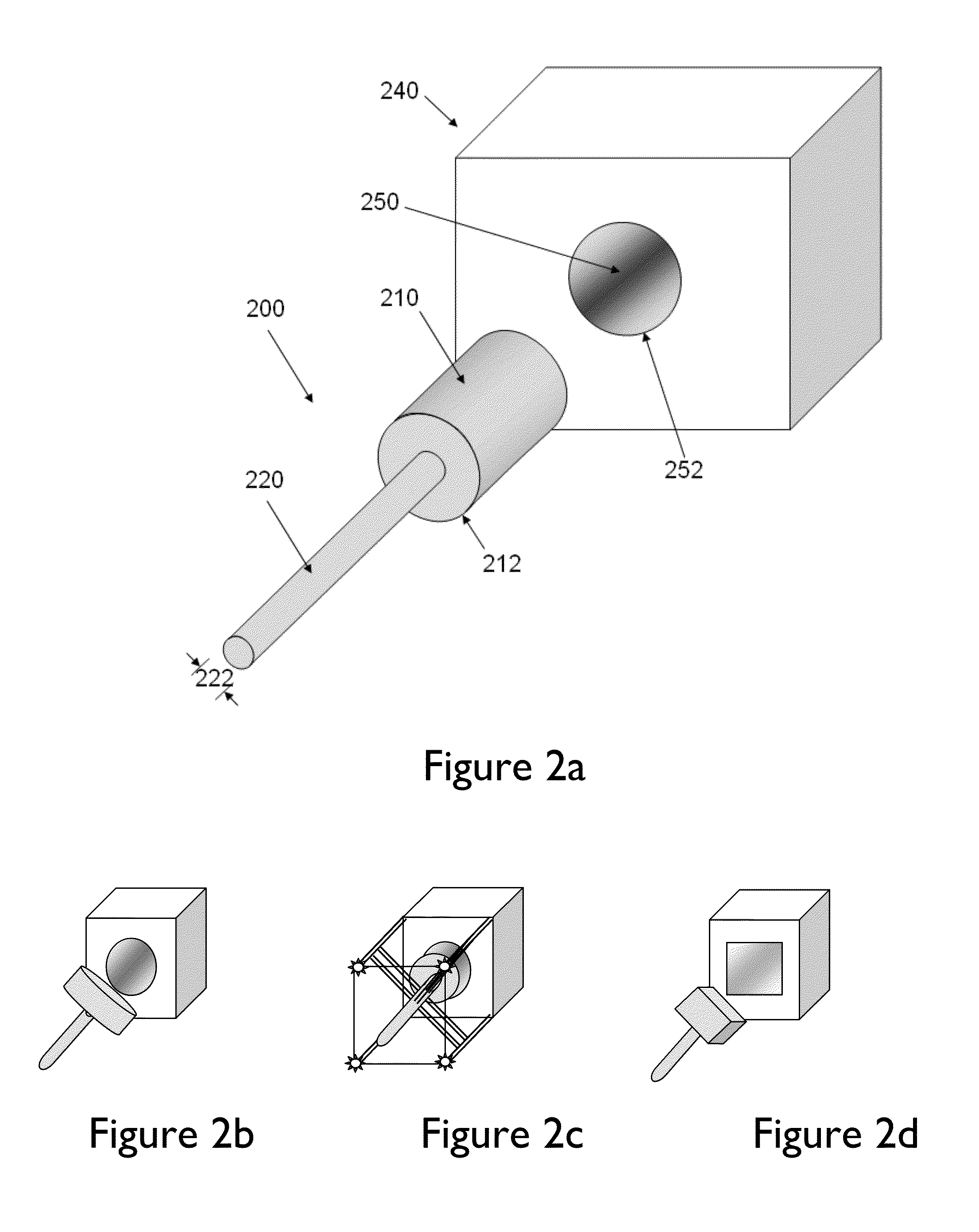

Ramrod for MRI and methods thereof

A ramrod for cleaning the bore of an MRI device, including: a head with a cross-section substantially identical in shape to the MRI bore's cross-section, the cross section having size slightly smaller than the MRI's bore's cross-section to fit snugly and movably within the bore, the head having at least one end, the head having a longitudinal axis; and a rigid extended longitudinal body rigidly connected to the at least one end, the body having a longitudinal axis. The passage of the ramrod through the bore removes particulates from the bore.

Owner:ASPECT IMAGING

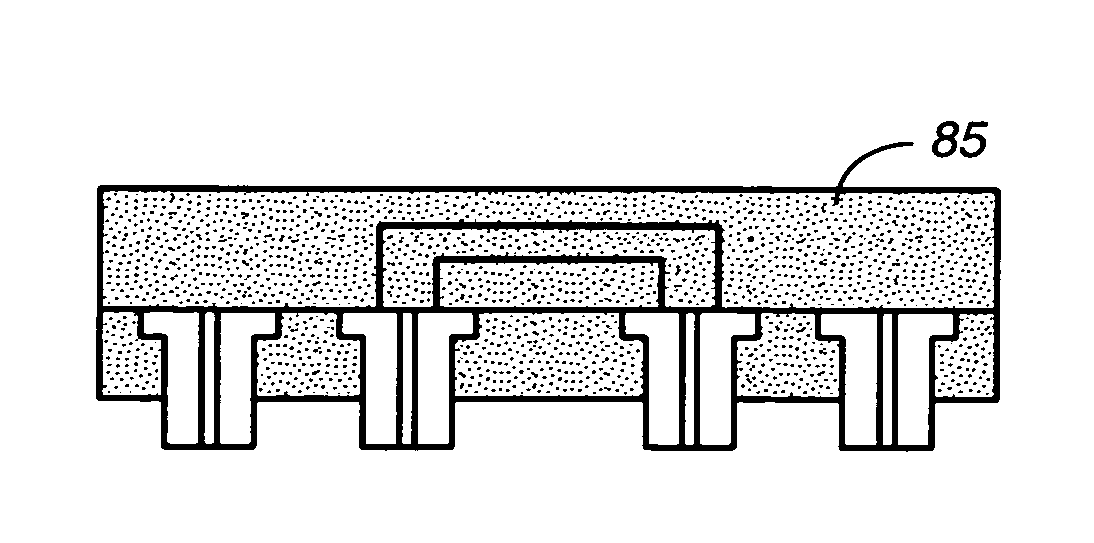

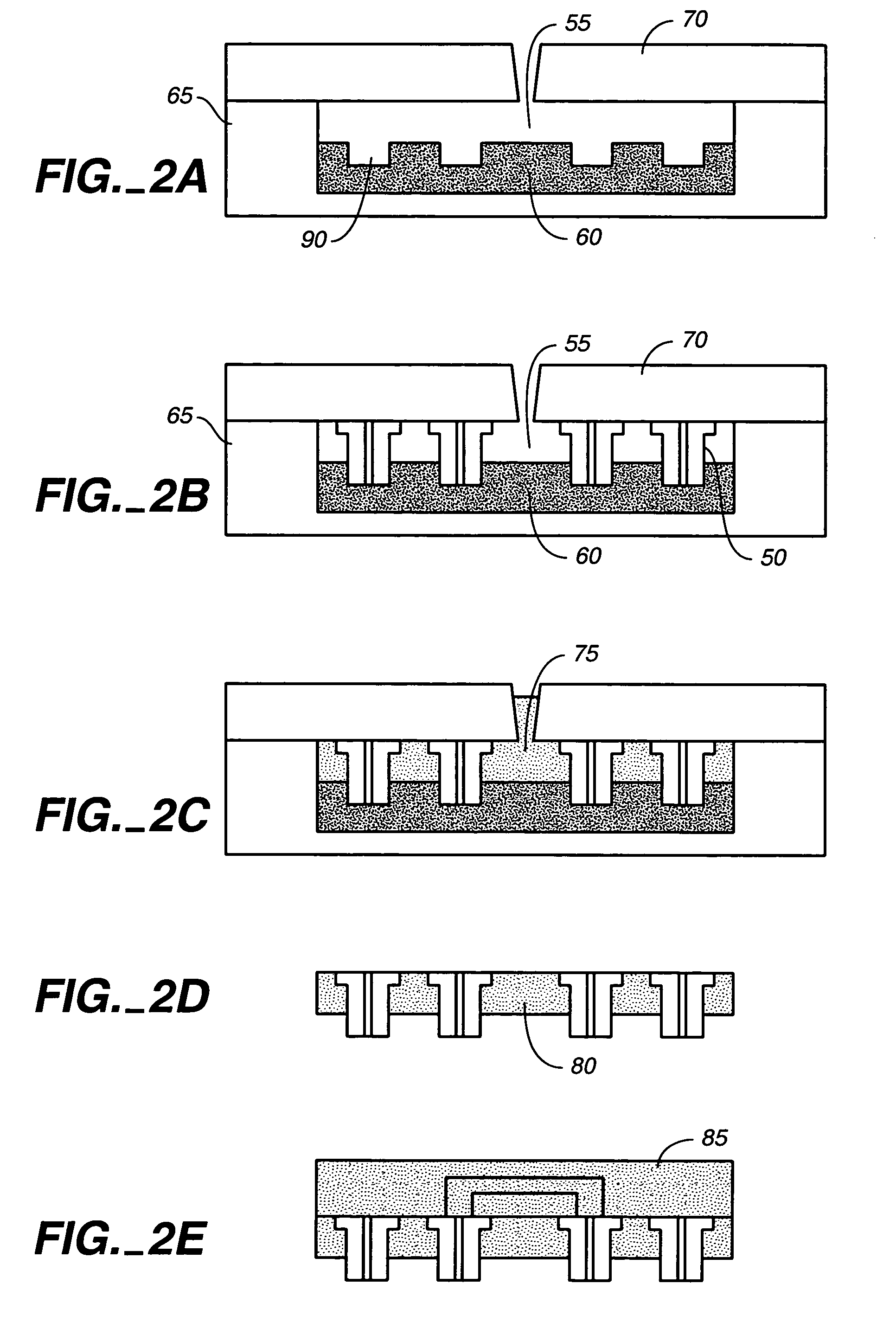

Microfluidic structures and methods for integrating a functional component into a microfluidic device

InactiveUS7351380B2Valve arrangementsPipeline expansion-compensationSolid substrateMaterials science

Owner:SANDIA NAT LAB

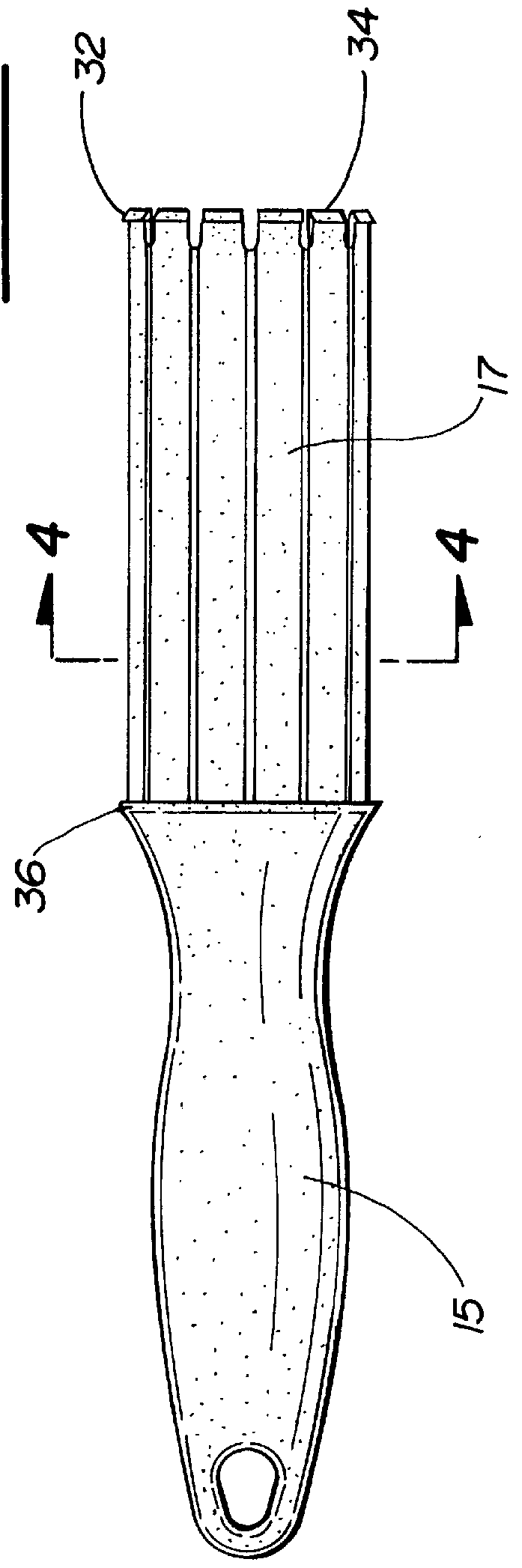

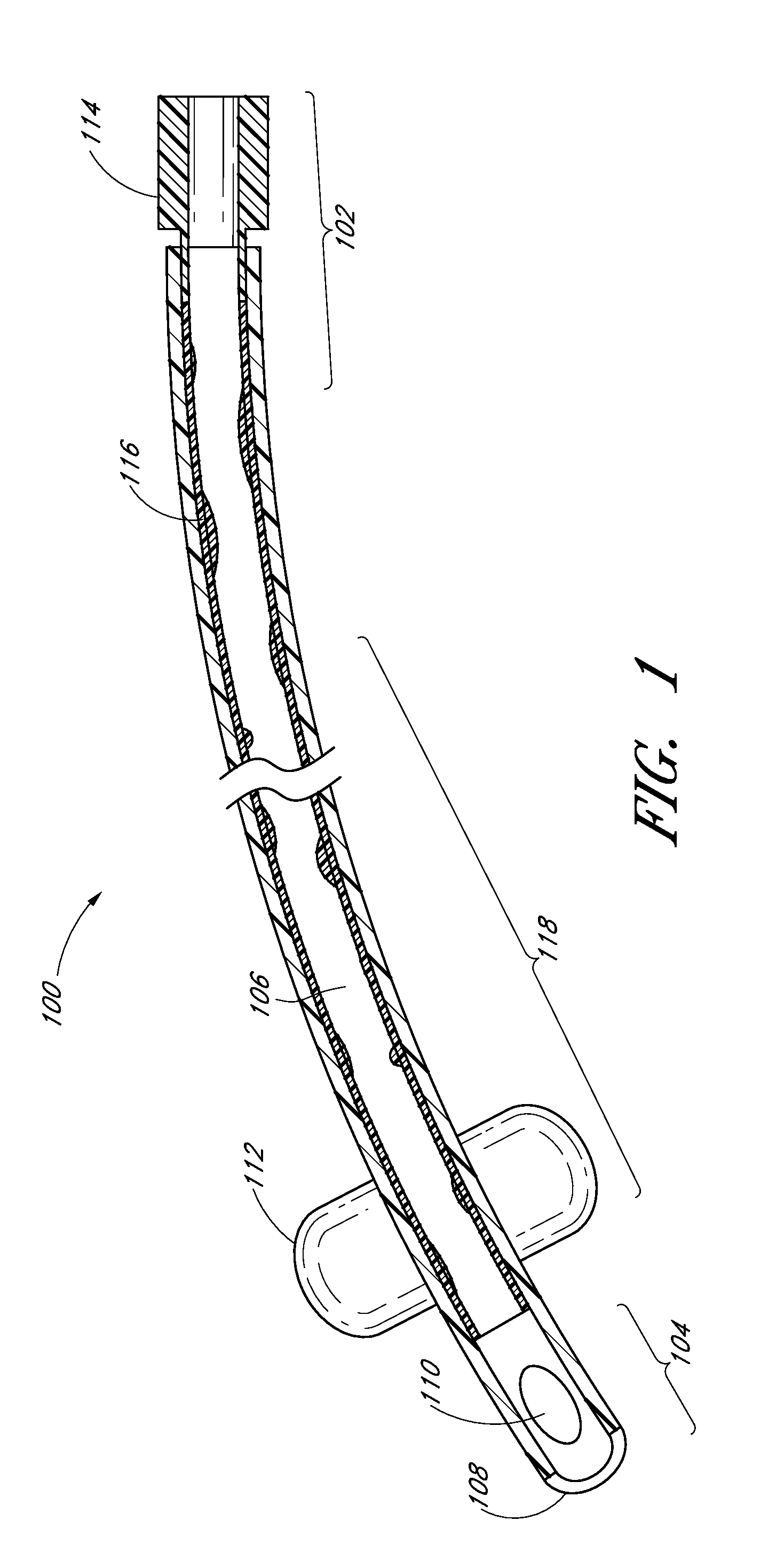

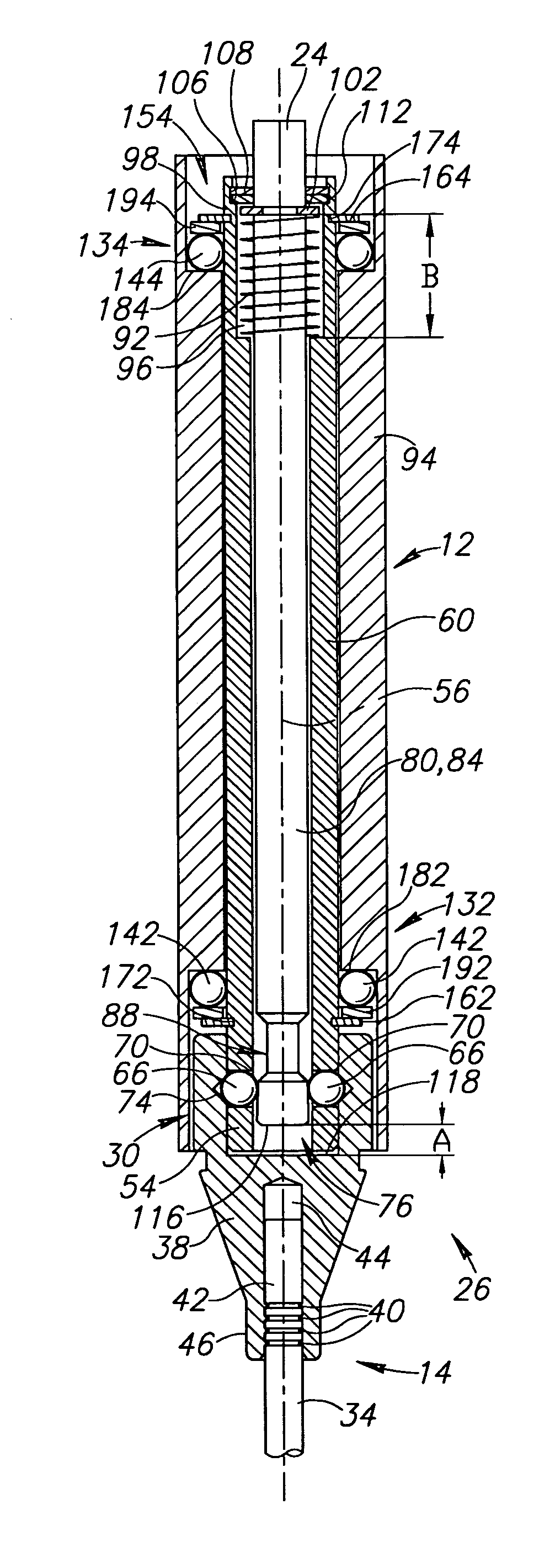

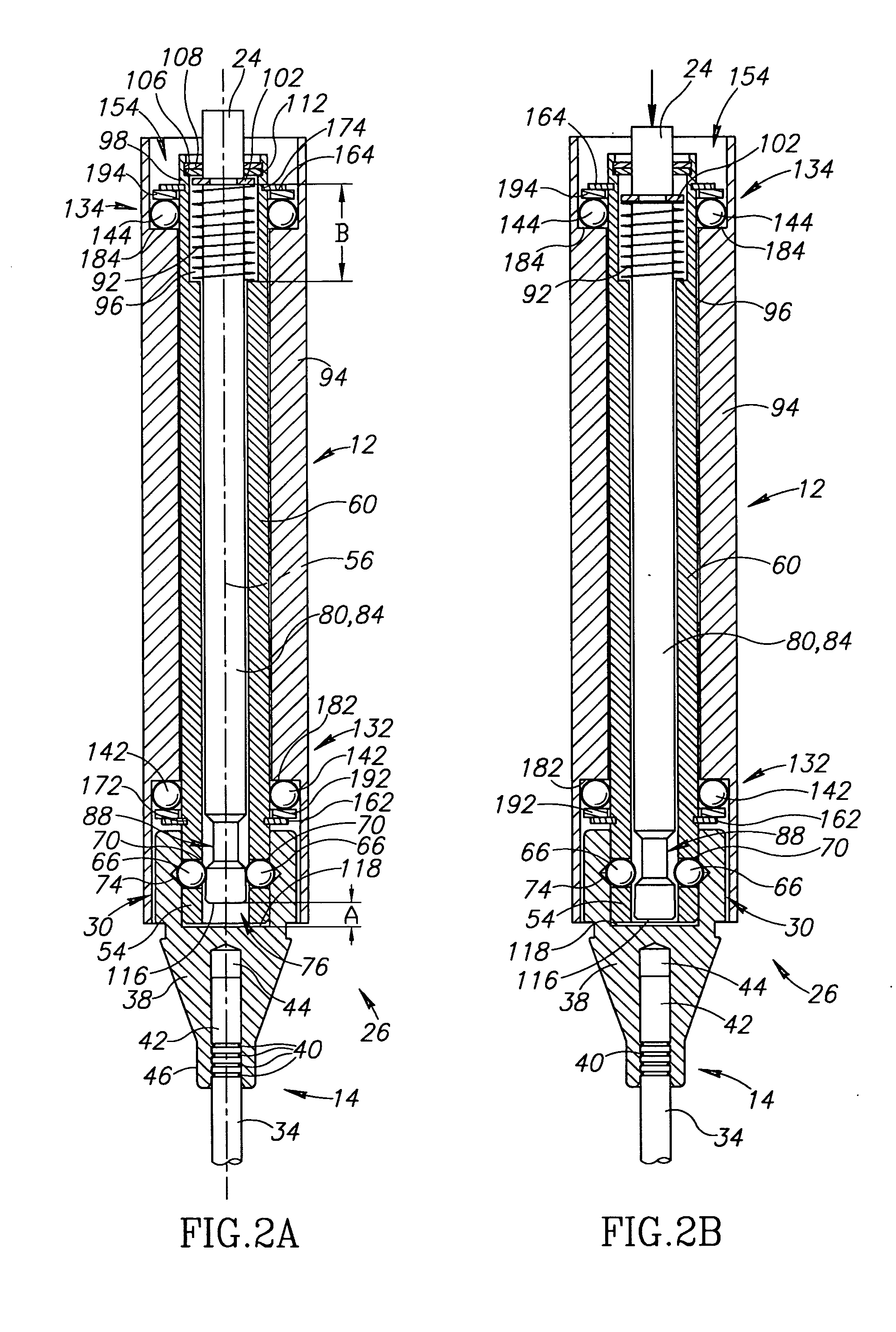

Gun barrel cleaning device with quick-detachable cleaning implement

InactiveUS20060277811A1Smooth rotationPrevent disengagementWeapon cleaningWeapon testingCouplingThrust bearing

A gun barrel cleaning device includes a quick-detachable coupling mechanism releasably coupling a handle to a cleaning implement for cleaning a gun barrel bore. A thrust bearing is preferably provided for supporting the cleaning implement on the handle and for facilitating axial rotation of the cleaning implement relative to the handle. The gun barrel cleaning device may comprise part of a gun barrel cleaning kit, which may include a variety of different cleaning implements. A novel sheath for storing a gun barrel bore-cleaning implement is also disclosed.

Owner:MICHAELS OF OREGON

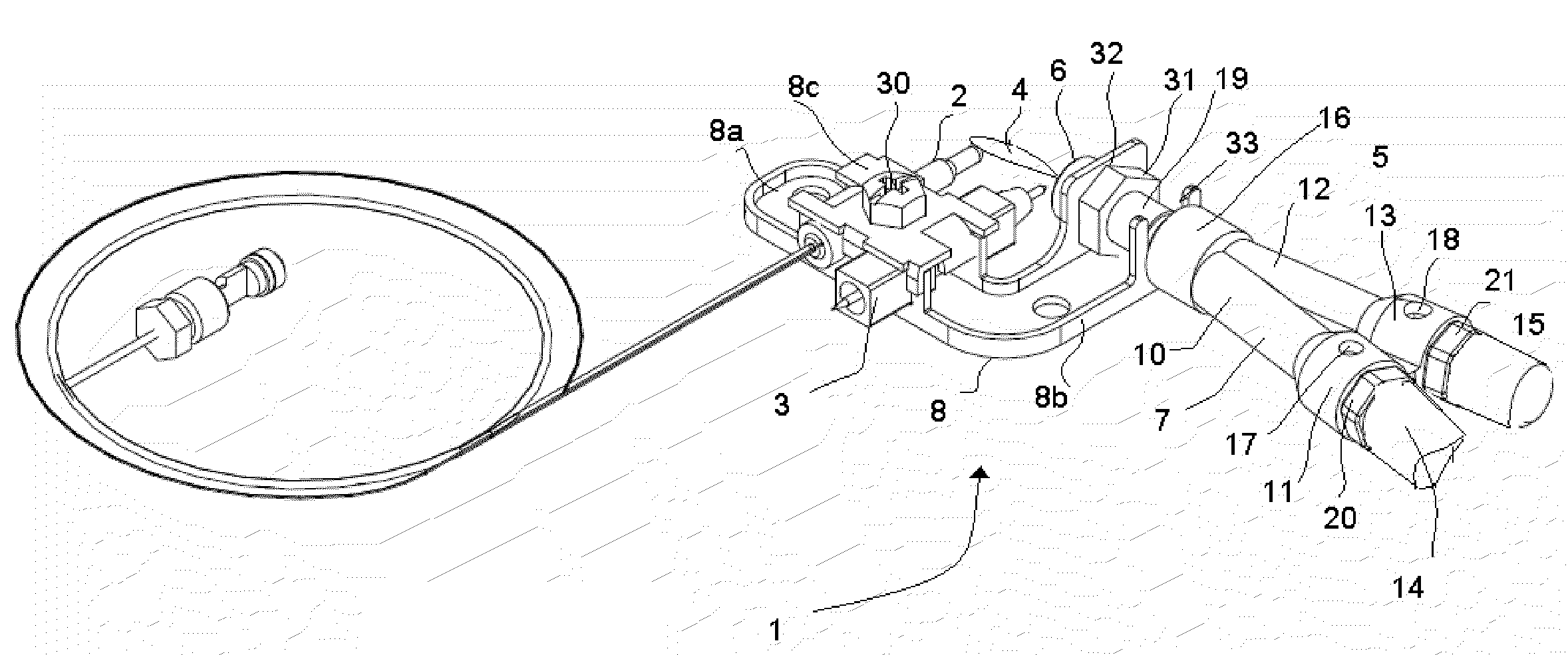

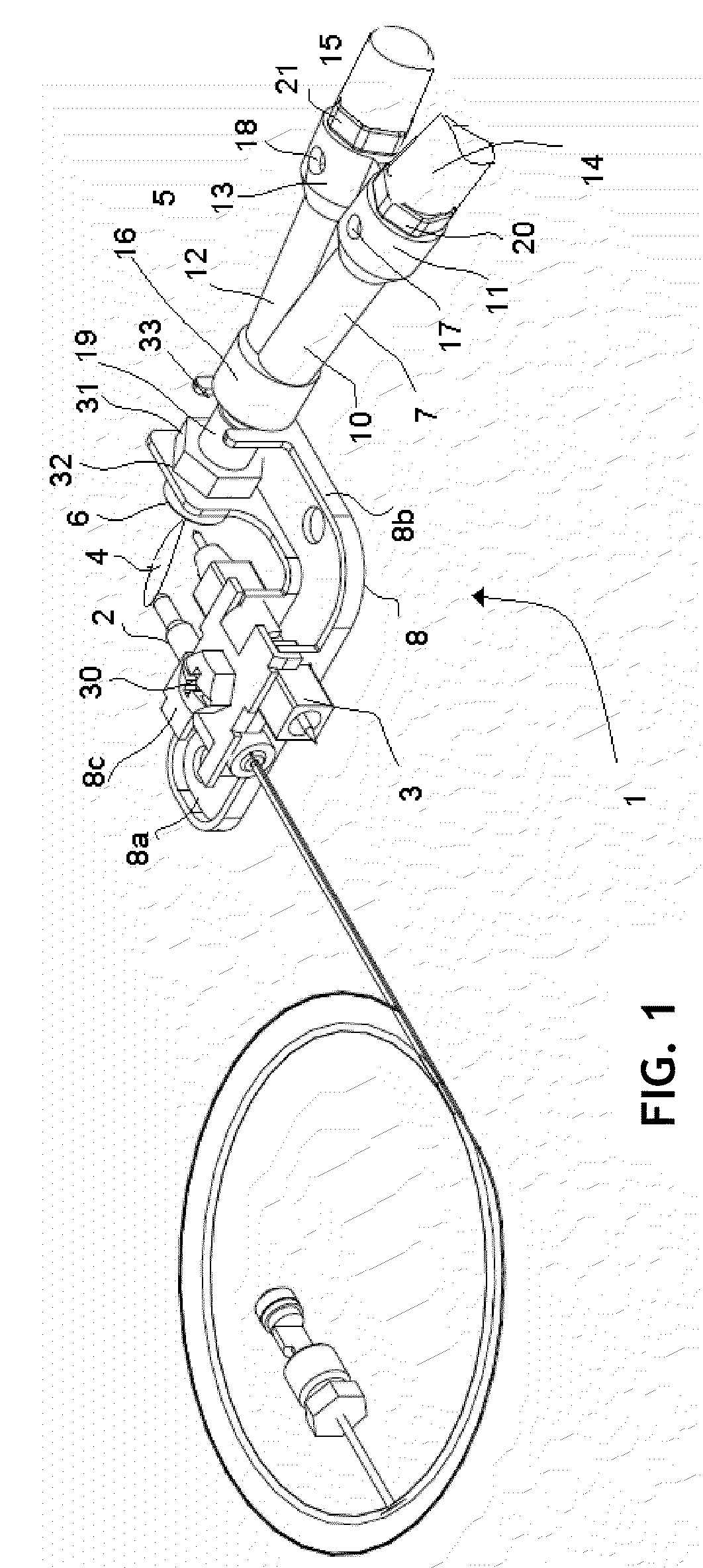

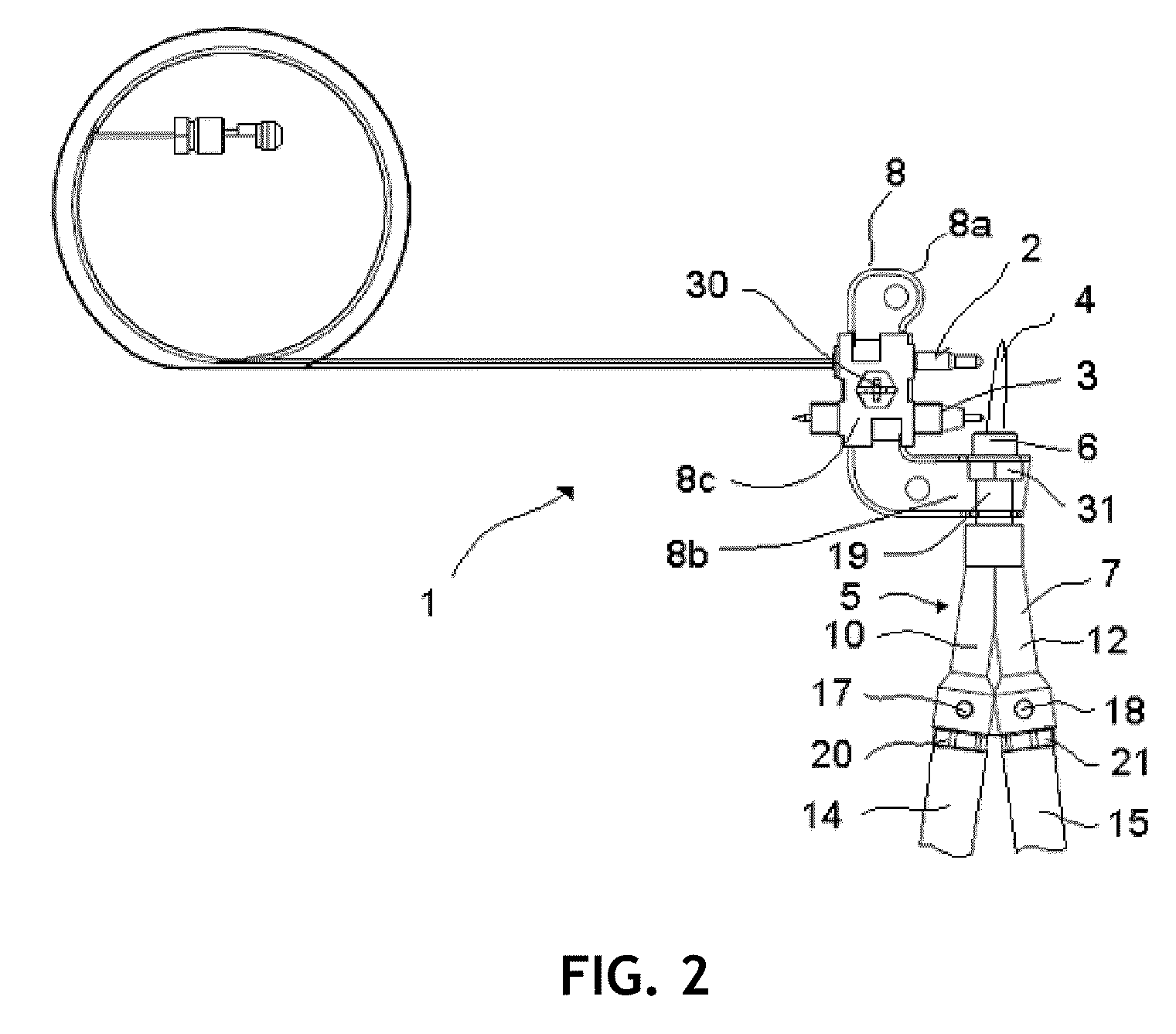

Multiple gas pilot burner

ActiveUS20090280448A1Small sizeLow costIncandescent ignitionPipeline expansion-compensationPower flowThermocouple

A multiple gas pilot burner assembly for a household heating appliance. The pilot burner includes an injector having a first conduit for receiving a flow of a first combustible fluid, a second conduit for receiving a flow of a second combustible fluid and a third conduit connected to and in fluid communication with the first and second conduits which is configured to receive the flow of the first combustible fluid from the first conduit or the flow of the second combustible fluid from the second conduit. A single nozzle at the outlet of the third conduit is provided for supplying a pilot flame. The assembly also includes a single flame igniter positioned to cause an ignition of the pilot flame at the nozzle and also a single thermocouple positioned to be heated by the pilot flame and to generate an electrical current when heated.

Owner:COPRECITEC

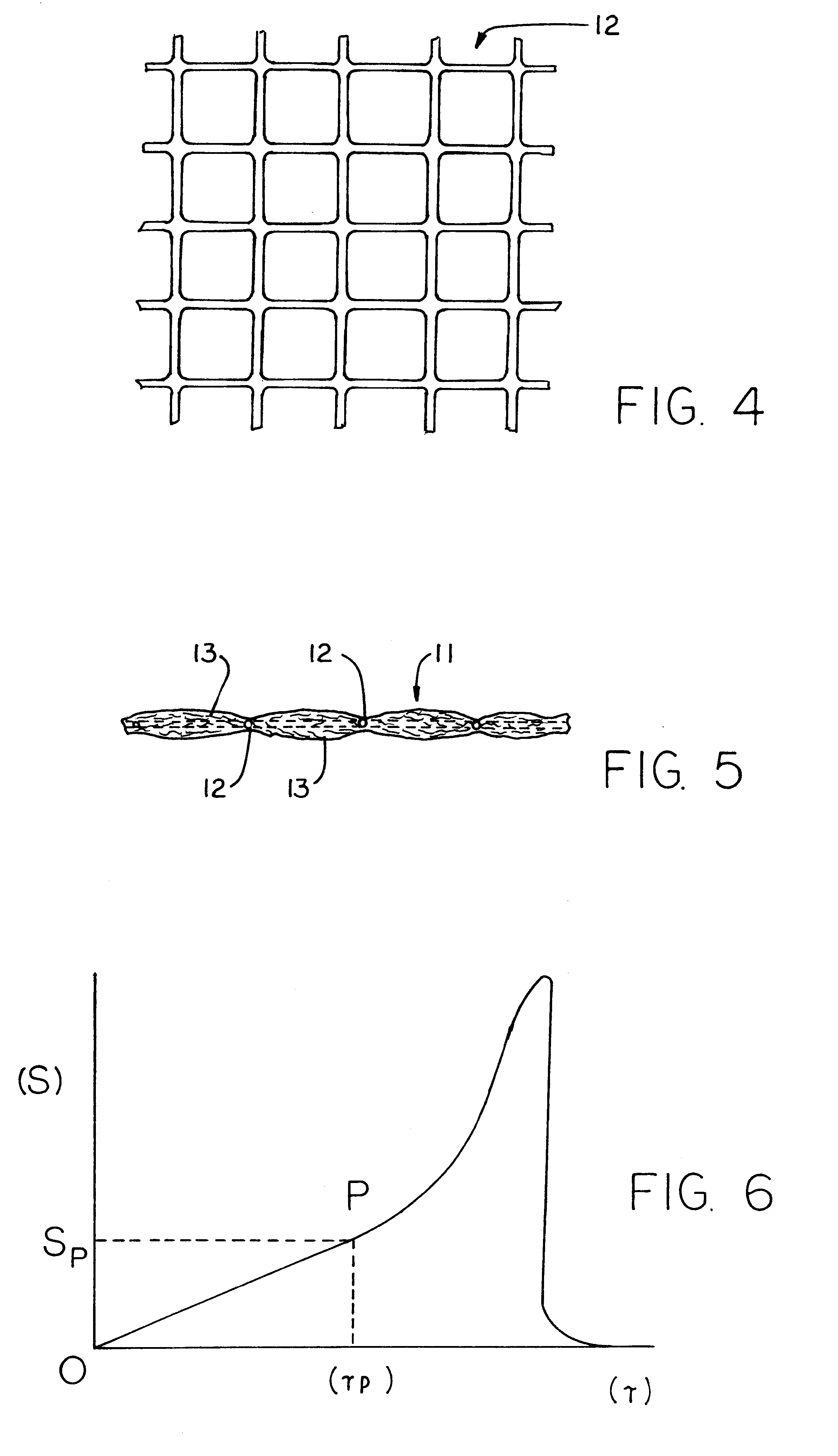

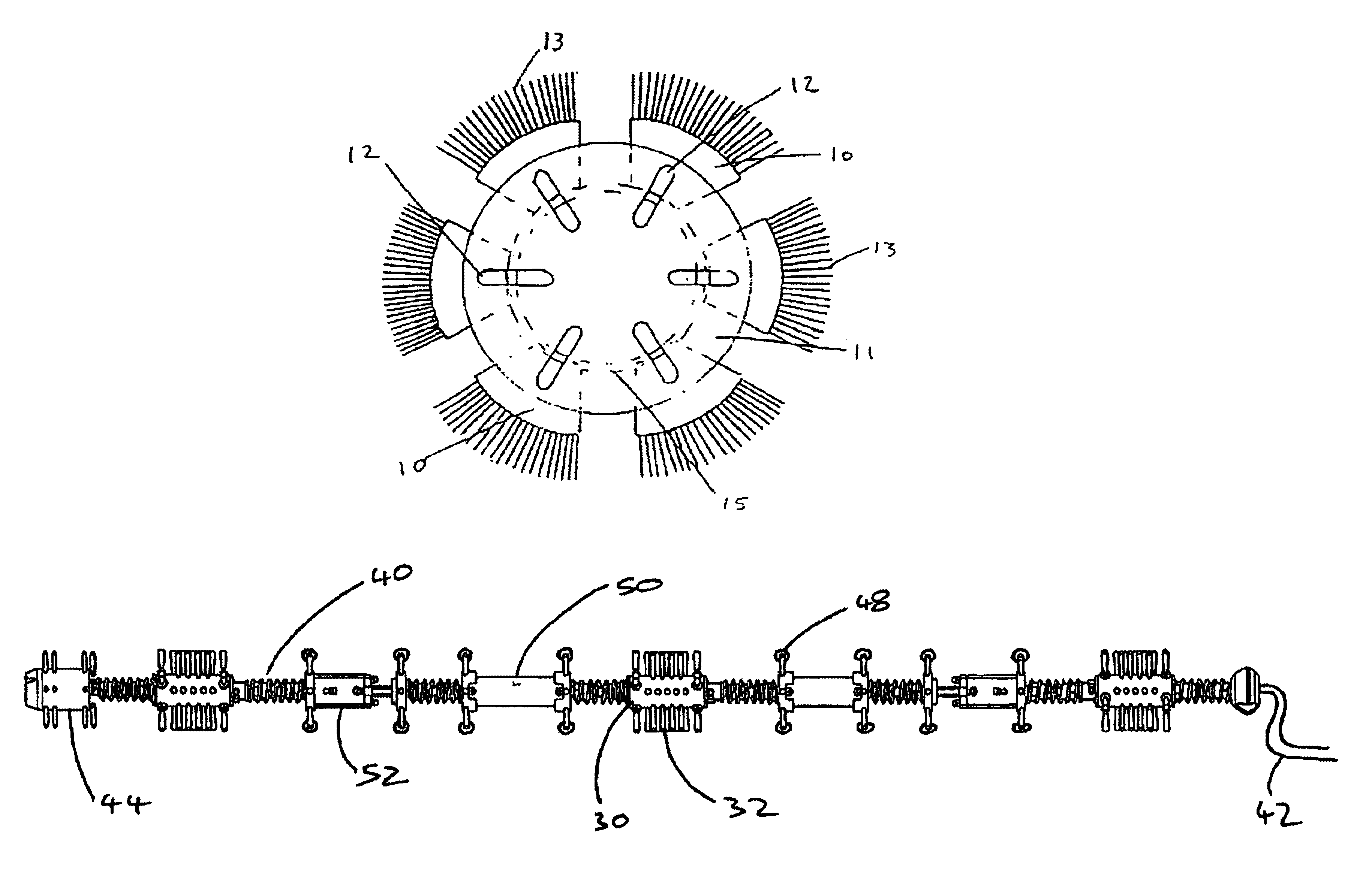

Surface-traversing vehicle

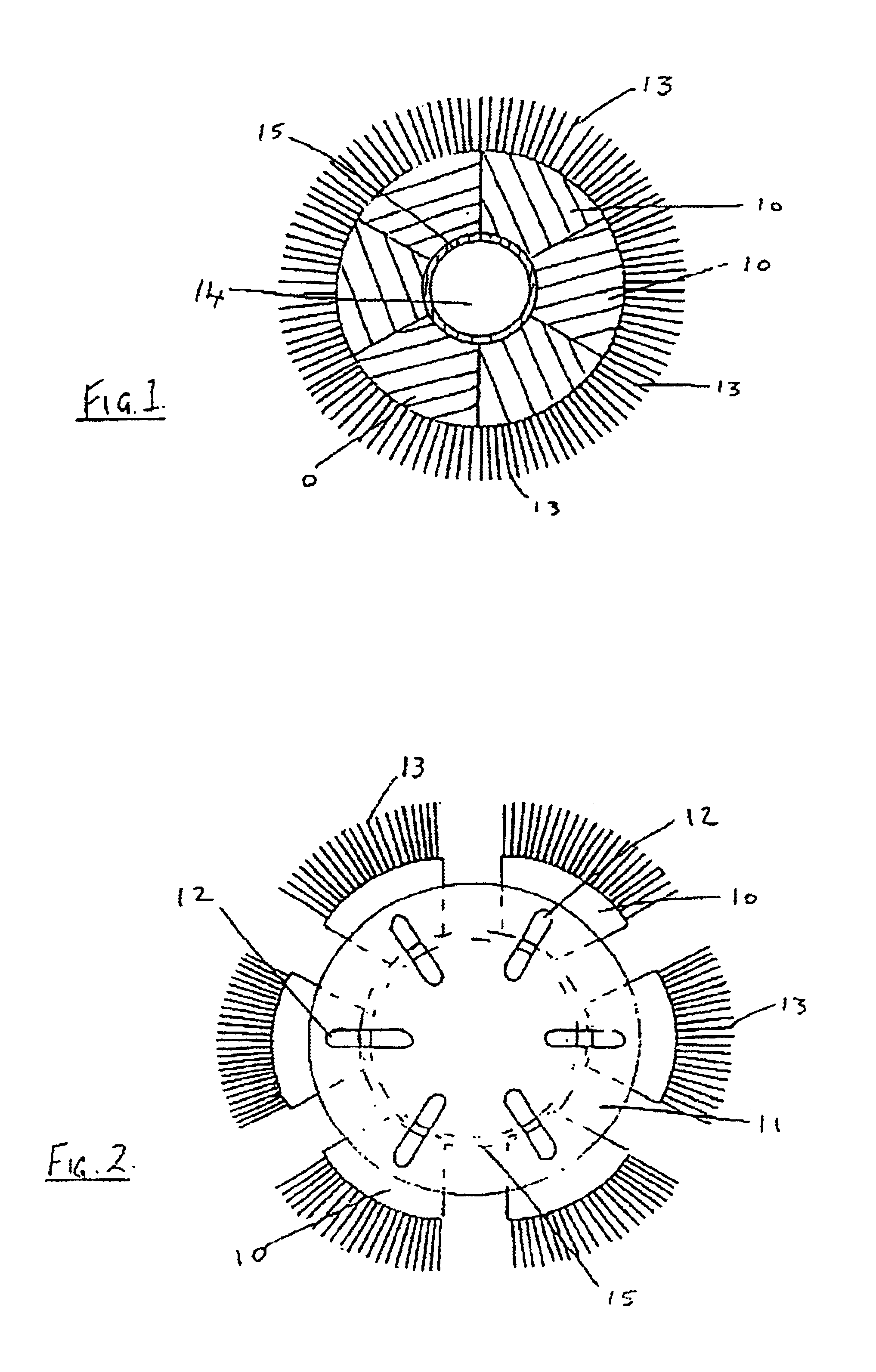

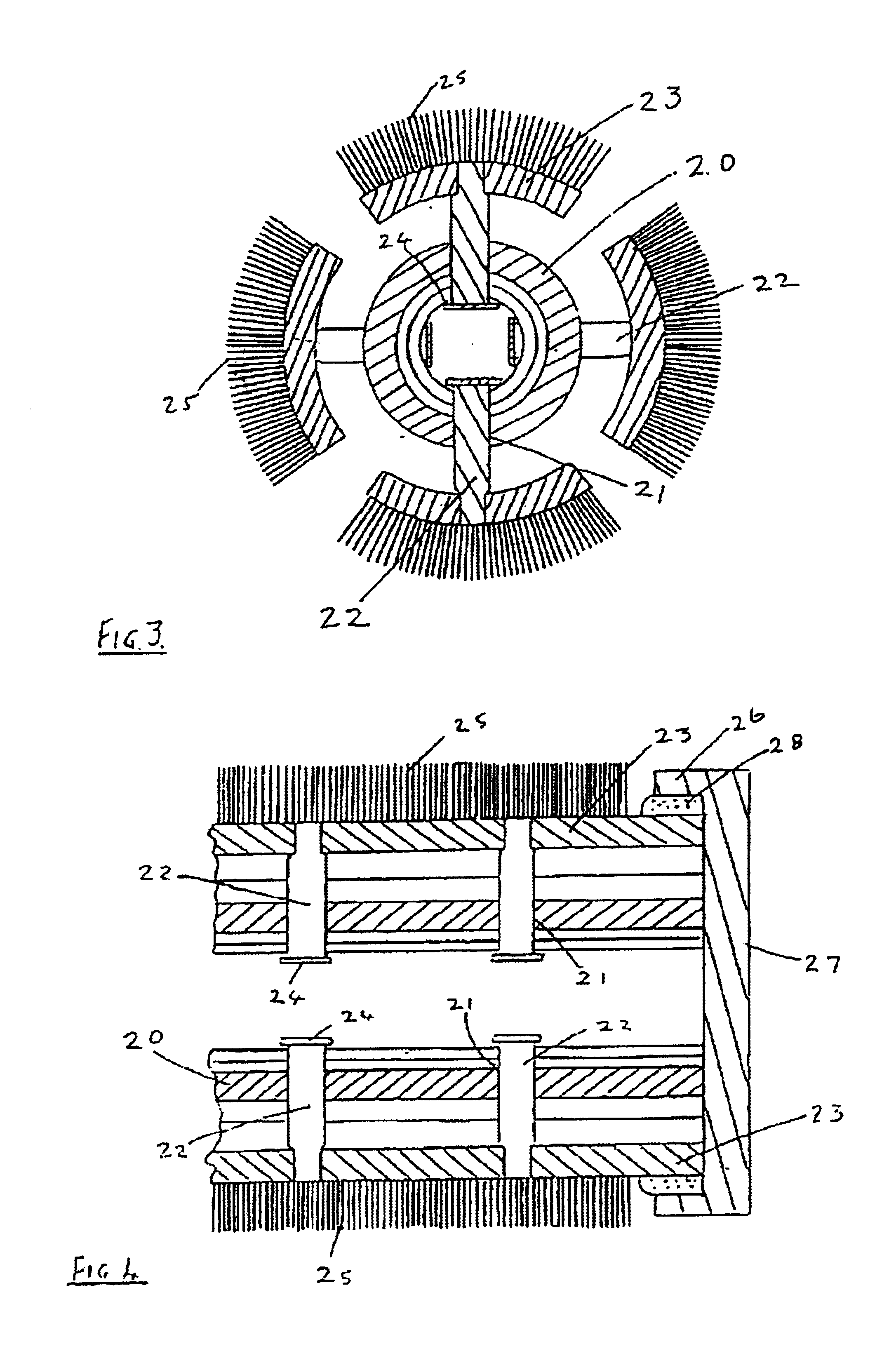

InactiveUS6775872B1Moved more readilyEasy to moveHollow article cleaningCleaning apparatusBristleEngineering

A vehicle for traversing a surface such as for carrying out an inspection, survey or maintenance operation upon that surface comprises two bodies interconnected by means to move the bodies towards and away from each other, each of those bodies being supported upon a multiplicity of resilient bristles (13; 25; 32) extending from it, the bristles of each body being mounted in groups upon bristle-carrying members (10; 23; 31) each guided for movement towards and away from the body, and fluid pressure means (25; 22; 34) to effect the guided movement of the bristle-carrying members in at least one of those directions.

Owner:DURHAM UNIV OF +1

Configurable device for cleaning the barrel of a firearm, and firearm cleaning kit containing components of device

ActiveUS20060236584A1Easy to carryReliably and effectively clean a wide variety of firearmsHollow article cleaningCleaning using toolsEngineering

Methods and devices are provided for cleaning firearm barrels, including those of military issue firearms, wherein the methods include a step for removing loose materials from within the barrel, a step for dislodging materials not removed during the first removal step, and a step for removing the materials dislodged during the dislodging step, as well as one or more optional cleaning steps to be performed in addition to or in lieu of the other cleaning steps, and wherein the firearm barrel cleaning device can be adapted to have different configurations for use during one or more of the various cleaning steps.

Owner:THE OTIS PATENT TRUST

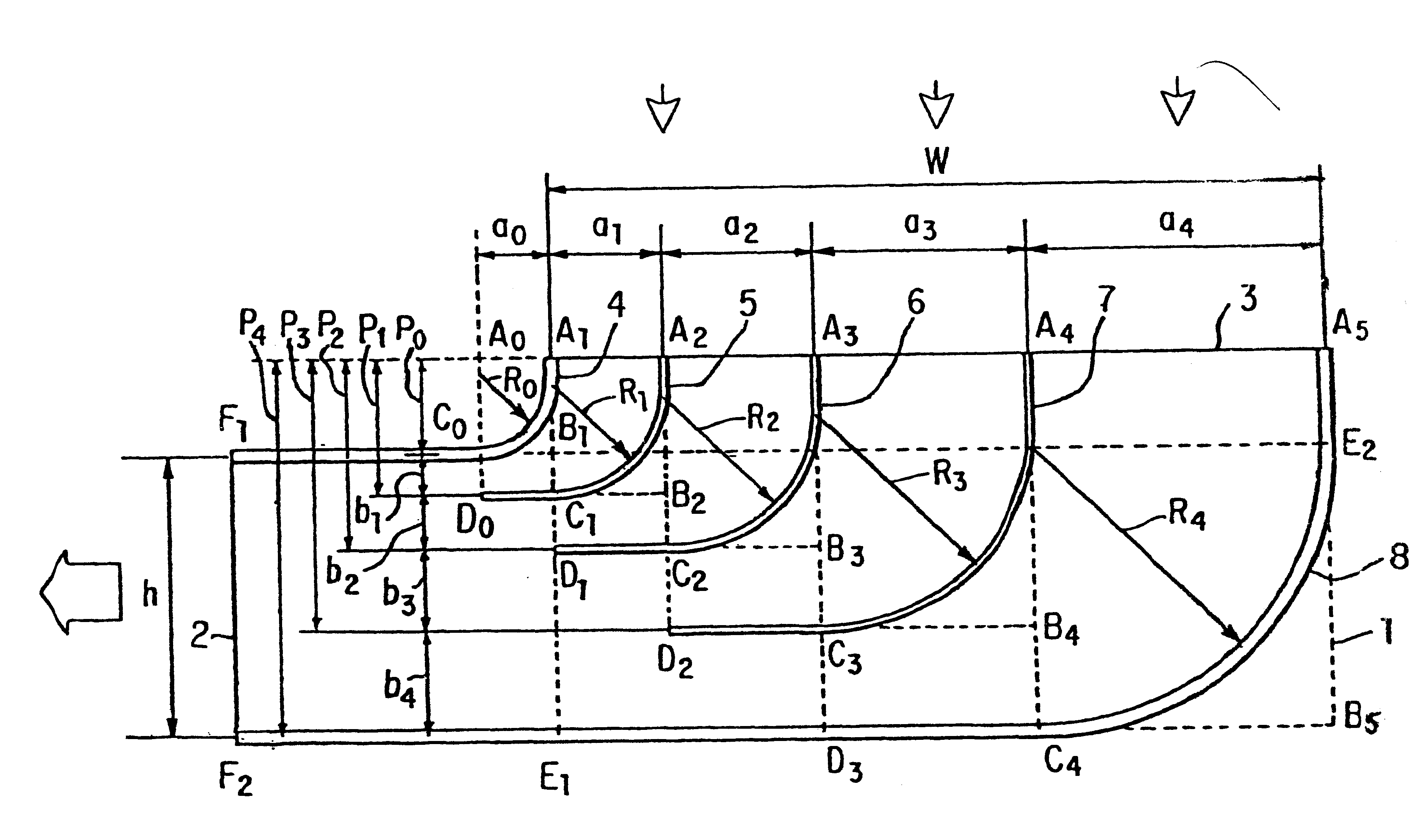

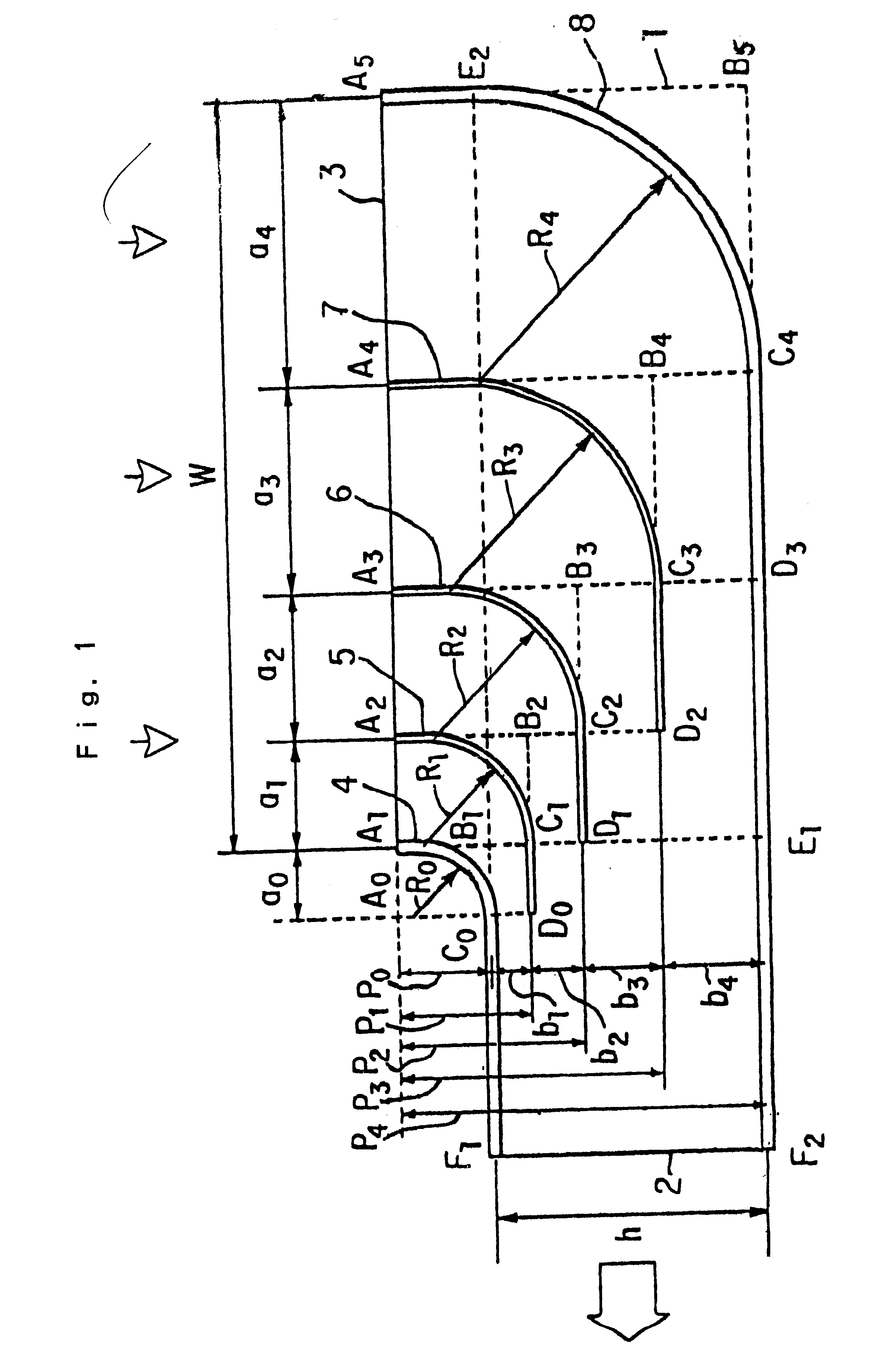

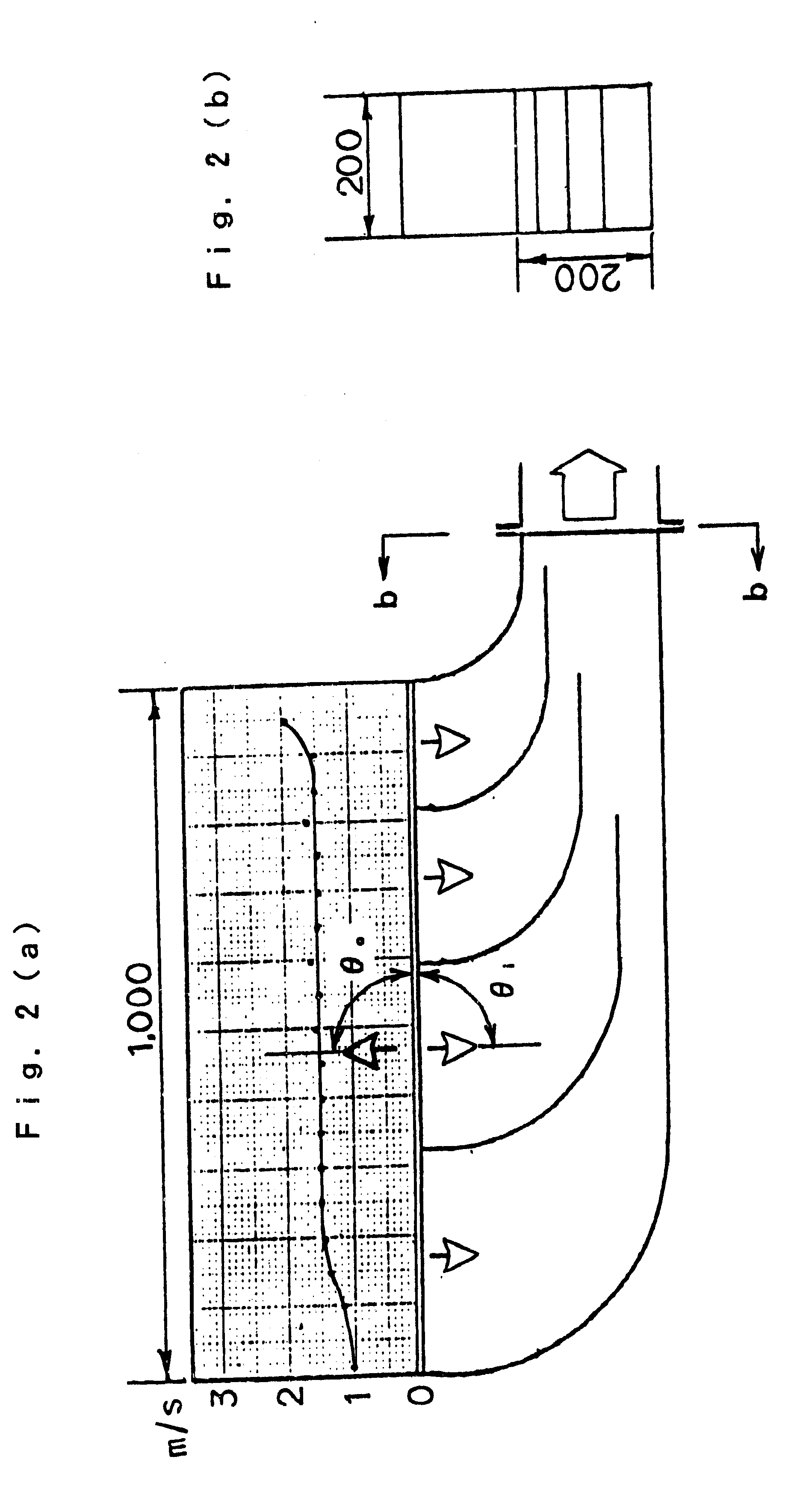

Suction elbow provided with built-in guide blades

InactiveUS6290266B1Evenly distributedSmall pressure lossPipeline expansion-compensationPump componentsEngineeringElbow

A suction elbow is divided in a plurality of sub-channels similar to each other by one or more guide vanes made of a curved plate and flat plates connected to the curved plate based on the following formulas.p0: overhang length at the inlet of the elbowh: outlet breadth of the elbowf: reduction ratio of the elbow (f=W / h)W: inlet breadth of the elbowm: number of sub-channels (m>=2)an: inlet breadth of n-th sub-channel (a0 indicates the radius of curvature of the inner side wall and am indicates the radius of curvature of the outer side wall)r: aspect ratio of the sub-channelsbn: outlet breadth of n-th sub-channel

Owner:KAWANO MICHIHIKO

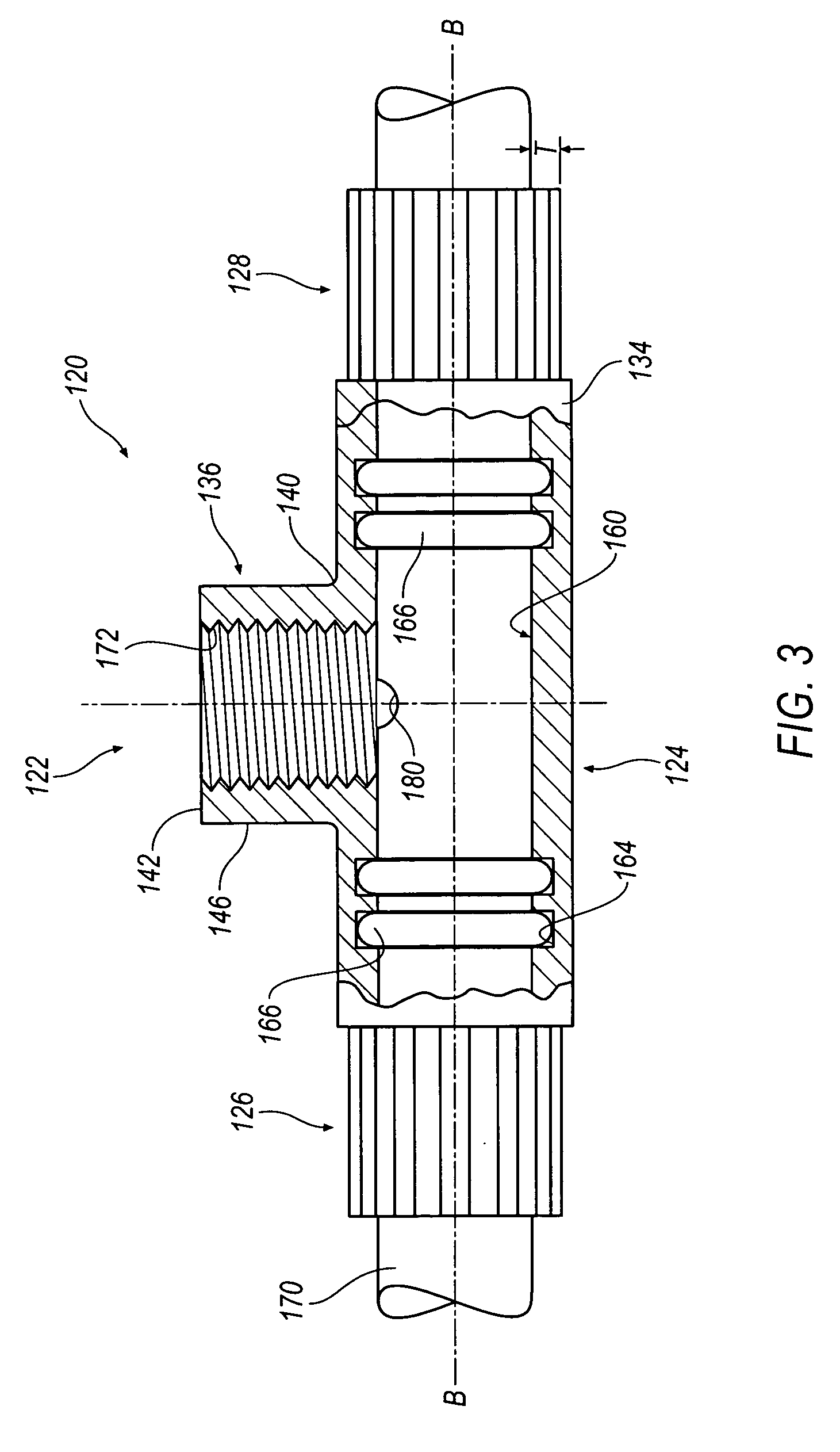

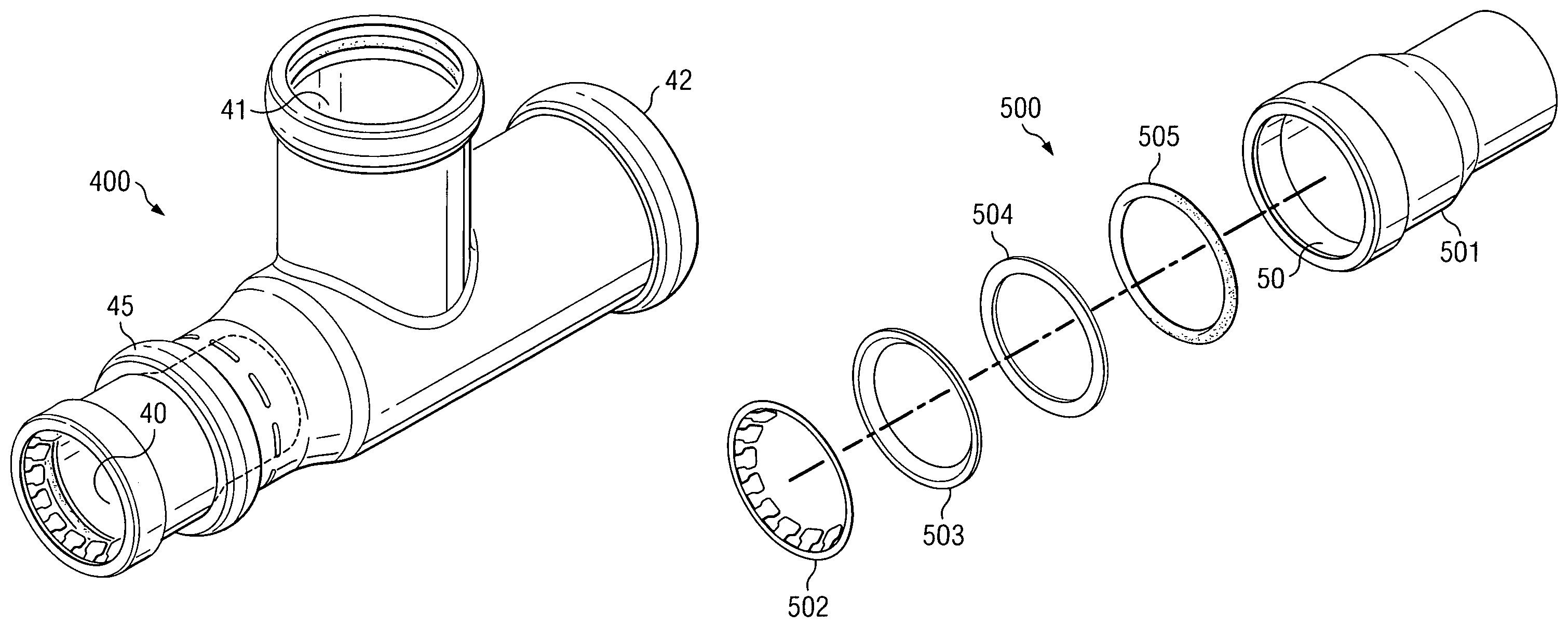

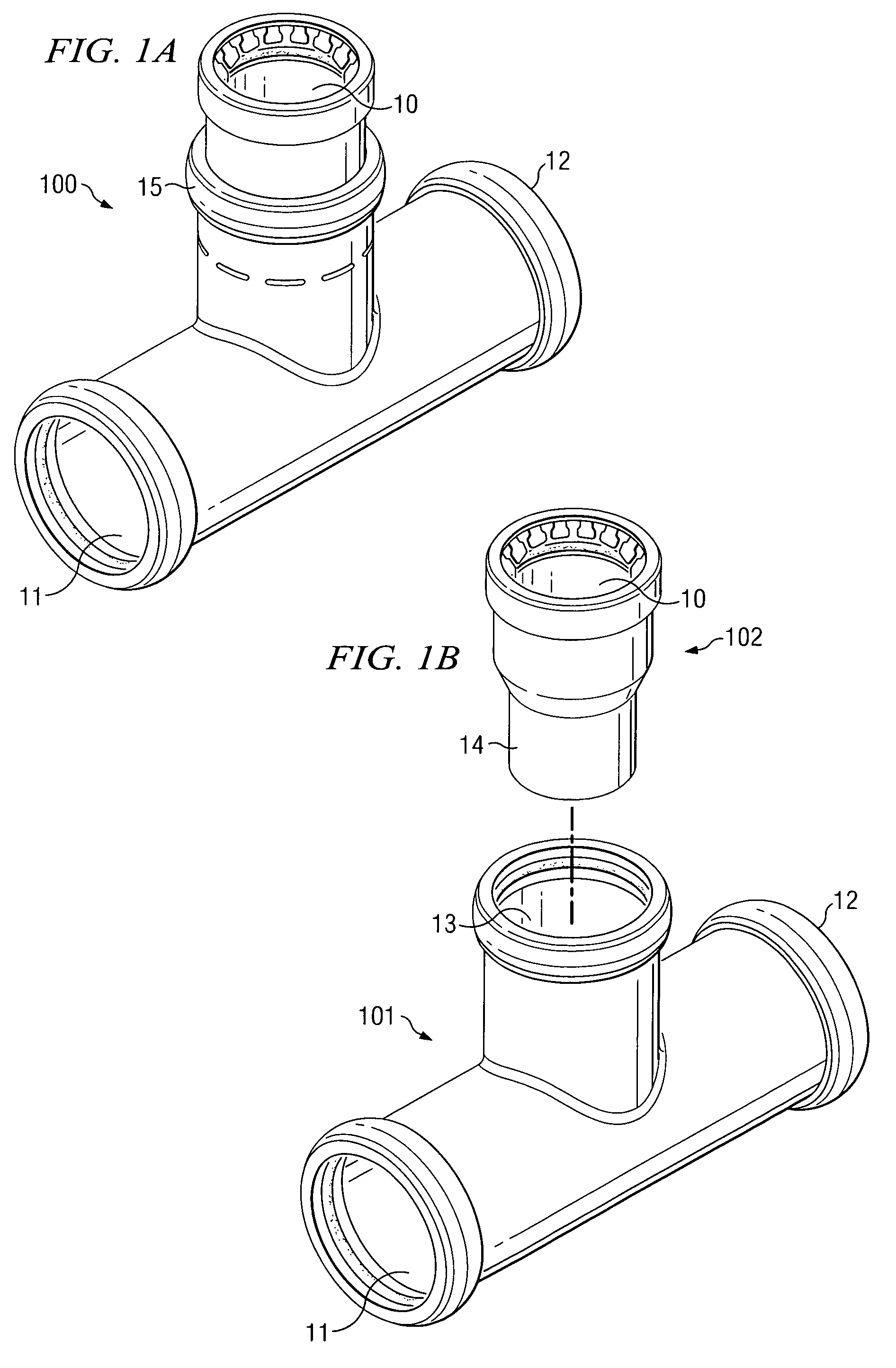

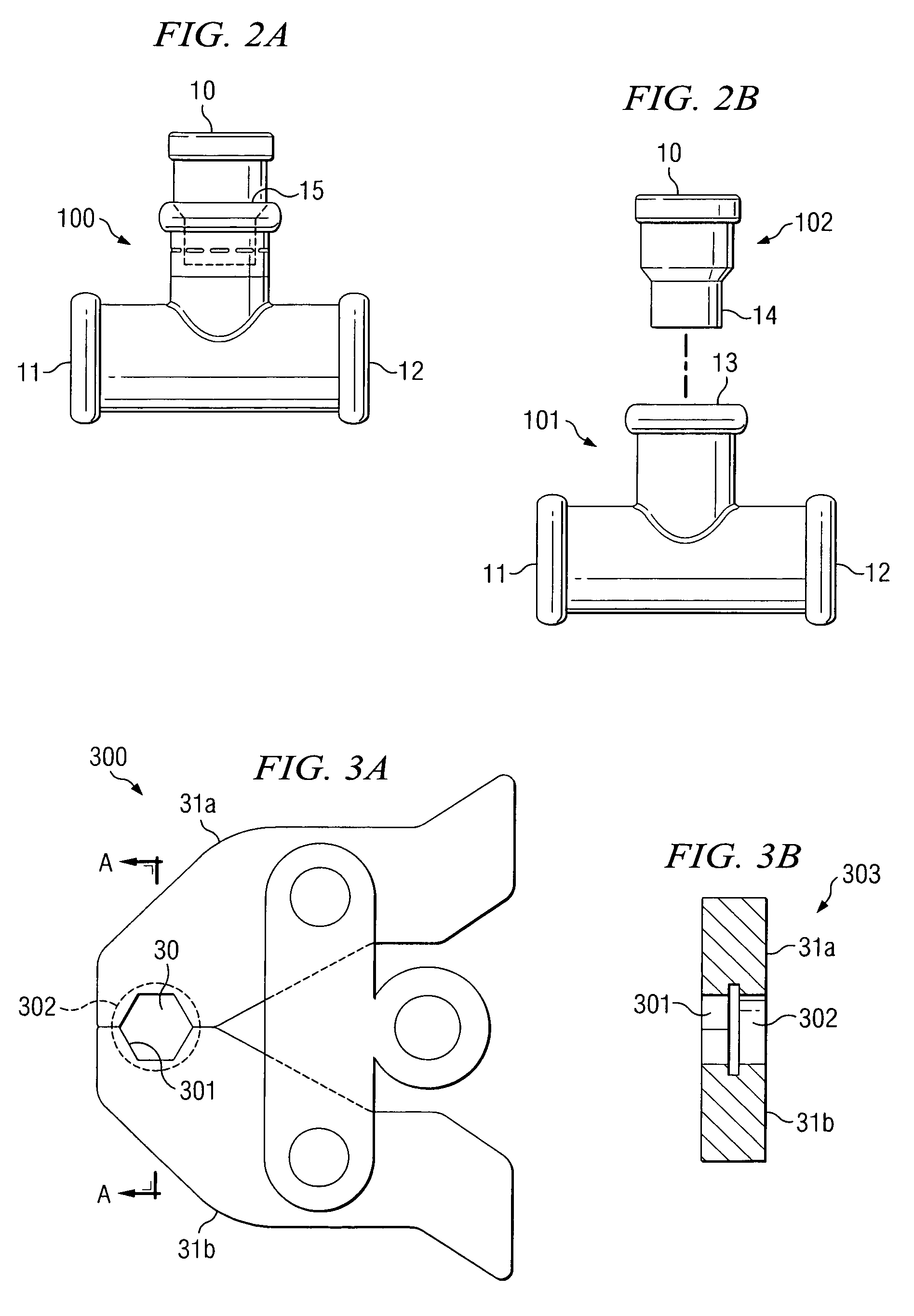

Transition tee coupling

InactiveUS7686346B1Installation time for fittingReduce the time required for installationSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

An improved coupling, such as a transition tee coupling, is described having press-connect fittings on the ends and a push-connect fitting on the outlet. The improved transition tee coupling is formed using a reduced-outlet tee having press-connect fittings on all three sockets. An unfinished end of a tailpiece having a push-connect fitting on the opposite end is inserted into the outlet socket of the press-connect tee. The press-connect fitting of the outlet tee is crimped using a special press tool jaw that does not damage the push fitting on the tailpiece.

Owner:ELKHART PRODS CORP

Bolt cleaning system

InactiveUS6983508B2Efficient removalEasy to cleanBowling gamesCarpet cleanersScrew threadAnchor bolt

A bolt cleaning system for removing debris from the threaded portions of anchor bolts. The bolt cleaning system includes a shaft member, an inner member attached to the shaft member having an annular member, a first cleaning unit removably positionable within the inner member, a connector member connectable to the inner member, an outer member connectable to the connector member, and a second cleaning unit removably positioned between the connector member and the outer member.

Owner:SAURER JAMES M

Roller for providing benefits to fabric

Owner:THE PROCTER & GAMBLE COMPANY

Mechanical joint for a gas turbine engine

ActiveUS20100316484A1Thermal response uniform thermalUniform thermal stressPipeline expansion-compensationPump componentsEngineeringGas turbines

A mechanical joint for a gas turbine engine includes:(a) an annular first component having an annular, radially-extending first flange; (b) an annular second component having an annular, radially-extending second flange abutting the first flange; (c) a plurality of generally radially-extending radial channels passing through at least one of the first and second flanges; (d) a plurality of generally axially-extending channels extending through the first flange and communicating with respective ones of the radial channels; and (e) a plurality of fasteners clamping the first and second flanges together.

Owner:GENERAL ELECTRIC CO

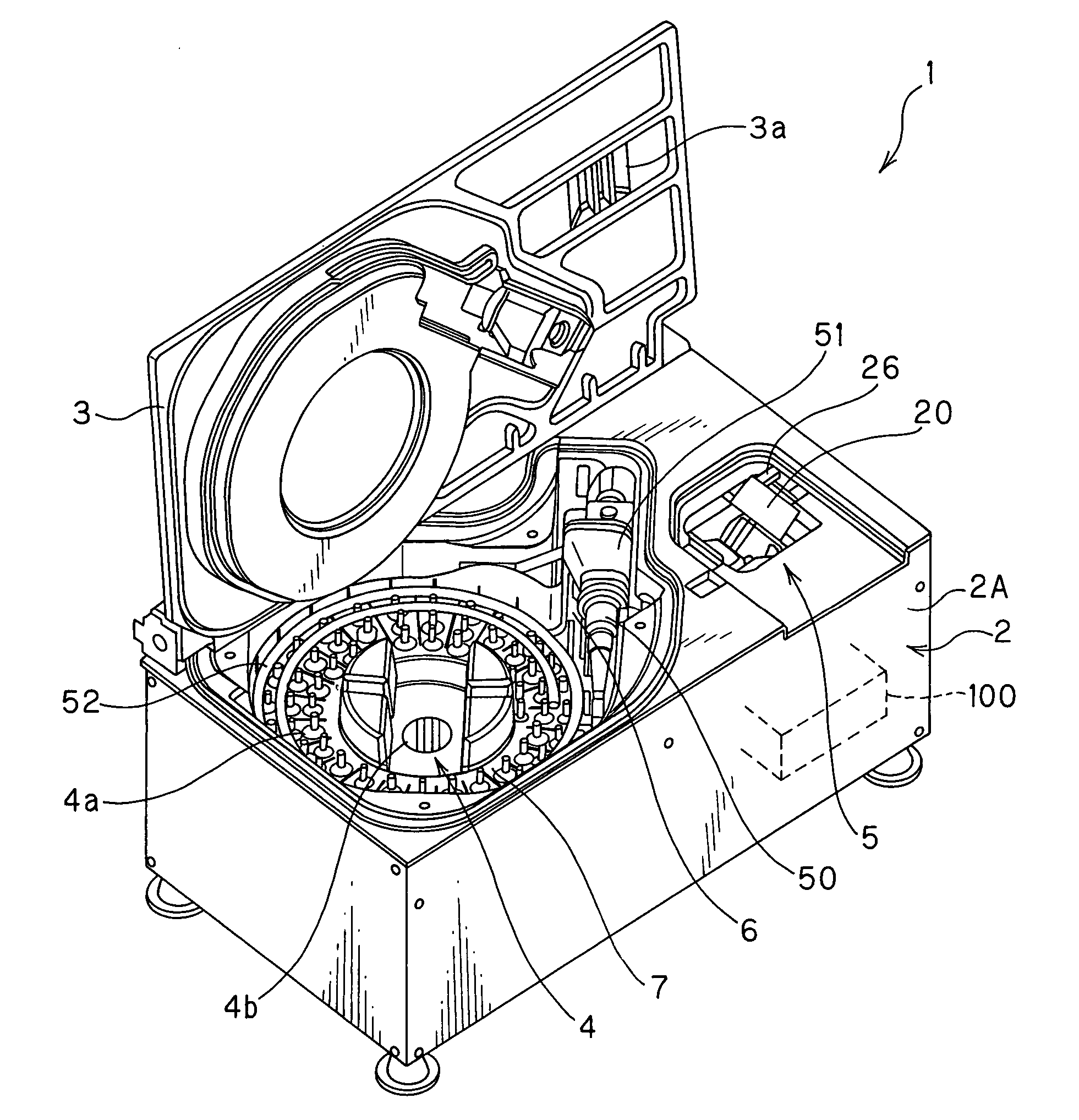

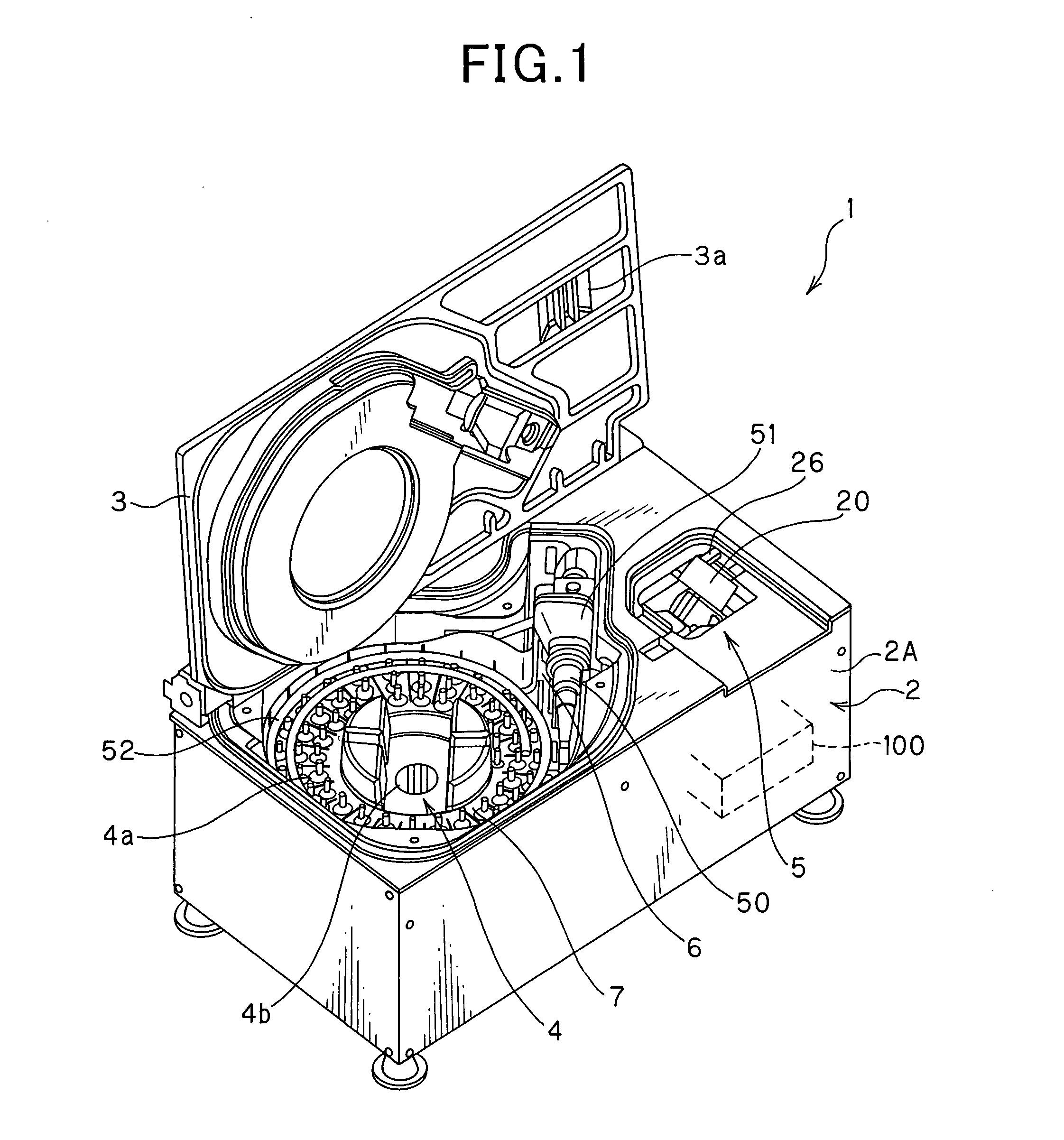

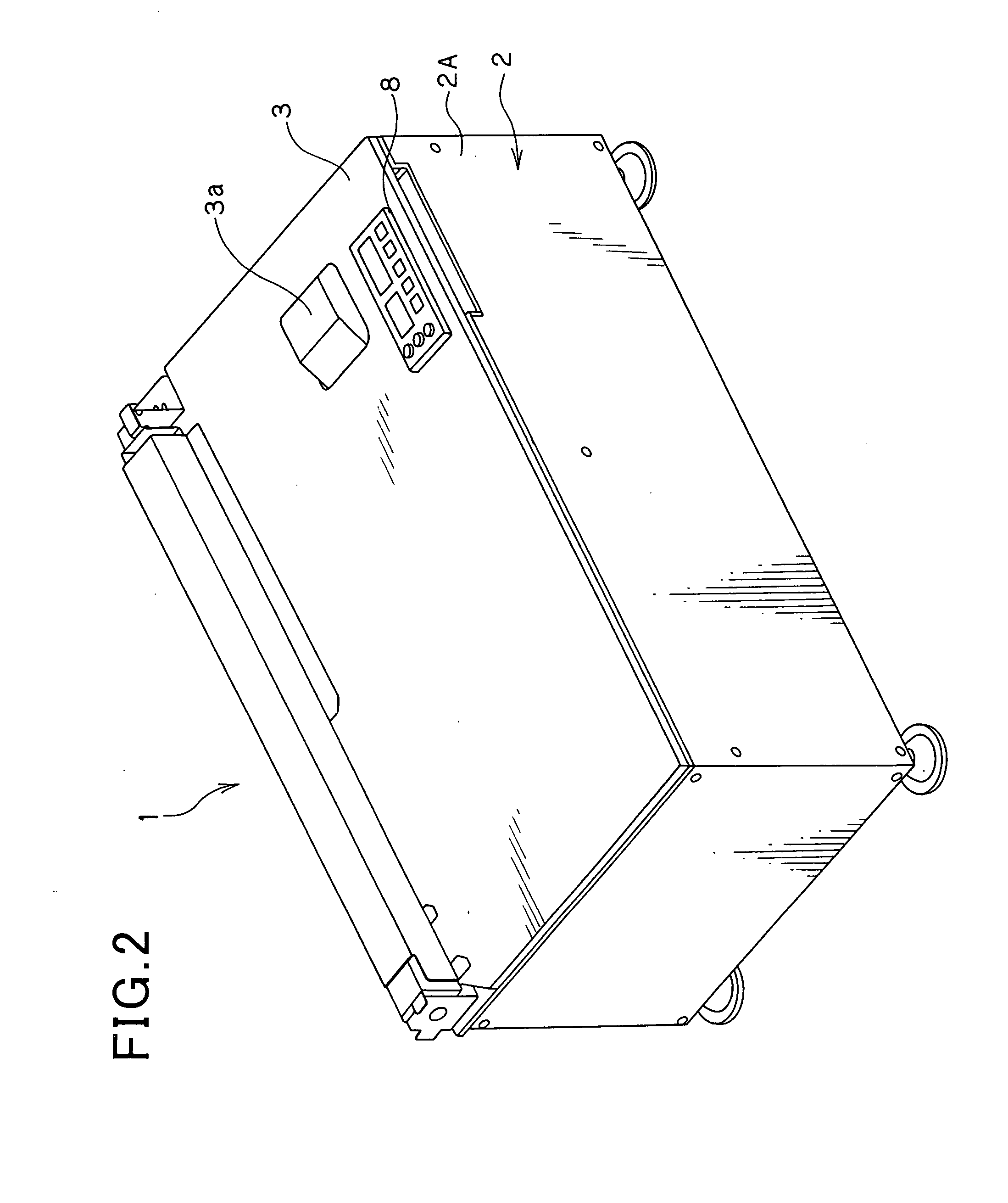

Apparatus for washing and disinfecting endoscope and brush unit for washing ducts of endoscope

InactiveUS20070234494A1Labor savingSimple working processBrush bodiesHollow article cleaningEngineeringMechanical engineering

An apparatus for washing and disinfecting an endoscope comprises a frame, a brush unit, and a lid. The frame is equipped with a washing bath accommodating therein the endoscope for washing and disinfection. The brush unit accommodates therein a brush for washing a duct of the endoscope and is detachably loaded to the frame at a predetermined position thereof to allow the brush to be inserted into the duct. The lid is attached to the frame to selectively open and close and formed to cover the washing bath and the brush unit loaded to the fame when the frame is closed. Further, the apparatus comprises a reuse-disabling device disabling the brush unit from being reused in association with the opening and closing actions of the lid. The reuse-disabling device prevents reuse of the brush unit which is poor in its washing performance due to being used already.

Owner:OLYMPUS MEDICAL SYST CORP

Adjustable fitting and pipe cleaning brush device

The invention outlined in the disclosure is an adjustable wire brush tool for cleaning either the inside or the outside end of a copper pipe or fitting in preparation for soldering the parts together. The tool includes a hollow cylindrical section with a first wire brush on the interior surface of the section. Attached at one end of the cylindrical section is a slightly smaller cylindrical section sized to hold a second cylindrical twisted steel brush having a hexagonal shaft that extends from the smaller section, opposite the larger cylindrical section. The twisted steel brush and attached shaft can be moved to extend the twisted brush beyond the open end of the larger cylindrical section, for insertion into a fitting to clean the fitting interior surface by attaching a power drill to the shaft and rotating the twisted steel brush attached thereto. To clean the outside of a pipe, the twist brush is retracted into the smaller section and secured to that section with an engaging means. The pipe is inserted into the larger section, and the drill is activated to rotate the shaft and attached larger section to clean the pipe outer surface. The tool overcomes the need for separate tools to perform each task and requires but one drill to perform either task as needed. The tool is sized to handle a particular diameter of pipe and fitting, with sizes ranging from one quarter inch to several inches.

Owner:THE MILL ROSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com