Gun barrel cleaning device with quick-detachable cleaning implement

a cleaning device and cleaning implement technology, applied in the direction of weapon cleaning, pipe units with cleaning apertures, weapons, etc., can solve the problems of misplaced or lost cleaning implements, prone to thread damage or stripping, and inconvenient thread connection of the cleaning rod system, so as to facilitate the rotation of the cleaning implement and be easily detachable from the handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

DETAILED DESCRIPTION OF PREFERRED EMBODIMENTS

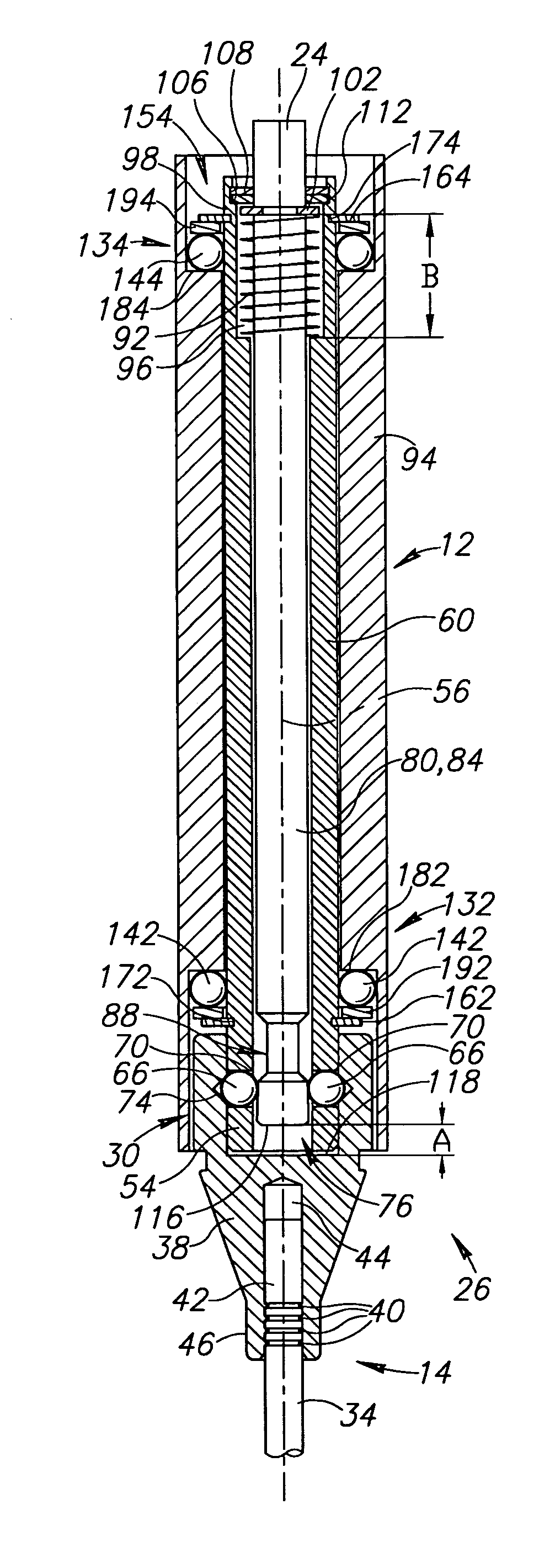

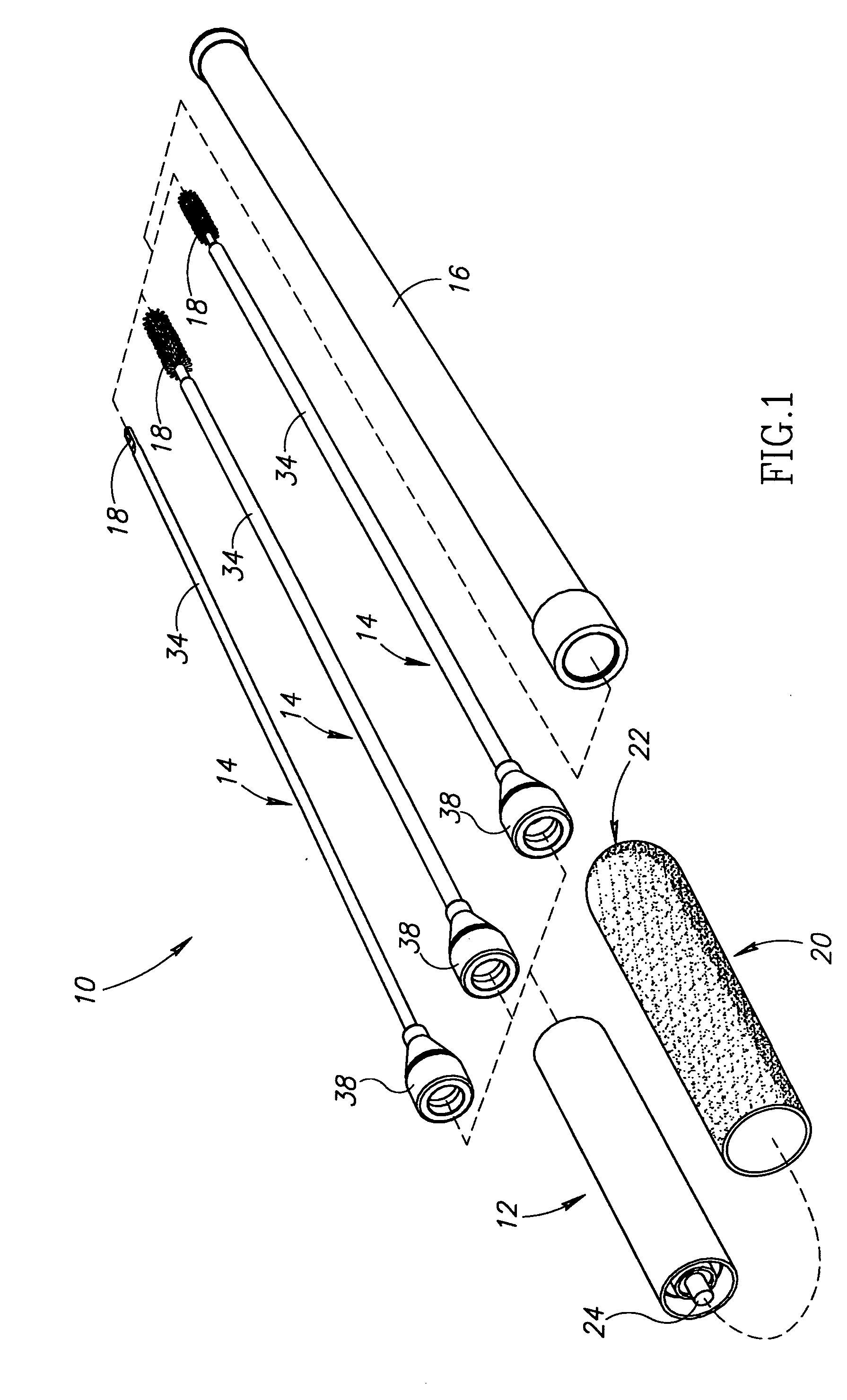

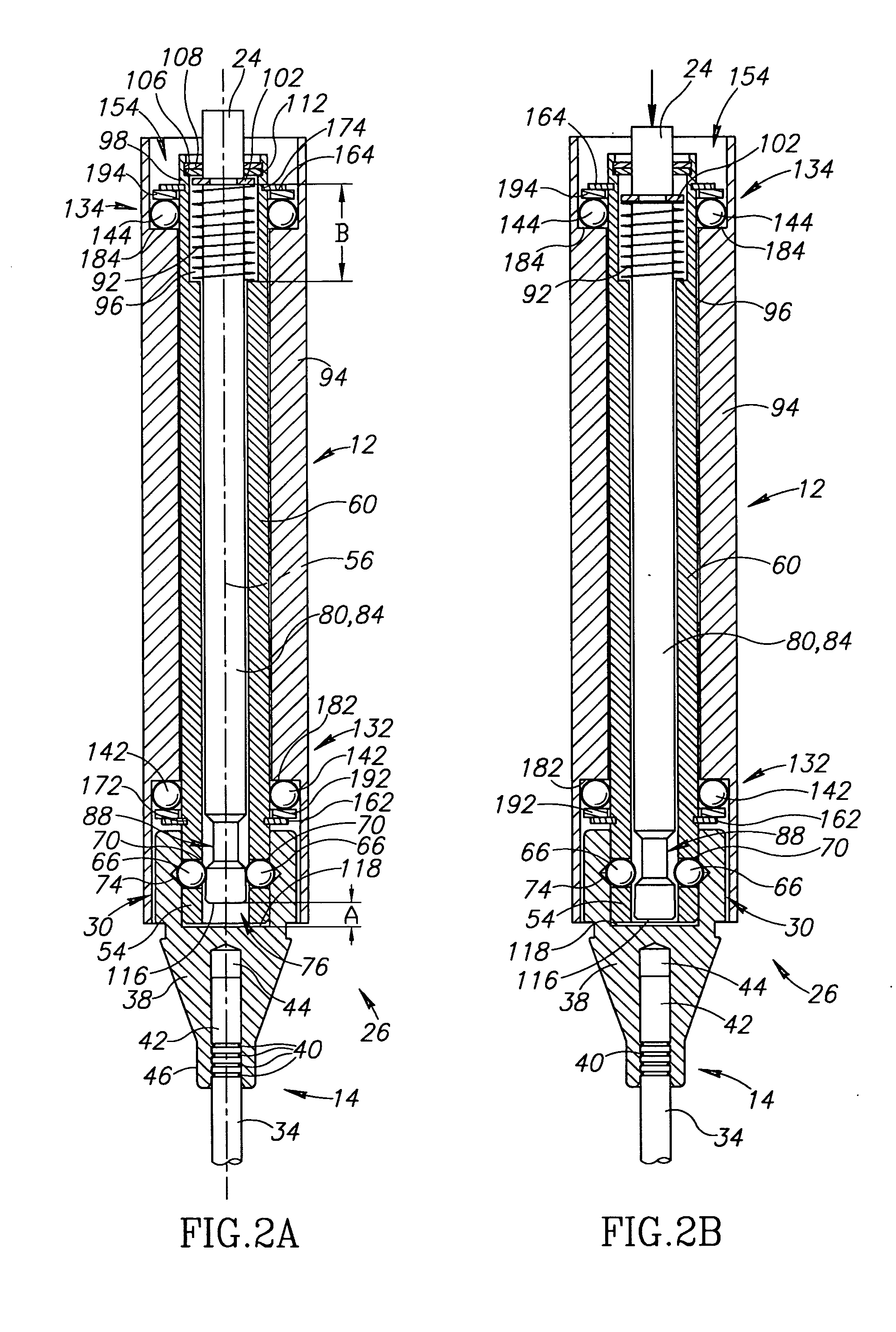

[0016] With reference to FIG. 1, a gun cleaning kit 10 includes a handle 12 and a variety of gun cleaning implements 14 interchangeably connectable to the handle. Each cleaning implement 14 may be inserted into a protective storage sheath 16 for storage and shipping, as described below in detail with reference to FIG. 3. Cleaning implements 14 may be provided in a variety of different lengths and gages sized to clean firearms of different calibers and various types of gun barrel bores. In addition, cleaning implements 14 may be equipped with a variety of different brushes, swabs, or jags at their working ends 18 for different cleaning applications. An optional grip 20 is press fit or otherwise secured around handle 12 to provide a comfortable and slip-resistant gripping surface for handle 12. Each of the cleaning implements 14 is preferably formed of a rigid, one-piece rod 34 for precision and durability. However, in some embodiments (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com