Patents

Literature

36results about How to "Uniform thermal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

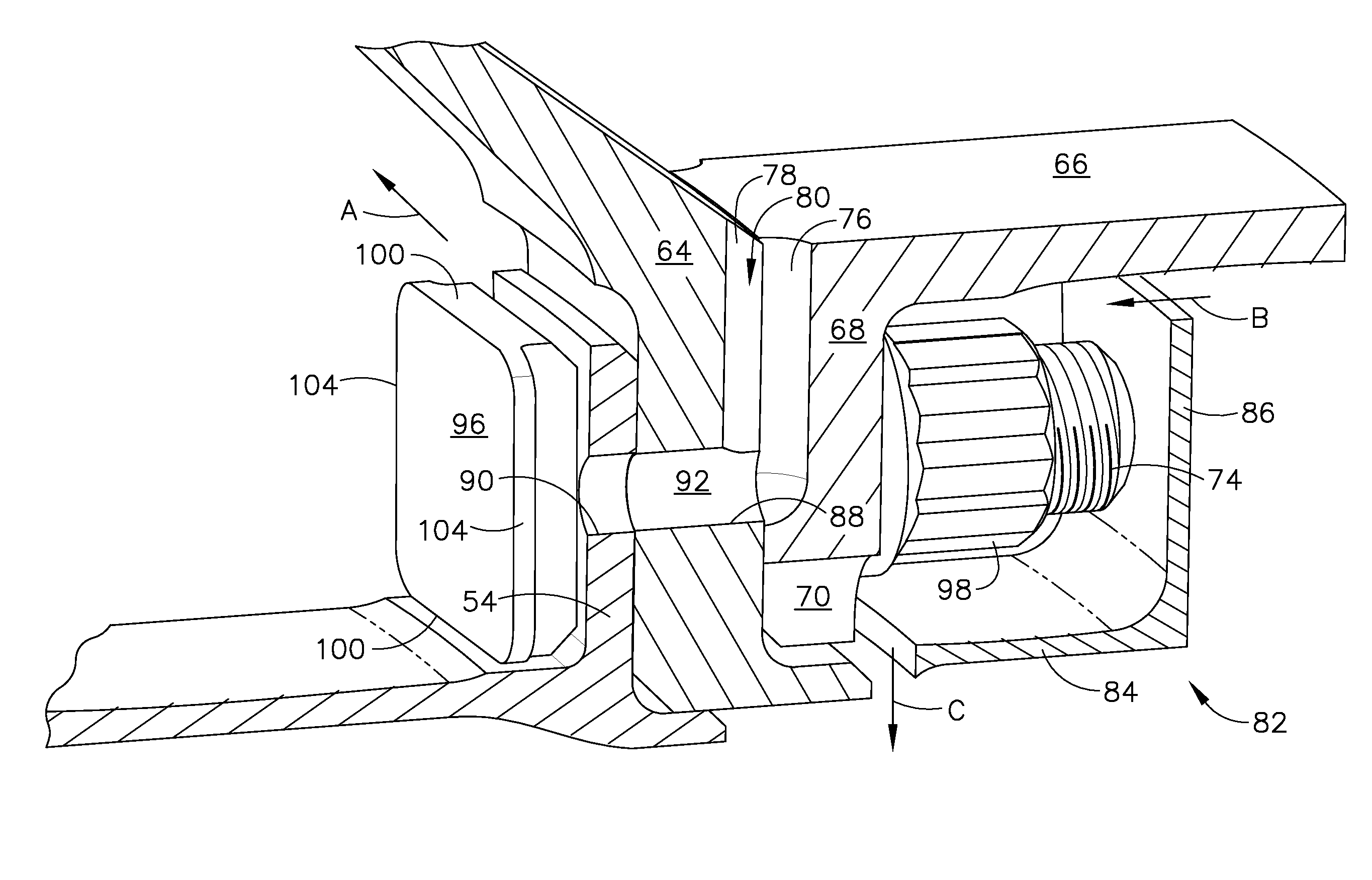

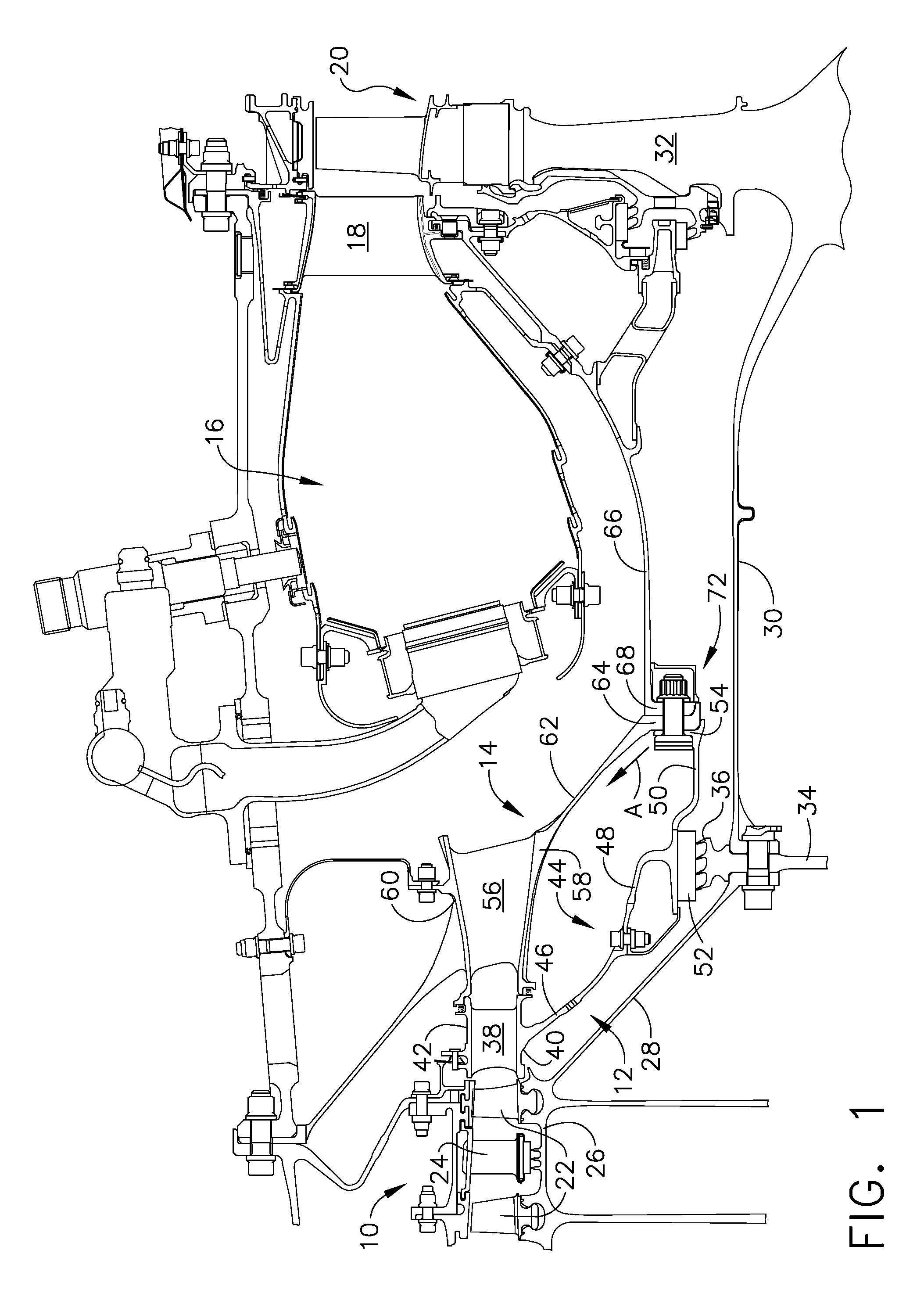

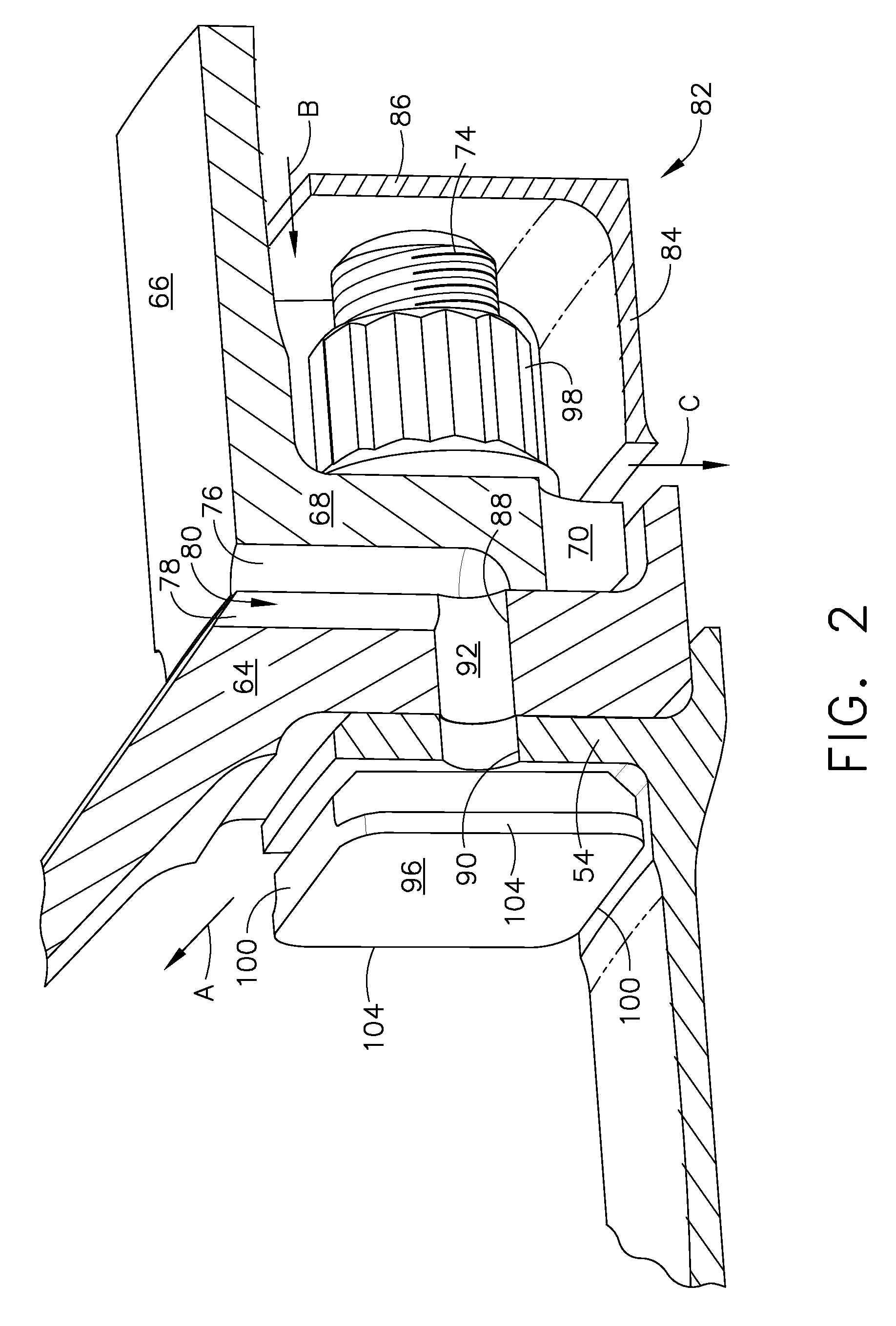

Mechanical joint for a gas turbine engine

ActiveUS8459941B2Controls are responsiveUniform thermal stressLocking fastenersReaction enginesEngineeringGas turbines

A mechanical joint for a gas turbine engine includes:(a) an annular first component having an annular, radially-extending first flange; (b) an annular second component having an annular, radially-extending second flange abutting the first flange; (c) a plurality of generally radially-extending radial channels passing through at least one of the first and second flanges; (d) a plurality of generally axially-extending channels extending through the first flange and communicating with respective ones of the radial channels; and (e) a plurality of fasteners clamping the first and second flanges together.

Owner:GENERAL ELECTRIC CO

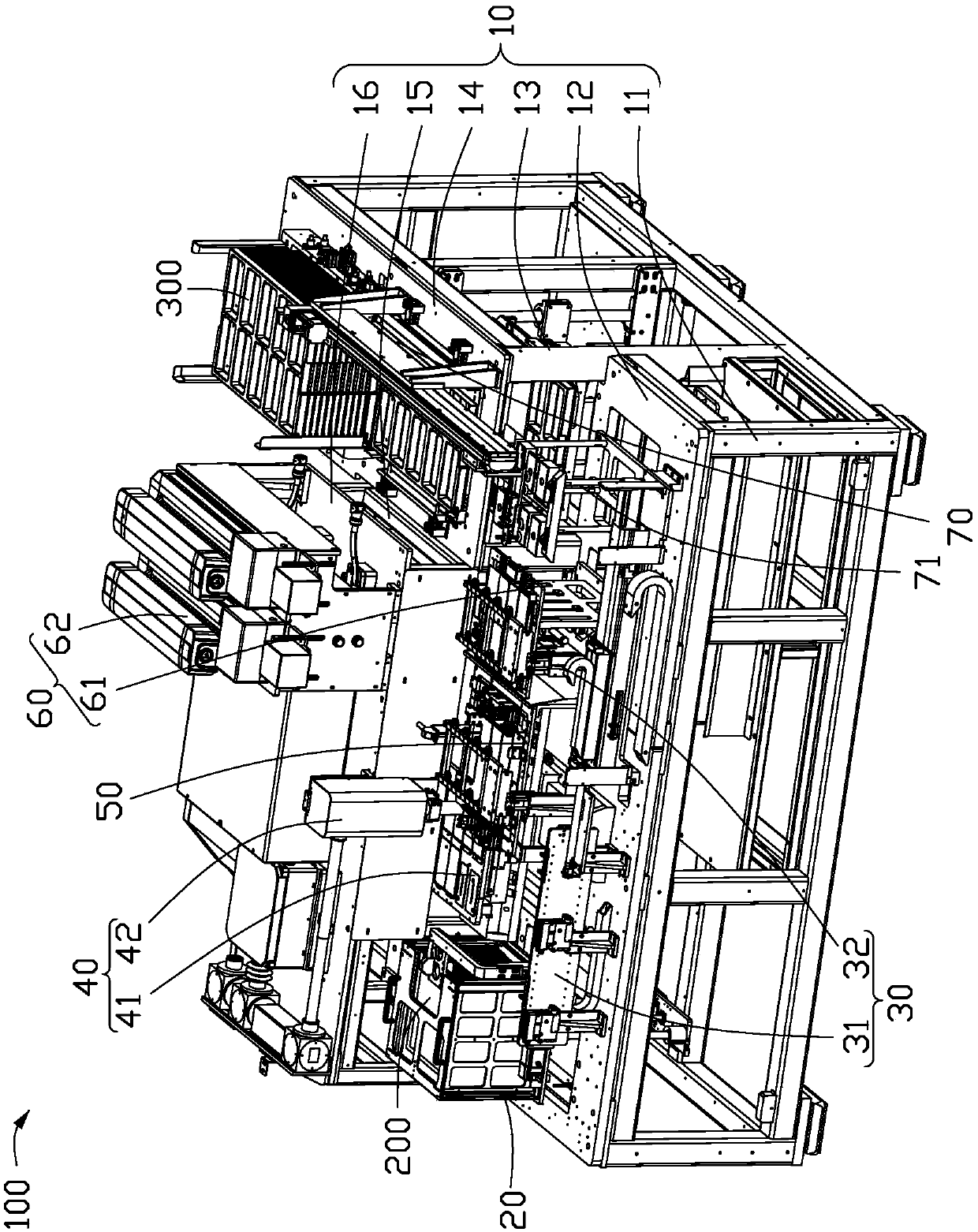

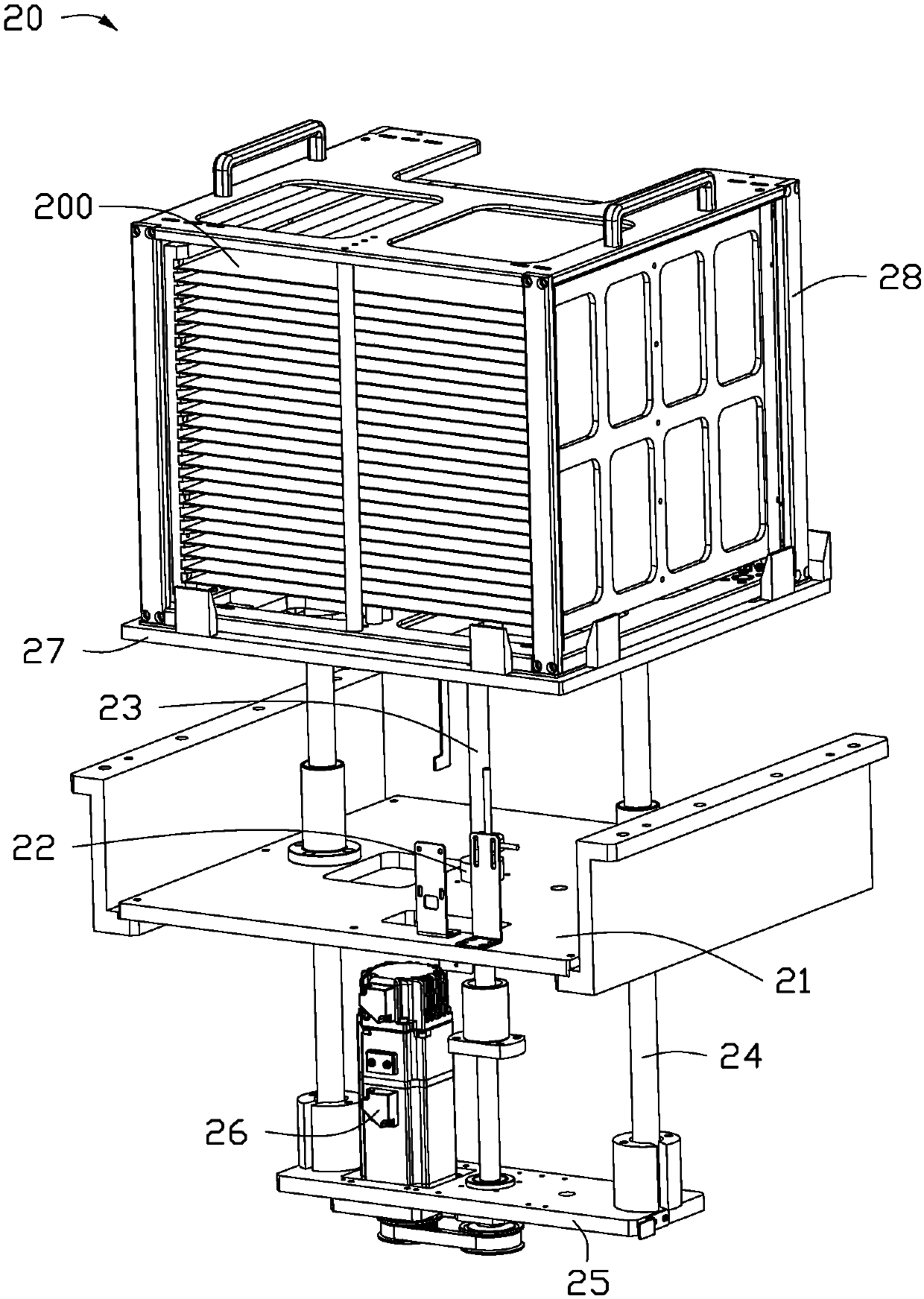

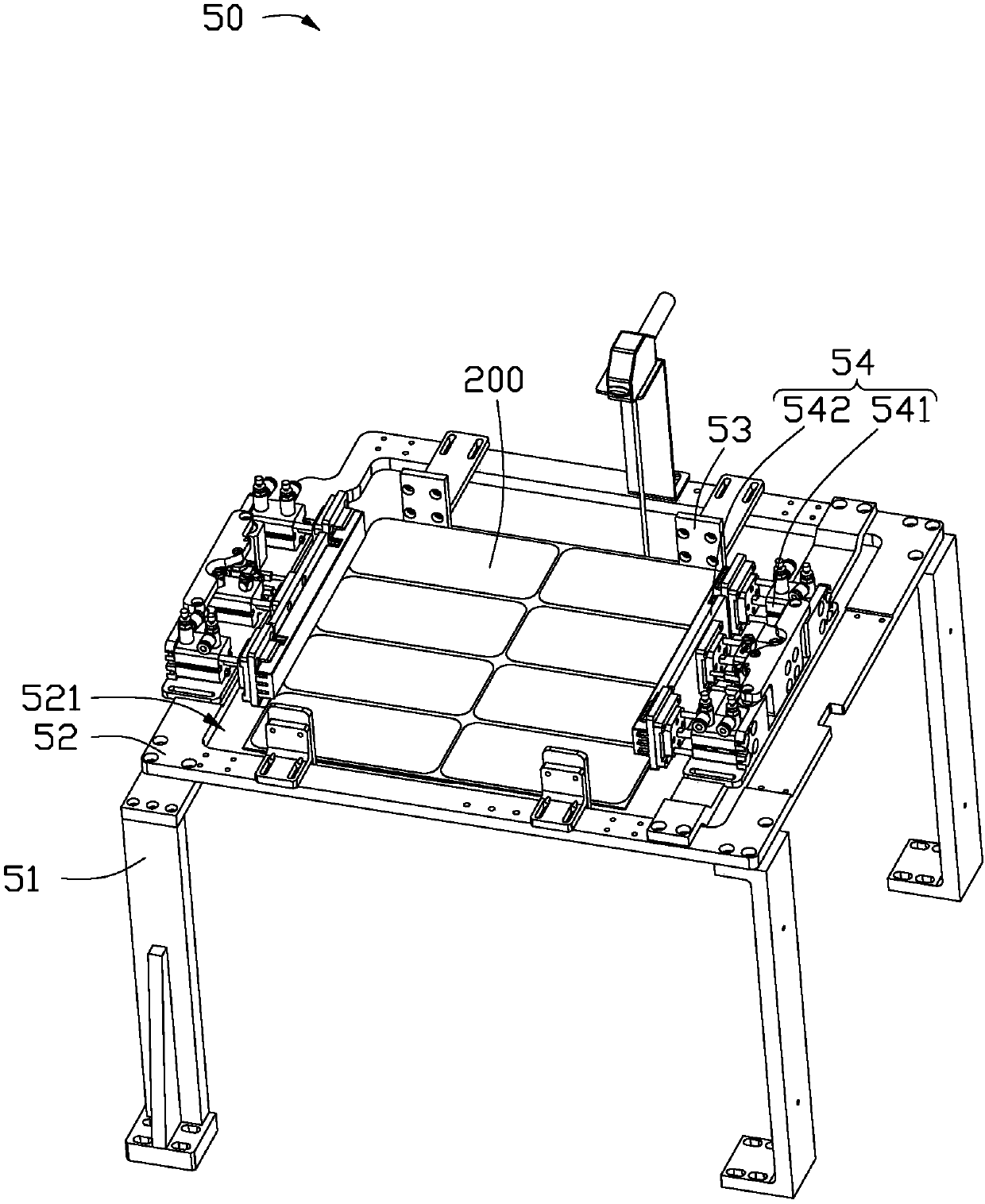

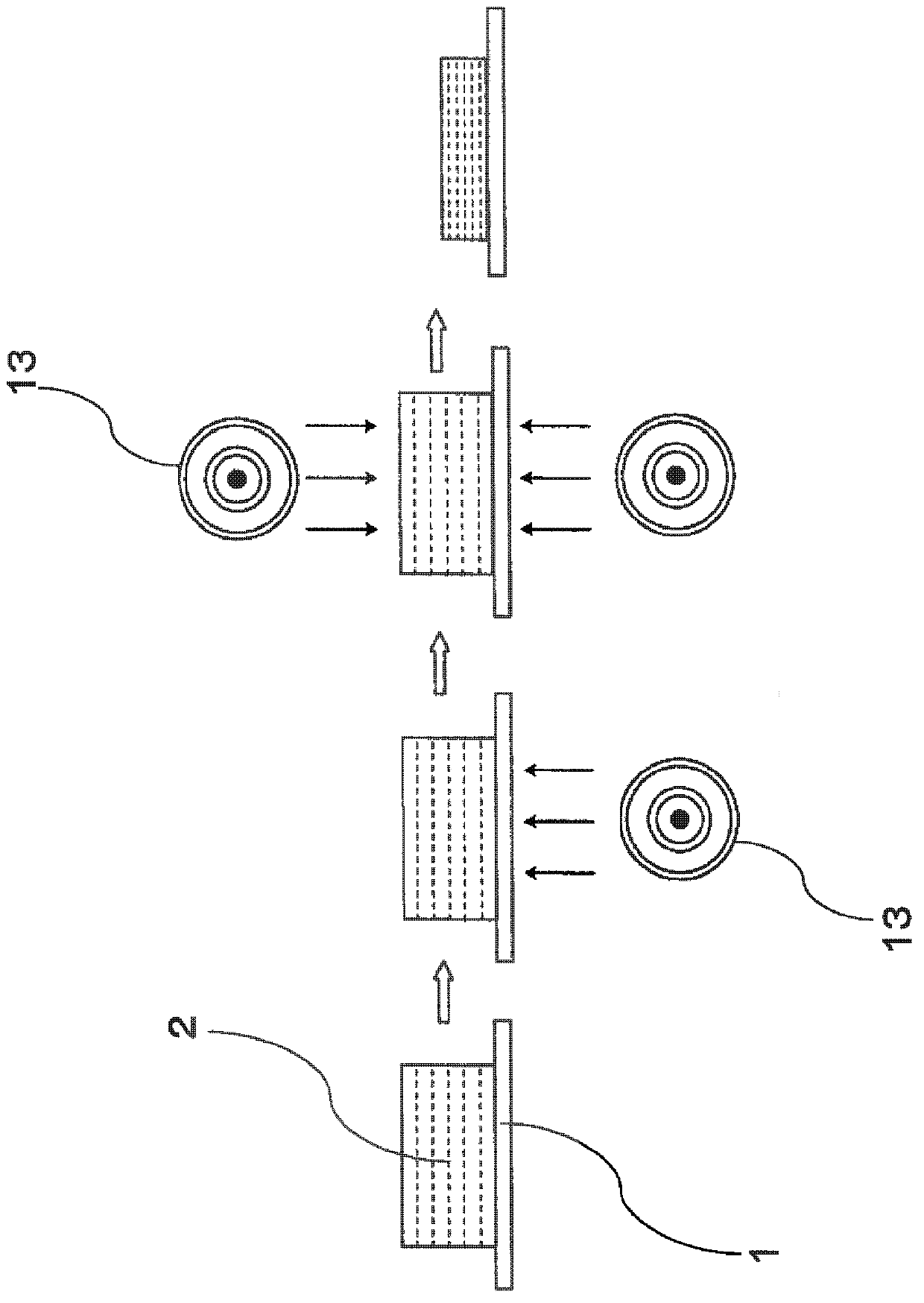

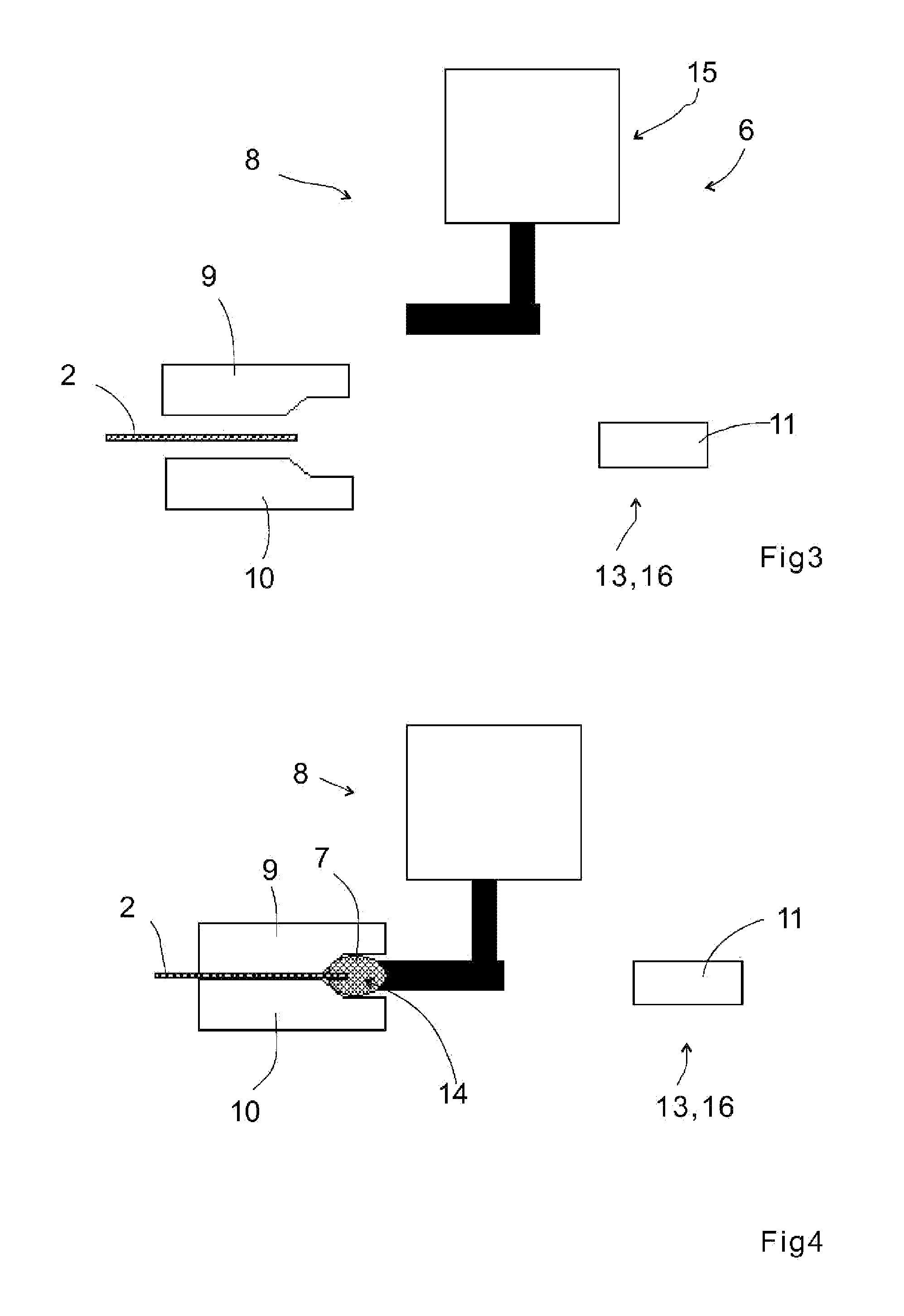

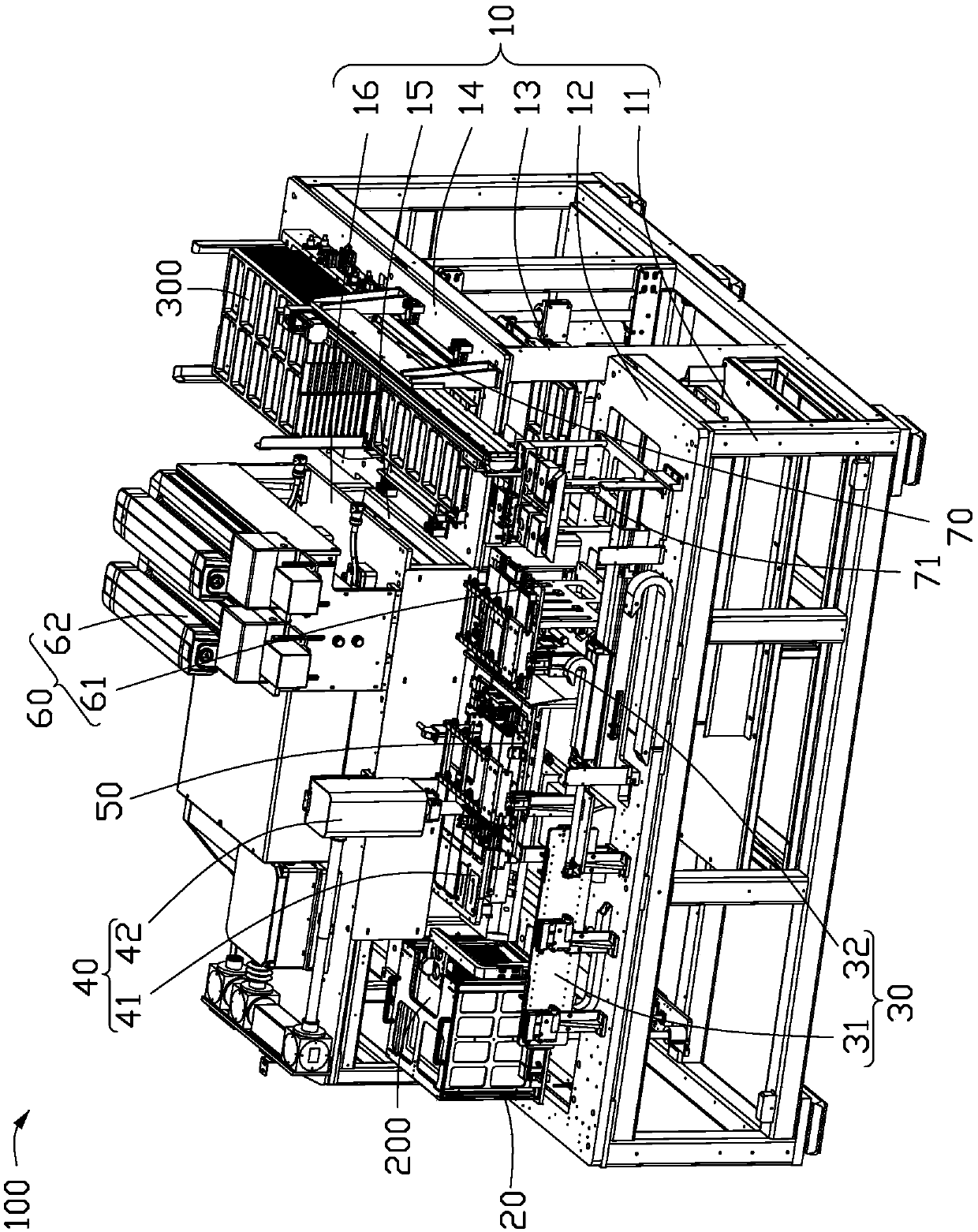

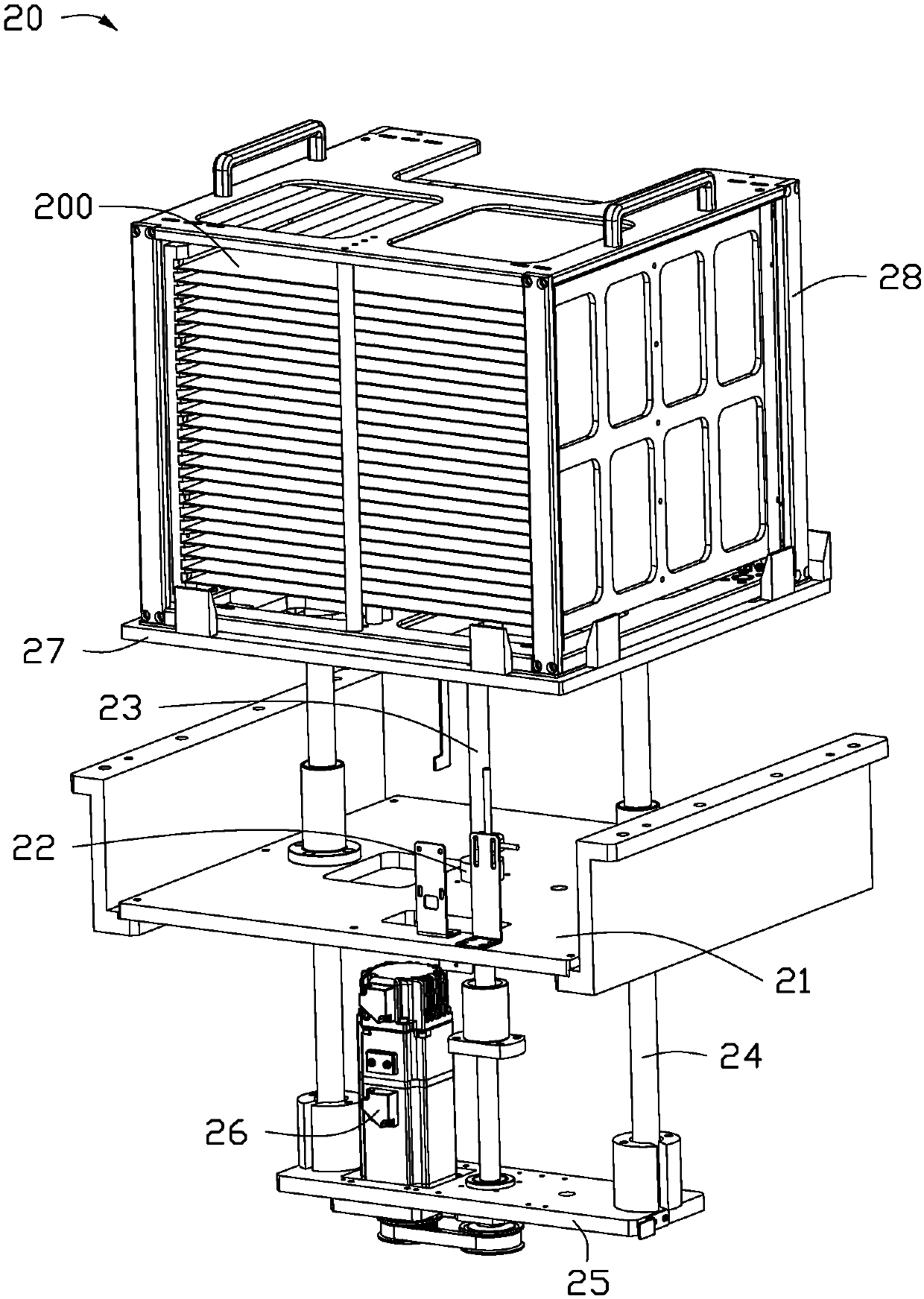

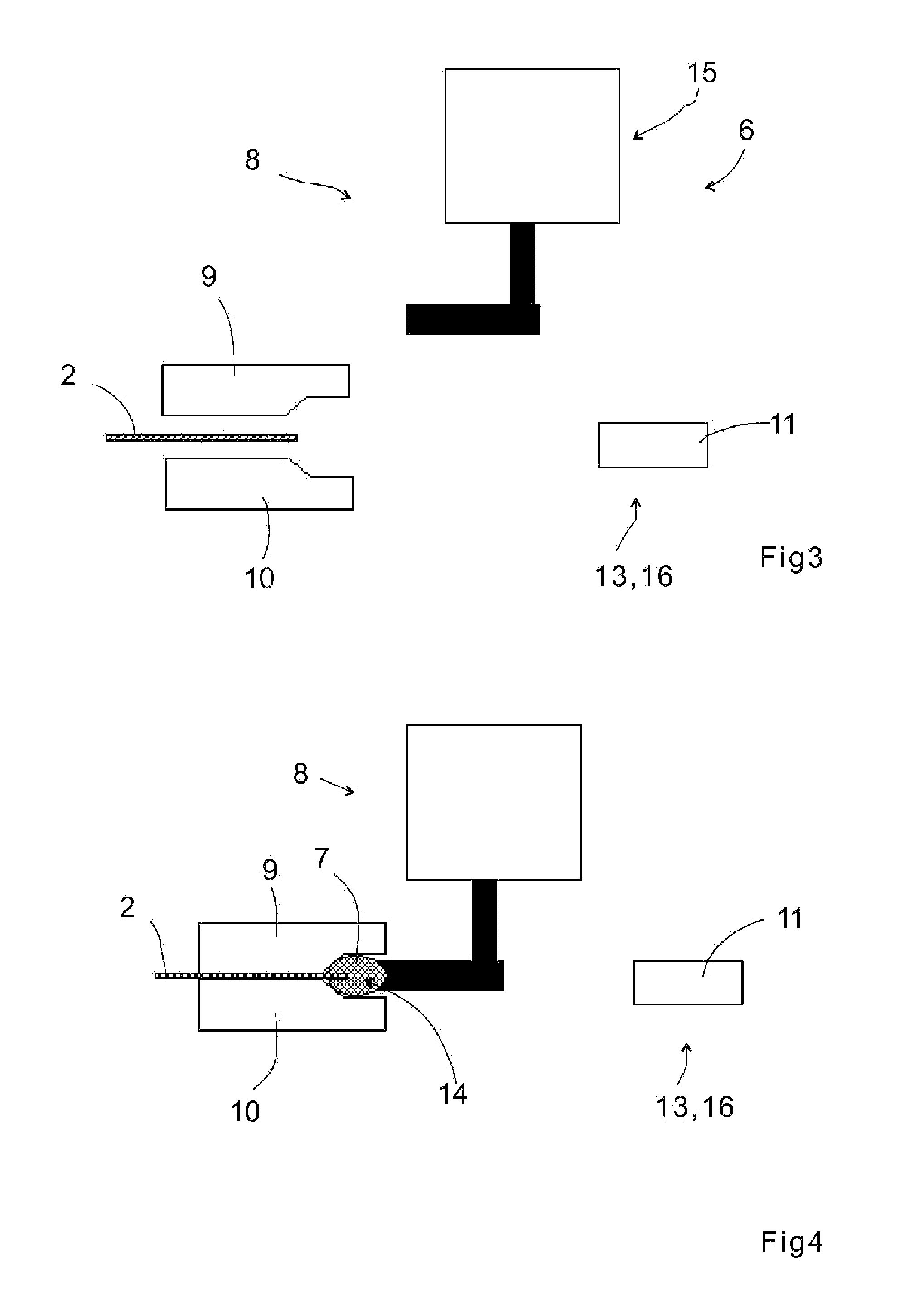

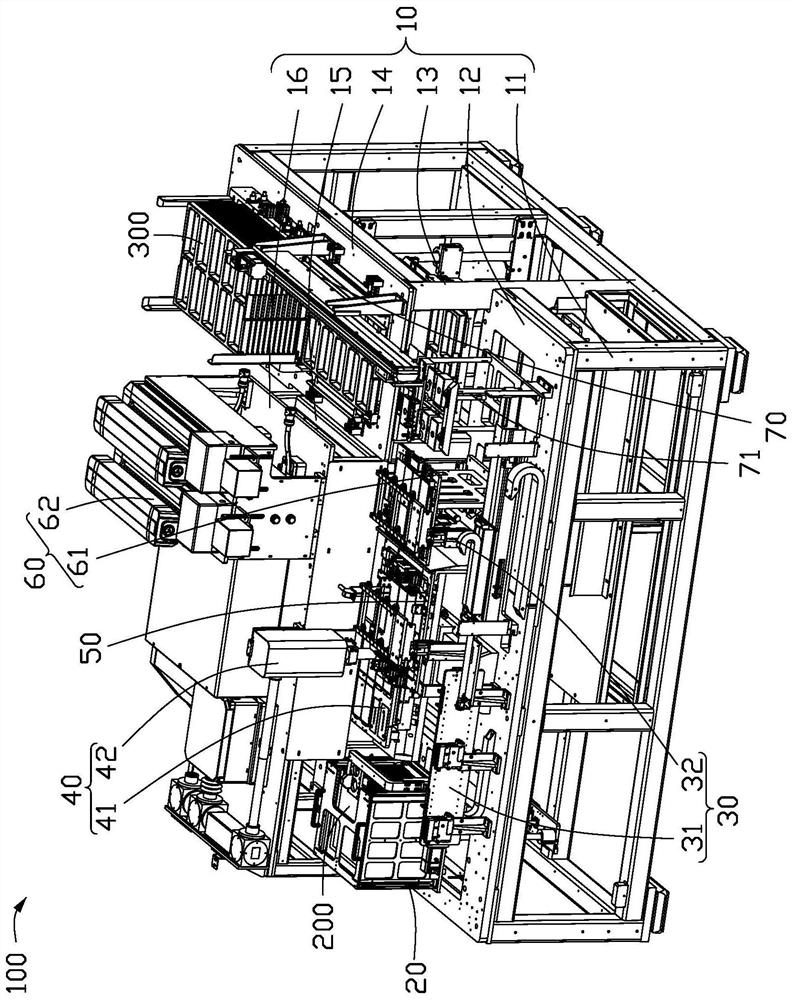

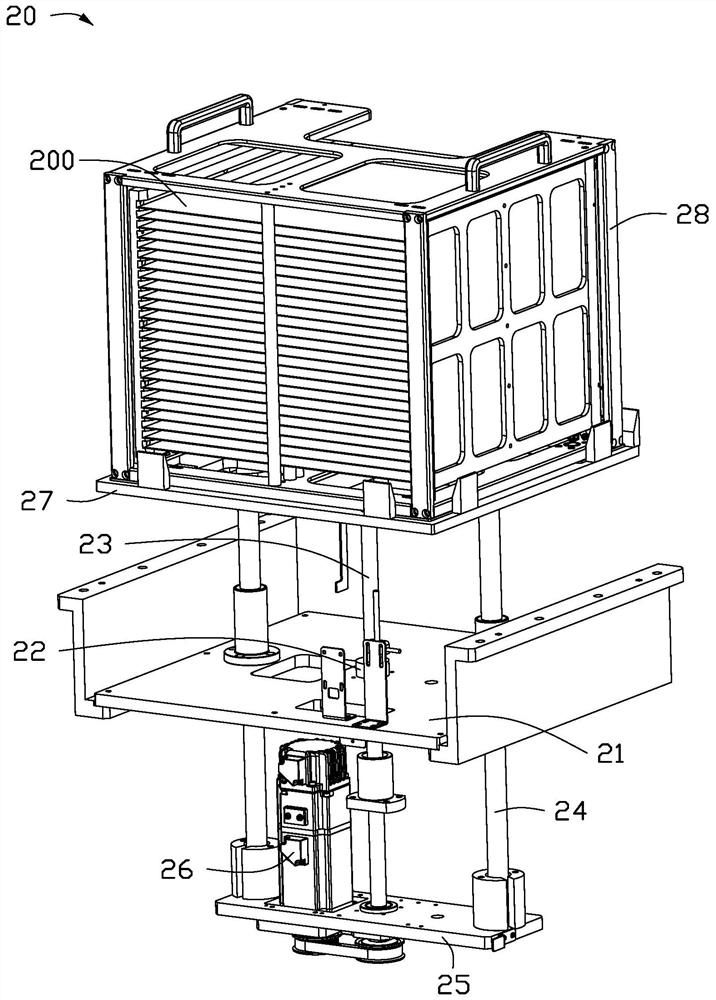

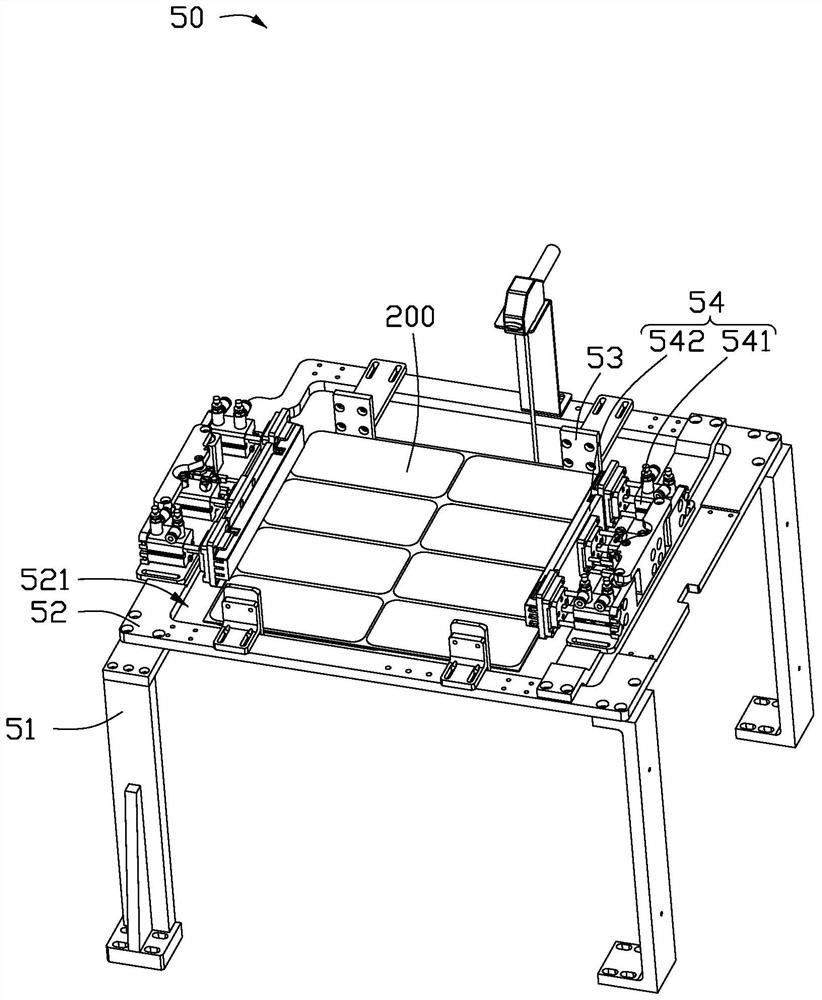

Laser cutting device

ActiveCN110204187AEffectively release thermal stressUniform thermal stressGlass severing apparatusLaser cuttingEngineering

The invention provides a laser cutting device. The laser cutting device comprises a machine table, a conveying mechanism, a cutting mechanism and a splitting mechanism, the cutting mechanism comprisesa moving platform and a laser cutter, the moving platform is used for storing workpieces and driving the workpieces to move according to a preset route, the laser cutter is used for emitting a laserbeam to pre-cut the workpieces on the moving platform and form a pre-cutting line, the laser cutting device further comprises a standing mechanism, the standing mechanism comprises a fixing frame, a carrier plate and two clamping assemblies, every clamping assembly comprises a clamping member and at least one clamping driving member, every clamping driving member is arranged on the carrier plate and adjacent to one side edge of the carrier plate, the clamping members are arranged on the clamping driving members and move under the driving of the corresponding clamping driving members to resistthe workpieces to in order to clamp and fix the workpieces and stand the workpieces for a preset time, and the splitting mechanism heats the stood workpieces along the pre-cut line to make the workpieces split along the pre-cut ling in order to realize the cutting of the workpieces.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

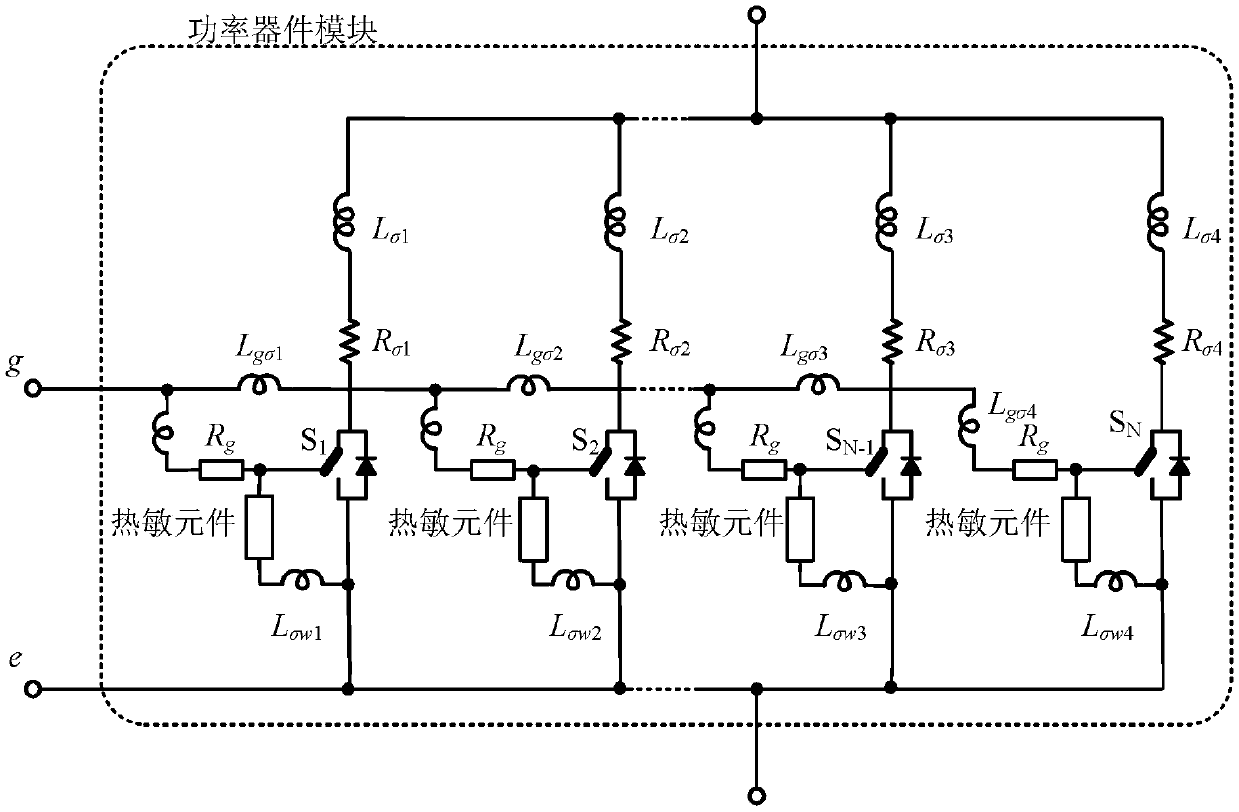

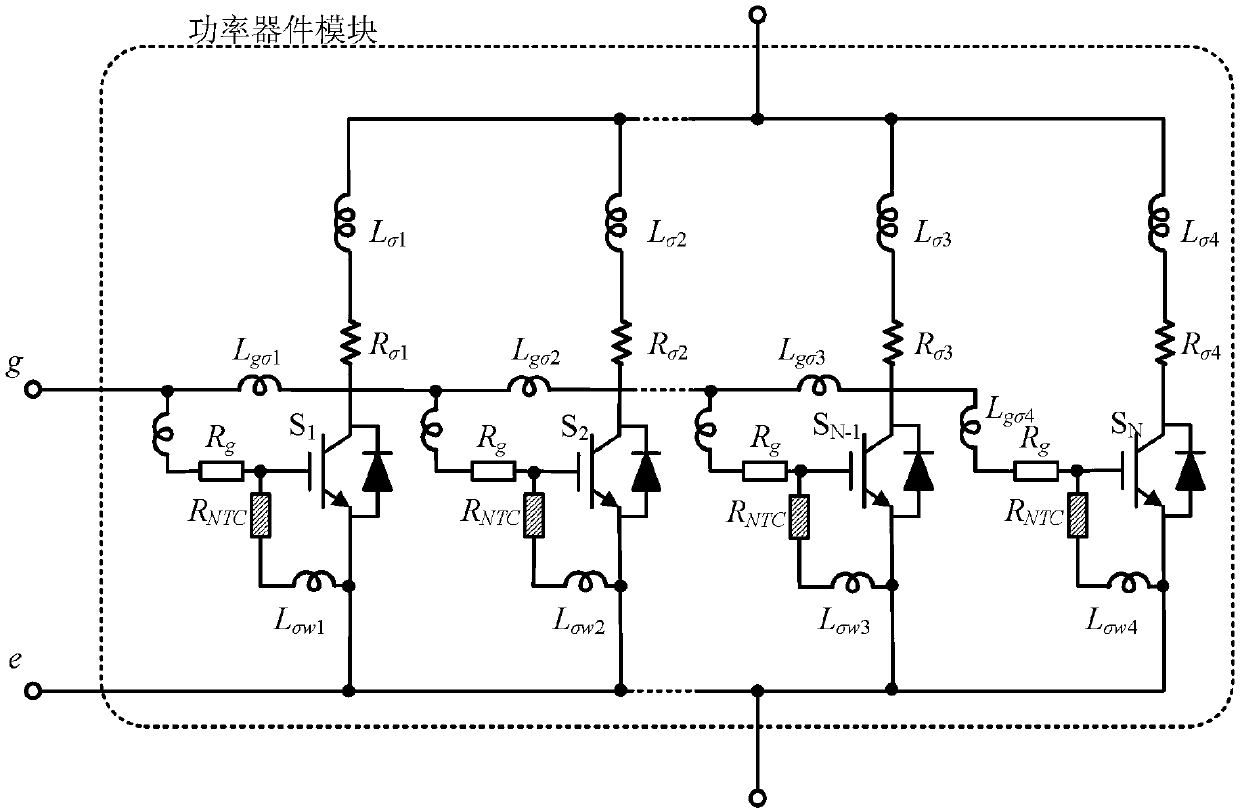

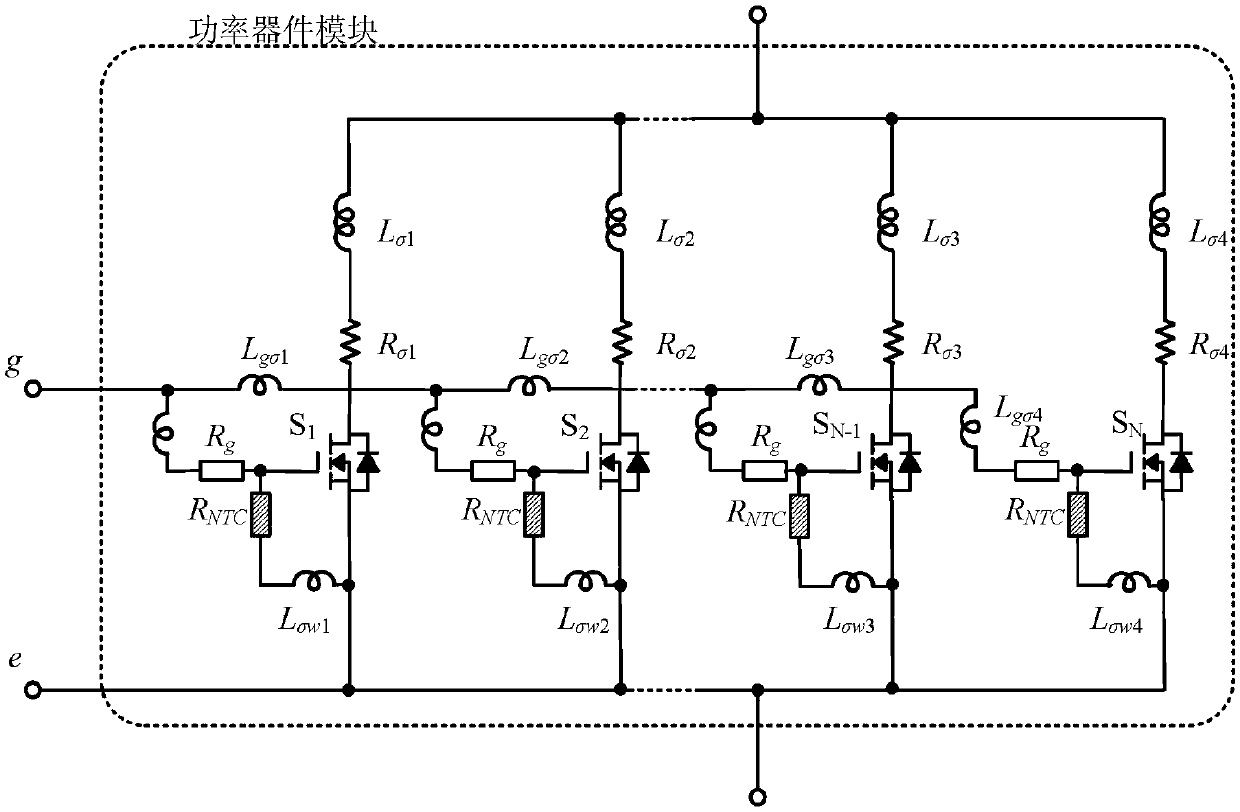

High-power semiconductor module suitable for balancing heat of internal power switch chip in short-circuit condition

ActiveCN108682672AUniform thermal stressSimple structureSolid-state devicesSemiconductor devicesHeat balanceHeat sensitive

The invention discloses a high-power semiconductor module suitable for balancing the heat of an internal power switch chip in a short-circuit condition. The high-power semiconductor module, accordingto a principle that the on-resistance of a power semiconductor device is controlled by gate voltage, adds an autonomous heat balance control circuit to each parallel device or each parallel chip in amodule, detects the temperature of the device by a temperature-sensitive element, and automatically adjusts the voltage applied to the gate of the device according to the parameters of the temperature-sensitive element, wherein the temperature-sensitive element can be a thermistor or voltage-regulator diode with a negative temperature coefficient. In the short-circuit condition, the temperature ofthe parallel chip rises, the thermistor achieves automatic feedback, the voltage applied to the gate of the chip decreases, the on-resistance of the device increases so as to automatically decrease the short-circuit current flowing through the chip. The passive heat balance control circuit of the invention is simple in structure and is easy to be integrated into a device driving board or high-power module, so that the parallel devices are thermally balanced, thereby improving the reliability of the power device.

Owner:ZHEJIANG UNIV

Drying method and coating film drying furnace for coating film formed on PET film surface

InactiveCN103328115AAvoid heating upIncrease temperatureDrying solid materials with heatPretreated surfacesVitrificationOrganic solvent

Owner:NGK INSULATORS LTD

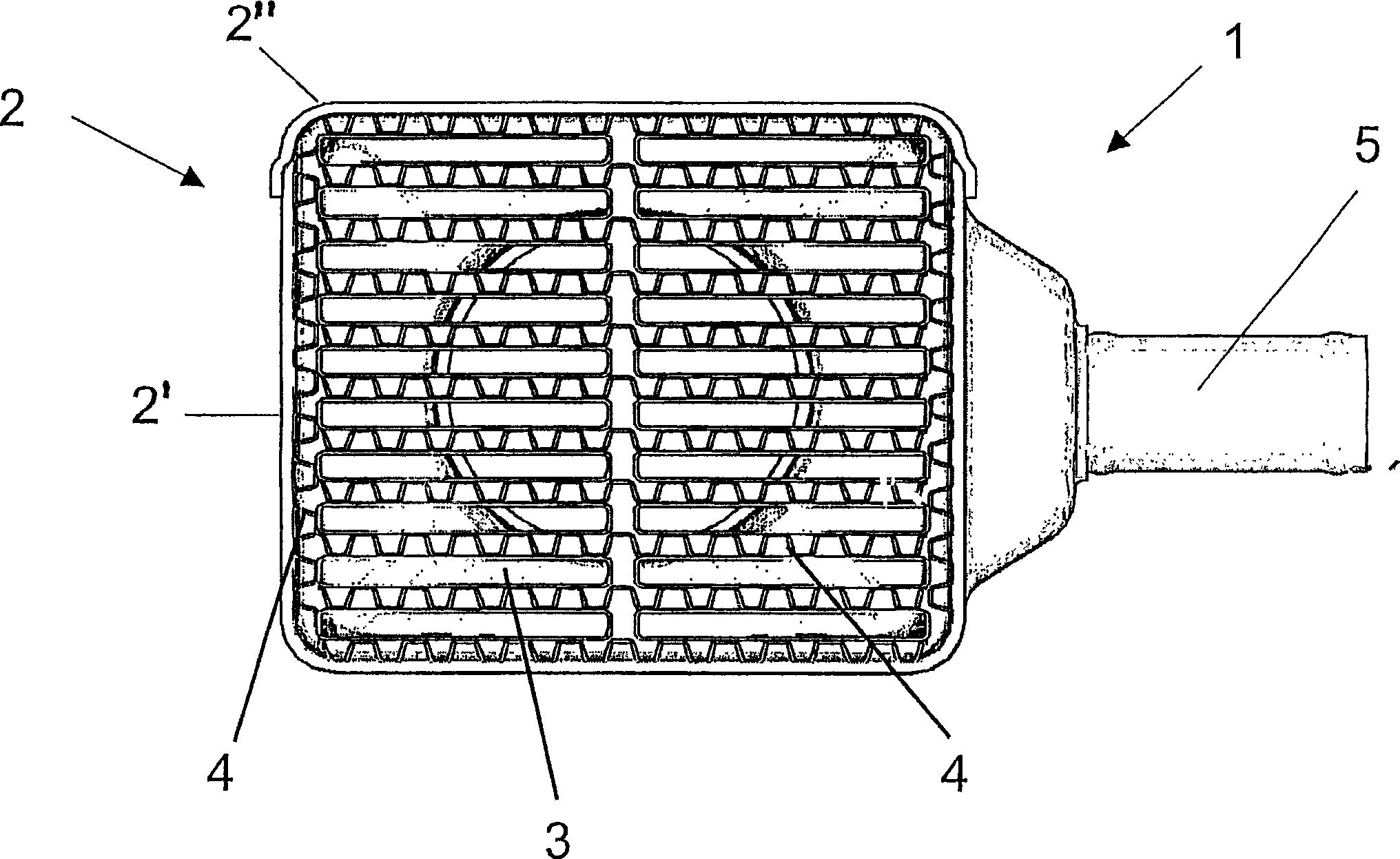

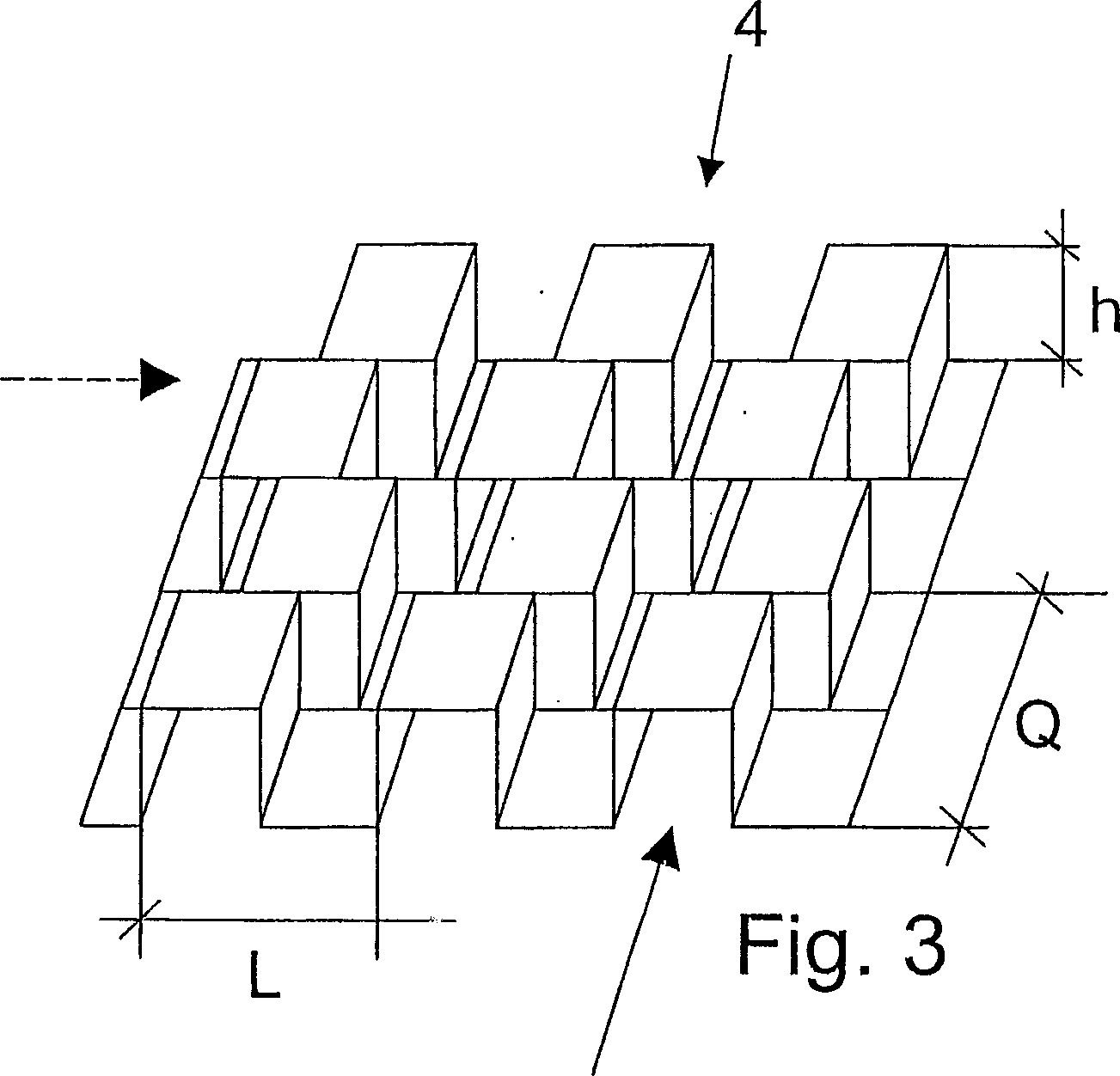

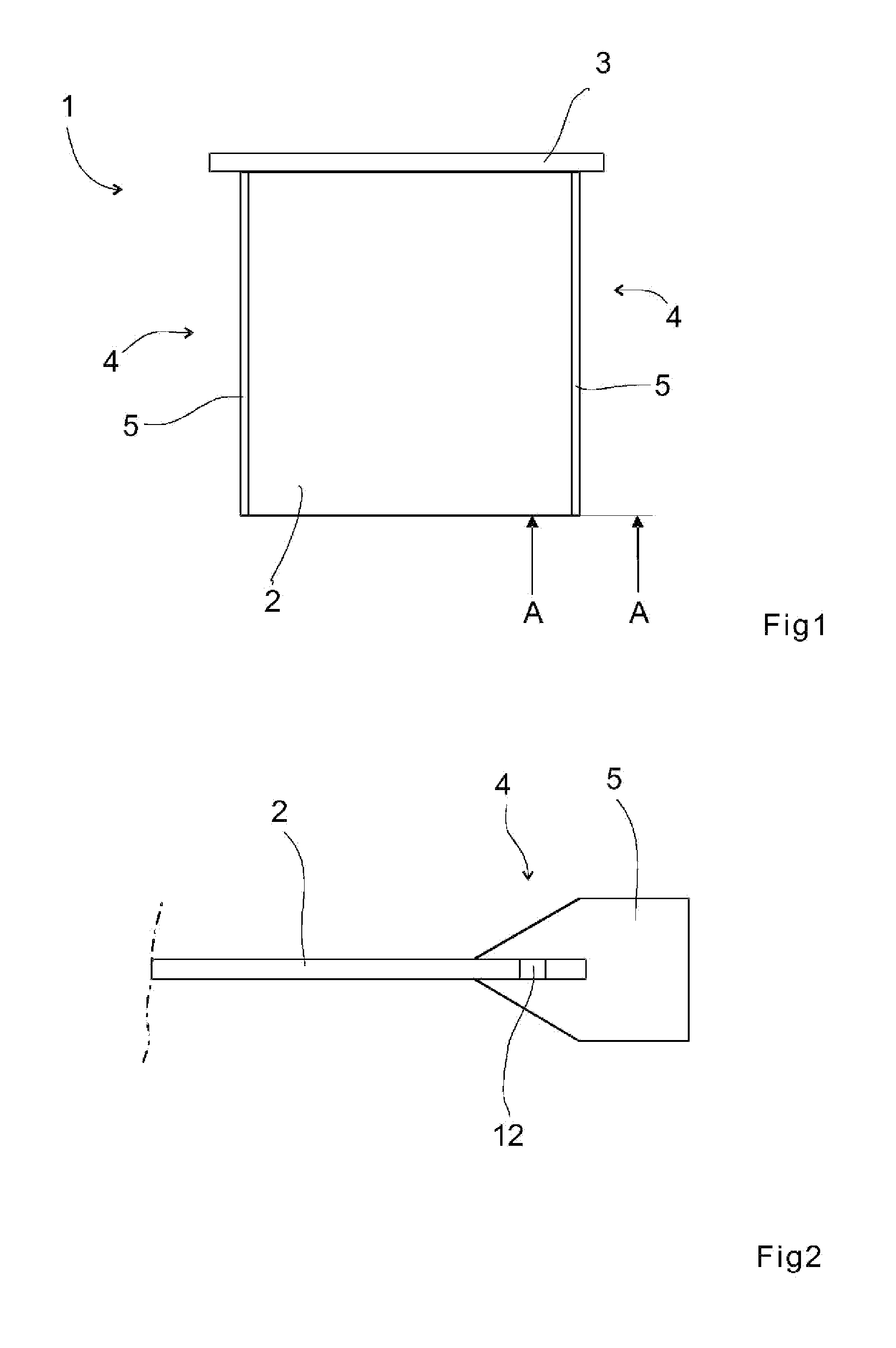

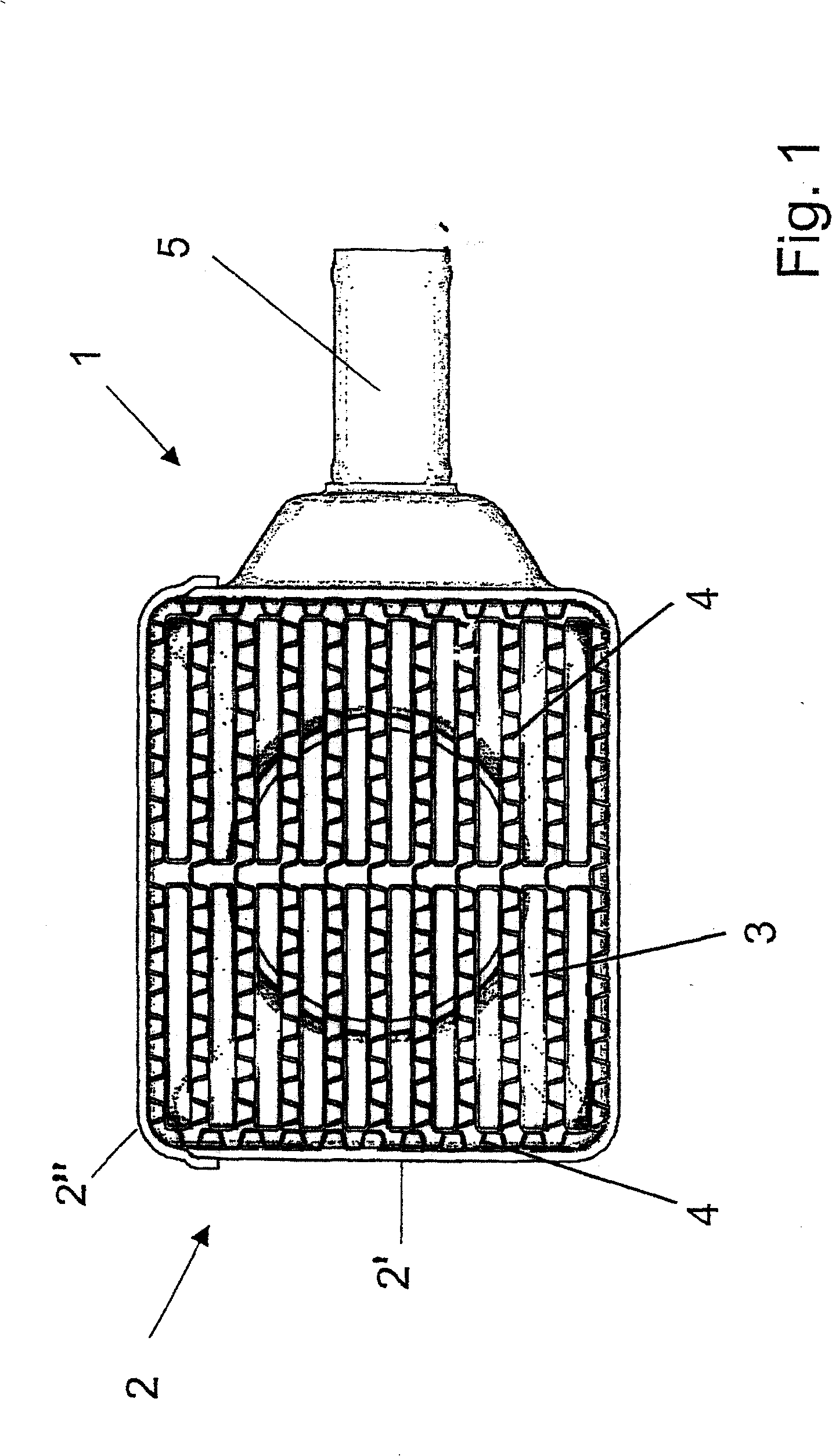

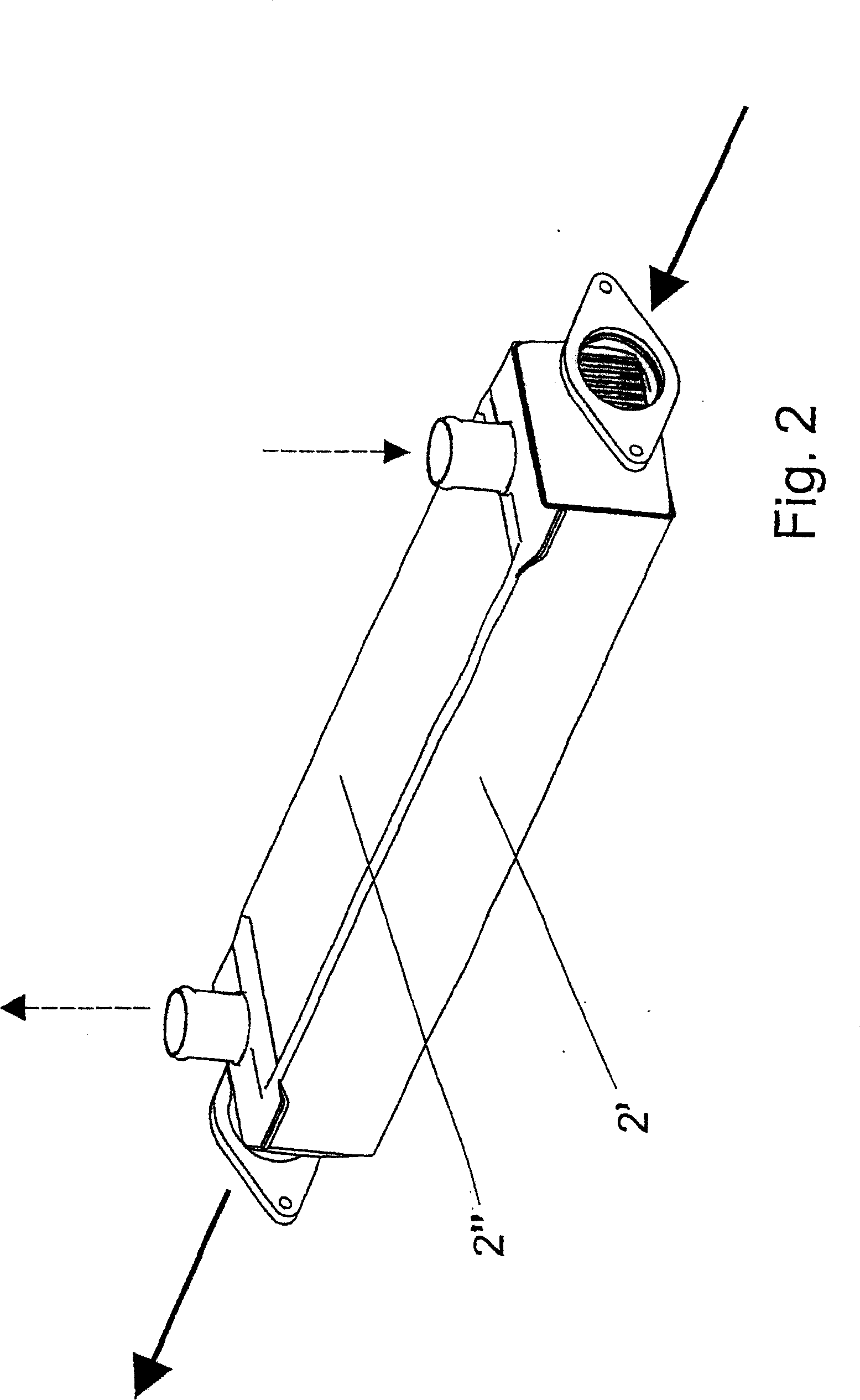

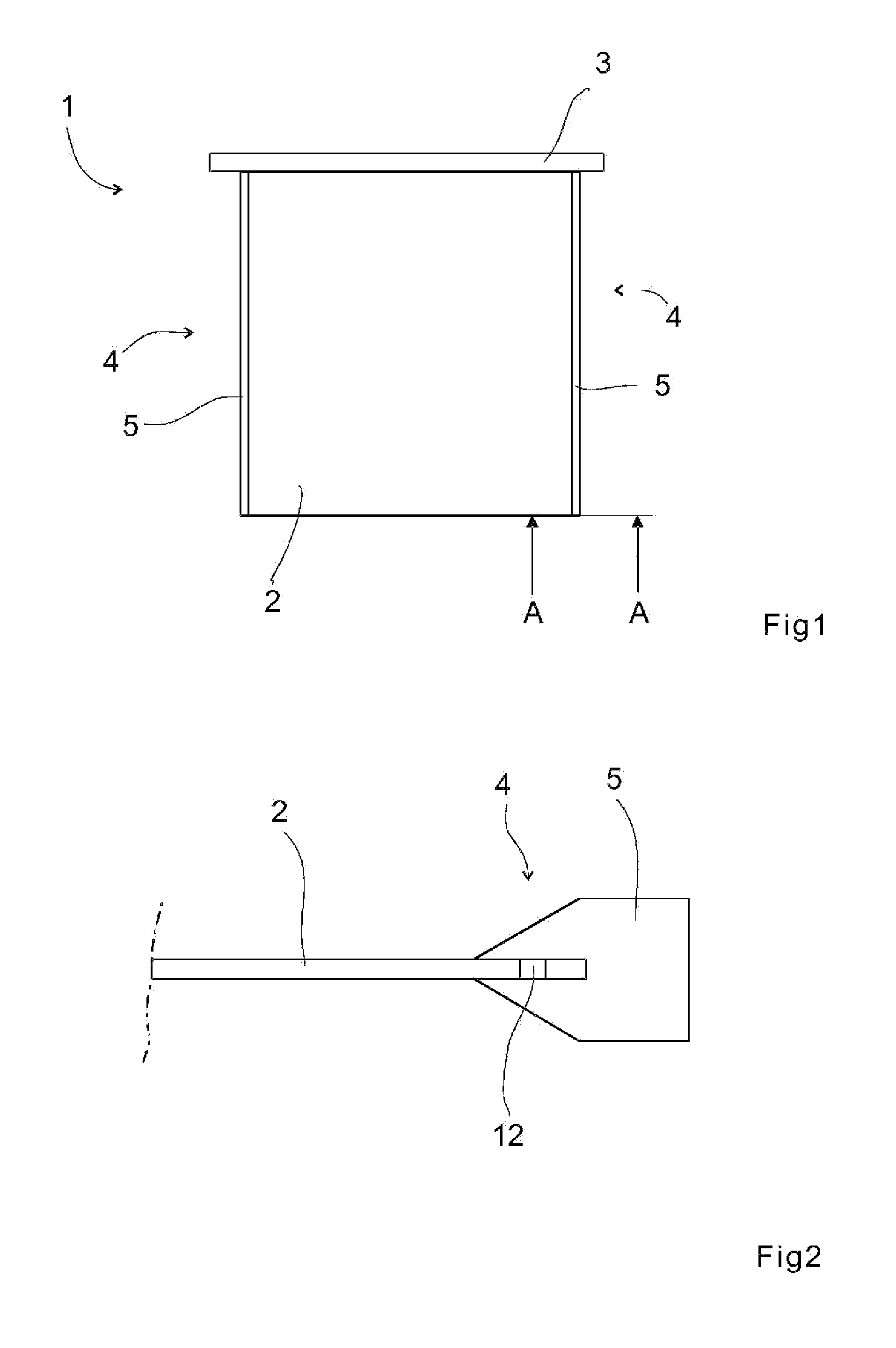

Heat exchanger

ActiveCN1898519APrevent sagSpeed up heat transferRecuperative heat exchangersHeat exhanger finsEngineeringHeat exchanger

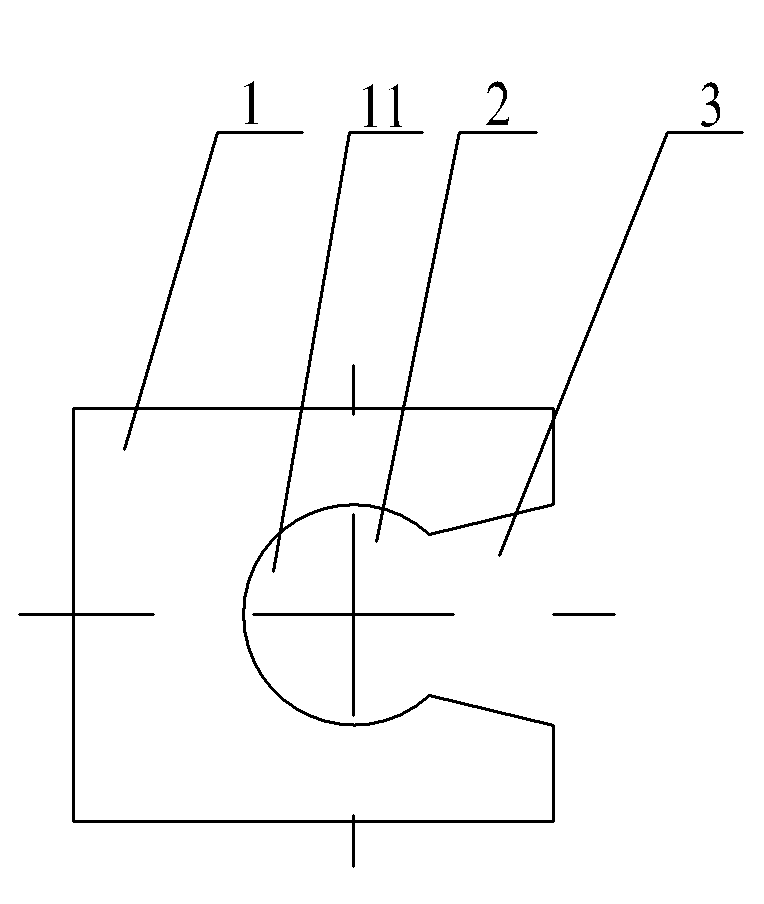

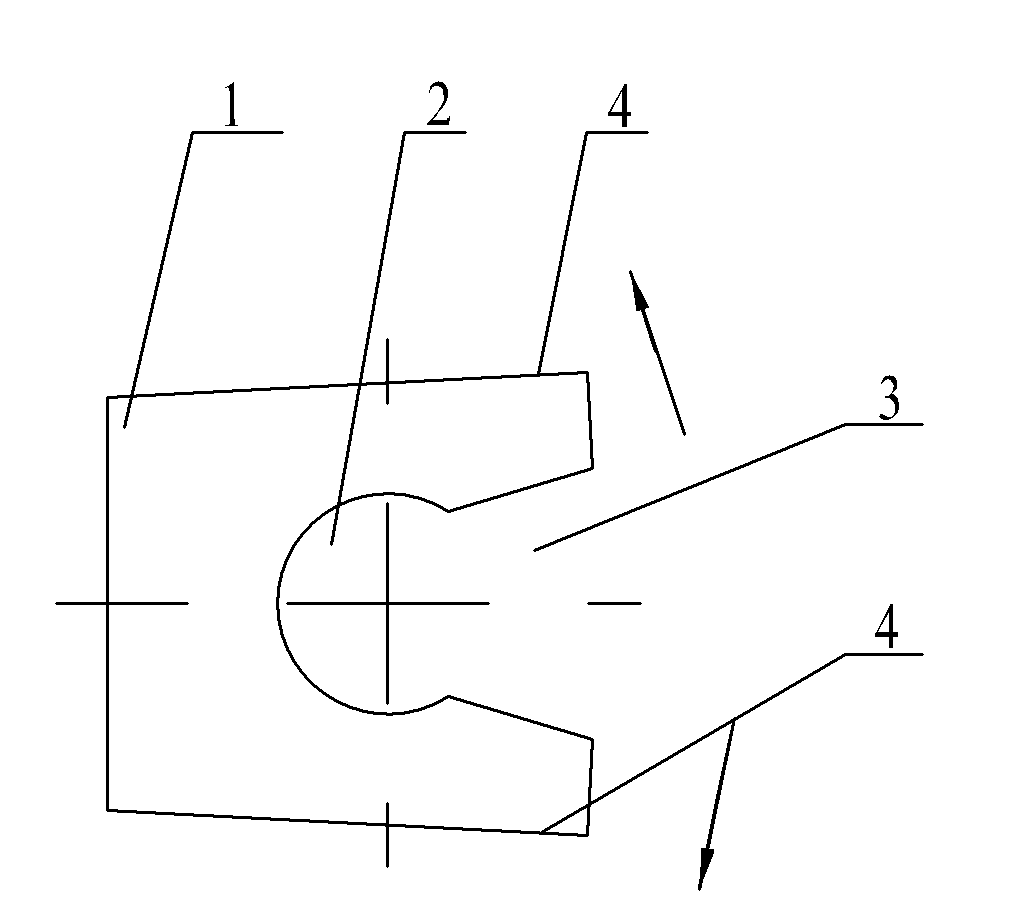

The invention relates to a heat exchanger (1), especially for motor vehicles, comprising a housing (2) and at least one pipe (3) disposed inside said housing (2). The heat exchanger is characterized in that structures (4) are provided in the area between the pipes (3) and the housing (2) and / or between the pipes (3).

Owner:BEHR GMBH & CO KG

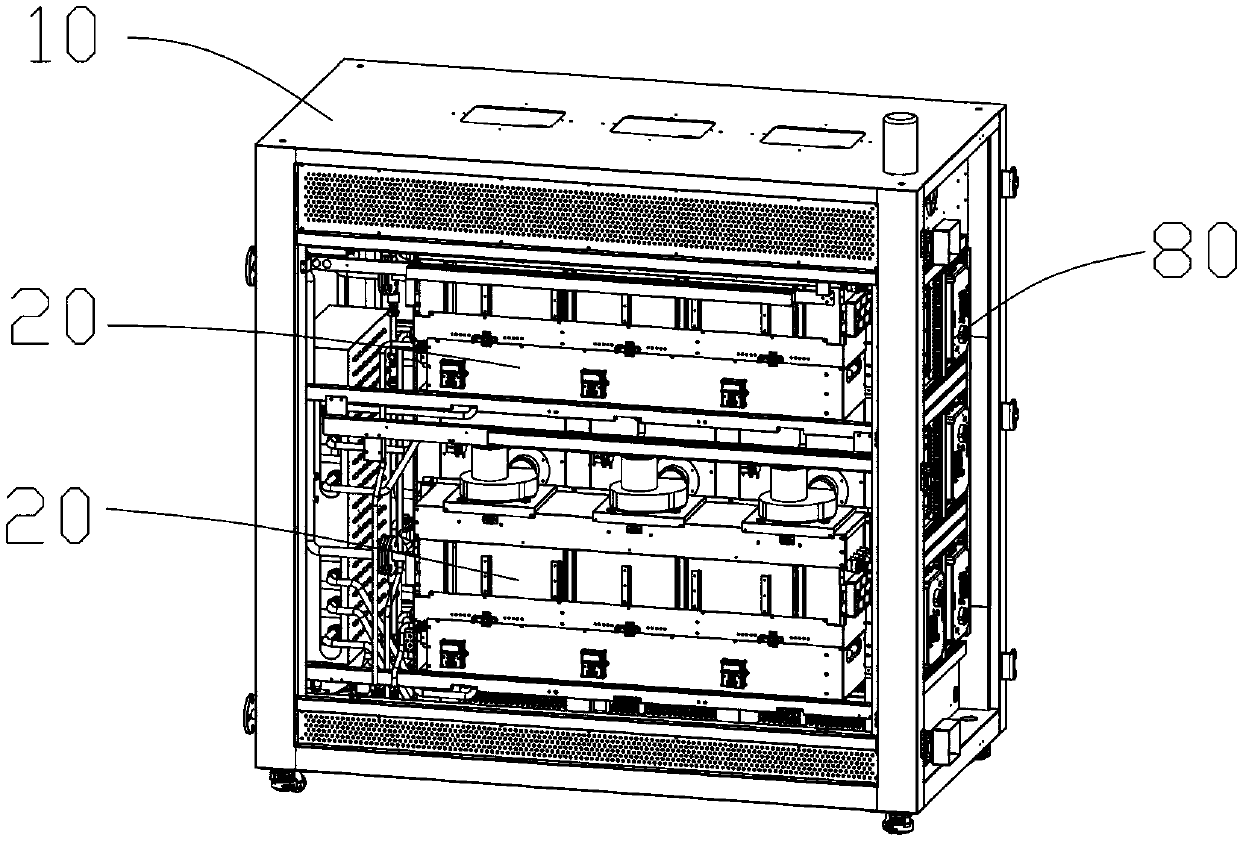

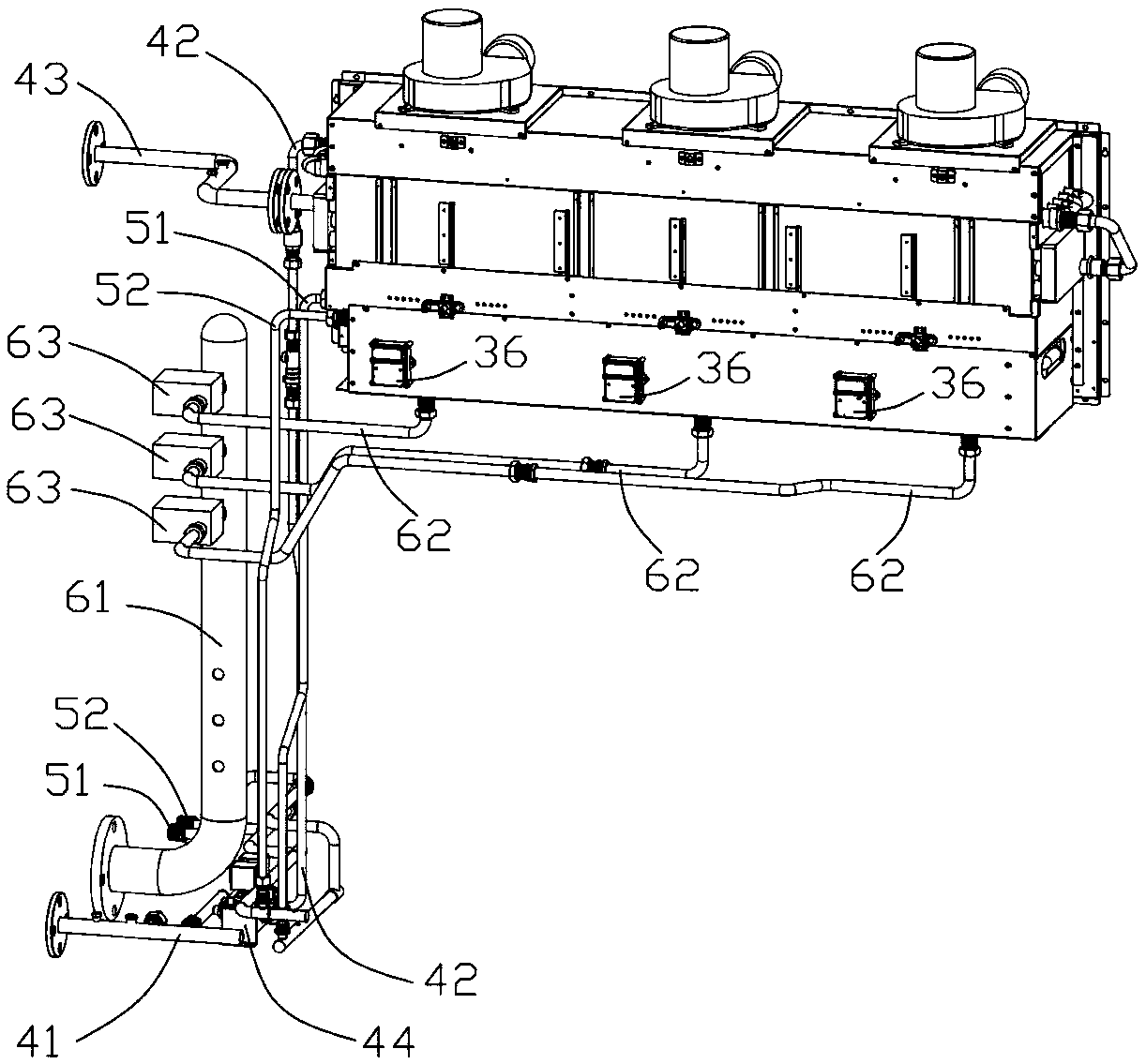

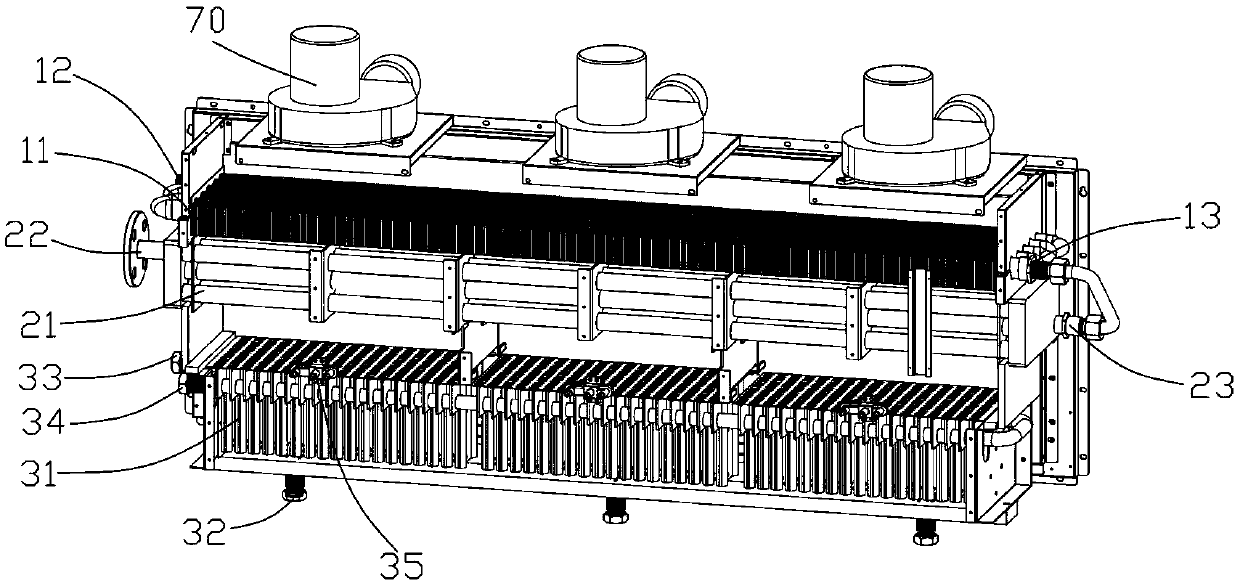

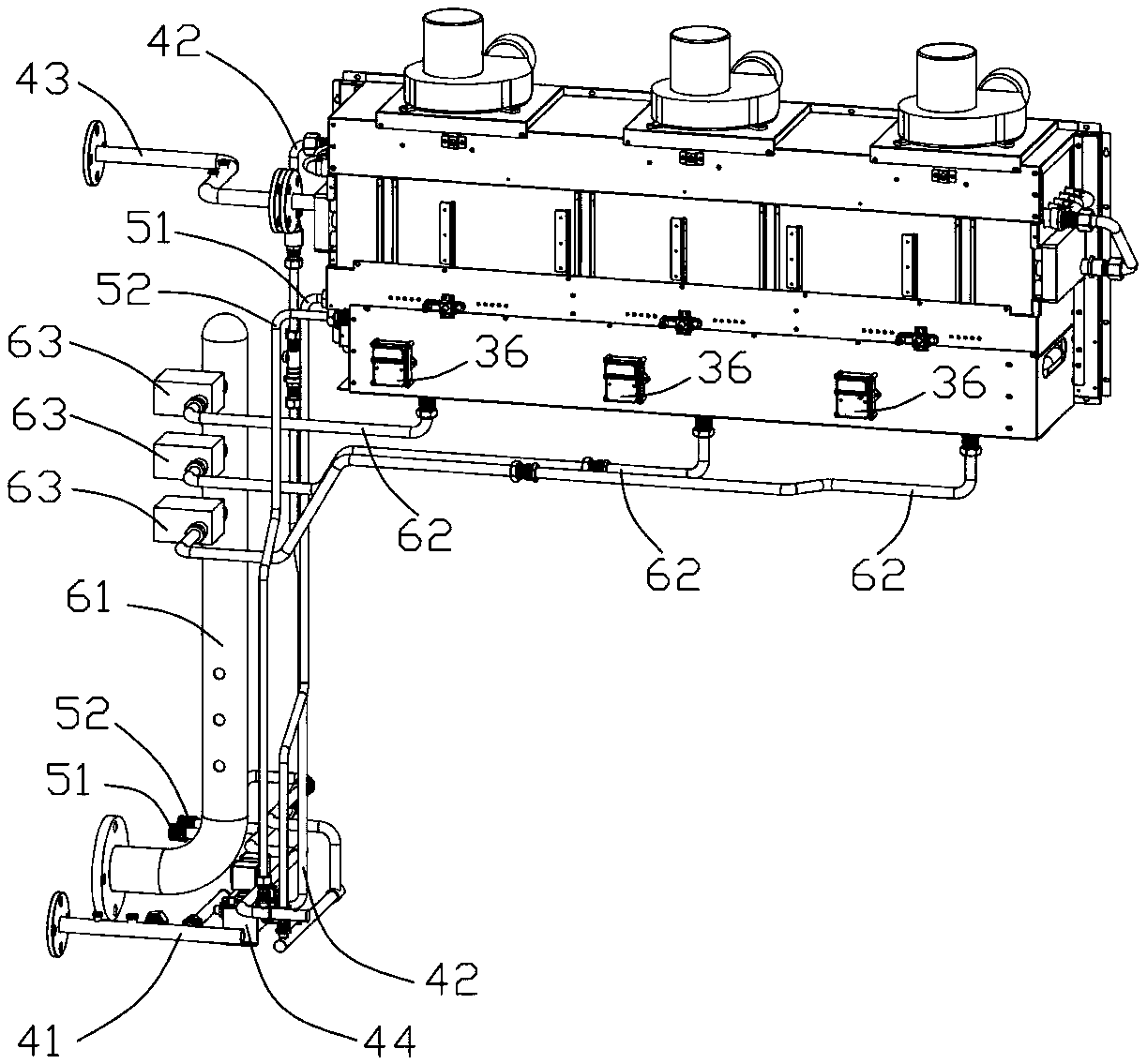

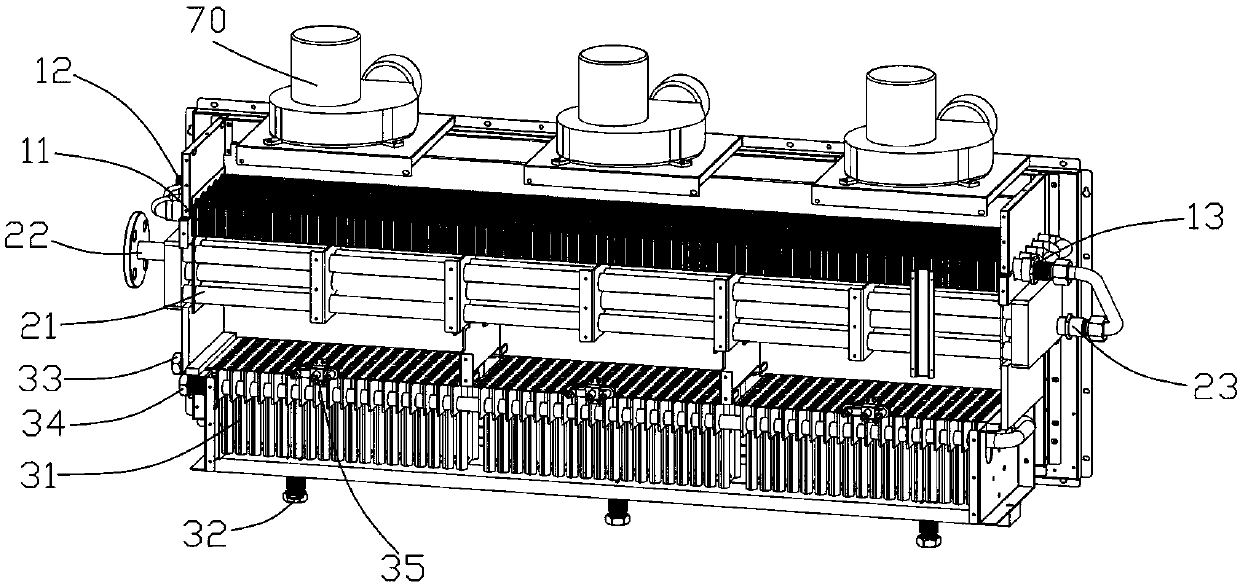

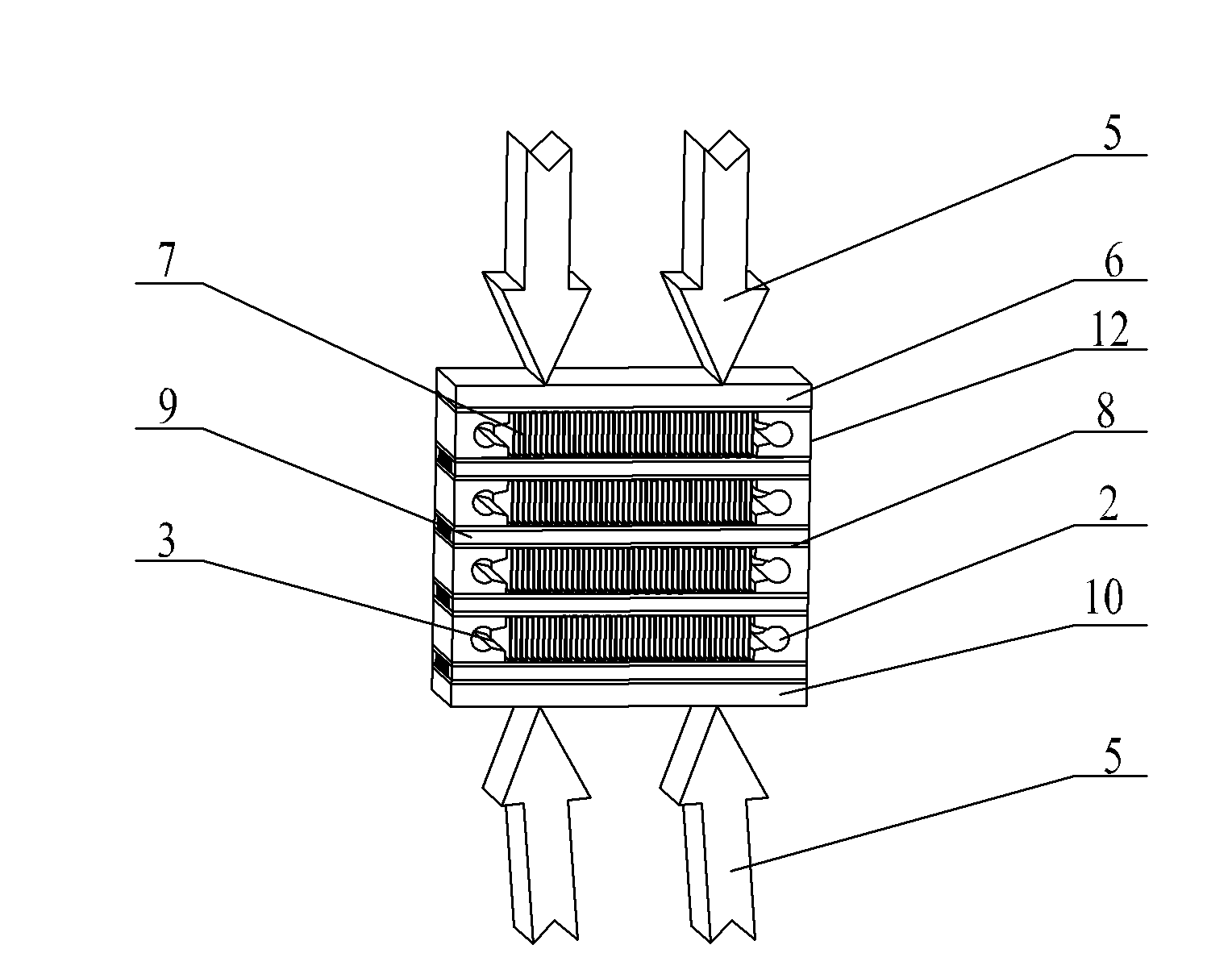

Gas steam generating equipment

PendingCN109654467AImprove qualityExtended pathStationary tubular conduit assembliesSteam boilersCombustion chamberCombustor

The invention discloses gas steam generating equipment. The gas steam generating equipment comprises a machine frame and more than one set of steam generating modules arranged in the machine frame, and each steam generating module comprises a combustion chamber, a finned heat exchanger, a tube type light tube heat exchanger and a low-nitrogen fire grate burner which are sequentially arranged in the combustion chamber from top to bottom; a cold water inlet and a hot water outlet are formed in each finned heat exchanger; each tube type light tube heat exchanger is provided with a hot water inletand a steam outlet; and the hot water outlets communicate with the hot water inlets. According to the steam generating equipment, the tube type light tube heat exchanges are adopted to be arranged inthe middle layers of the combustion chambers and serve as vaporization layers, so that heat absorbed by cold water is more sufficient, and higher-quality steam can be produced. The bottom layers of the combustion chambers adopt the brand-new low-nitrogen fire grate combustors, so that the heat exchange amount is improved, and meanwhile, the generation of nitrogen oxide is reduced, and the gas steam generating equipment is energy-saving and environment-friendly.

Owner:广东念智节能科技有限公司

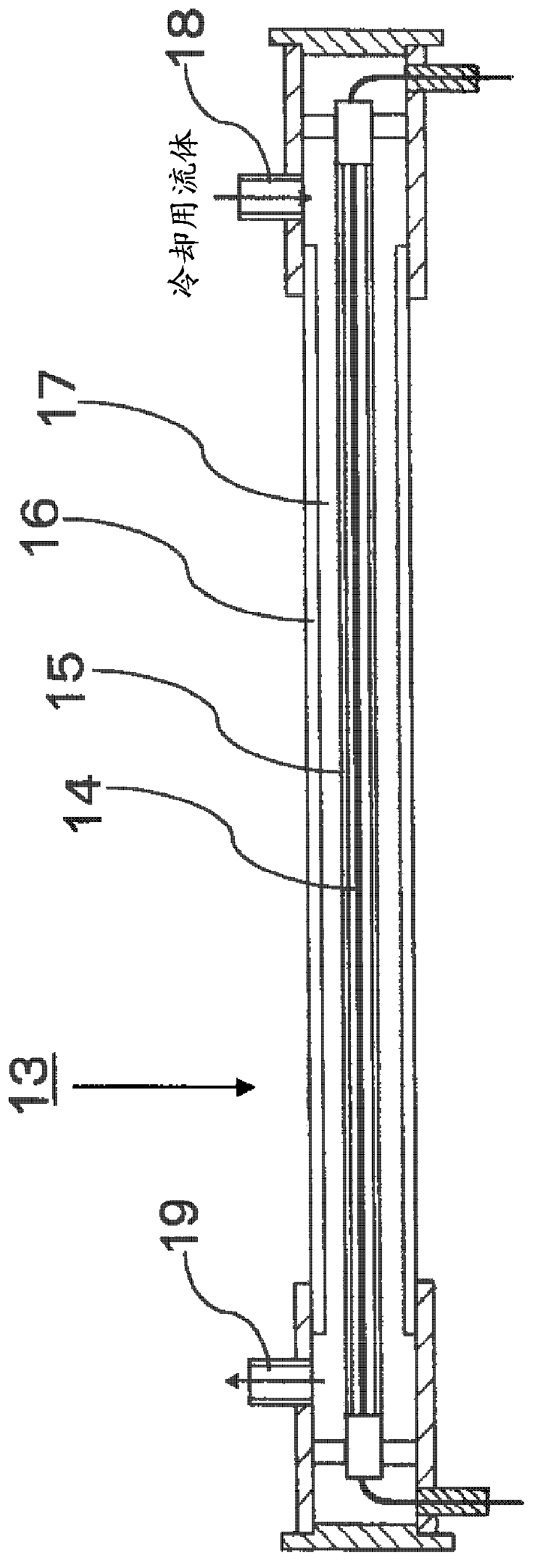

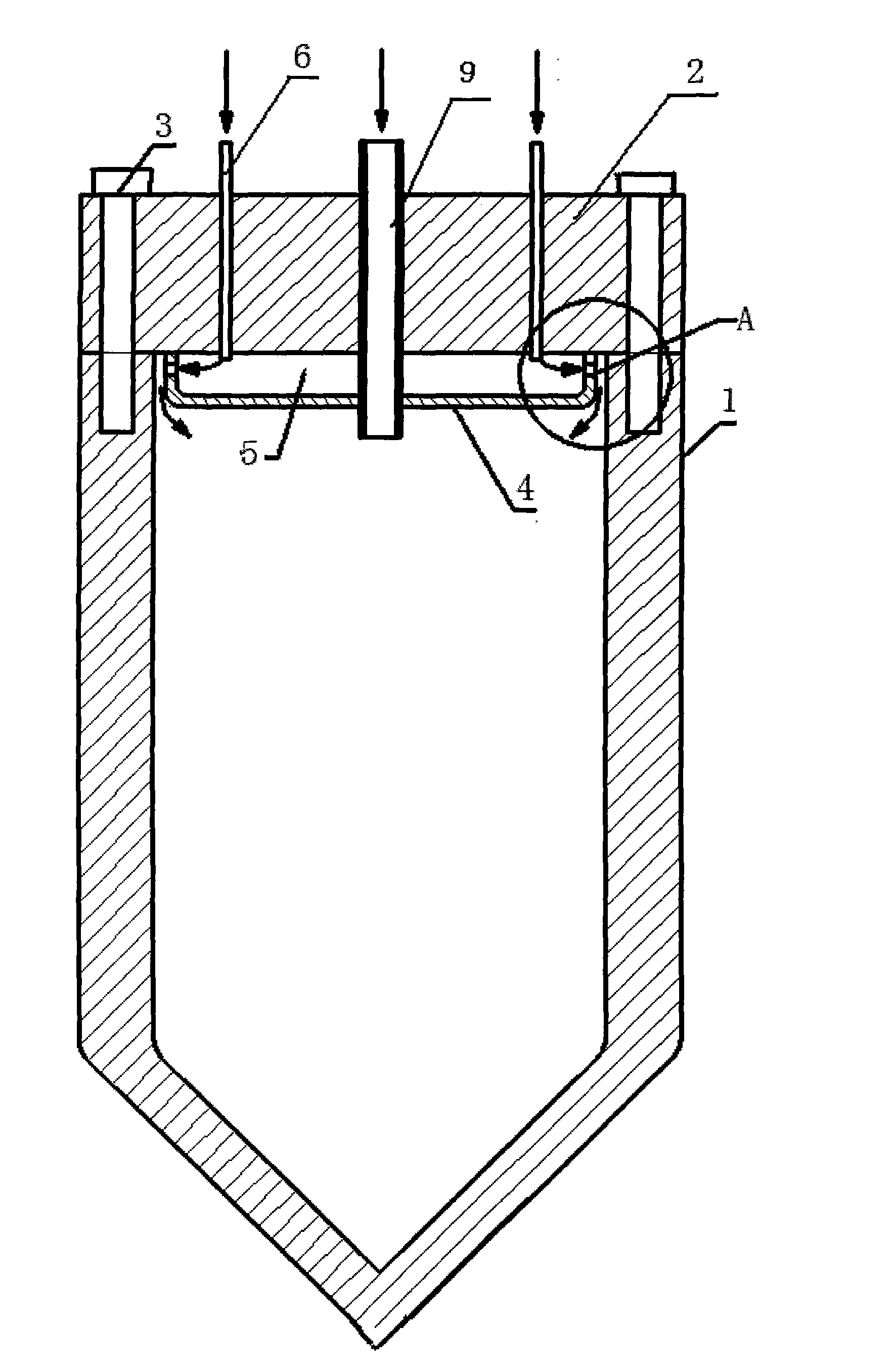

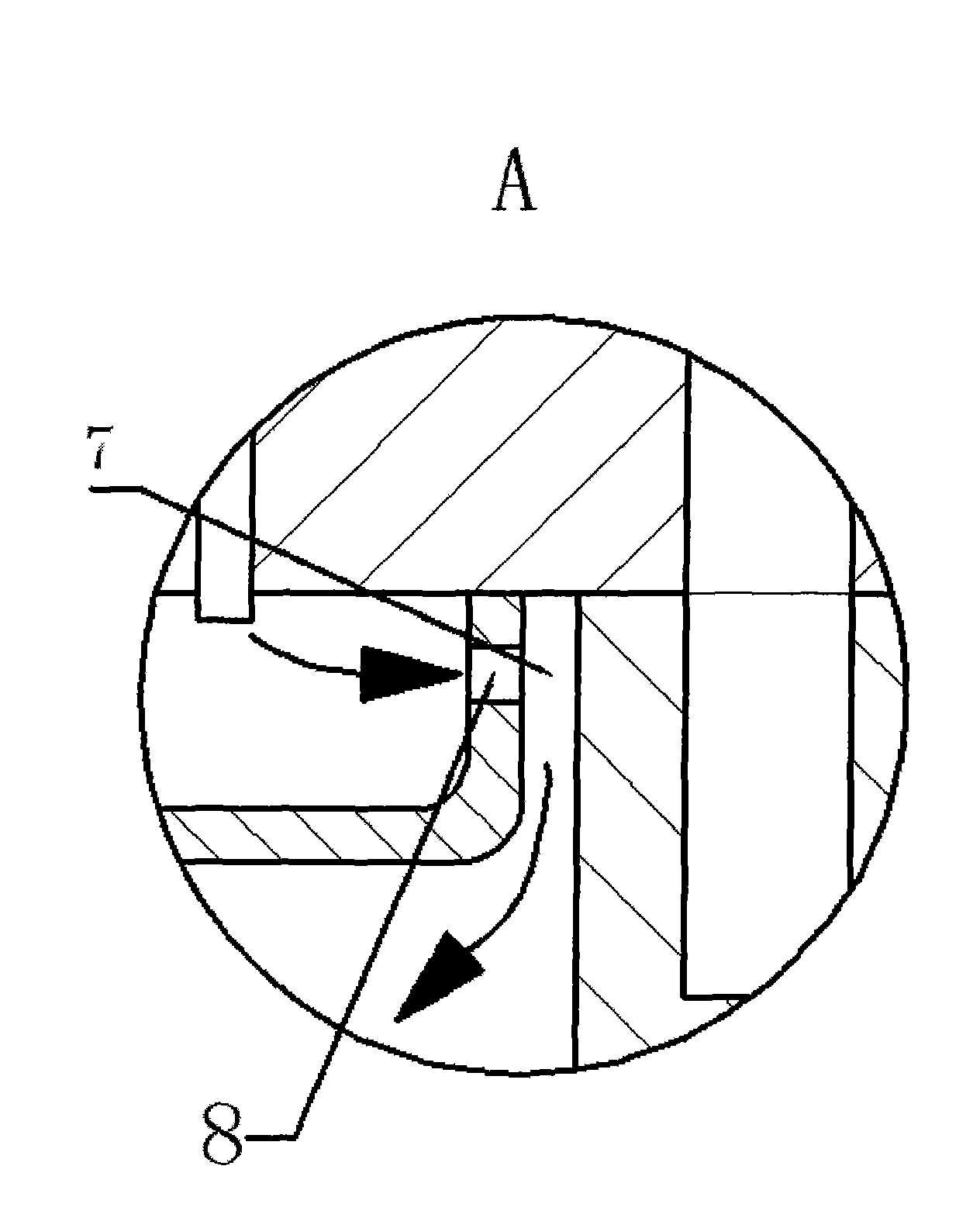

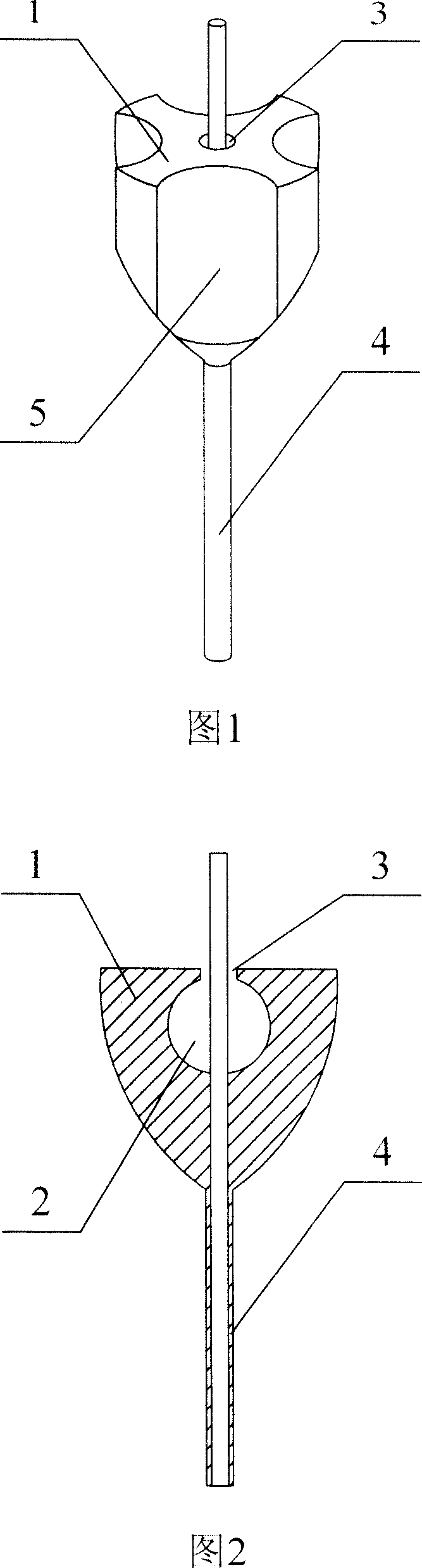

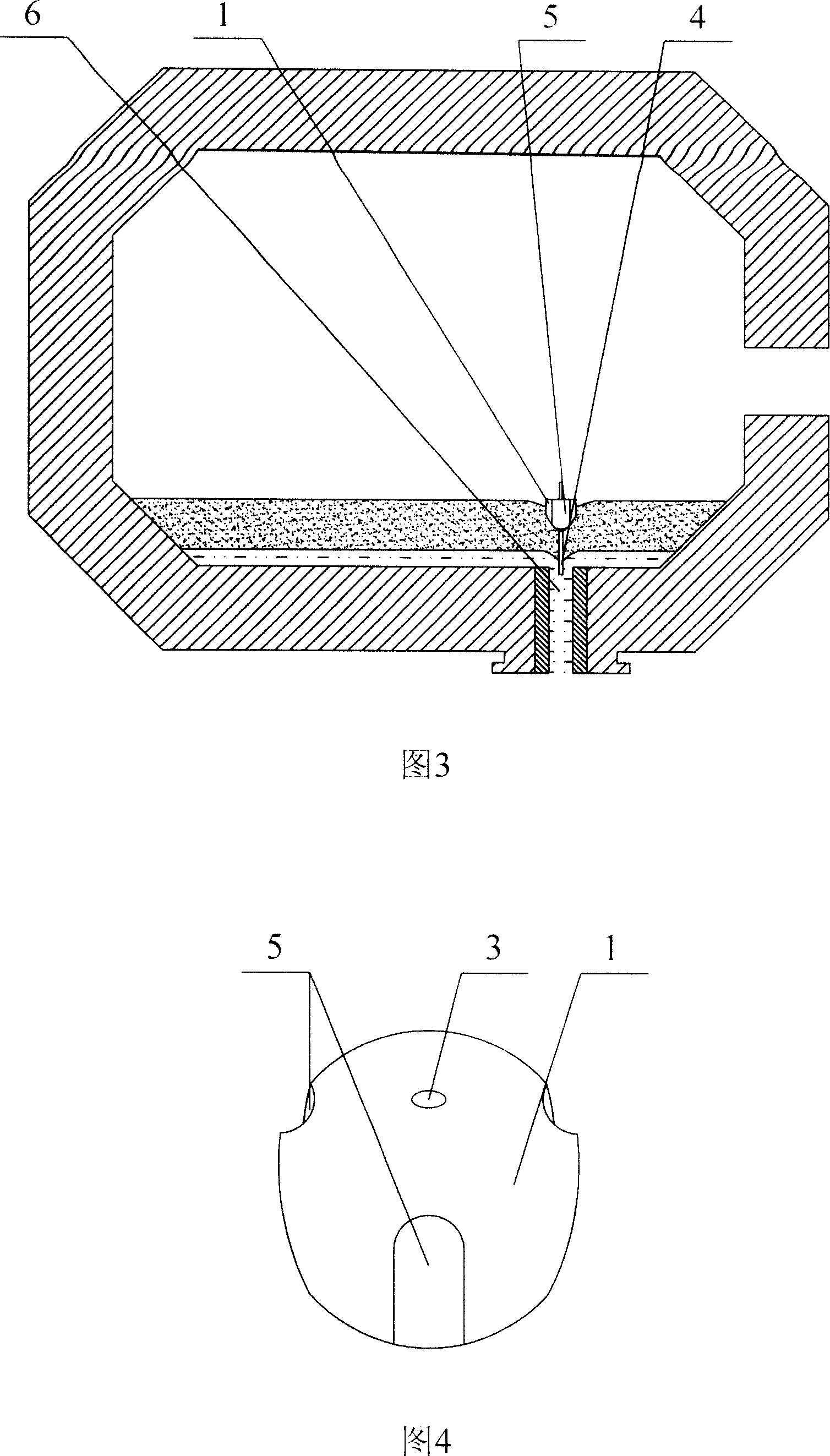

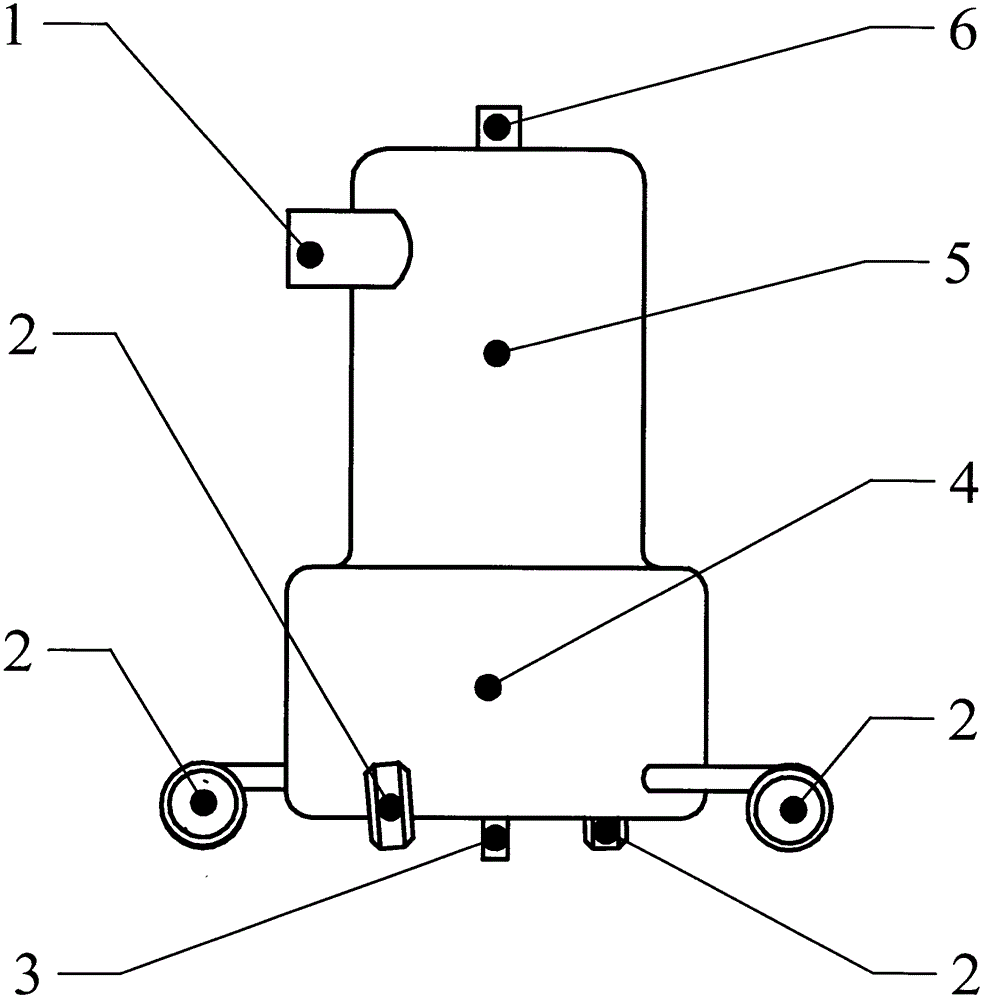

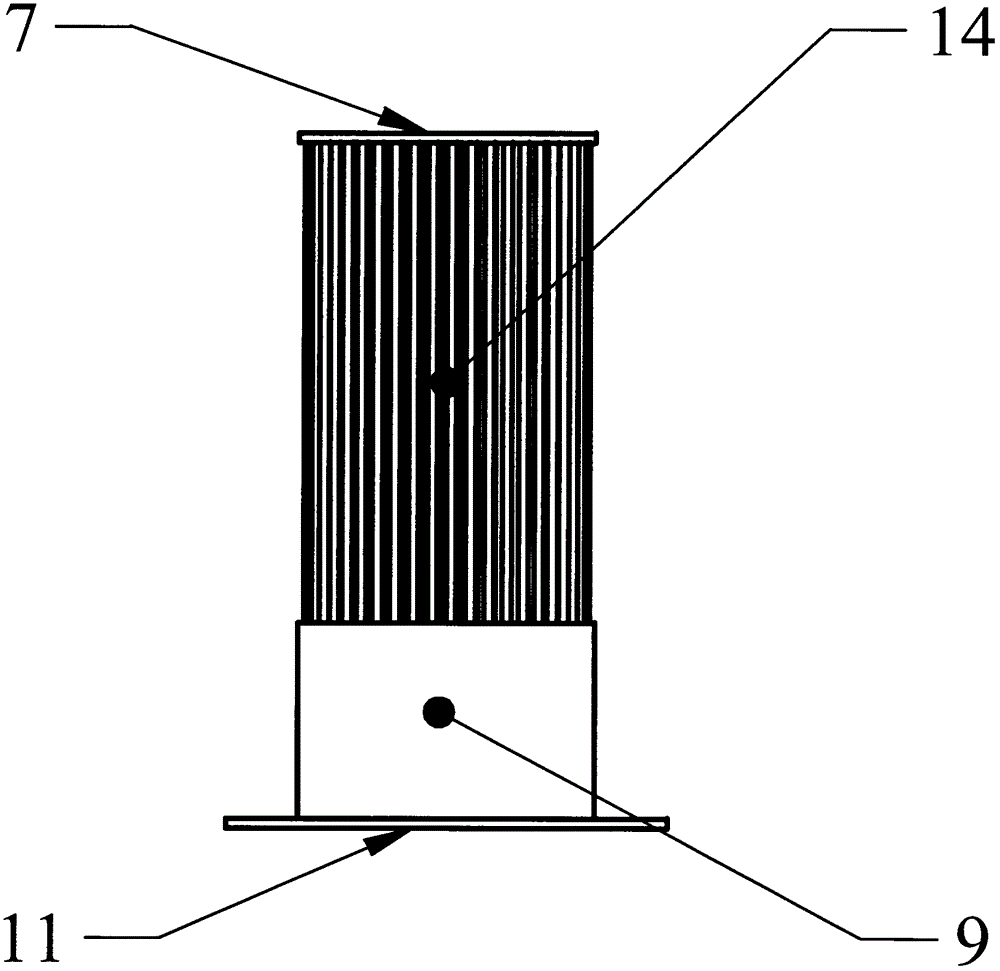

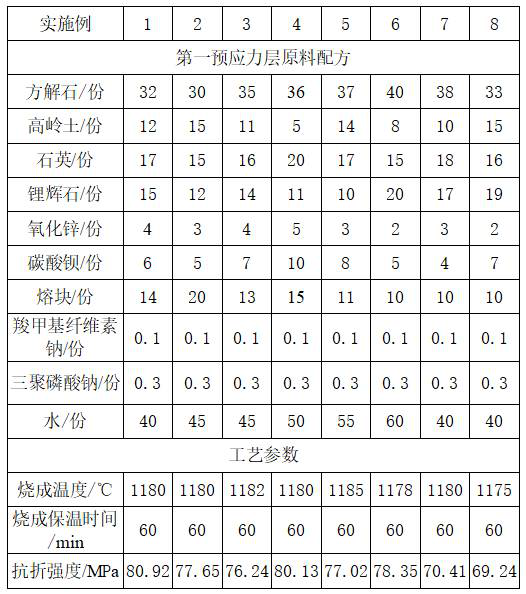

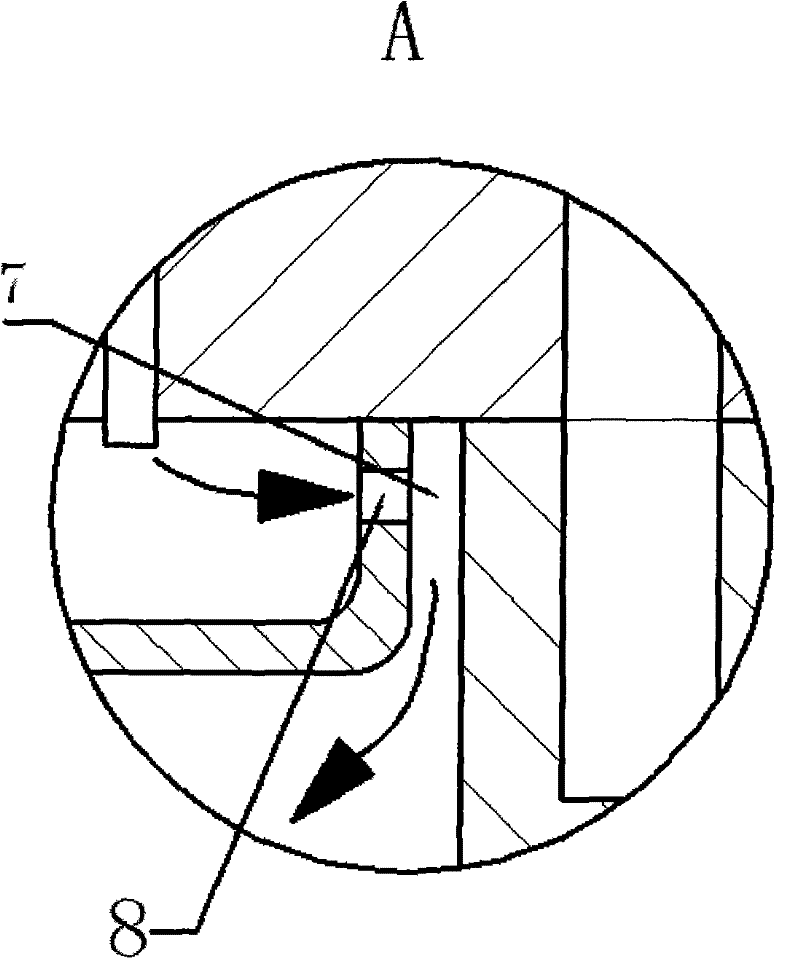

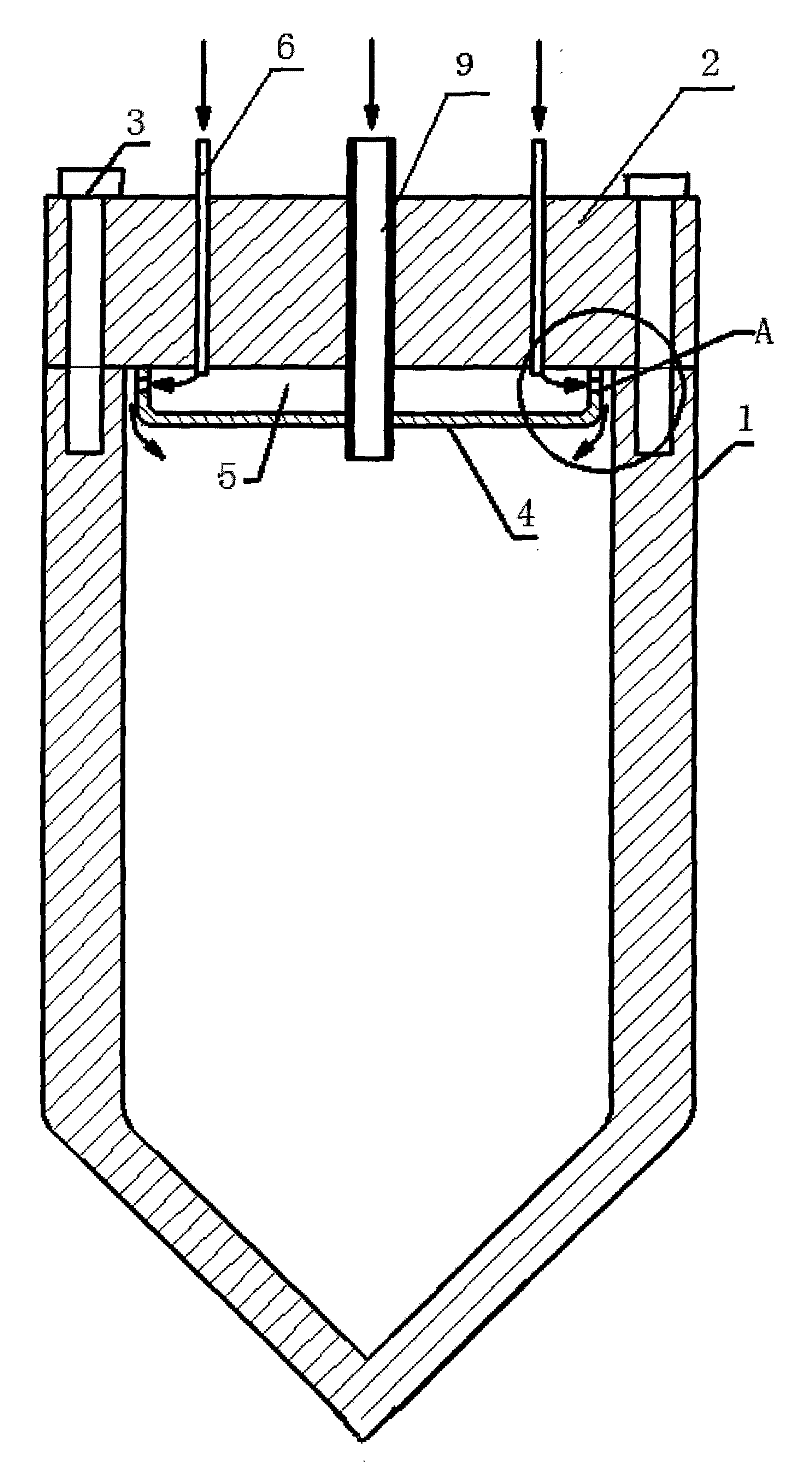

Pressure-bearing device with cooling function for supercritical water treatment

InactiveCN101570359AUniform thermal stressExtended service lifeWater/sewage treatment by oxidationEngineeringWater treatment

The invention belongs to the field of supercritical water treatment of waste organic substances, and discloses a pressure-bearing device with cooling function for the supercritical water treatment. The device comprises a barrel body (1) and an end cover (2), and is characterized in that the lower surface of the end cover (2) is provided with a cooling cavity (5), the outer wall of the cooling cavity (5) and the inner wall of the barrel body (1) form an annular narrow slit (7), the lateral wall of the cooling cavity (5) is provided with a jet hole (8), and a water inlet (6) of the cooling cavity is arranged on the upper surface of the end cover (2).

Owner:XI AN JIAOTONG UNIV +1

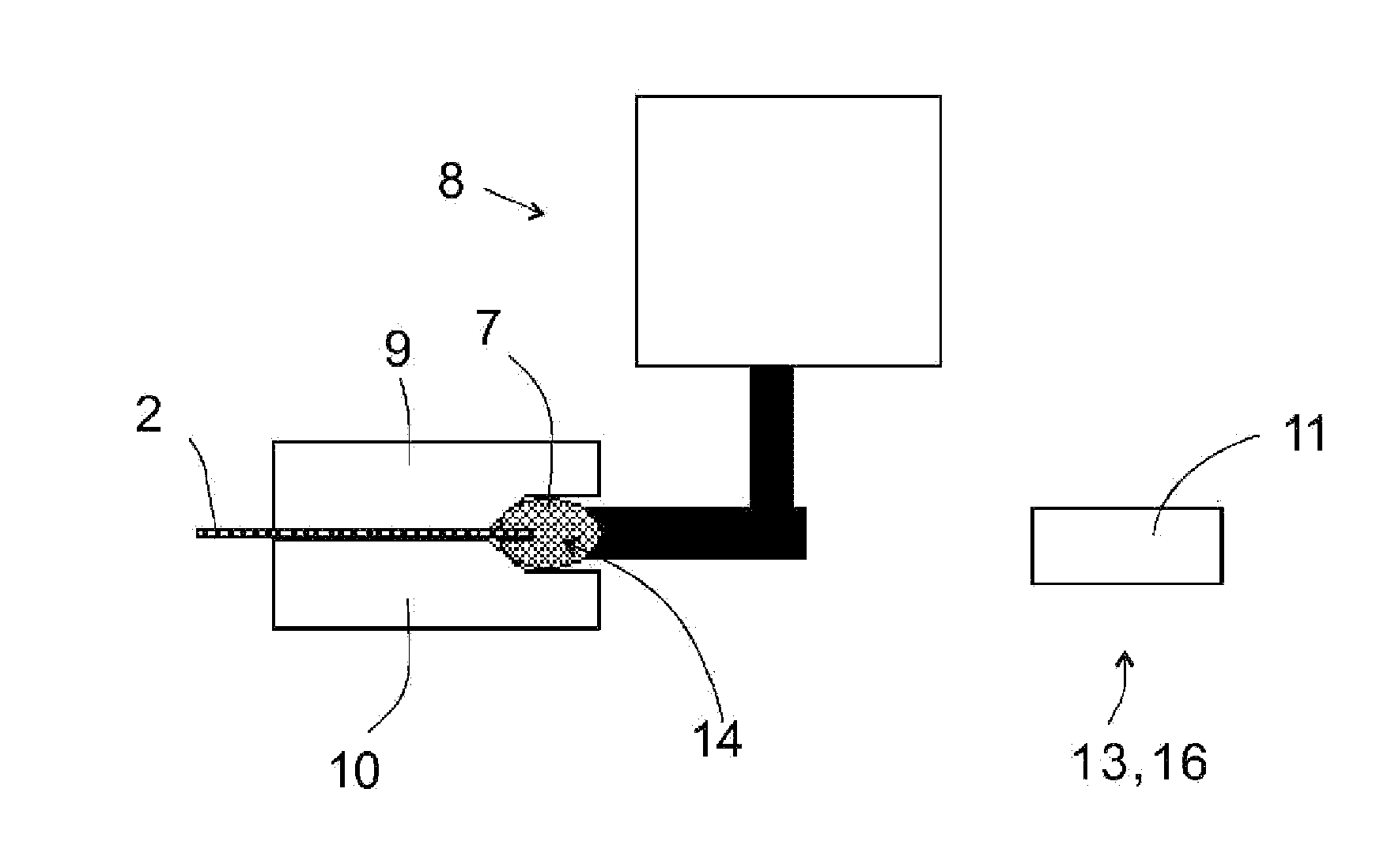

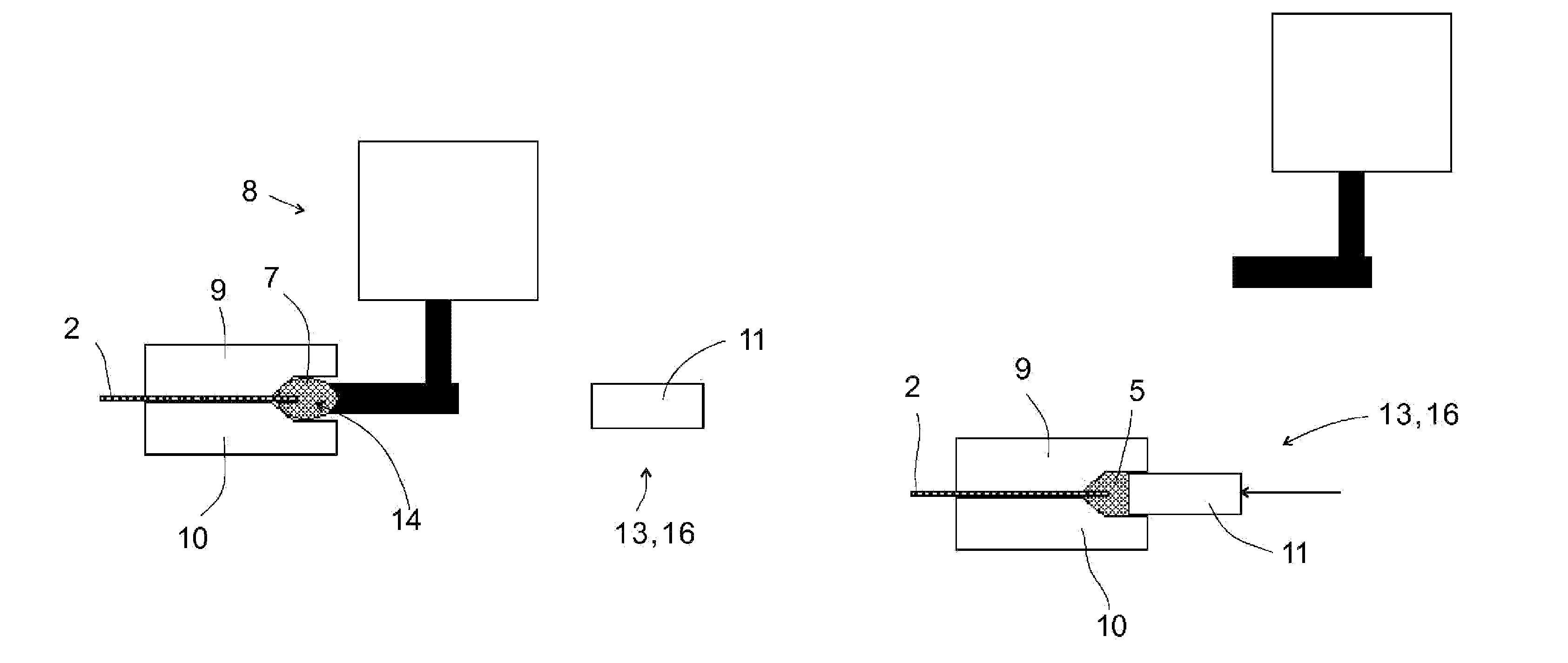

Method and equipment for providing the edge of a starting sheet with a dielectric strip

ActiveUS20110210478A1Improve permeabilityUniform qualityConfectionerySemiconductor/solid-state device manufacturingMetalMaterials science

A device for providing the edge of a starting sheet of an electrode used in the electrolytic refining or recovery of metals with a dielectric part comprises a die space, in which the edge of the starting sheet of the electrode can at least partly be fitted, and a feeding device of the dielectric material for feeding the dielectric material into the die space. The device comprises changing members of the volume of the die space for pressing the dielectric material in the die space to that edge of the starting sheet of the electrode, which is at least partly fitted in the die space.

Owner:METSO OUTOTEC (FINLAND) OY

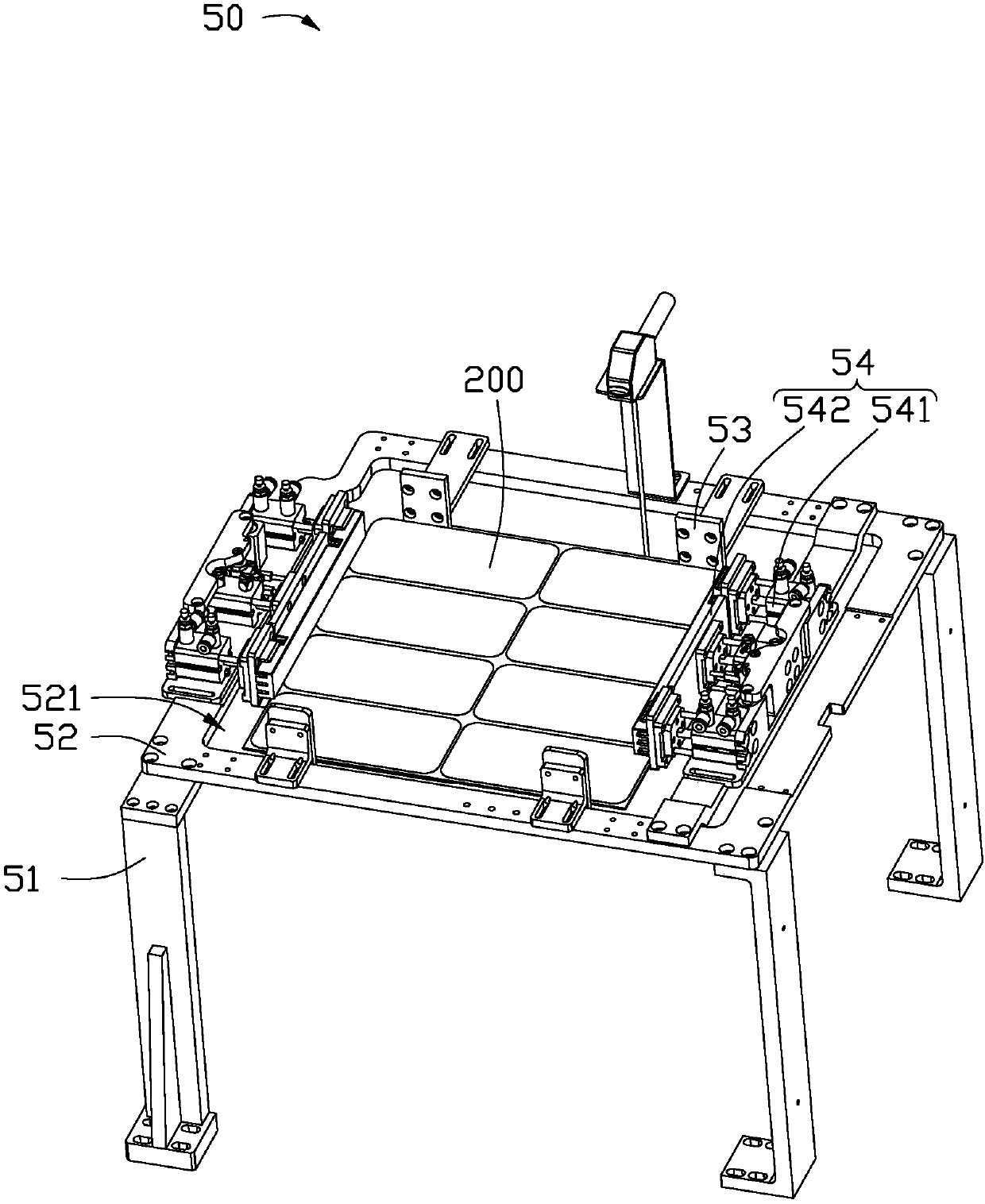

Laser cutting method

ActiveCN110202271AUniform thermal stressAvoid chippingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention provides a laser cutting method which comprises the following steps of providing a laser cutting device. The laser cutting device comprises a machine table, a conveying mechanism, a cutting mechanism, a standing mechanism and a splitting mechanism, wherein the cutting mechanism comprises a moving platform and a laser cutter; the splitting mechanism comprises a fixed jig and at leastone heating laser; the conveying mechanism takes and places a workpiece onto the moving platform; the laser cutter emits a laser beam to precut the workpiece located on the moving platform and forms aprecutting line; the conveying mechanism takes and places the precut workpiece onto the standing mechanism from the moving platform, and the precut workpiece is stood for a preset time; the conveyingmechanism takes and places the stood workpiece onto the fixed jig from the standing mechanism; and each heating laser is used for emitting a laser beam to heat the workpiece located on the fixed jigalong the precutting line, so that the workpiece is split under the impact of a heat stress along the precutting line so as to be cut. The laser cutting method has high cutting yield.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

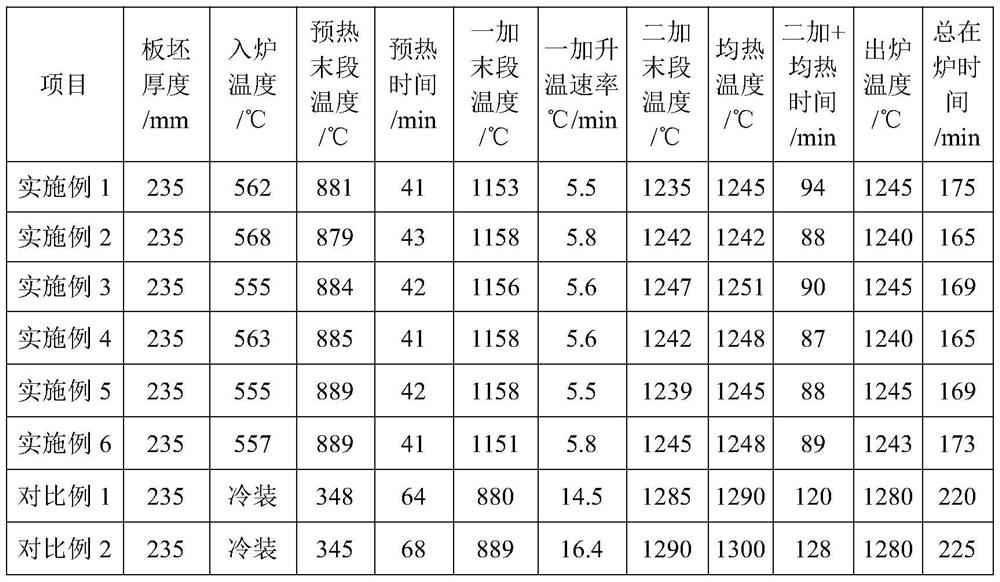

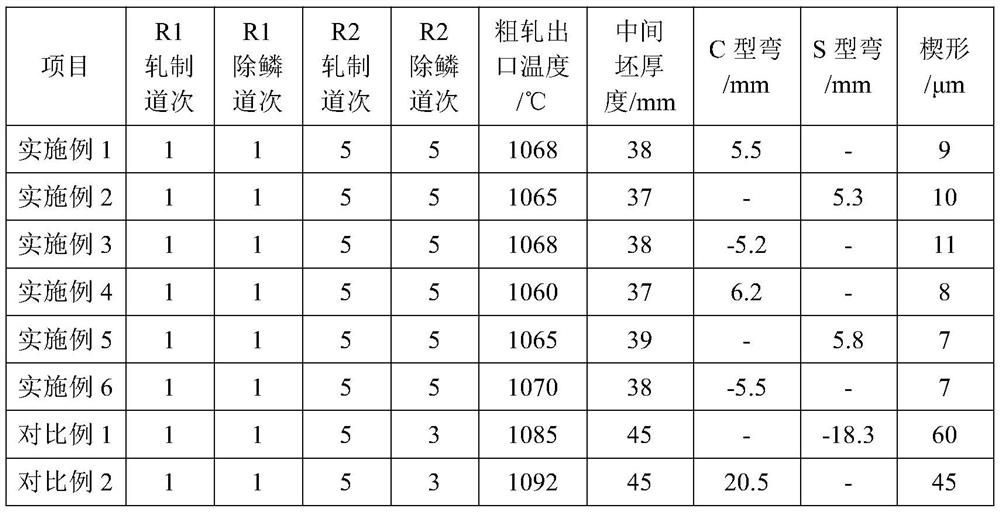

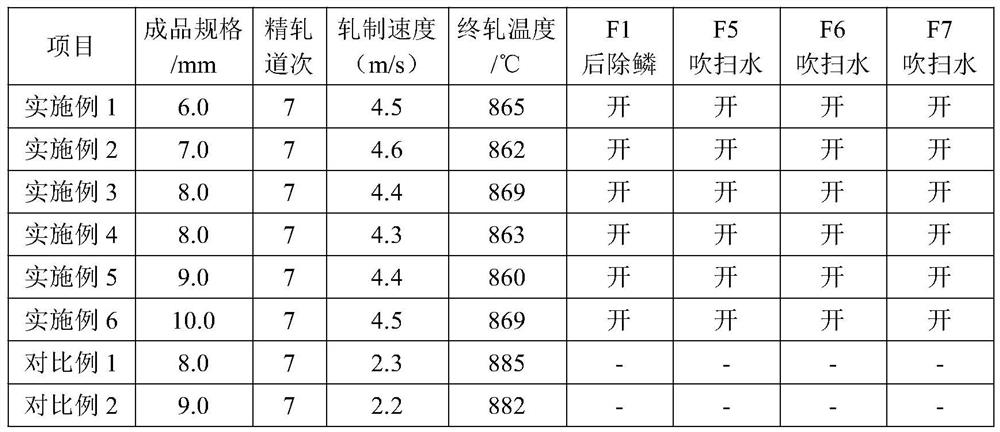

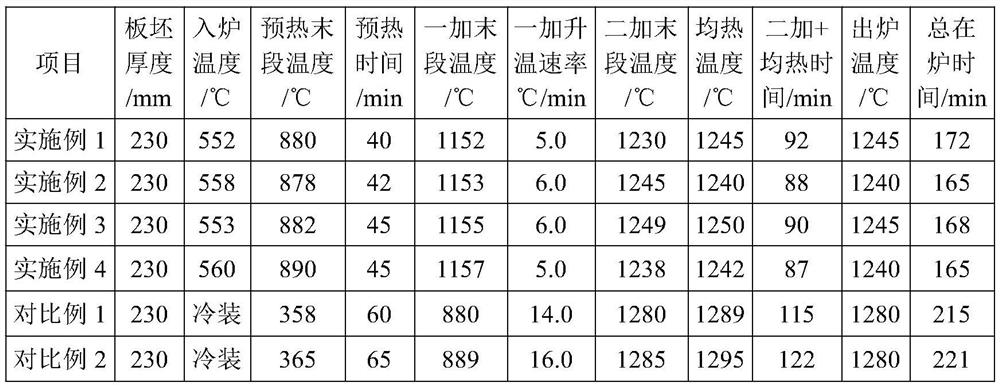

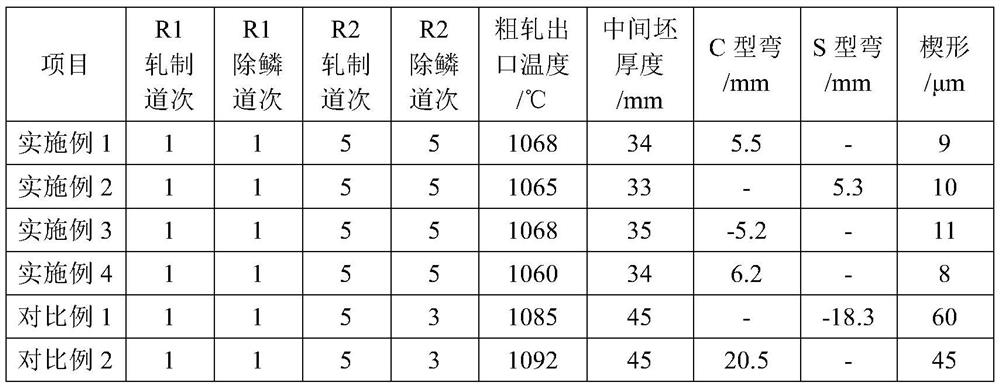

Plate shape control method of high-strength steel for commercial vehicle longitudinal beam

ActiveCN112077152AReduce cooling-heating historySmall footprintTemperature control deviceProfile control deviceShape controlControl mode

Owner:武汉钢铁有限公司

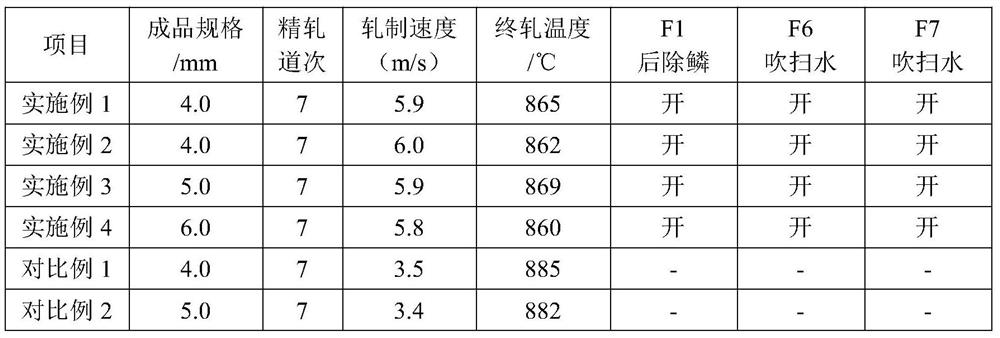

Plate shape control method for steel for hot-rolled high-strength stirring tank body

ActiveCN112108527AReduce cooling-heating historySmall footprintTemperature control deviceRollsProduction lineTemperature control

Owner:武汉钢铁有限公司

Low density converter steel tapping slag bridge

The low density slag stopper for converter tapping is made of common refractory material in revolution body shaped, has cavities with vent hole communicated with the upper surface of the slag stopper and apparent density of 1.5-2.8 g / cu cm. The low density slag stopper for converter tapping has simple structure, no need of balancing iron block, easy use, good slag stopping effect and high steel tapping efficiency.

Owner:武钢集团有限公司

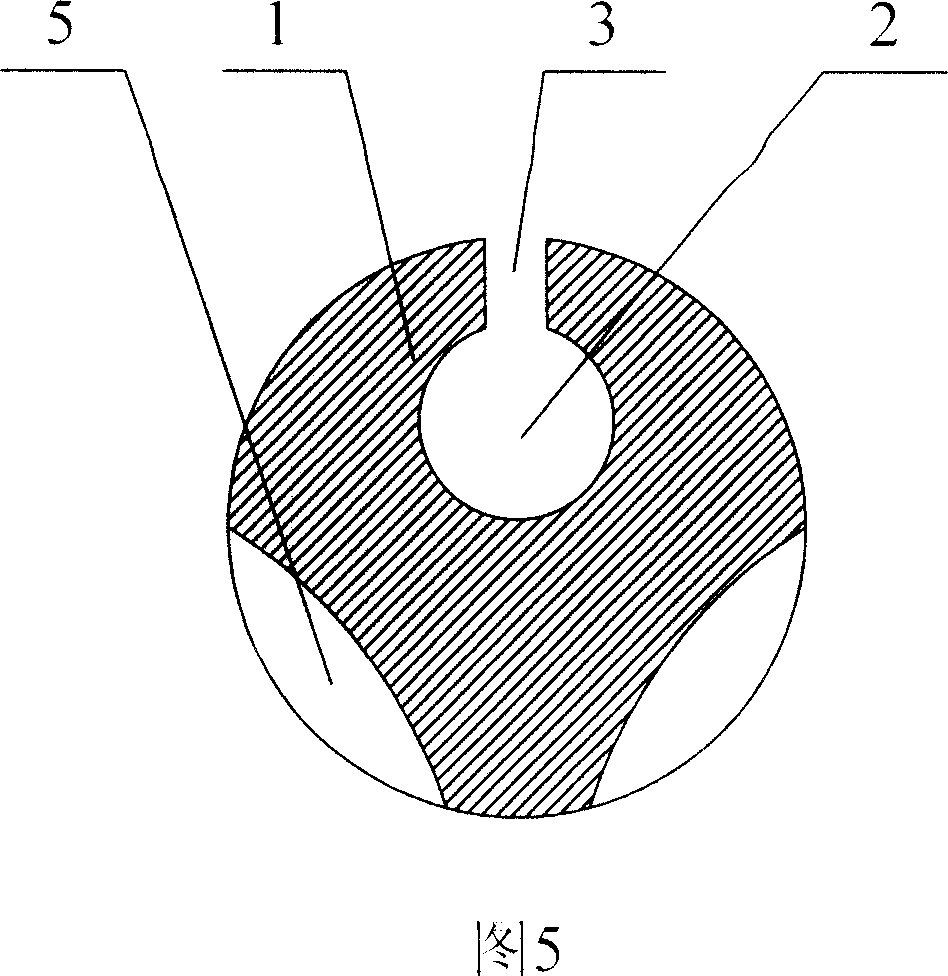

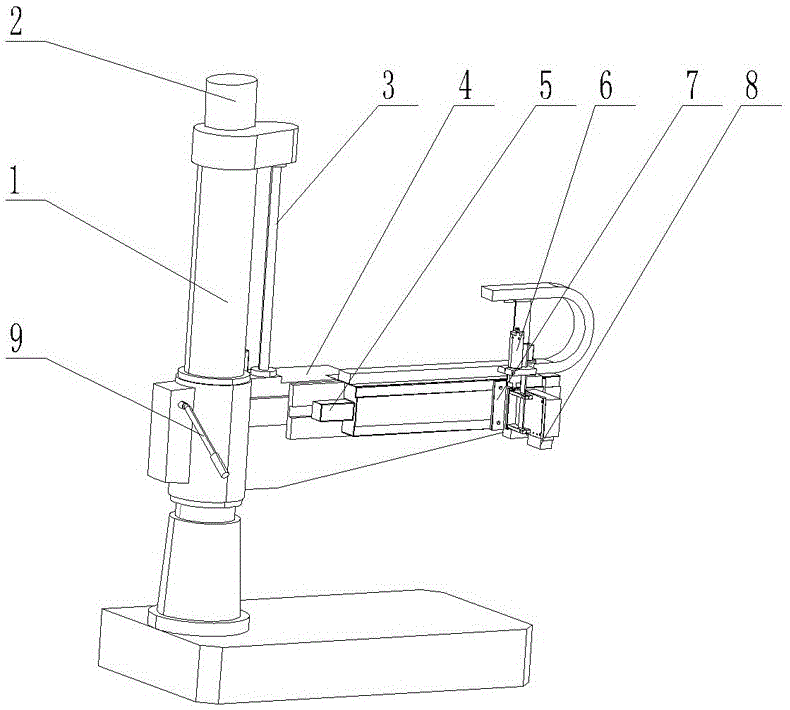

Laser surface strengthening machining device and method for plane type valve sealing surface

InactiveCN106513995AHigh precisionImprove machining accuracyIncreasing energy efficiencyLaser beam welding apparatusRocker armEngineering

The invention discloses a laser surface strengthening machining device for a plane type valve sealing surface. The machining device is characterized by comprising a control cabinet, a powder feeding device and a laser machining device; a controller is arranged in the control cabinet; the laser machining device is provided with a stand column sleeved with a rocker arm capable of rotating in all directions; a first sliding platform capable of moving horizontally is arranged on the rocker arm; a second sliding platform capable of moving vertically is mounted on the first sliding platform; a laser head and a powder feeding head are arranged on the second sliding platform; the powder feeding head is connected with the powder feeding device; the rocker arm moves vertically on the stand column; the vertical movement of the rocker arm and the vertical movement of the second sliding platform form a double-Z-axis structure; and machining stations are arranged on the periphery of the stand column. The double-Z-axis structure is adopted, the device has the high precision for adjusting the machining position of a machined piece, and the machining process and the preparation process of the device do not interfere with each other, so that the device has the advantages that the machining precision is high, the quality of a machined layer is well controlled, the device is convenient and simple to operate and the like. The invention further discloses a machining method.

Owner:浙江久恒光电科技有限公司

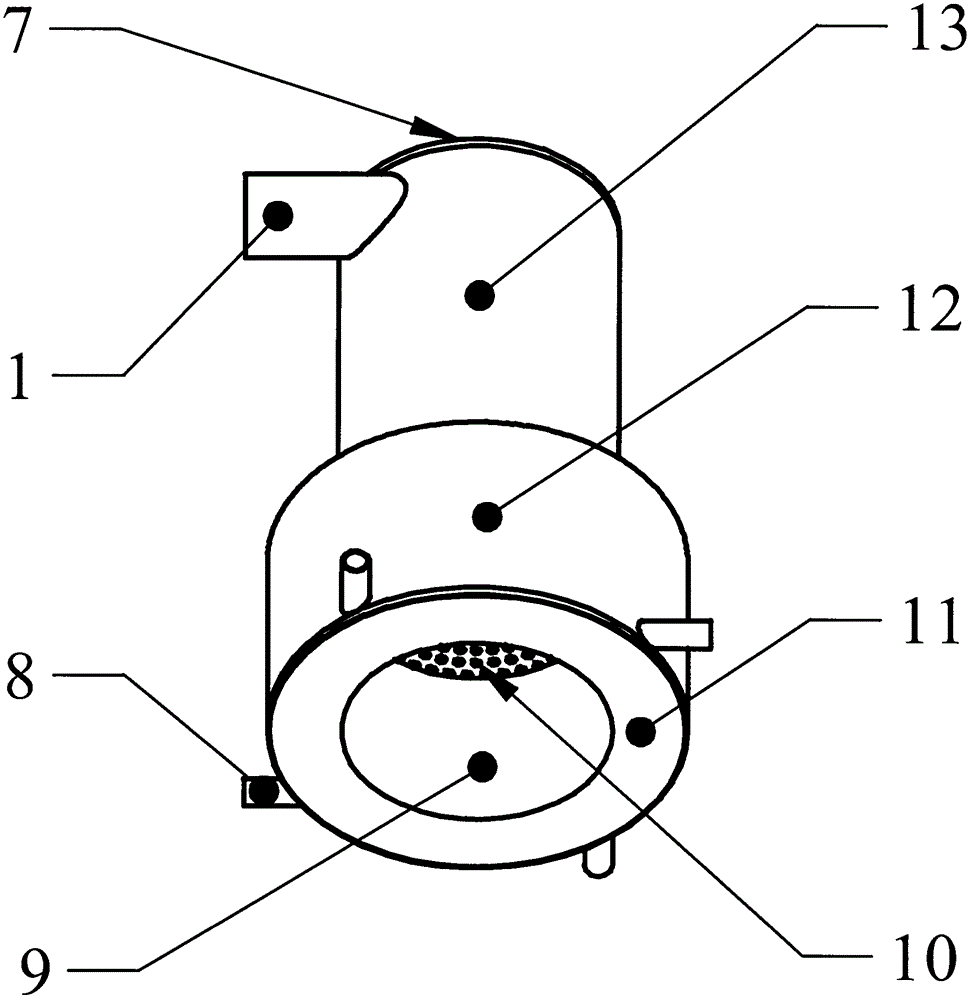

Oil and gas fired boiler having annular combustion chamber

The present invention provides an oil and gas fired boiler having an annular combustion chamber. The oil and gas fired boiler is provided with a shell, a furnace and water pipes. A plurality of combustion engines are configured at the periphery of the shell, and the furnace is arranged in the center of the shell. The annular combustion chamber is positioned at a lower portion in the furnace, and the water pipes are positioned at an upper portion in the furnace. The annular combustion chamber is communicated with the upper portion in the furnace to form a smoke flow channel for combustion heat exchange. A space between the furnace and the shell and spaces inside the water pipes form water evaporation upstream channels. The boiler is compact in integral structure, simple in geometrical shape, small in size and high in strength, heat exchange is convenient and sufficient, and thermal stress of the furnace is uniform. The advantage that no solid waste residue is discharged from an oil and gas fired boiler is fully performed, and requirements on fast assembly, modularization and integral assembly of a middle-large sized oil and gas fired boiler can be substantially satisfied. The history that an oil and gas fired boiler uses a structure of a coal fired boiler will be ended. The oil and gas fired boiler having the annular combustion chamber is a boiler according with oil and gas fired characteristics.

Owner:孔令斌

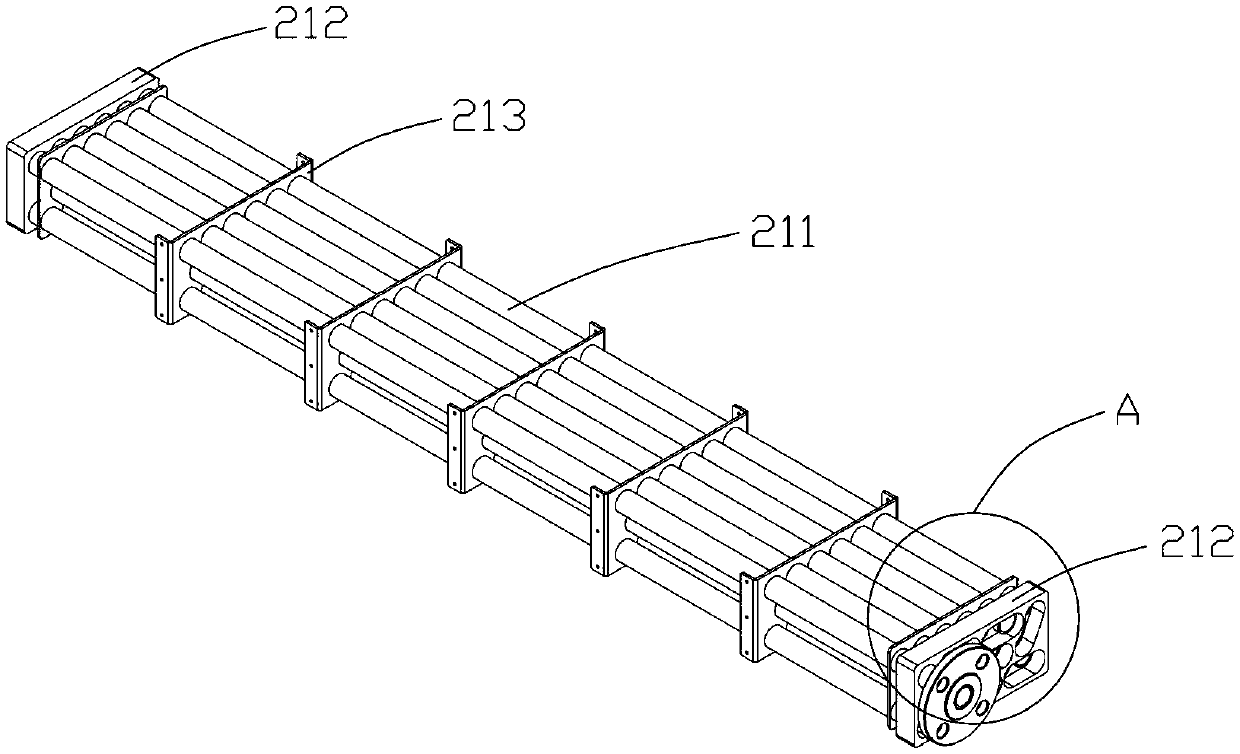

Steam generation module

PendingCN109654468AImprove qualityExtended pathStationary tubular conduit assembliesSteam boilersCombustion chamberEngineering

The invention discloses a steam generation module. The steam generation module comprises a combustion chamber, a finned heat exchanger, a tube type light tube heat exchanger and a low-nitrogen fire grate burner, wherein the finned heat exchanger, the tube type light tube heat exchanger and the low-nitrogen fire grate burner are sequentially arranged in the combustion chamber from top to bottom; acold water inlet and a hot water outlet are formed in the finned heat exchanger; the tube type light tube heat exchanger is provided with a hot water inlet and a steam outlet; and the hot water outletcommunicates with the hot water inlet. The steam generation module is novel in structure, the improved tube type light tube heat exchanger is adopted to replace a traditional fin type heat exchangerto be placed in the middle layer of the combustion chamber, heat absorbed by the cold water is more sufficient, and higher-quality steam can be produced. A brand-new low-nitrogen fire grate combustoris adopted by the bottom layer of the combustion chamber, so that the heat exchange amount is improved while the generation of nitric oxide is reduced, and the steam generation module is energy-savingand environment-friendly.

Owner:广东念智节能科技有限公司

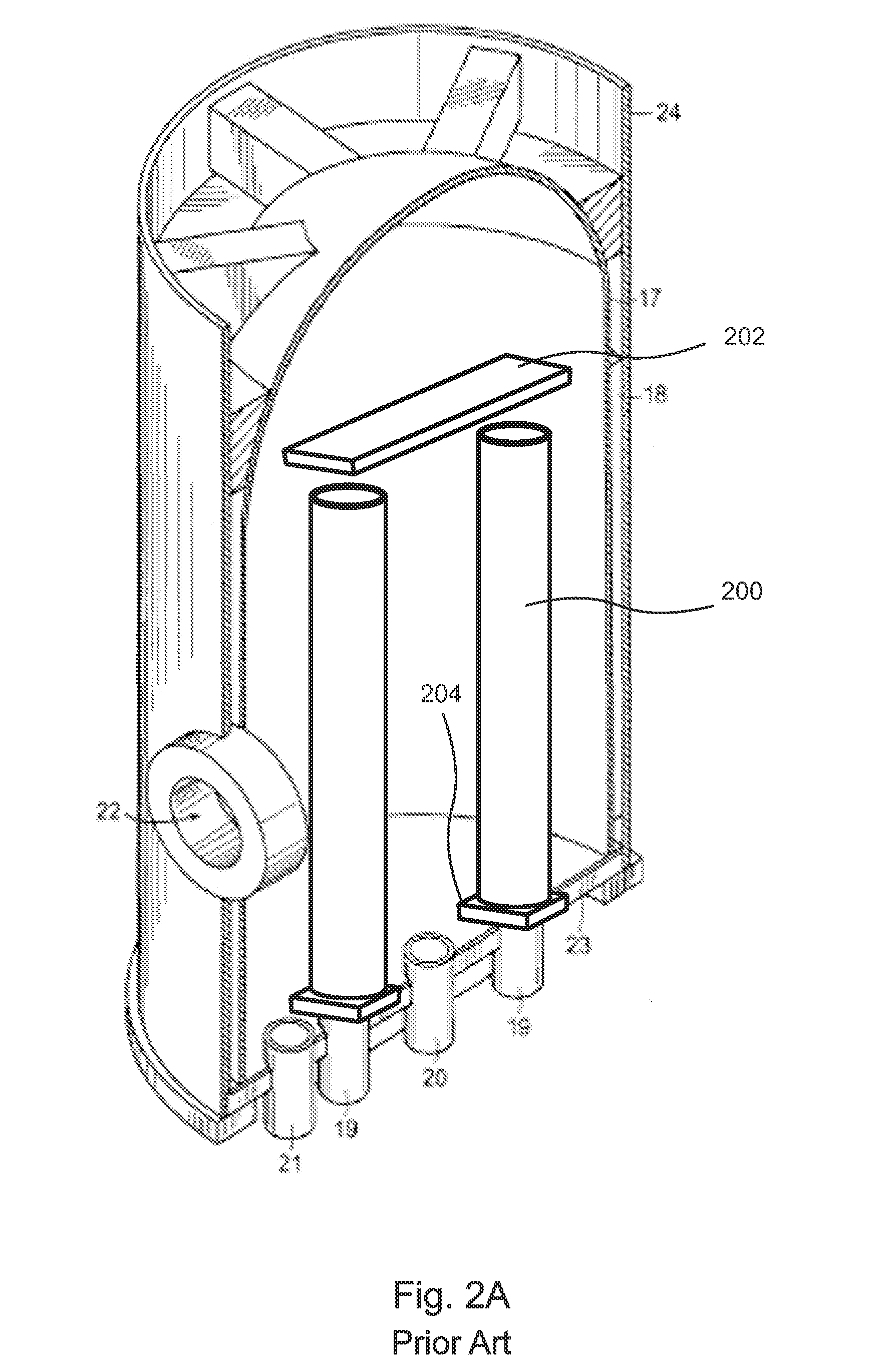

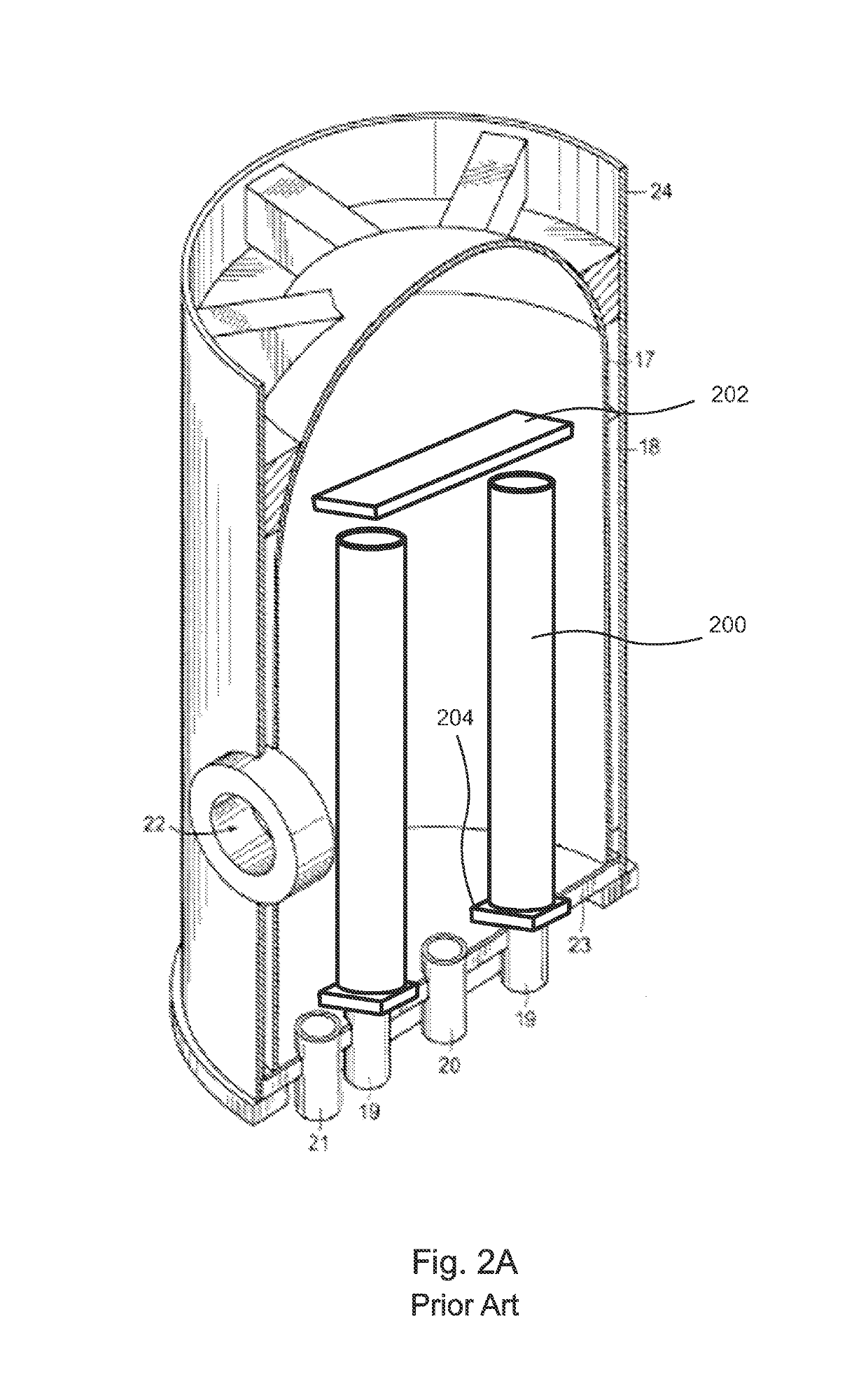

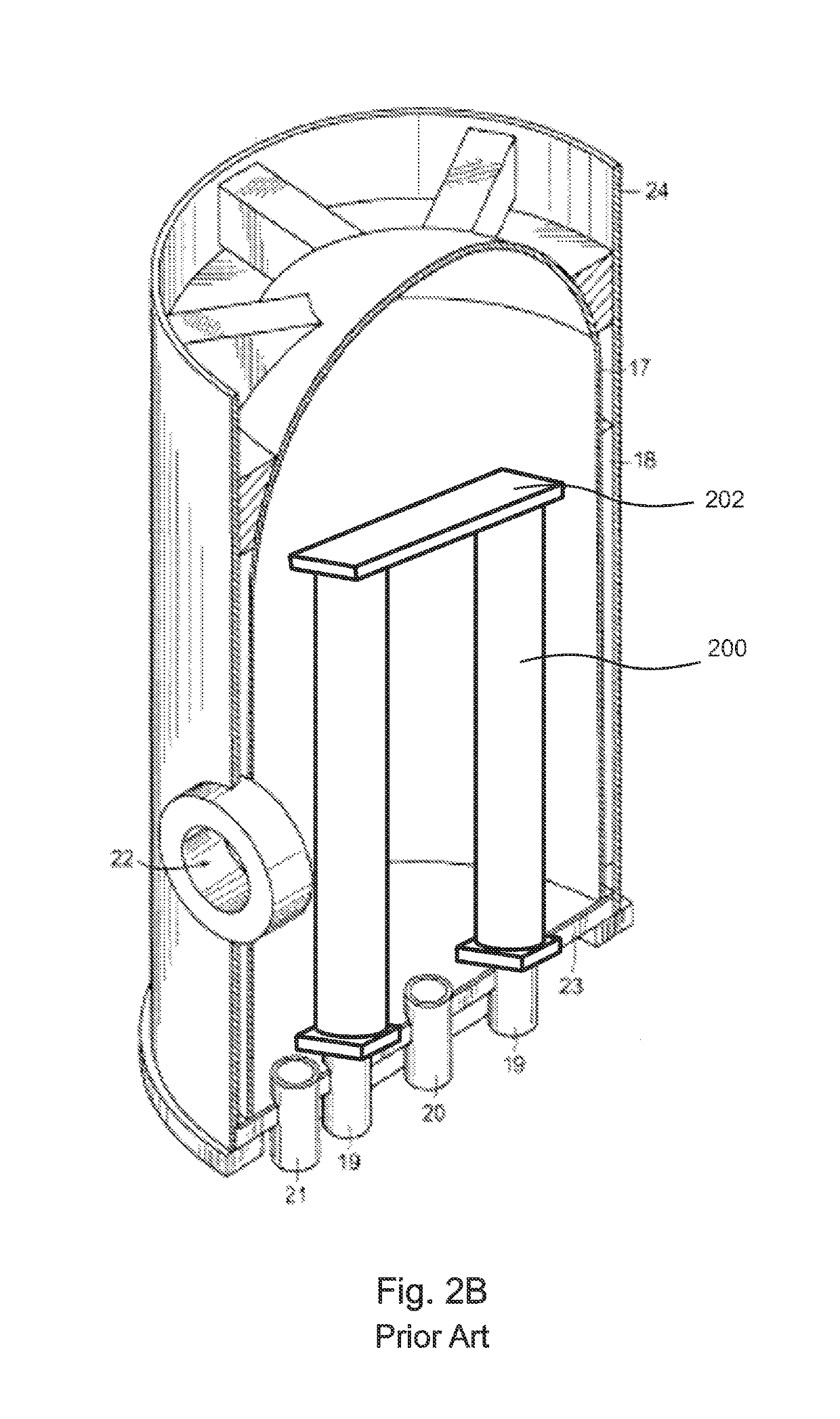

Reactor filament assembly with enhanced misalignment tolerance

ActiveUS20150211111A1High strengthIncreased longevityPolycrystalline material growthFrom chemically reactive gasesMechanical engineeringSilicon

A tubular filament assembly for a CVD silicon deposition reactor is disclosed that provides consistent, low resistance connections to vertical tubular filaments by forming slidable connections between upper and / or lower ends of the tubular filaments and shaped elements cooperative with the bridge and / or the support chucks, so that the connections are insensitive at least to small variations in tilt angle of the vertical filaments and / or the horizontal bridge. The shaped elements can be incorporated into or separate and cooperative with the bridge and / or the chucks. Various embodiments are described.

Owner:ADVANCED MATERIAL SOLUTIONS LLC

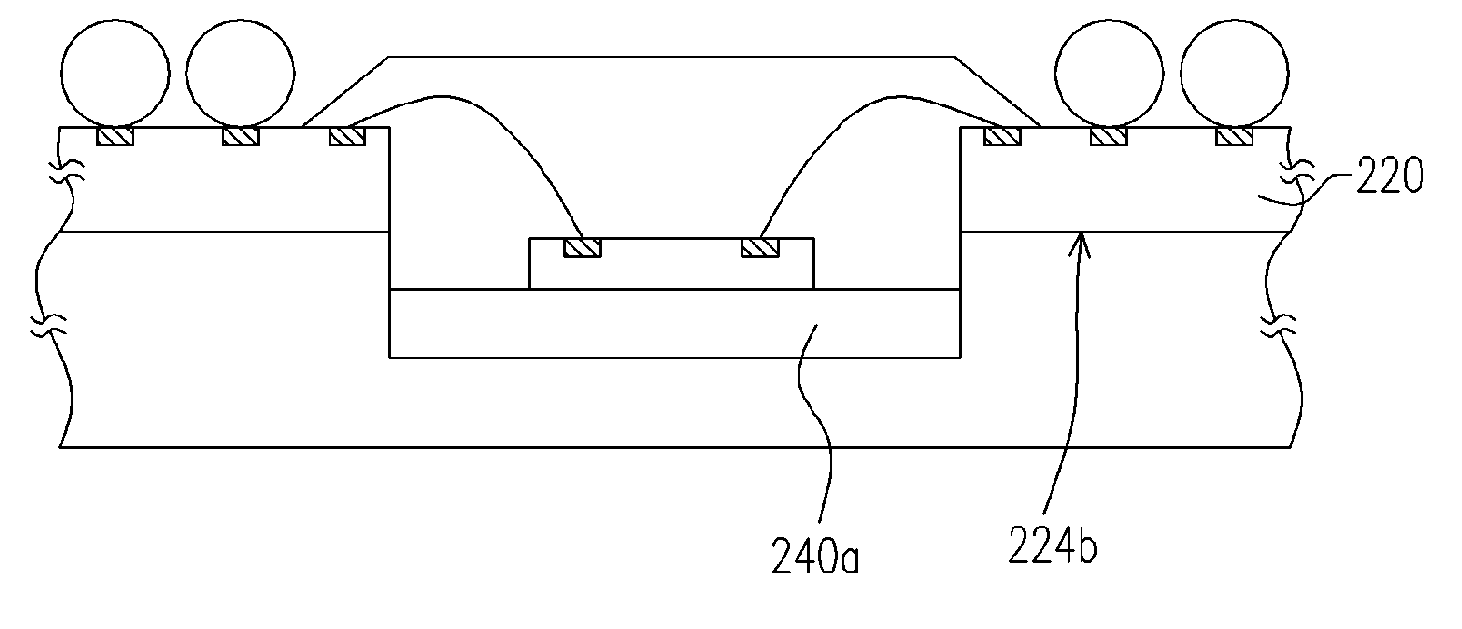

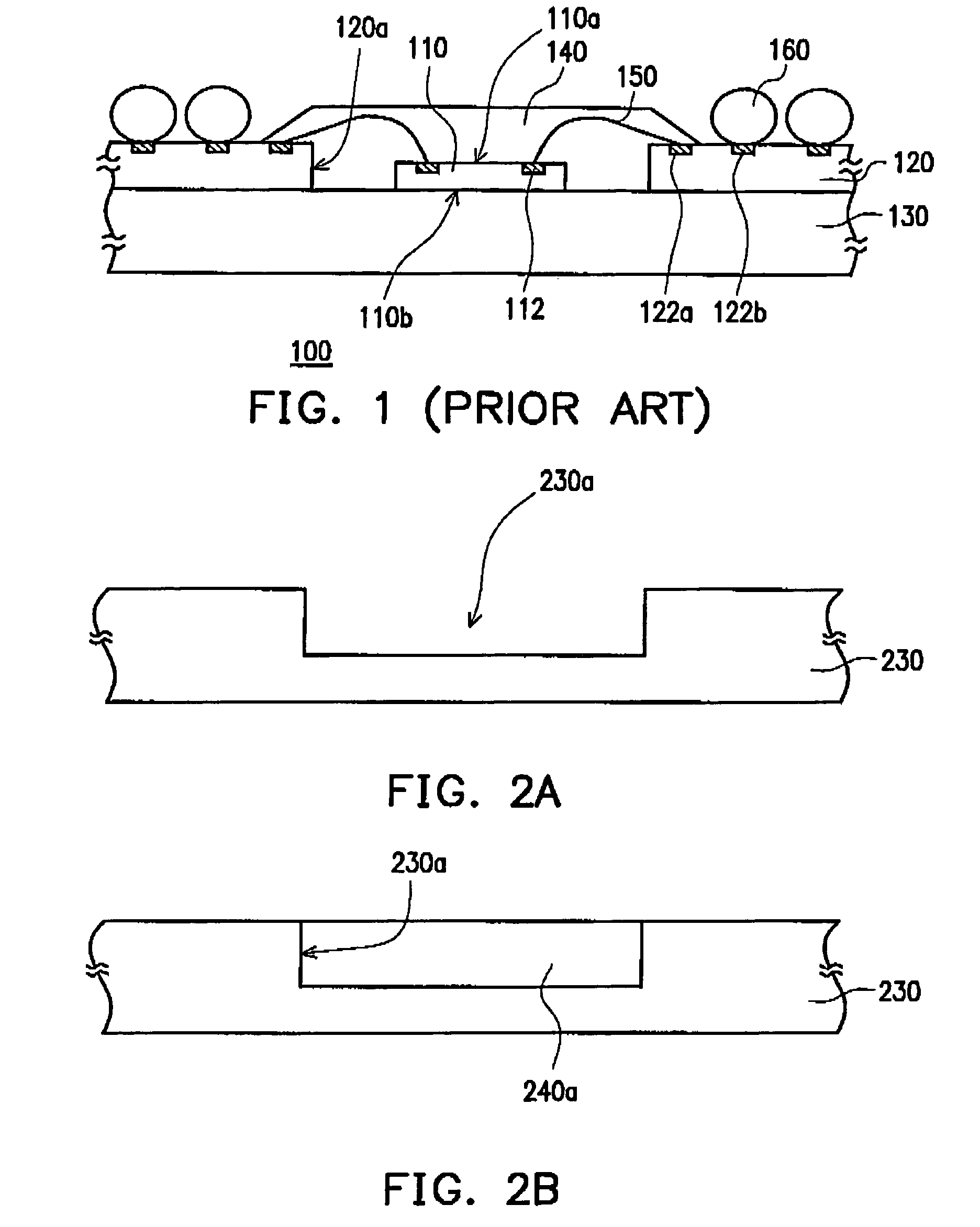

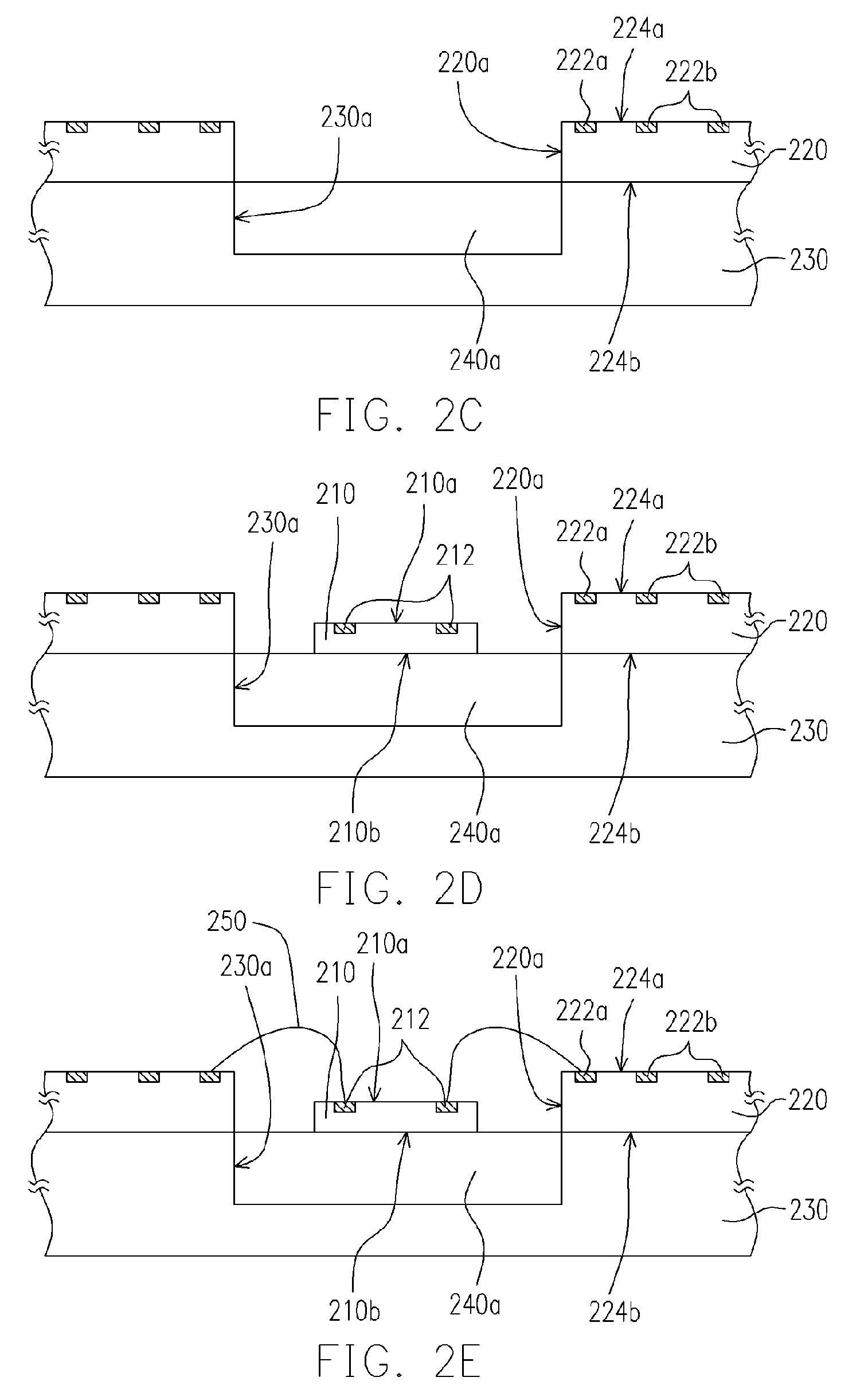

Chip package structure and chip packaging process

InactiveUS7335982B2Reduce crackingUniform thermal stressSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

A chip packaging process is provided. First, a cavity is formed on a heat sink. A first encapsulant is formed on the bottom of the cavity. A circuit substrate is disposed over the heat sink. The circuit substrate has an opening that corresponds in position to the cavity. Thereafter, a chip is disposed on the first encapsulant and the chip is electrically connected to the circuit substrate. Finally, a compound is deposited over the first encapsulant and the chip to form a chip package. The chip package is warp resistant and the chip packaging process increases overall production yield.

Owner:ADVANCED SEMICON ENG INC

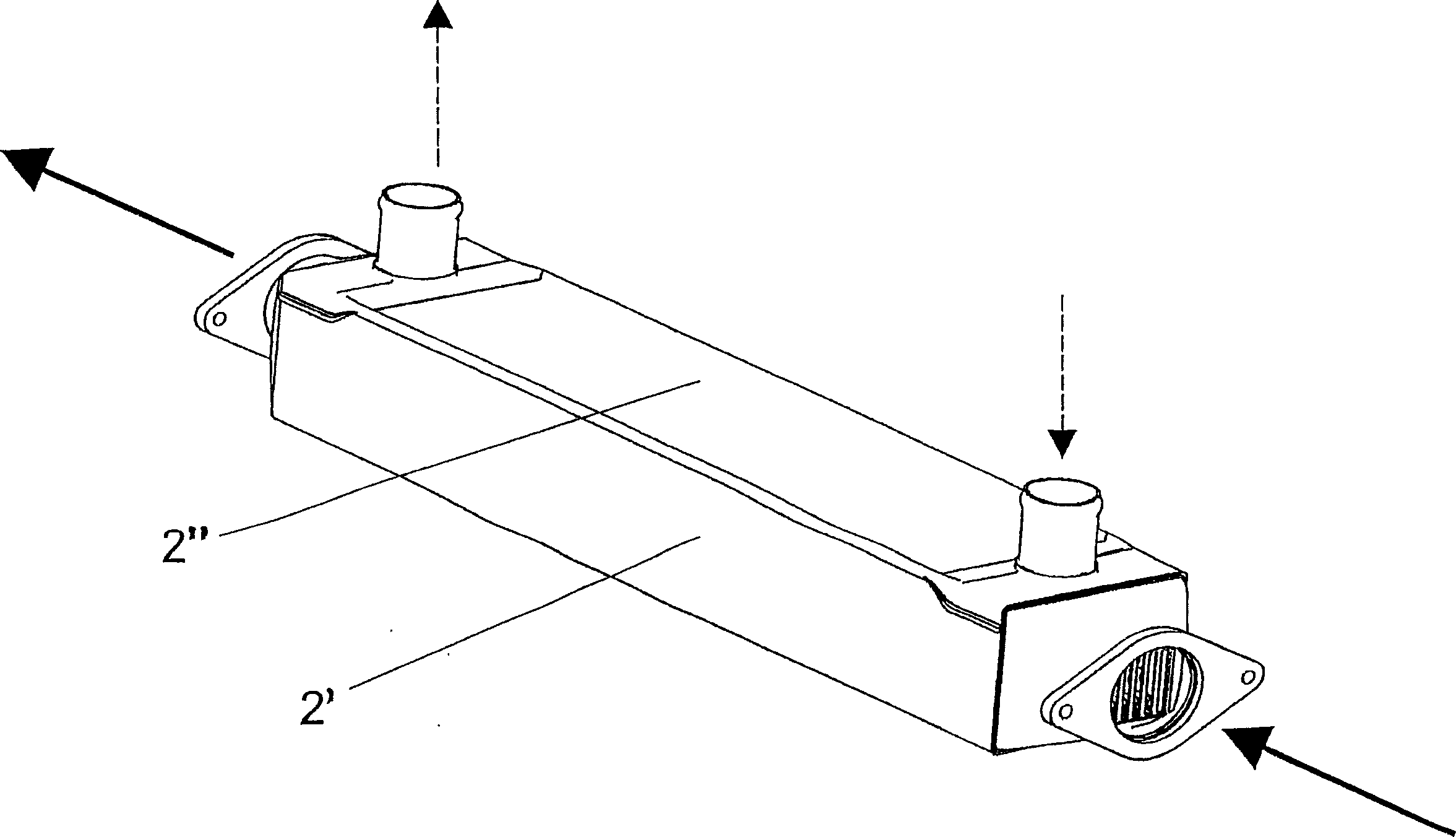

Heat exchanger

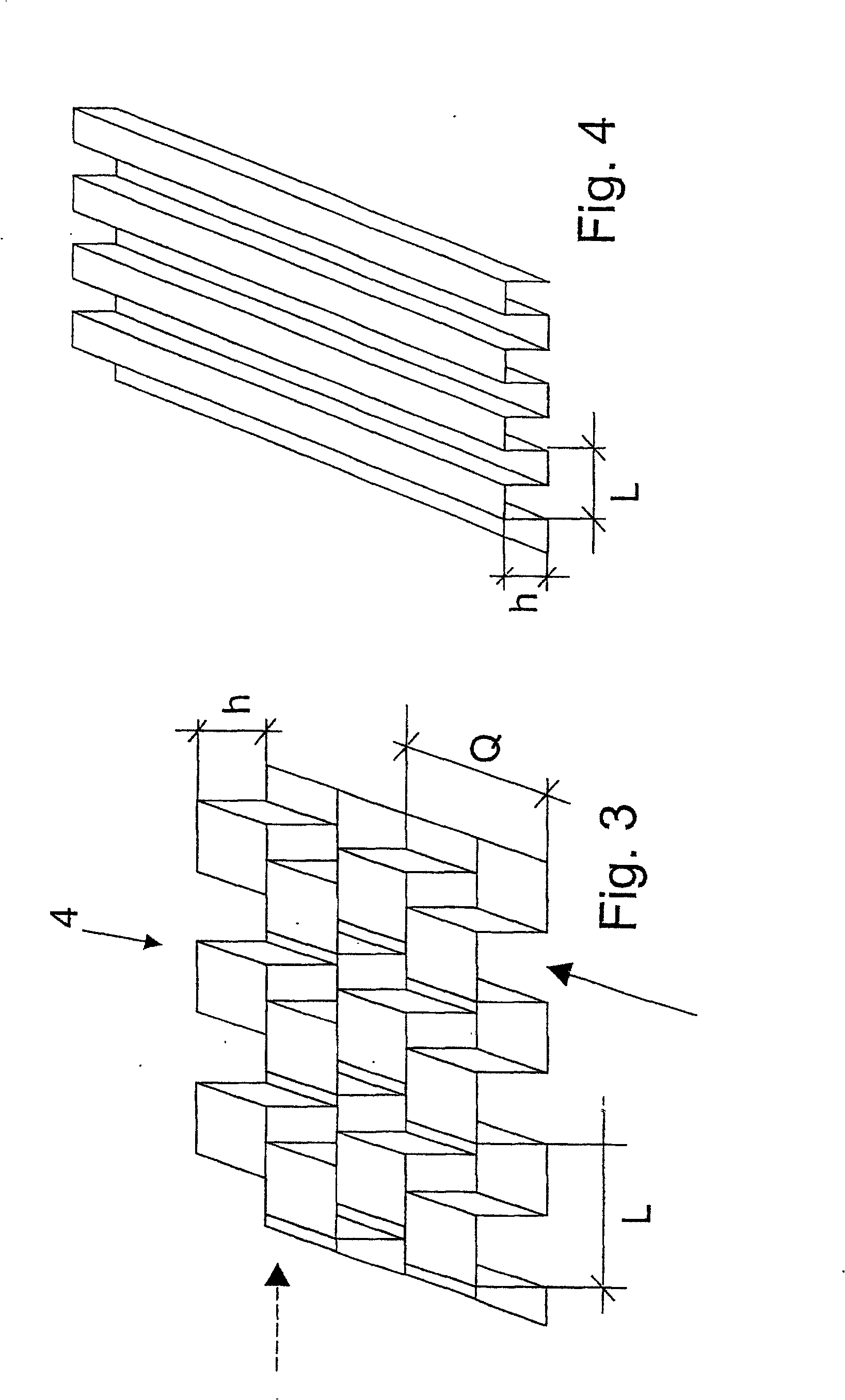

ActiveCN100447518CPrevent sagSpeed up heat transferRecuperative heat exchangersHeat exhanger finsPlate heat exchangerMetal sheet

The exhaust gas heat exchanger (1) for a road vehicle internal combustion engine has a square- or rectangular-section housing (2). It is made of a U-section (2') with a shallow inverted U- section lid (2''). The interior contains an array of flattened rectangular-section tubes (3) with fins (4) made of corrugated metal sheet between them. Cooling fluid may flow past the fins to cool hot exhaust gas before entering silencers and catalysers. The exhaust gas may flow straight through and the cooling fluid may flow through side connections (5).

Owner:BEHR GMBH & CO KG

Low-cost high-weldability seal

The invention relates to a low-cost high-weldability seal which comprises a seal body, wherein a through-going positioning hole is arranged in the seal body, two opening parts are arranged on the seal body at a side face of the positioning hole, an opening end of the positioning hole is arranged between the two opening parts, the opening parts expand outwards, and the distance between the end parts of the two opening parts close to the opening end is larger than the distance between the end parts of the two opening parts close to the positioning hole. In the invention, as a first adjusting hole is located at the middle part of the seal body, the weight of the seal is reduced; thus, the weight of a core body of a heat exchanger is reduced, the power consumption for the brazing is saved, and the cost for the product is reduced; the low-cost high-weldability seal has the advantages of small heat capacity, small contraction distortion, uniform heat stress, good welding performance with peripheral connecting pieces and high brazing qualification rate; when the seal body is assembled in the core body, the compression resilience of the opening parts and a clamping force are balanced by the action of the clamping force, so that the seal body is beneficial of compaction and control of the gap between weld seams, and therefore the core body has good weldability; moreover, the low-cost high-weldability seal has the advantages of simple and compact structure and convenience for installation and use, wide application range, safety and reliability.

Owner:WUXI MASHAN YONGHONG HEAT EXCHANGER

Jun porcelain sky blue glaze and preparation method thereof

The invention relates to the technical field of jun porcelain glaze, in particular to jun porcelain sky blue glaze and a preparation method thereof. Frit is prepared from the following raw materials in parts by weight: feldspar, quartz, fluorite, talc, wollastonite and a phosphorus compound. The glaze slip is prepared from the following raw materials in parts by weight: frit, clay, ferric oxide, strontium carbonate, copper oxide, titanium oxide, cobalt oxide, manganese oxide and hydroxypropyl methyl cellulose; through quartz, fluorite, talc and a phosphorus compound, glaze pinhole defects areeliminated, glaze gloss is increased, finished product quality is improved, and glaze gloss is increased. The amounts of feldspar and quartz are reasonably configured, and a good middle layer is formed between the glaze layer and the green body so that the green body and the glaze are tightly combined; the thermal stress between the blank and the glaze is uniform, the stress between the blank andthe glaze is weakened, and the mechanical strength of the Jun porcelain is improved; through high-temperature 'reducing flame' and twice low-temperature 'oxidizing flame' calcination, colored metal generates different reactions at different temperatures to display different colors so that the sky blue glaze is variable in color.

Owner:禹州市神器钧窑有限公司

Method and equipment for providing the edge of a starting sheet with a dielectric strip

ActiveUS8617443B2Improve permeabilityUniform qualityConfectionerySemiconductor/solid-state device manufacturingMaterials scienceMetal

A device for providing the edge of a starting sheet of an electrode used in the electrolytic refining or recovery of metals with a dielectric part comprises a die space, in which the edge of the starting sheet of the electrode can at least partly be fitted, and a feeding device of the dielectric material for feeding the dielectric material into the die space. The device comprises changing members of the volume of the die space for pressing the dielectric material in the die space to that edge of the starting sheet of the electrode, which is at least partly fitted in the die space.

Owner:METSO OUTOTEC (FINLAND) OY

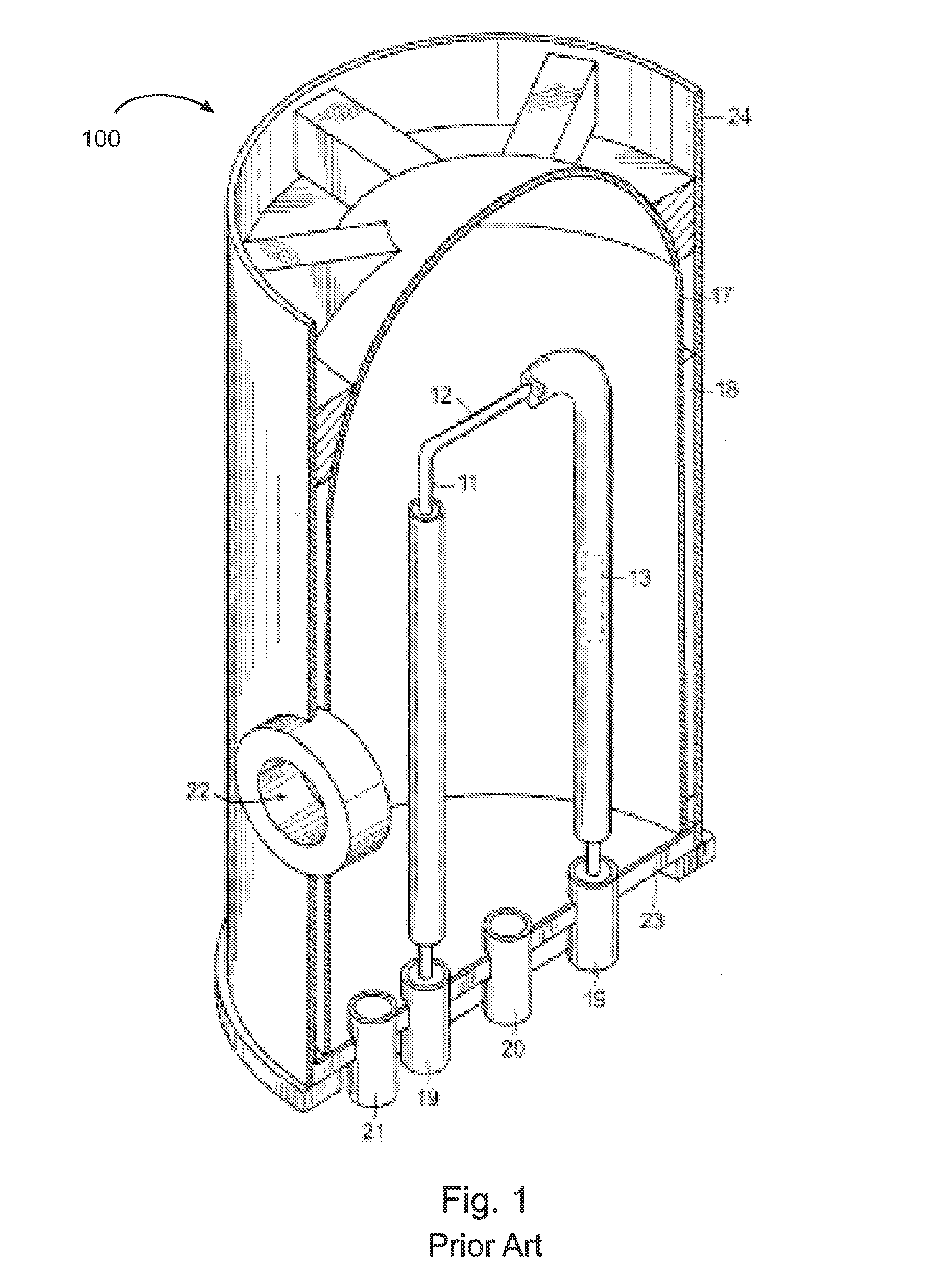

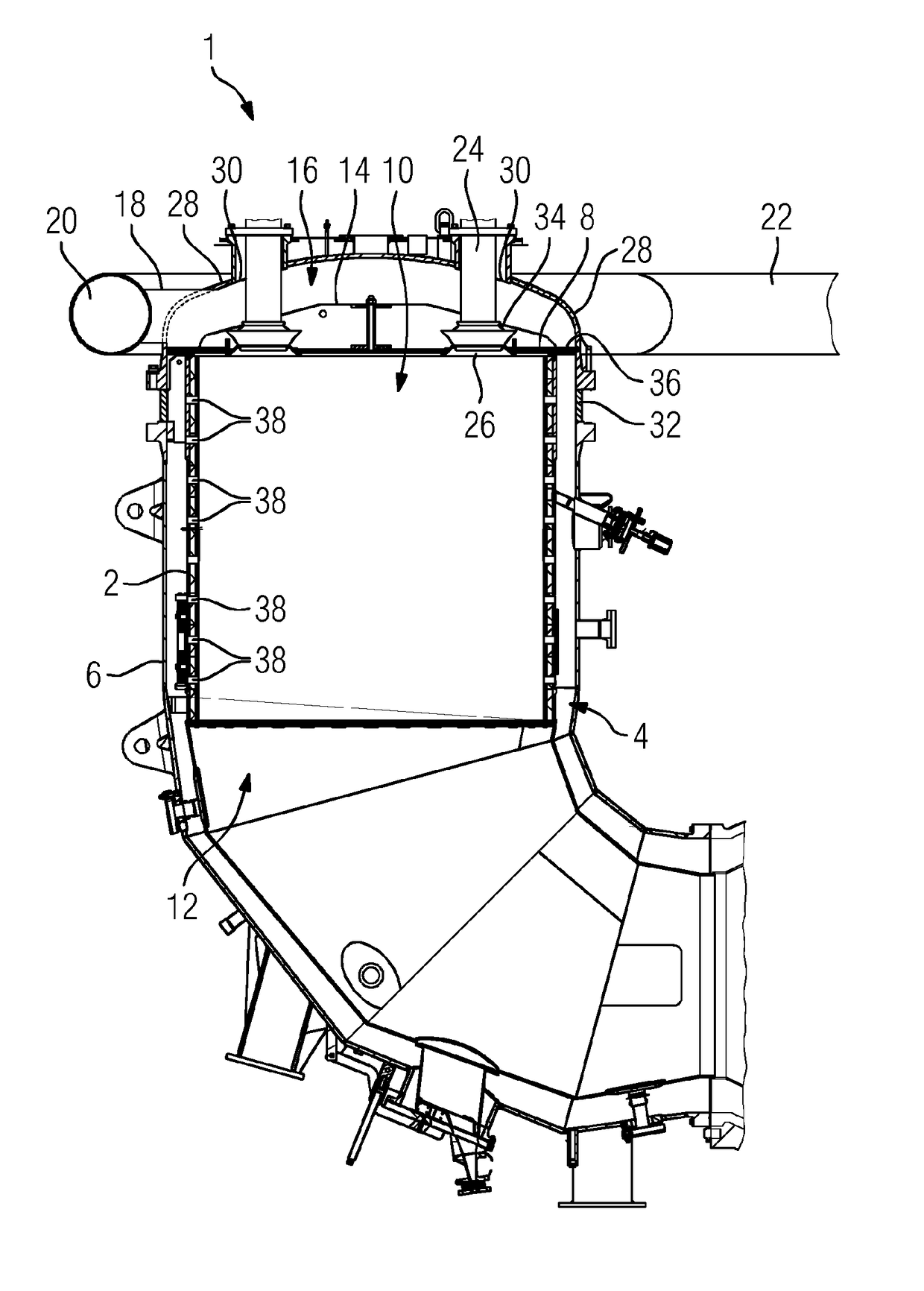

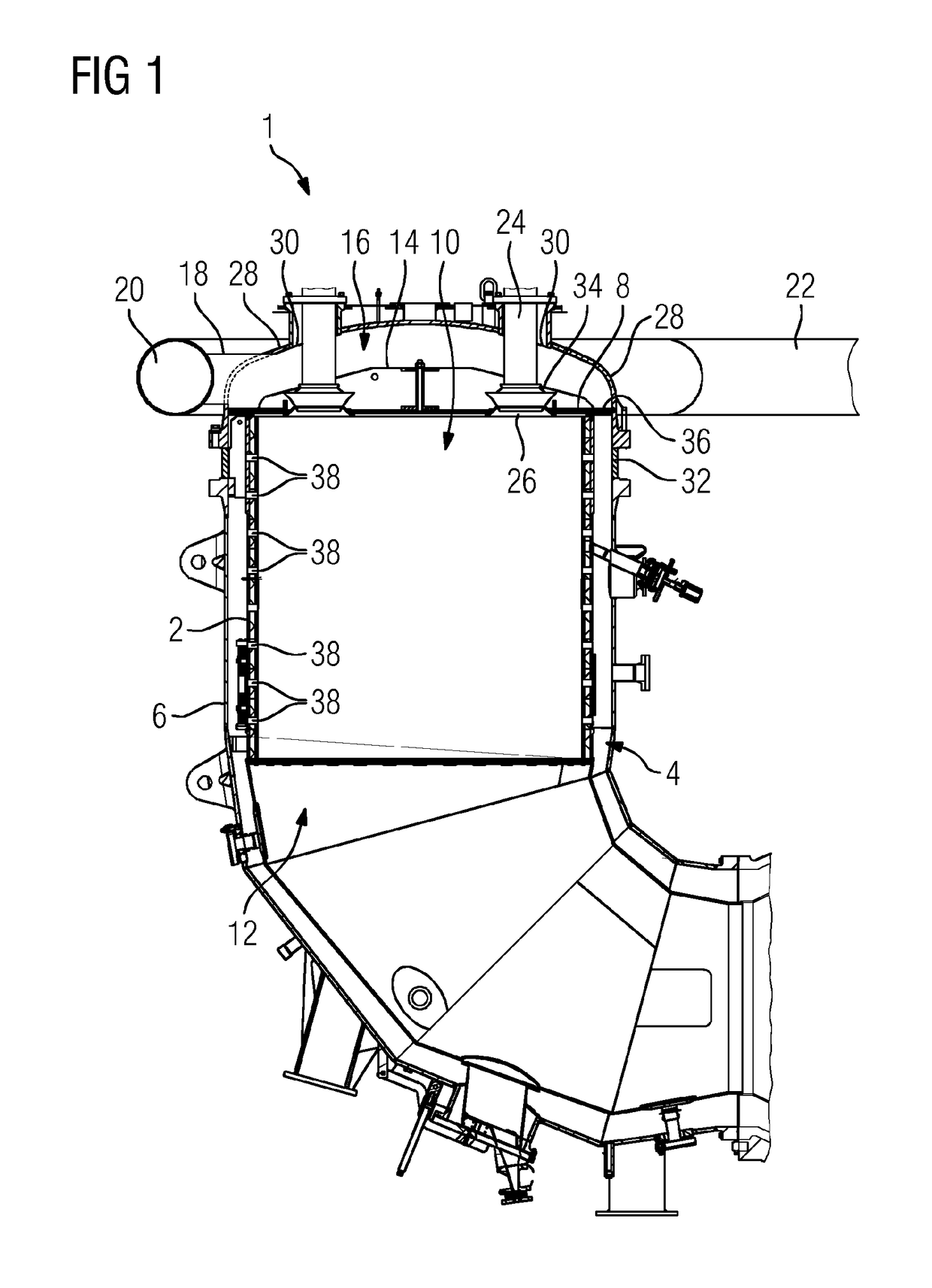

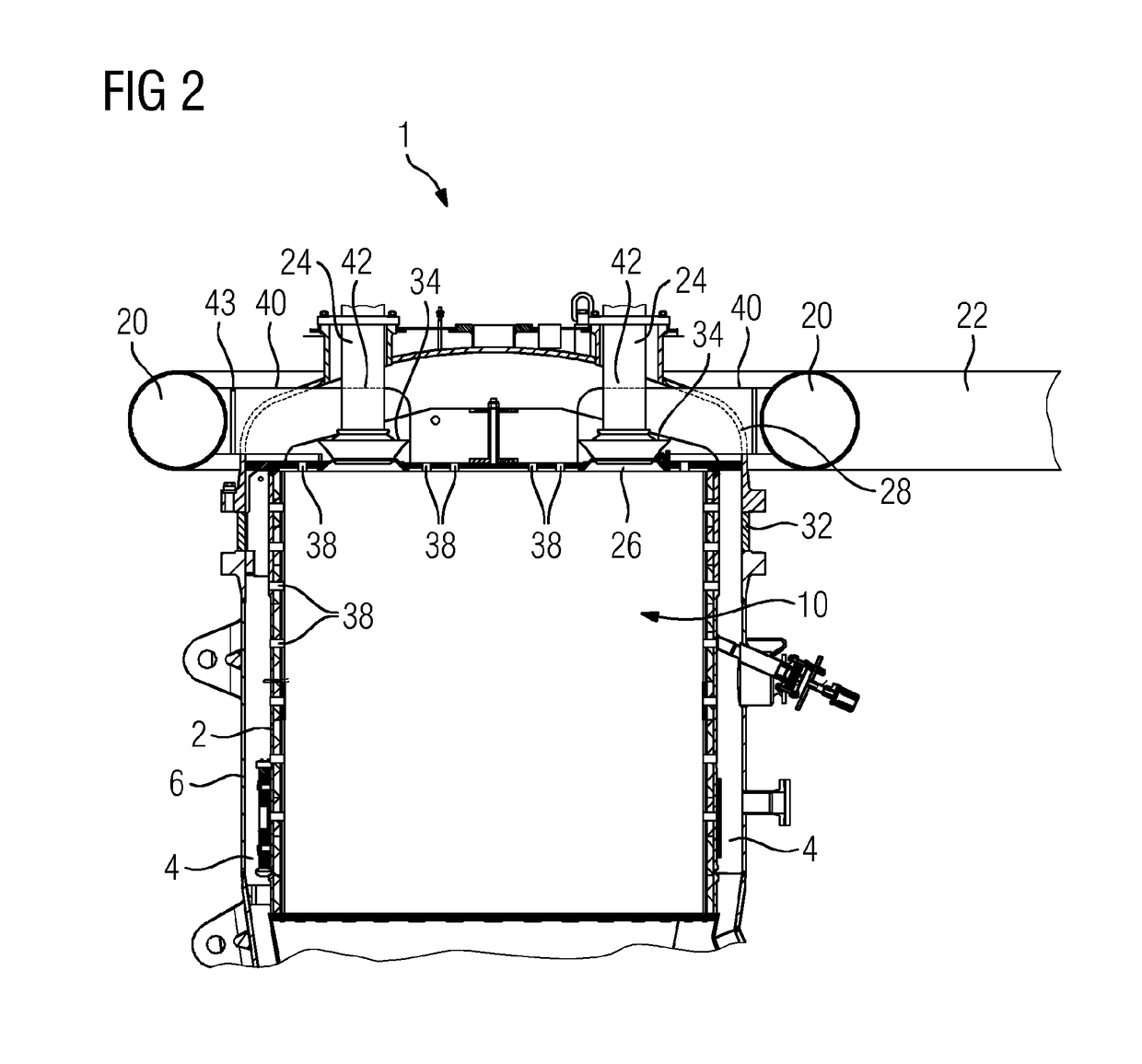

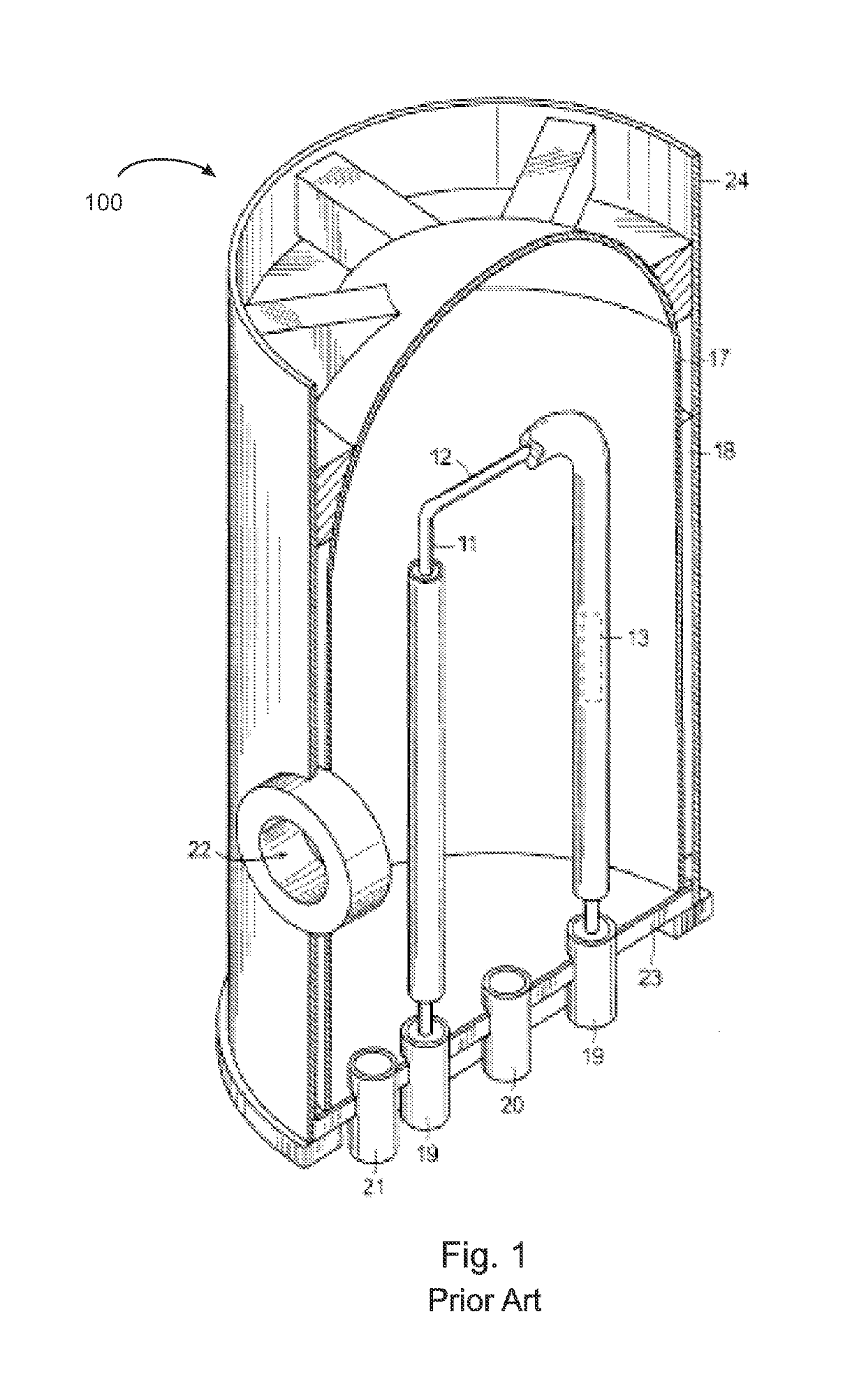

Silo combustion chamber for a gas turbine

InactiveUS20170130961A1Uniform thermal stressReduce the temperatureContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A silo combustion chamber for a gas turbine having a flame tube having an inner wall and flame tube base delimiting a combustion chamber; an outer wall surrounding the inner wall, forming a cavity; an annular chamber at least partly surrounding the outer wall and a number of supply lines fluidically coupled to the hot side of a heat exchanger during operation of the turbine; a number of burners, each of which opens into the combustion chamber on the outlet side through an opening in the flame tube base. The oxygen supply is fluidically connected to the annular chamber. A collecting chamber is arranged over the flame tube base. The annular chamber is connected to the collecting chamber via each connecting piece, each burner is fluidically connected to the collecting chamber to supply oxygen. The cavity between the inner and outer wall is locally fluidically separated from the collecting chamber.

Owner:SIEMENS AG

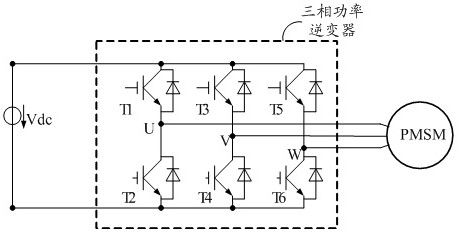

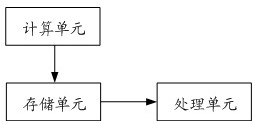

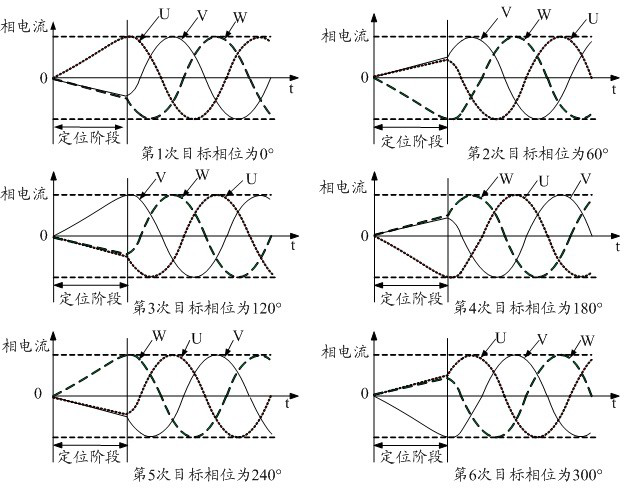

Permanent magnet synchronous motor rotor positioning control system and air conditioner

PendingCN113922726AImprove thermal stressUniform thermal stressElectronic commutation motor controlMechanical apparatusPower inverterElectric machine

The invention discloses a permanent magnet synchronous motor rotor positioning control system and an air conditioner. The control system comprises: a calculation unit which is used for calculating a target phase theta (i) of motor rotor positioning when i is greater than or equal to 1 and less than N: theta (1) = 0 degree, theta (i + 1) = theta (i) + [delta] theta, wherein N = 360 degrees / [delta] theta and is a multiple of 6, and i is a natural number; a storage unit that stores a target phase theta (i) ( i is greater than or equal to 1 and less than N) for starting a cycle; and a processing unit used for setting the d-axis current of the motor as a first value and setting the q-axis current of the motor as a second value in a motor rotor positioning stage, and controlling the motor rotor to be alternately positioned to a target phase theta (i) which is ranked from small to large in the starting cycle. The thermal stress of the power switch element in the three-phase power inverter is balanced by rotating the target phase positioned by the motor rotor, and the service life of the three-phase power inverter is prolonged.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

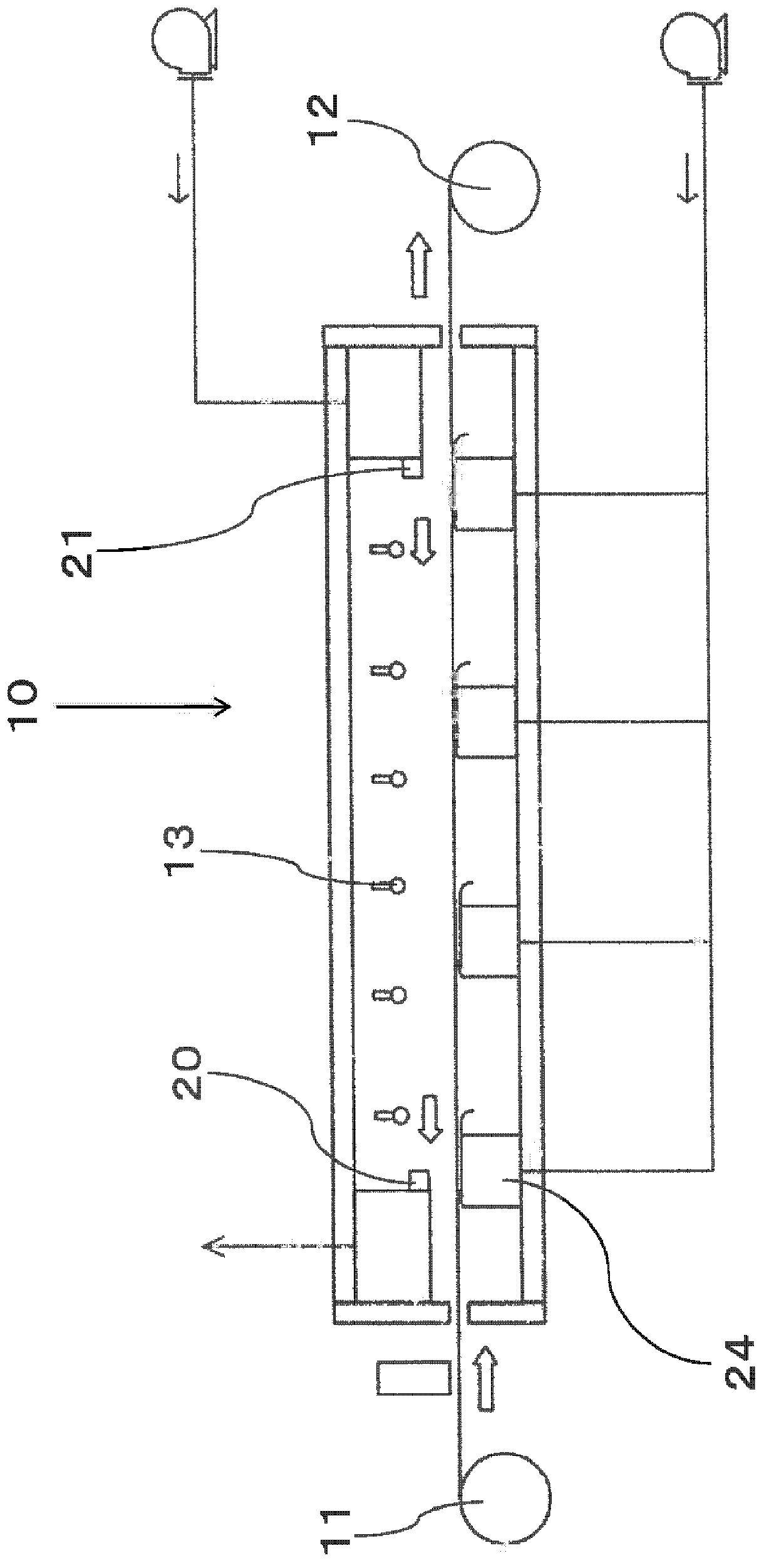

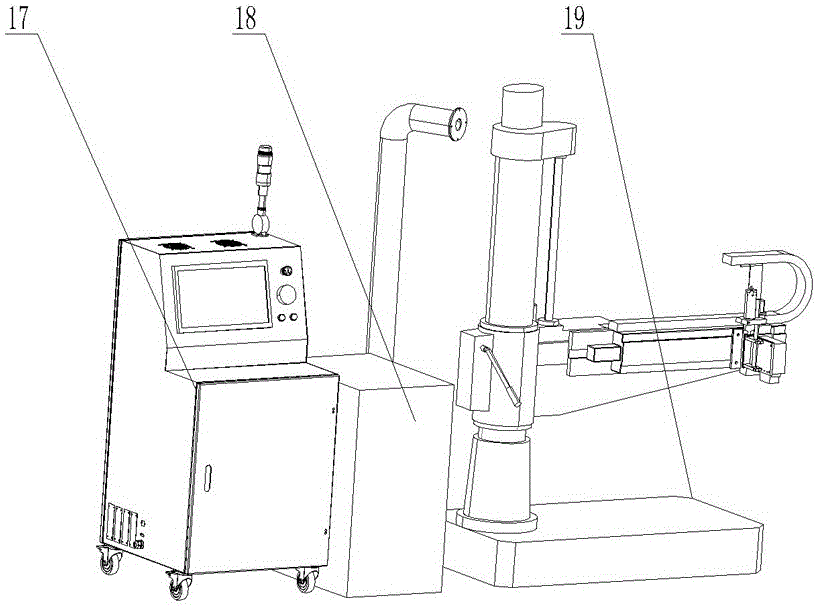

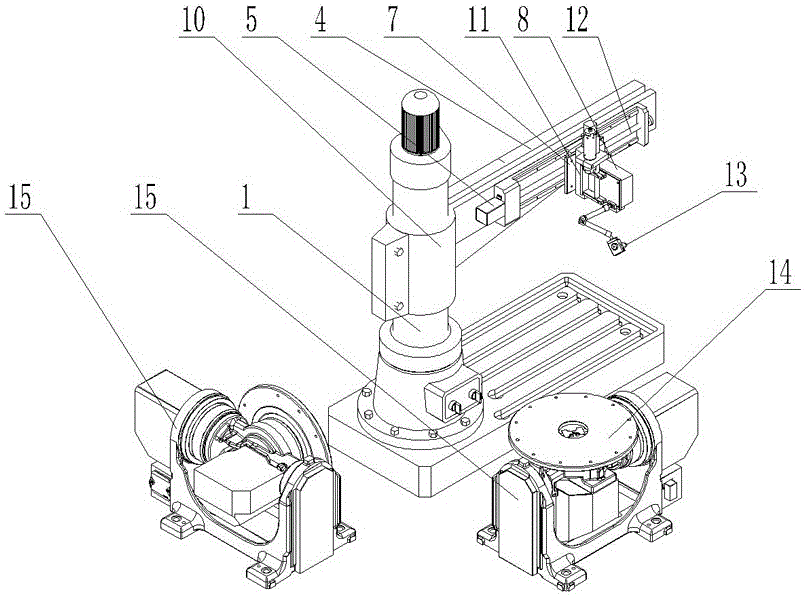

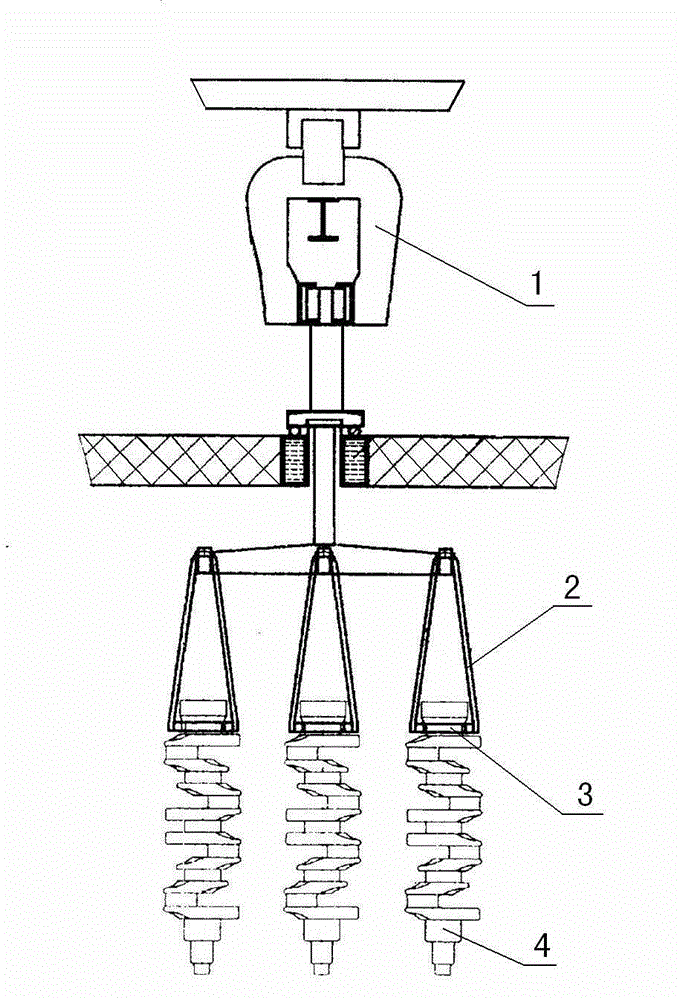

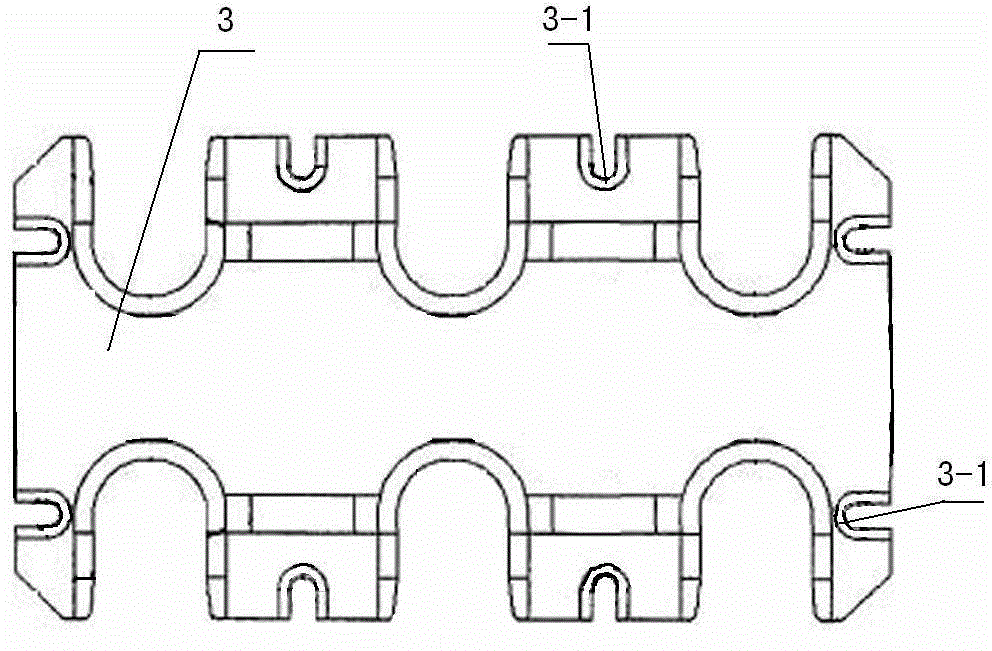

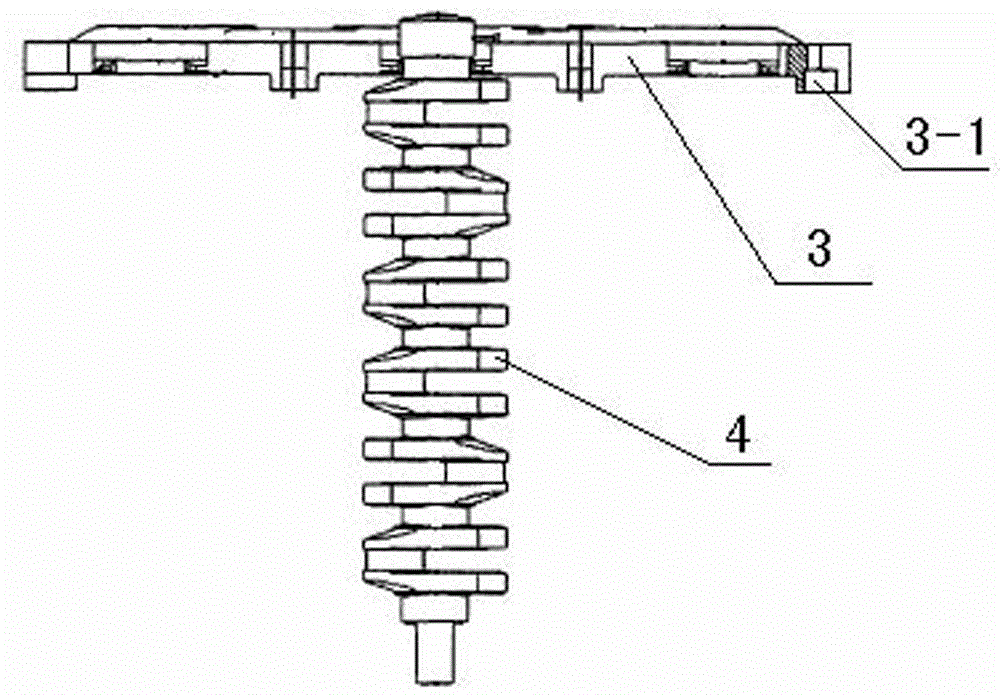

Normalizing equipment of marine nodular cast iron crankshaft

InactiveCN104831051AReduce hardness differenceUniform thermal stressFurnace typesHeat treatment furnacesTreatment fieldEngineering

The invention discloses normalizing equipment of a marine nodular cast iron crankshaft, relating to the heat treatment field. The normalizing equipment comprises a suspended type electric heating furnace with a conveying chain and an automatic rotating cooling device, wherein a suspended hanging appliance comprising a boom and a hanger plate is arranged in the suspended type electric heating furnace, and boom holes are formed at the periphery of the hanger plate; the automatic rotating cooling device comprises a base provided with a rotating shaft and a motor, and the motor is connected with the rotating shaft by a transmission mechanism; a rotating frame movably connected with the boom is arranged at the top end of the rotating shaft, and a cooling air sprayer is arranged near the rotating frame. The normalizing equipment solves the problems that during normalization of the crankshaft, as a placement table of a crankshaft blank from a heat treatment furnace cannot rotate and one side of the crankshaft is blown by a fan all the time, the hardness difference of the cross section of the casting can reach more than HBW50 due to non-uniform cross section tissues caused by coarse grains of certain parts of the crankshaft, the mechanical property of the product is influenced, and the crankshaft can be bent and deformed due to large stress difference.

Owner:GUANGXI WUZHOU YUNLONG PORT & SHIP MACHINERY MFG

Reactor filament assembly with enhanced misalignment tolerance

InactiveUS10450649B2Increasing strength and longevityLower resistancePolycrystalline material growthFrom chemically reactive gasesElectrical resistance and conductanceMechanical engineering

A tubular filament assembly for a CVD silicon deposition reactor is disclosed that provides consistent, low resistance connections to vertical tubular filaments by forming slidable connections between upper and / or lower ends of the tubular filaments and shaped elements cooperative with the bridge and / or the support chucks, so that the connections are insensitive at least to small variations in tilt angle of the vertical filaments and / or the horizontal bridge. The shaped elements can be incorporated into or separate and cooperative with the bridge and / or the chucks. Various embodiments are described.

Owner:ADVANCED MATERIAL SOLUTIONS LLC

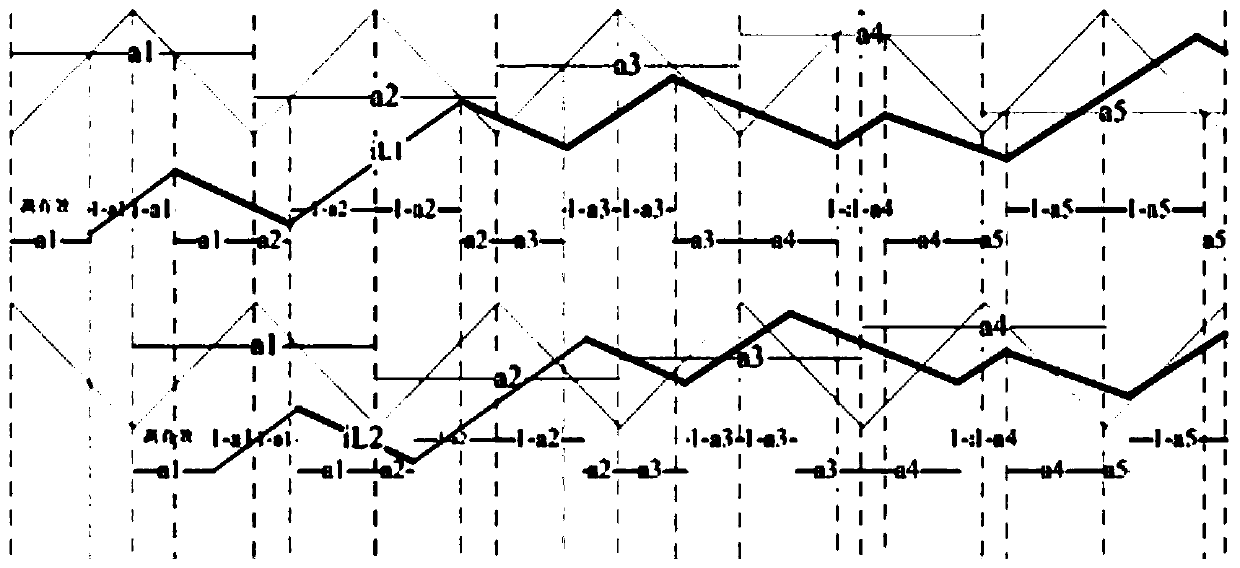

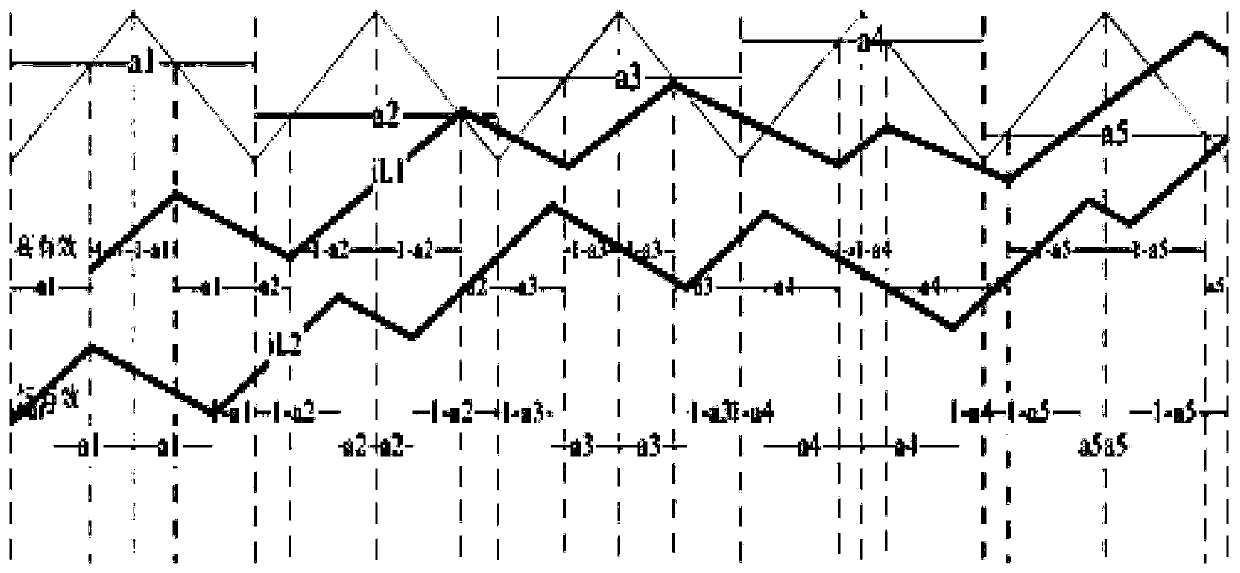

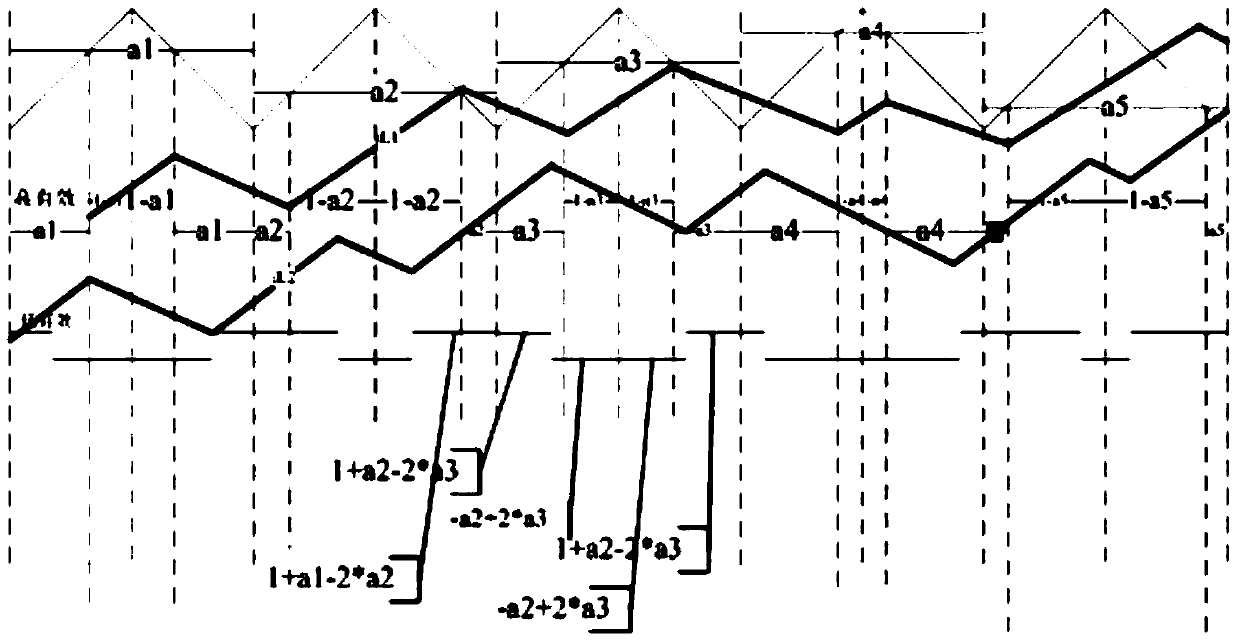

A control method for interlaced phase shifting of a photovoltaic inverter and a photovoltaic inverter

ActiveCN105141167BSimple designReduce input current ripple amplitudeAc-dc conversionPhotovoltaic energy generationCapacitancePhase shift control

The invention provides an interleaving phase-shift control method for a photovoltaic inverter and the photovoltaic inverter. Interleaving control on the control quality is realized; and an input current ripple amplitude value is reduced by prediction control and time compensation strategies in the control process, so that the design of an electro-magnetic interference (EMI) filter is simplified. Relatively low filter capacitance and boost inductance are permitted to be adopted by increase of the current ripple frequency, so that the size of the overall system is reduced; and the power density of the system is improved. The overall system is relatively uniform in thermal stress to obtain relatively high reliability; meanwhile, the thermal loss of the system can be reduced; and the service life of the overall system is prolonged.

Owner:AISWEI NEW ENERGY TECHNOLOGY (YANGZHONG) CO LTD

laser cutting method

ActiveCN110202271BUniform thermal stressAvoid chippingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The present invention proposes a laser cutting method, which includes the following steps: providing a laser cutting device, the laser cutting device includes a machine table, a transmission mechanism, a cutting mechanism, a static mechanism and a split mechanism, the cutting mechanism includes a mobile platform and a laser cutter, The split mechanism includes a fixed jig and at least one heating laser; the transfer mechanism picks and places the workpiece on the mobile platform; the laser cutter emits a laser beam to pre-cut the workpiece on the mobile platform and form a pre-cut line; the transfer mechanism pre-cuts the workpiece on the mobile platform. The cut workpiece is taken from the mobile platform to the static mechanism and rested for a preset time; the transmission mechanism takes the static workpiece from the static mechanism to the fixed fixture; each heating laser emits a laser beam The workpiece located on the fixed jig is heated along the pre-cutting line, so that the workpiece is split along the pre-cutting line under the impact of thermal stress to realize the cutting of the workpiece. The above-mentioned laser cutting method has a high cutting yield.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

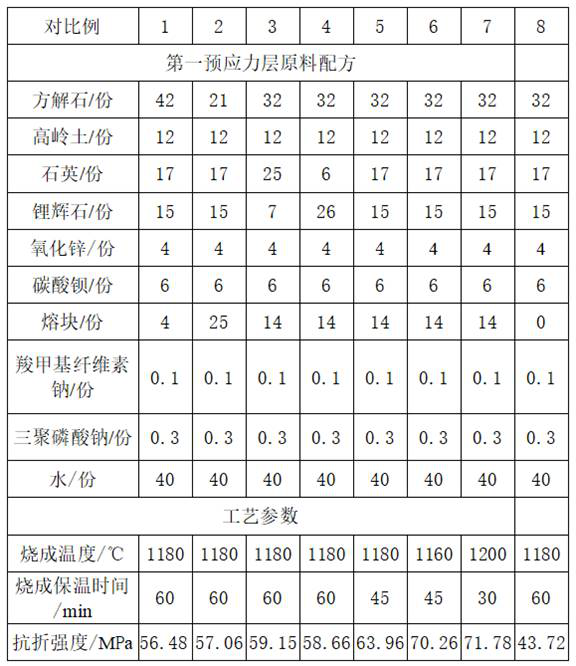

A kind of prestressed ceramics and preparation method thereof

The invention discloses a prestressed ceramic and a preparation method thereof, comprising a green body and a first prestressed layer on the surface of the green body, the thermal expansion coefficient of the first prestressed layer is smaller than that of the green body; the raw material of the first prestressed layer Including calcite, kaolin, quartz, spodumene, zinc oxide, barium carbonate and frit; wherein, the raw materials of frit include kaolin, quartz, talc, dolomite, alumina, zinc oxide, wollastonite and spodumene. In the prestressed ceramics of the present invention, the first prestressed layer is respectively arranged on the surface and the bottom surface of the green body, and when the ceramic is subjected to a certain external tensile stress, it will be offset by the prestressed force of the first prestressed layer, thereby greatly improving The strength and toughness of the ceramics prevent the ceramic structure from being destroyed, and solve the problems of low impact resistance and low strength of the existing ceramics. Preferably, the prestressed ceramics of the present invention belong to the field of architectural ceramics.

Owner:佛山市东鹏陶瓷发展有限公司 +2

Pressure-bearing device with cooling function for supercritical water treatment

InactiveCN101570359BEvenly distributedAvoid direct contactPressure vessels for chemical processWater/sewage treatment by oxidationEngineeringWater treatment

The invention belongs to the field of supercritical water treatment of waste organic substances, and discloses a pressure-bearing device with cooling function for the supercritical water treatment. The device comprises a barrel body (1) and an end cover (2), and is characterized in that the lower surface of the end cover is provided with a concave top cover (4), a cooling cavity (5) is formed by the concave top cover (4) and the lower surface of the end cover (2), the outer wall of the cooling cavity (5) and the inner wall of the barrel body (1) form an annular narrow slit (7), the lateral wall of the cooling cavity (5) is provided with a jet hole (8), and a water inlet (6) of the cooling cavity is arranged on the upper surface of the end cover (2).

Owner:XI AN JIAOTONG UNIV +1

Method for producing large-size thin ceramic bricks by microwave and hot air composite drying

The invention relates to a method for producing large-size thin ceramic bricks by microwave and hot air composite drying, and belongs to the technical field of ceramic brick body dehydration production process. The method has the main technical characteristic that: the ceramic brick body is dried by using microwave and hot air respectively. The method comprises the following steps of: putting theceramic brick body with moisture content of 16 to 18 percent into a microwave drying room to perform drying treatment; and allowing the ceramic brick body to enter a hot air drying room to perform microwave forming drying and hot air dying. The method has the advantages of high drying speed, uniform heating and drying, high forming quality of products, high thermal efficiency, balanced thermal stress, time conservation, and capability of making the ceramic brick body uniformly changed during dehydrating and drying by microwave dehydrating and drying at first, and the method also has the advantage of reducing the dehydrating cost of the ceramic brick body by dehydrating and drying the ceramic brick body with the hot air.

Owner:中国国检测试控股集团陕西有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com