Normalizing equipment of marine nodular cast iron crankshaft

A ductile iron and crankshaft technology is applied in the field of special equipment for heat treatment of normalizing of ductile iron crankshaft castings for marine use, which can solve the problems of workpiece deflection and deformation, uneven cross-sectional structure, differences in structure stress and thermal stress, etc. The effect of uniform stress and tissue stress distribution and uniform material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following, the present invention will be further described in conjunction with the embodiments:

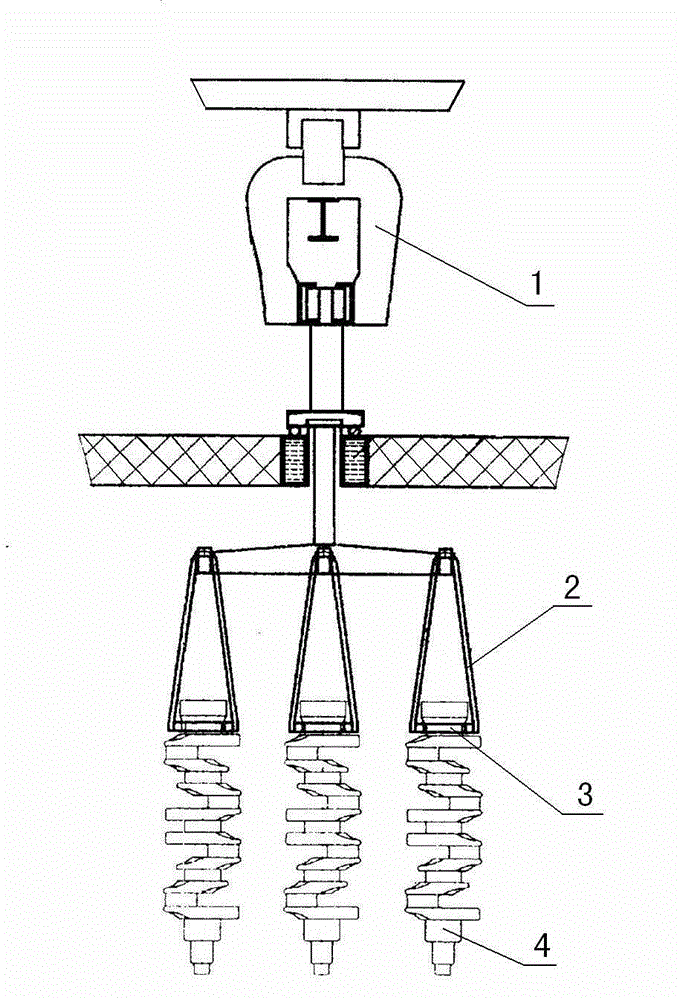

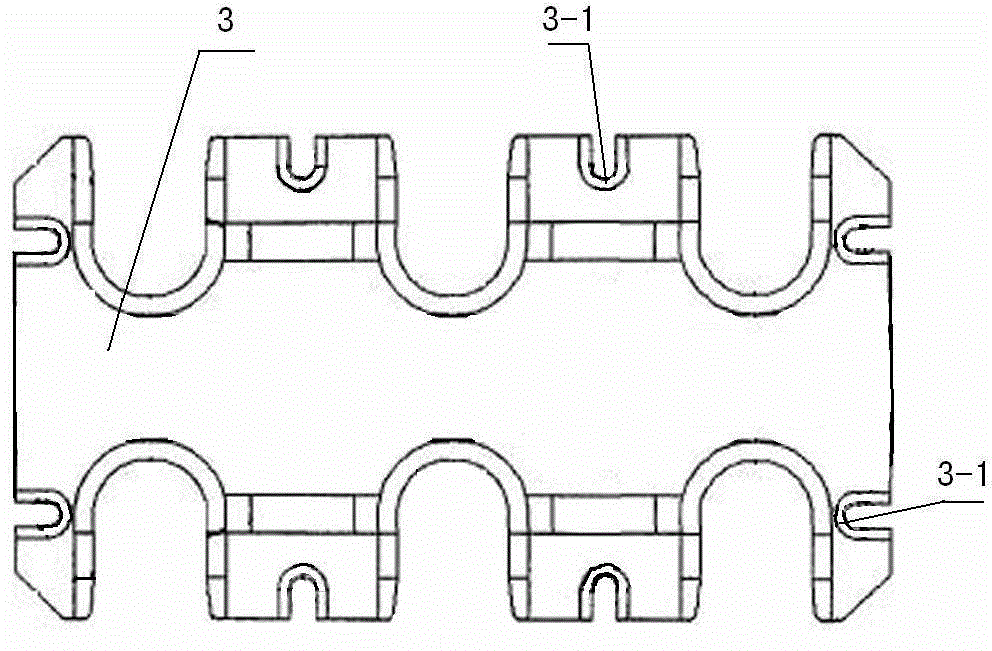

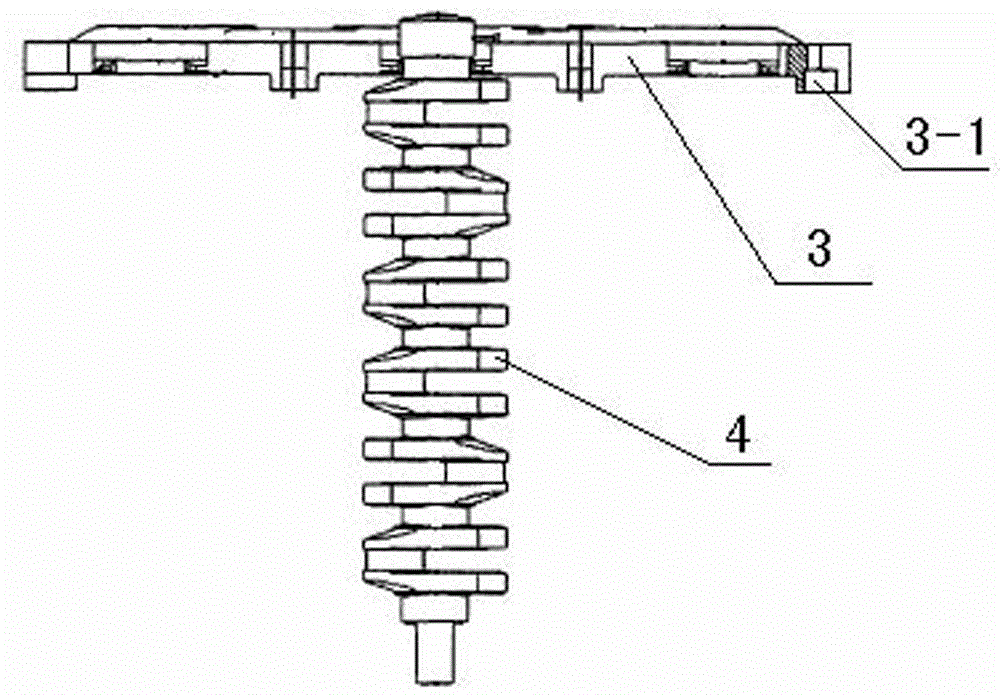

[0013] Figure 1 to Figure 4 The normalizing equipment for marine ductile cast iron crankshafts includes a suspended heating electric furnace with a conveyor chain 1 and an automatic rotary cooling device. The suspended heating electric furnace is provided with a hanging spreader hanging on the conveying chain 1; the hanging spreader includes a boom 2 and a hanging plate 3 with six U-shaped grooves, there are hanging rod holes 3-1 movably assembled with the hanging rod 2 around the hanging plate 3; the automatic rotating cooling device includes a base on which a rotating shaft 5 and a motor 8 are installed 6. The motor 8 is connected to the rotating shaft 5 through a transmission mechanism 7 consisting of a reducer and a transmission gear set; the top of the rotating shaft 5 is provided with a rotating frame 10 for movably connecting with the boom 2, and a tuyere is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com