Drying method and coating film drying furnace for coating film formed on PET film surface

一种干燥方法、膜表面的技术,应用在对表面涂布液体的装置、预处理表面、干燥固体物料等方向,能够解决降低生产率、大量时间、降低层叠工序尺寸精度等问题,达到防止升温、防止扩散的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1)

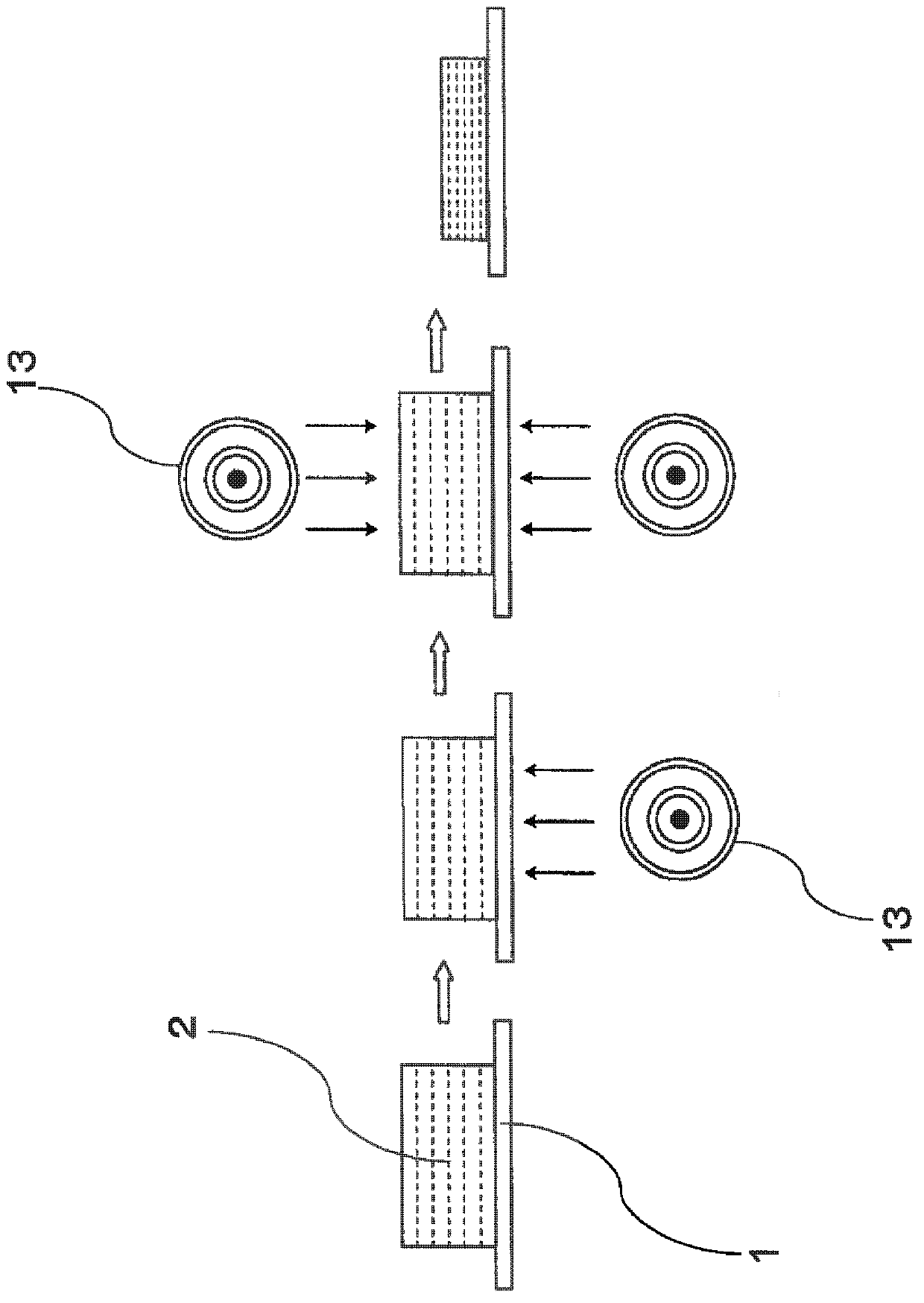

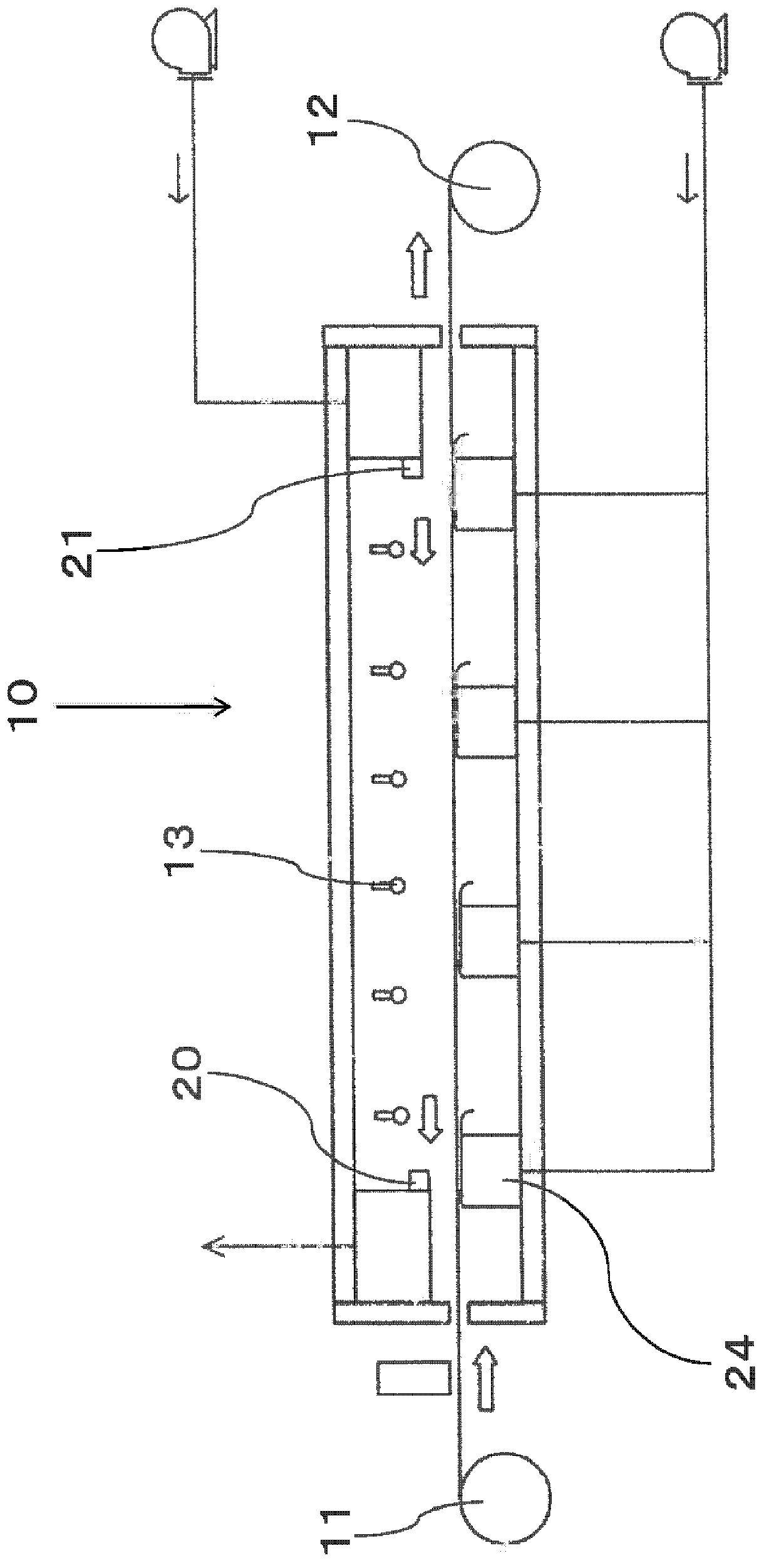

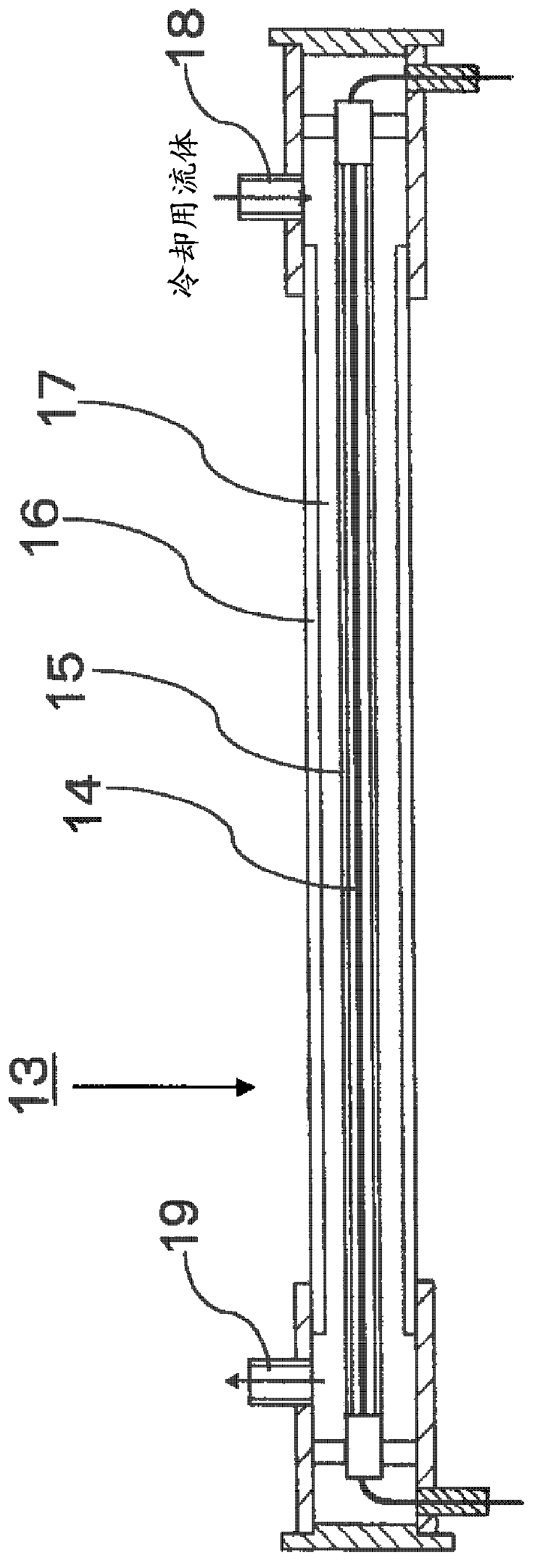

[0029] figure 1 1 is a schematic enlarged cross-sectional view of a coating film, 1 is a PET film (polyethylene terephthalate film) as a base film, and 2 is a coating film formed on the surface. The coating film 2 of this embodiment is obtained by dispersing a solute such as barium titanate powder 3 which is a type of ceramic powder in an organic solvent together with an organic binder, and terpineol or the like is used as the organic solvent. In addition, it is a matter of course that the types of these ceramic powders or organic solvents etc. can be changed depending on the target product.

[0030] In general, water or organic solvents have an absorption spectrum of 3.5 μm or less, so they absorb infrared rays with a dominant wavelength of 3.5 μm or less and are heated and evaporated more efficiently, but PET resins are hardly affected by infrared rays with a dominant wavelength of 3.5 μm or less. The physical properties of the heating. In addition, in figure 1 In the sta...

Embodiment approach 2)

[0056] The present invention is not limited to the above-mentioned Embodiment 1, but can also be applied to a thick film type in which the thickness of the coating film is 100 μm to 2 mm. Embodiment 2 is explained below. The drying oven 10 used is the same as that of the first embodiment described above.

[0057] In embodiment 2, in figure 1 In the state before drying shown on the left, the thickness of the PET film 1 is 10-100 μm, and the thickness of the coating film 2 is 100 μm-2 mm.

[0058] When the coating film formed on the surface of the PET film has a film thickness of 100 μm or more, the temperature of the upper and lower surfaces of the coating film is not uniform during the drying process, and deformation caused by thermal stress is likely to occur. However, in this embodiment, first, only from The back side of the coated PET film is irradiated with infrared rays with a dominant wavelength of 3.5 μm or less, and then the coated PET film is irradiated with infrare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com