Six-phase alternating-current motor variable-frequency speed regulation system and use method thereof

一种交流电机、变频调速的技术,应用在电气元件、机电装置、电动组件等方向,能够解决电机损坏、电解液干枯、铁心和线圈过热等问题,达到提高使用寿命、降低不稳定性、避免受潮的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

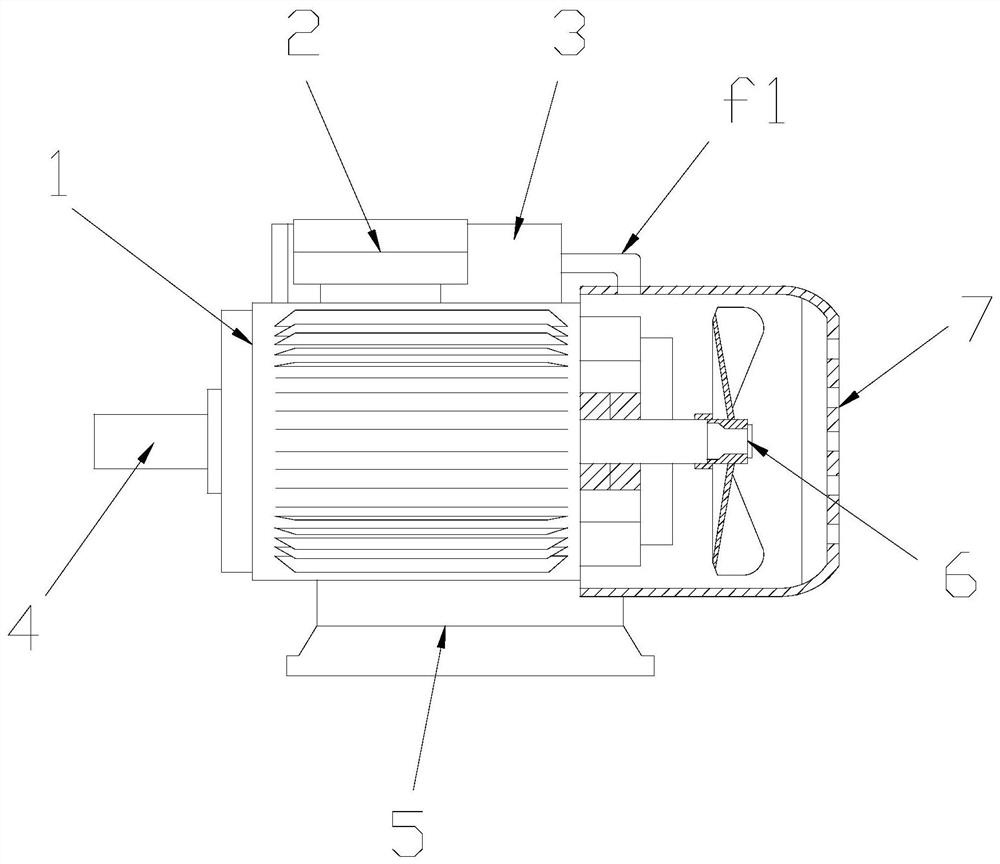

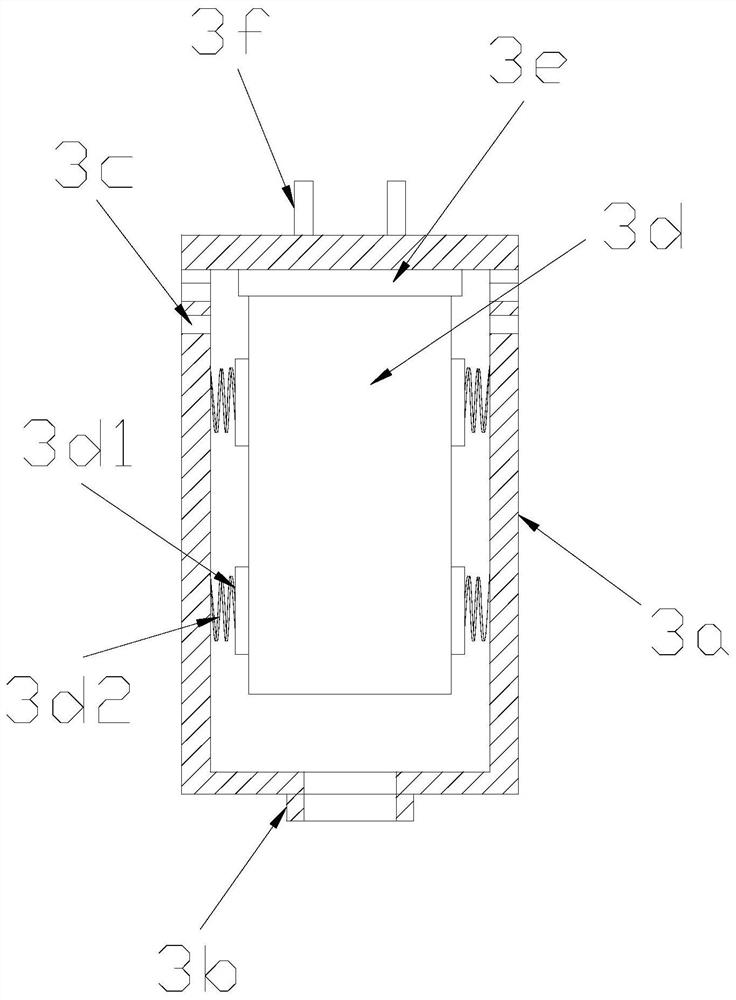

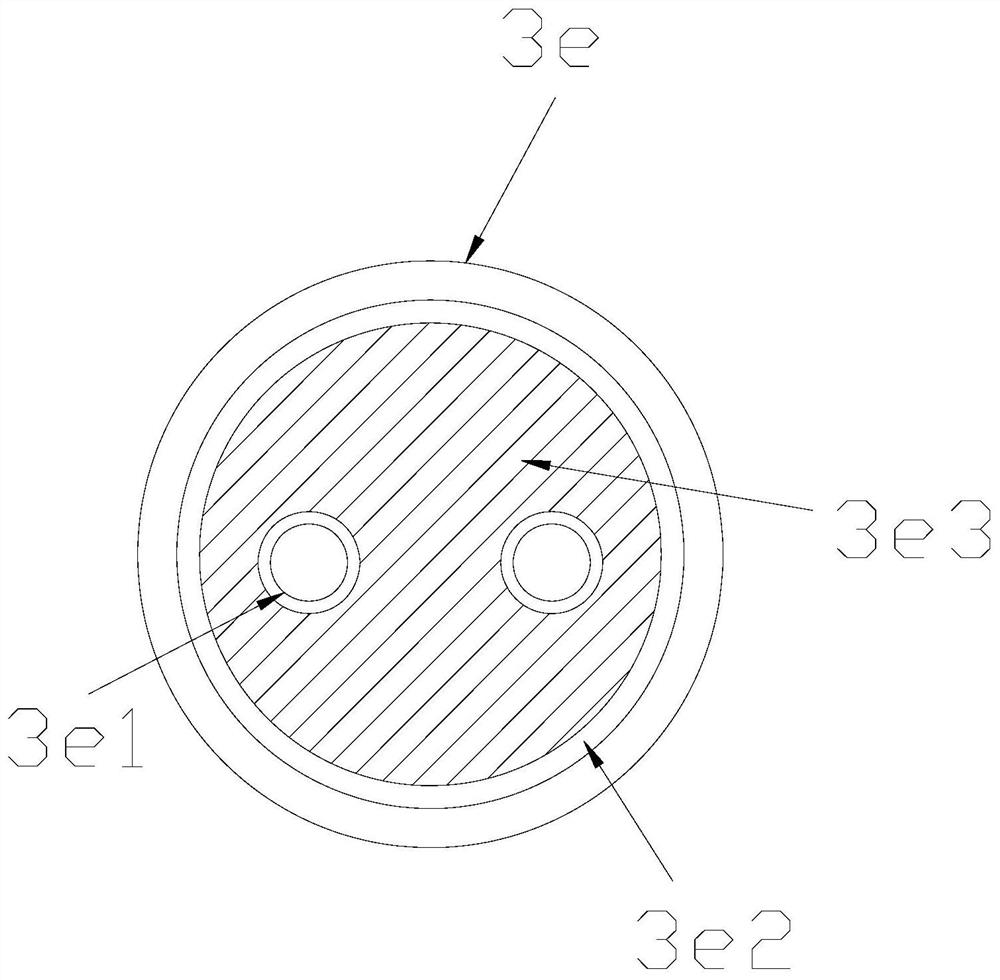

[0029] see Figure 1-Figure 3 , the present invention provides a six-phase AC motor frequency conversion speed regulation system and its use method, its structure includes a six-phase AC motor 1, a frequency converter 2, a capacitor protection mechanism 3, a rotor 4, a base 5, a cooling fan 6, a dust cover 7. A frequency converter 2 is provided on the top of the six-phase AC motor 1, the six-phase AC motor 1 is electrically connected to the frequency converter 2, and a capacitive protection mechanism 3 is installed on the surface of the six-phase AC motor 1, The capacitive protection mechanism 3 is connected with the frequency converter 2, the bottom of the six-phase AC motor 1 is provided with a base 5, the six-phase AC motor 1 and the base 5 are an integrated structure, and the six-phase AC motor 1 and the base 5 are of an integrated structure. A rotor 4 is provided in the middle position of the phase AC motor 1, the six-phase AC motor 1 is mechanically connected to the roto...

Embodiment 2

[0037] see Figure 1-Figure 6 , the present invention provides a six-phase AC motor frequency conversion speed regulation system and its use method. The dust cover 7 is composed of a cover body 7a, an air inlet 7b, a sound insulation layer 7c, a bonding plate 7d, and a water absorption mechanism 7e. The surface of the cover 7a is provided with an air inlet 7b, and the inside of the cover 7a is provided with a bonding plate 7d, and the cover 7a and the bonding plate 7d are connected by a sound insulation layer 7c, and the bonding plate 7d is provided with more than two water absorbing mechanisms 7e, and the above-mentioned laminating plate 7d is fixedly connected with the water absorbing mechanisms 7e.

[0038] The water absorbing mechanism 7e is composed of a supporting ring 7e1, a swinging piece 7e2, a rotating shaft 7e3, a torsion spring 7e4, and a ball dust mechanism 7e5. The inner side of the supporting ring 7e1 is provided with more than two swinging pieces 7e2. Ring 7e1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com