Oil and gas fired boiler having annular combustion chamber

A gas-fired boiler and combustion chamber technology, applied in the field of boilers, to achieve the effect of large variable range, widely popularized and used, and uniform thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

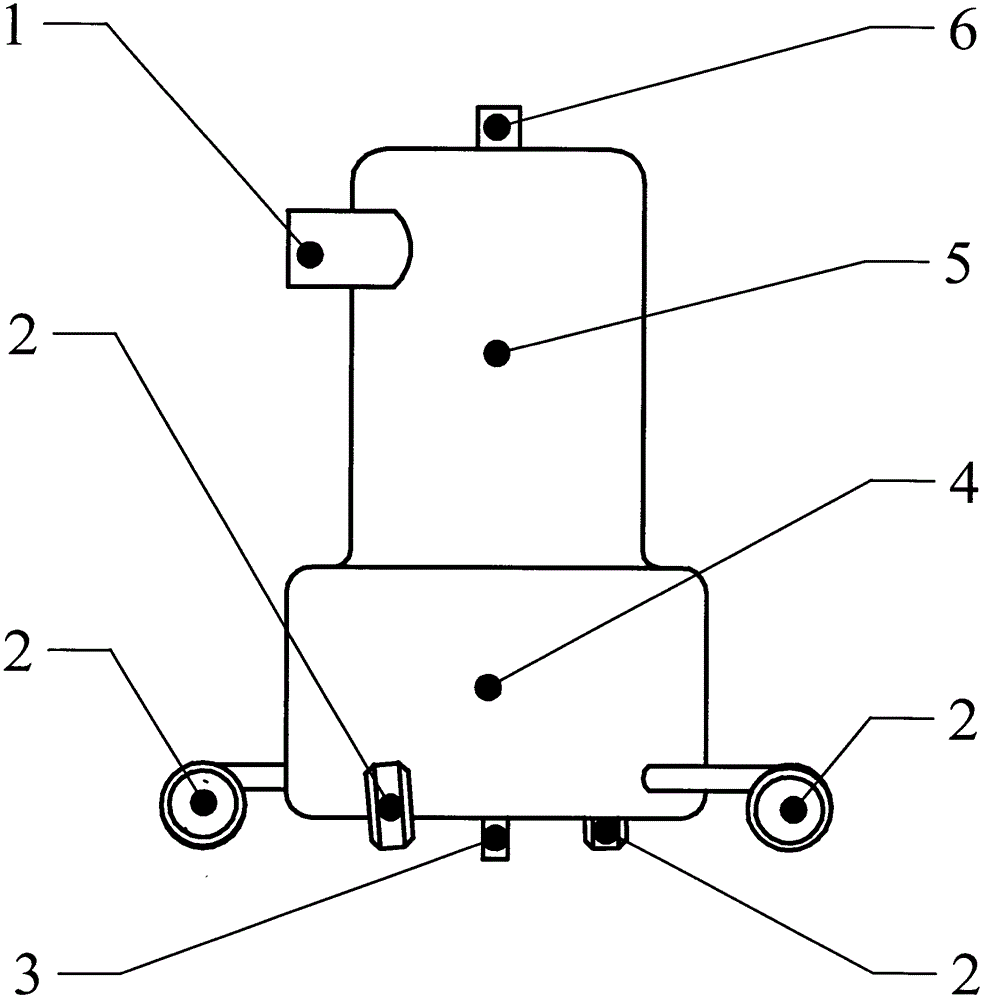

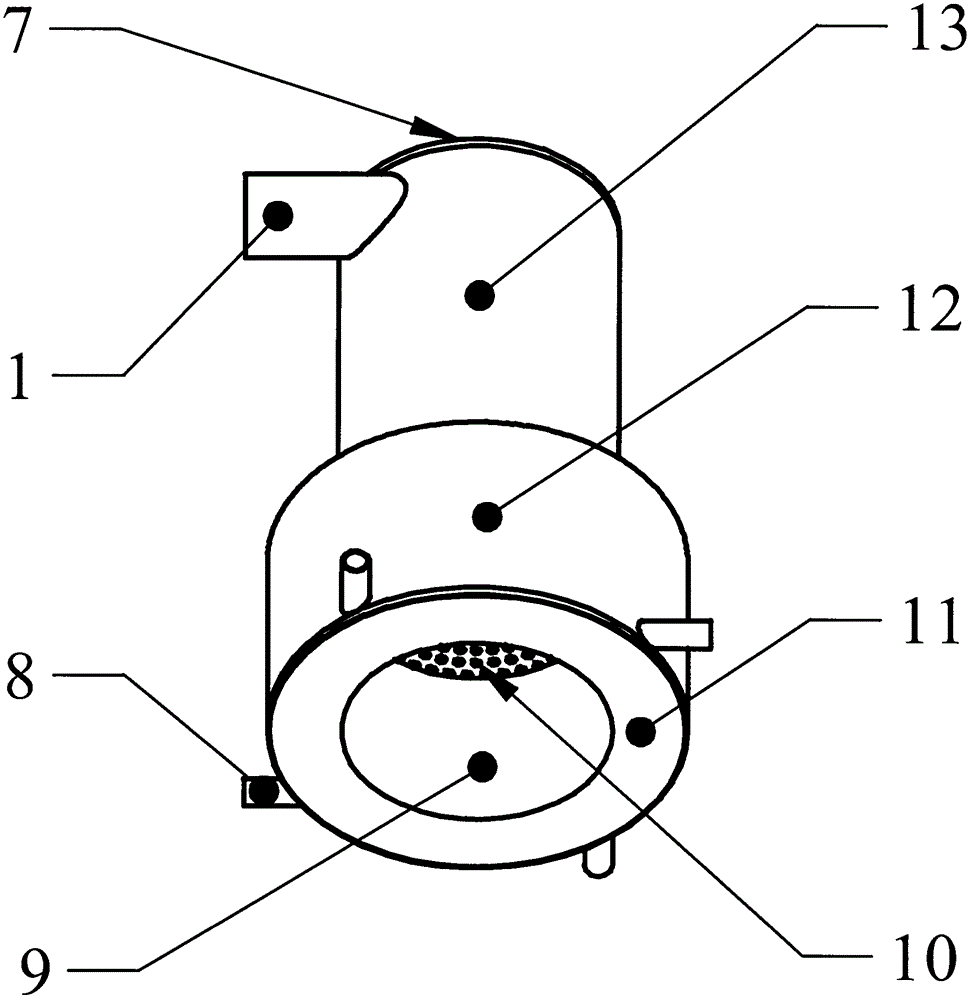

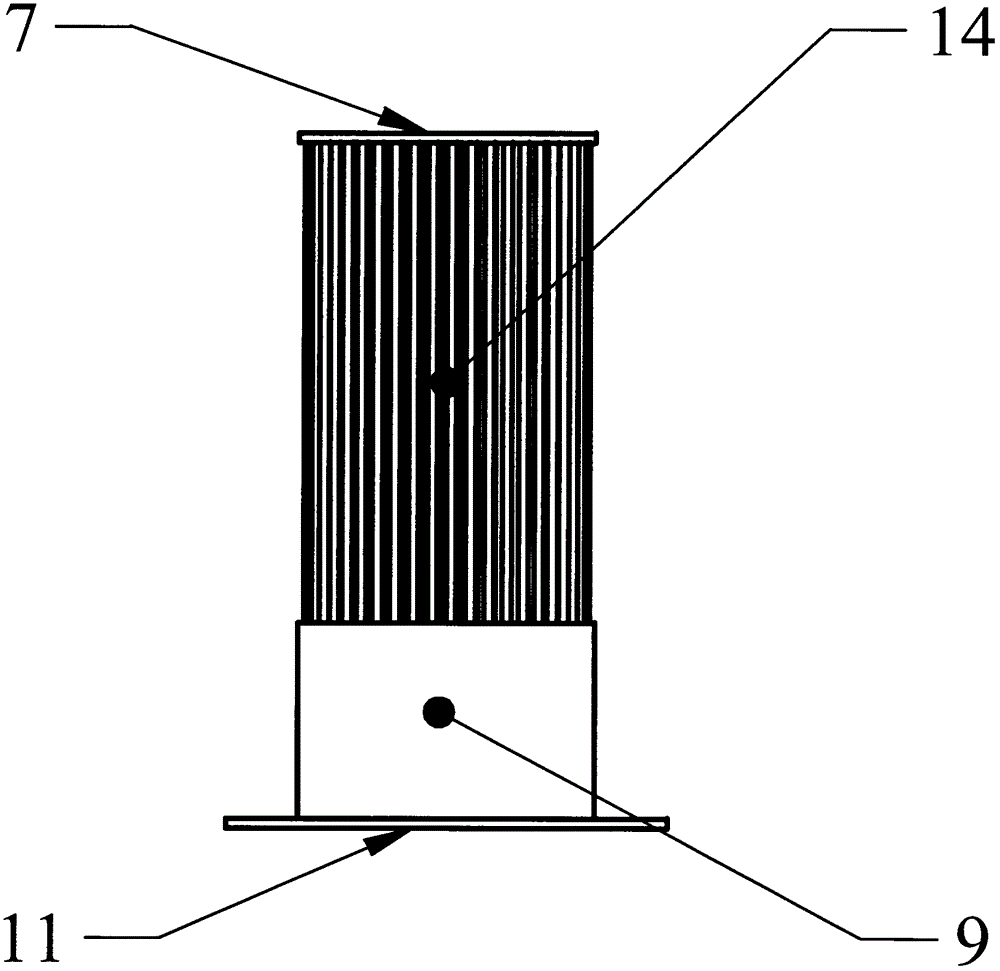

[0017] Embodiment 1: The structure of the fuel-fired gas-fired steam boiler in the annular combustion chamber is as follows figure 1 as shown, figure 2 is the furnace structure diagram, image 3 It is the internal structure diagram of its furnace. The pot shell is arranged upright, four burners 2 are arranged in the same direction along the tangent line of the furnace outside the pot shell, and the furnace is placed in the center of the pot shell. The upper cylinder 5 of the pot shell has an outlet that communicates with the outside of the pot shell and the flue gas discharge pipe 1 in the furnace. There are 4 inlets of pipelines 8 communicating with the outside of the pot shell and the combustion chamber in the furnace gall on the bottom cylinder 4 of the pot shell. The flame injection pipe of the burner 2 is inserted into the combustion chamber through the pipeline 8 connecting the outside of the pot shell and the combustion chamber in the furnace. The pipe 8 connecting...

Embodiment 2

[0019] Example 2: The structure of the fuel-fired gas hot water boiler in the annular combustion chamber is as follows Figure 4 As shown, only one burner is configured due to the small heating power. The water inlet pipe 16 of the hot water boiler is arranged on the top of the pot shell, the water outlet pipe is arranged on the annular combustion chamber, the water outlet pipe leads into the annular hot water tank 15 outside the upper cylinder of the pot shell, and a hot water valve is installed on the hot water tank 15 .

[0020] The working process of embodiment 2 is: the hot water boiler water inlet pipe 16 connects the running water pipe and connects the running water, and the burner ignites and burns. Water temperature just can open the hot water valve on the hot water tank 15 and get hot water when water temperature reaches prescribed temperature. The tap water pipe automatically replenishes water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com