Low-cost high-weldability seal

A weldable, low-cost technology, applied in the field of low-cost high-weldability seals, seals, and seals for aluminum plate-fin heat exchanger core welding, which can solve the problem of affecting the welding of peripheral thin-walled connectors and brazing Soldering qualification rate, affecting product quality and other issues, to achieve the effect of saving brazing power consumption, good weldability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

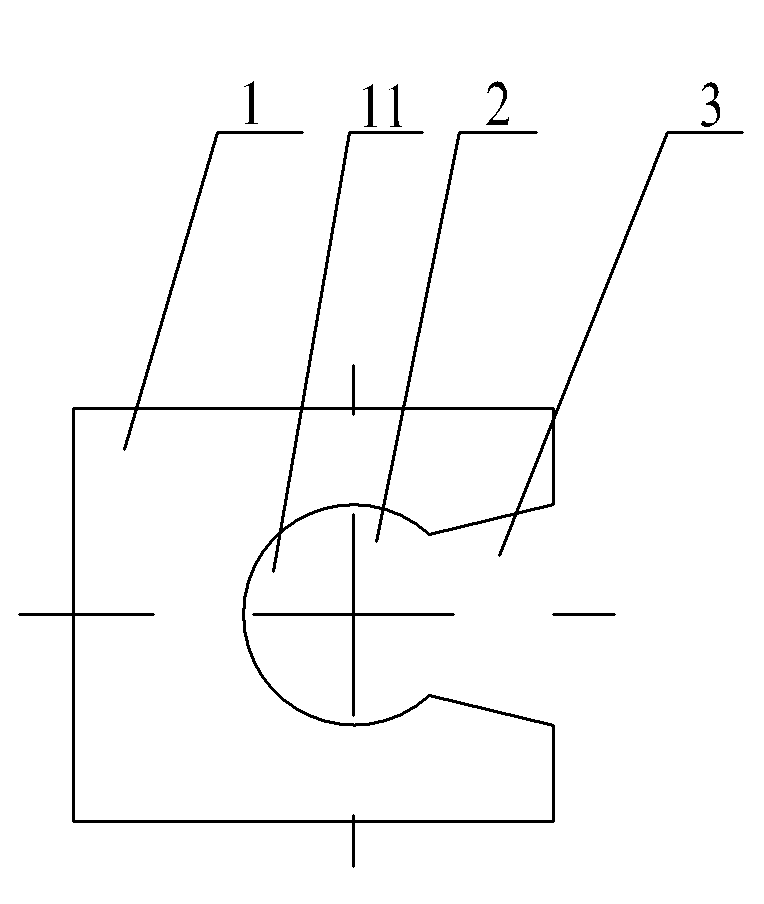

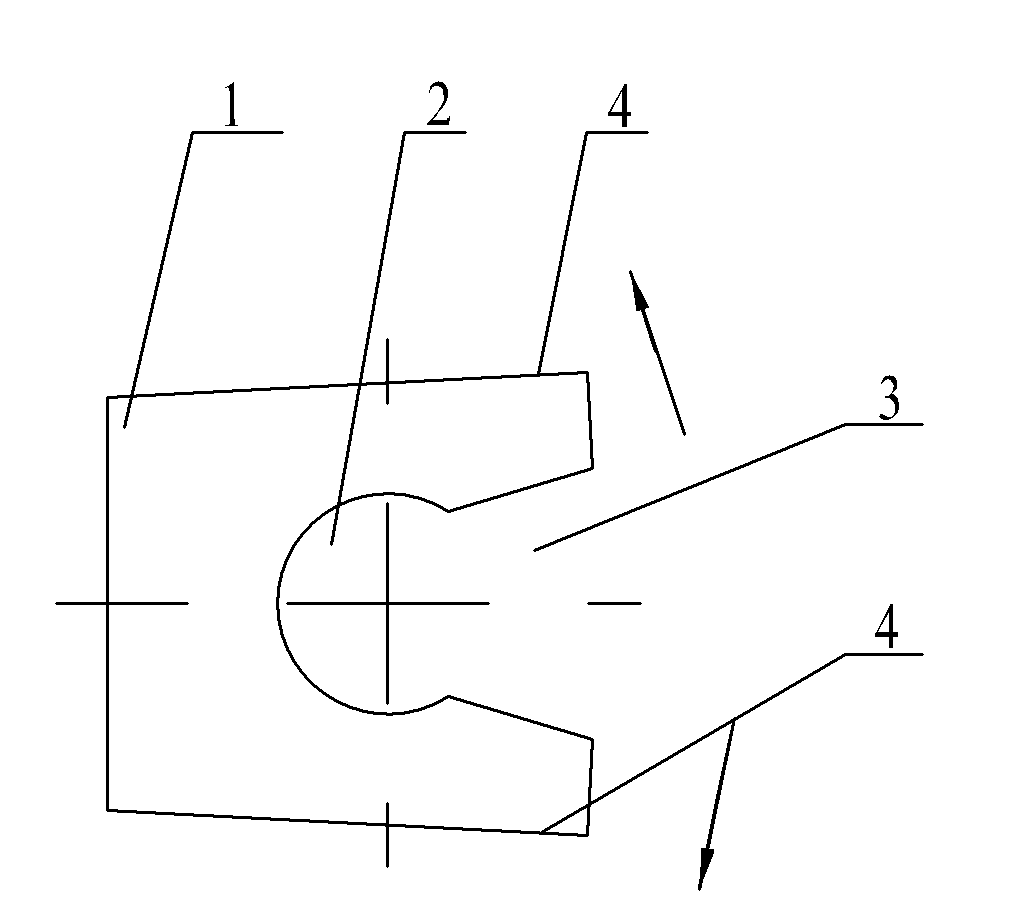

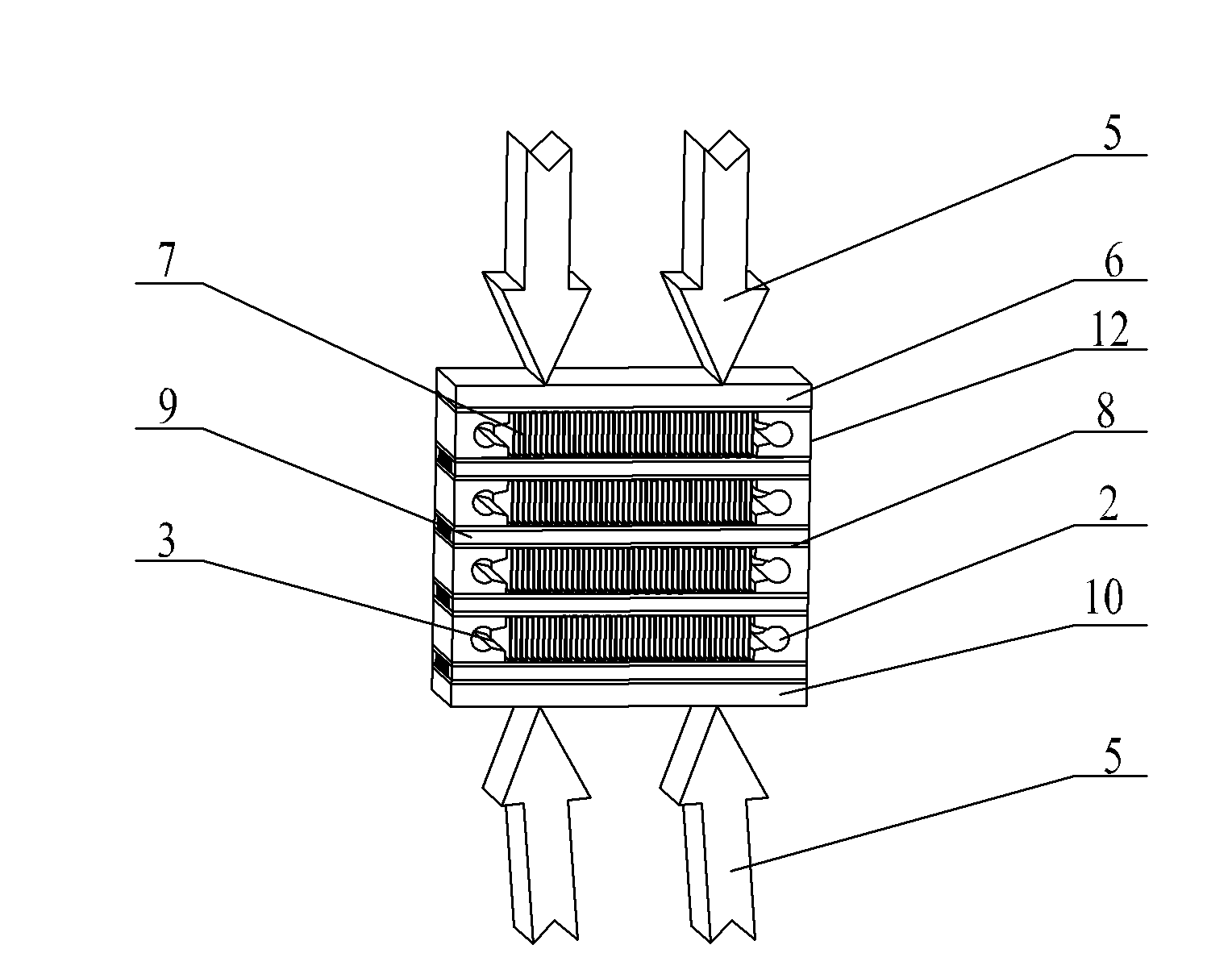

[0014] Such as Figure 1~Figure 3 As shown: the present invention includes a seal body 1, a first adjustment hole 2, a second adjustment hole 3, an opening part 4, a clamping force 5, an upper cover plate 6, fins 7, a partition 8, a hot side heat dissipation part 9, The lower cover plate 10 , the positioning hole 11 and the cold side heat dissipation part 12 .

[0015] Such as figure 1 with figure 2 As shown: In order to ensure the brazing quality of the plate-fin heat exchanger, the seal includes a seal body 1, and the seal body 1 is provided with a through positioning hole 11, and the axis of the positioning hole 11 is located at the axis of the seal body 1. on the same line. There are two openings 4 on the seal body 1 on the side of the positioning hole 11, and the opening end of the positioning hole 11 is formed between the two openings 4; The distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com