Heat exchanger

A technology of heat exchangers and exchangers, applied in the direction of heat exchange equipment, heat exchangers, heat exchanger types, etc., can solve problems such as process and material limitations, increased cooling liquid, and increased specific power of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

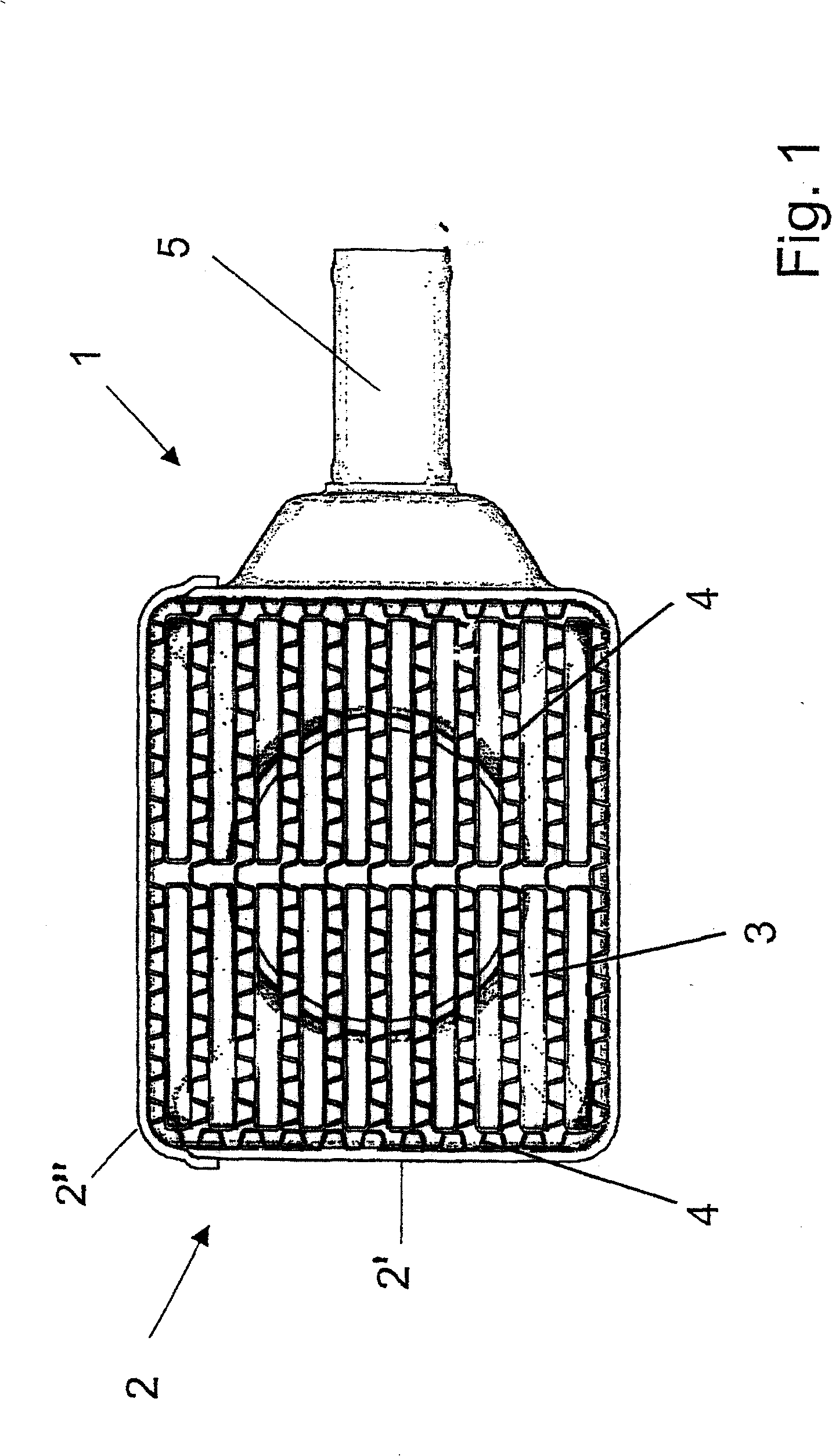

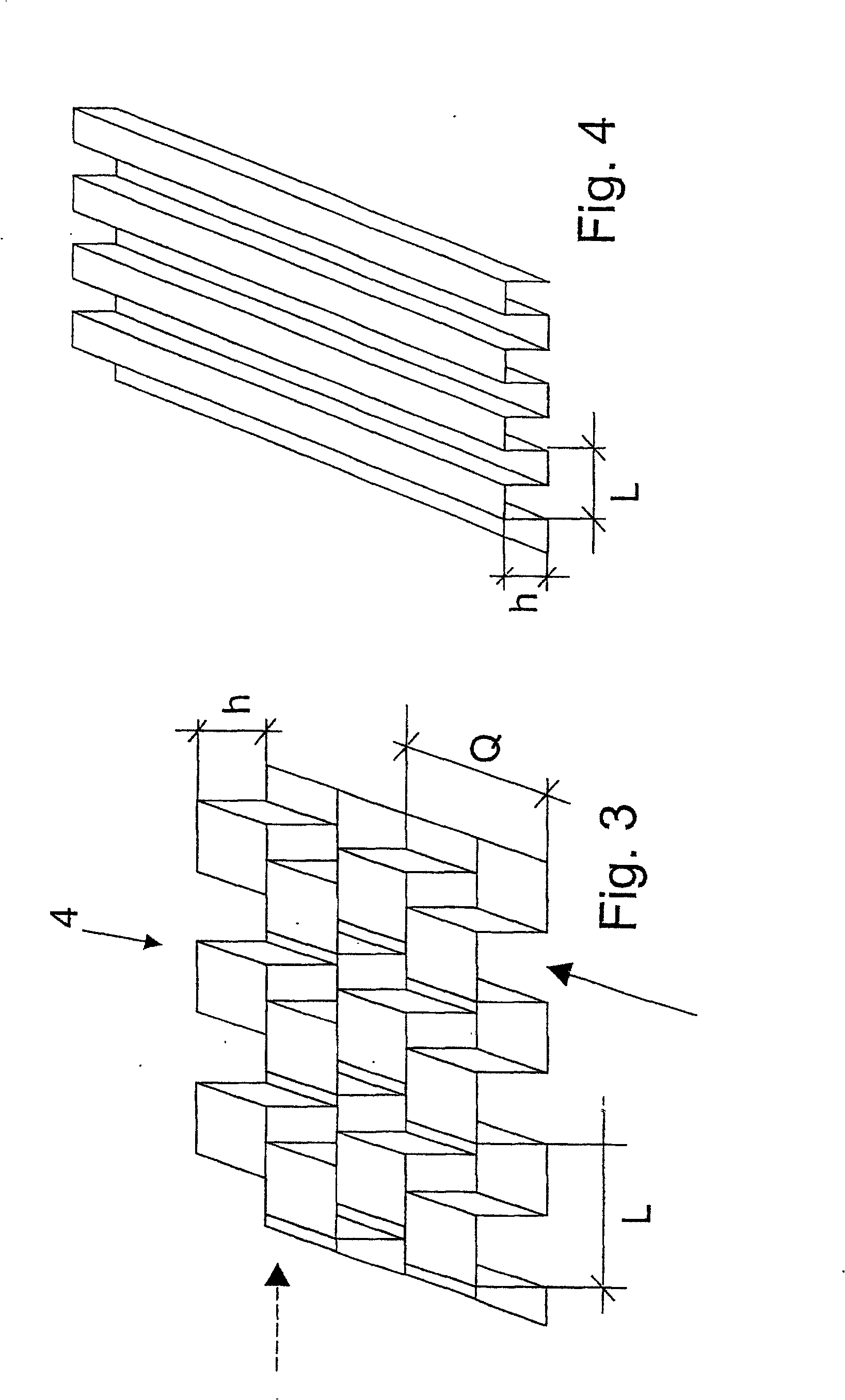

[0021] The exhaust gas heat exchanger 1 has a two-part housing 2 and a plurality of tubes 3 arranged in the housing 2 . Between the tubes 3 and between the housing 2 and the tubes 3 there are finned plates 4 as structural elements, where the finned plates 4 have a saw-toothed structure according to the above-described embodiment, as shown in FIG. 3 , and will This will be described in detail later. Here, the tube 3 is a flat tube.

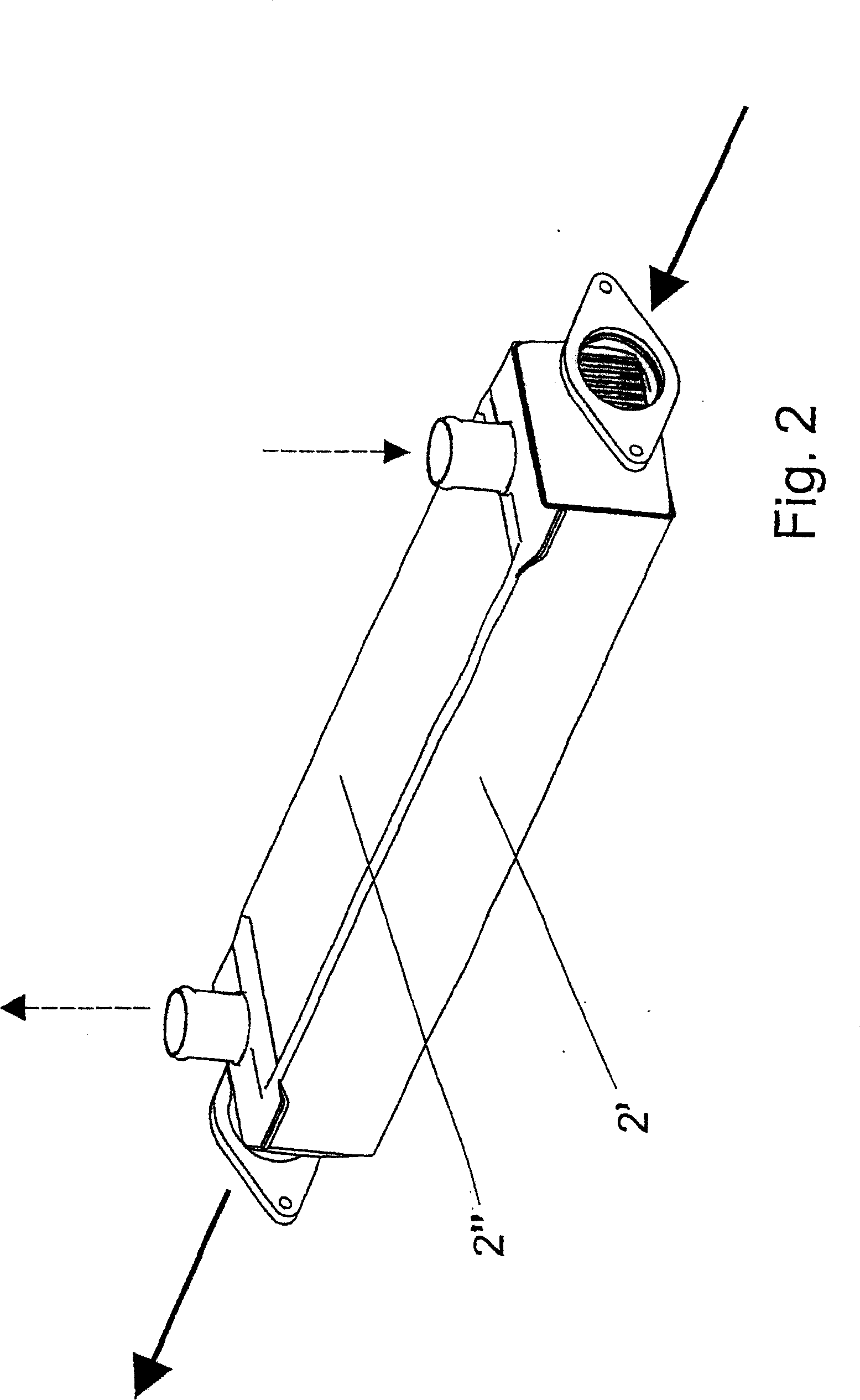

[0022] Exhaust gas from the engine to be cooled (gaseous first medium) flows in the pipe 3 , and in FIG. 2 the direction of flow is indicated by two arrows drawn in solid lines. The tube 3 is arranged in the housing 2 and consists of a U-shaped first housing part 2' and a housing cover 2", wherein the cover is placed on the first housing part 2' from above .In order to allow the coolant (liquid second medium) to flow in and out, two coolant connections 5 are provided in the housing cover 2 ", while in Fig. 2 the flow direction of the coolant in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com