Laser surface strengthening machining device and method for plane type valve sealing surface

A valve sealing and surface strengthening technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of high energy consumption, large dilution rate, and high strengthening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

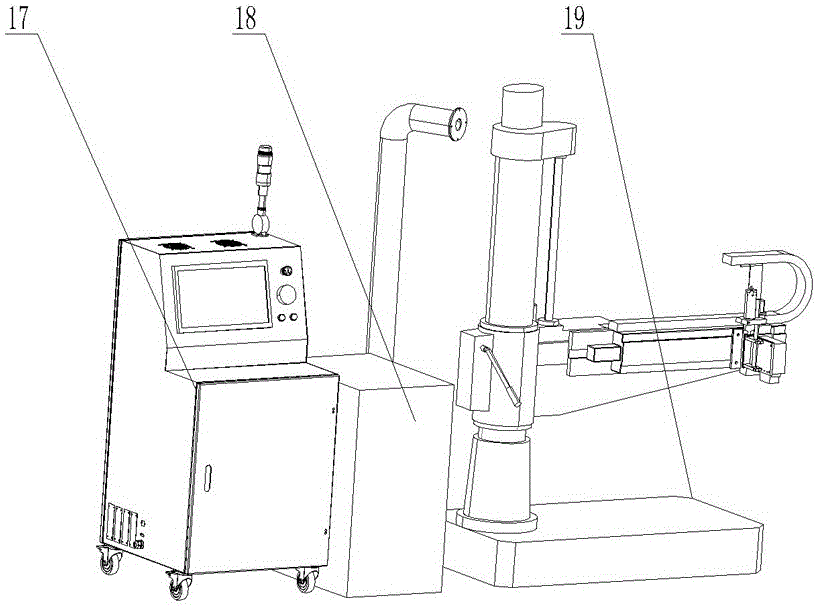

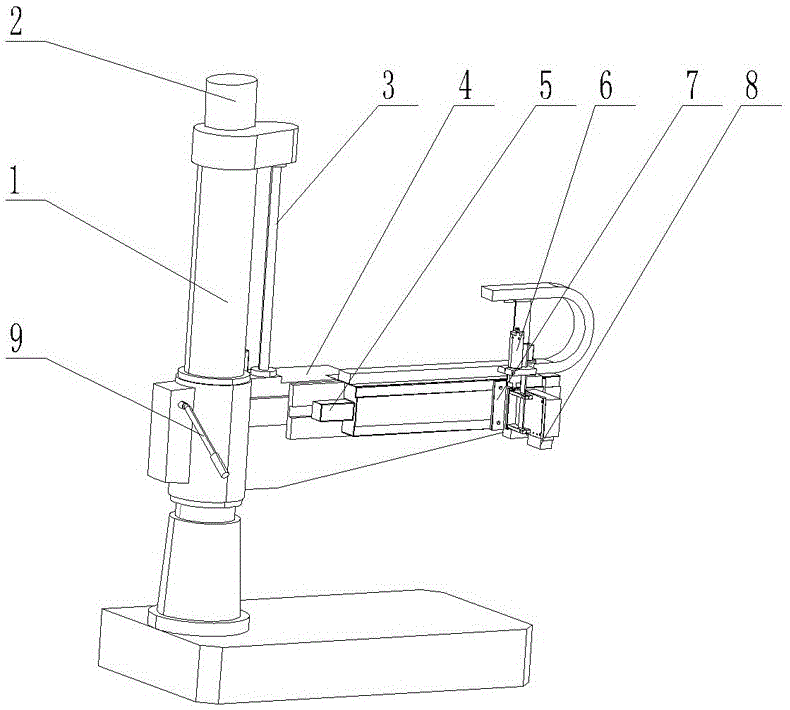

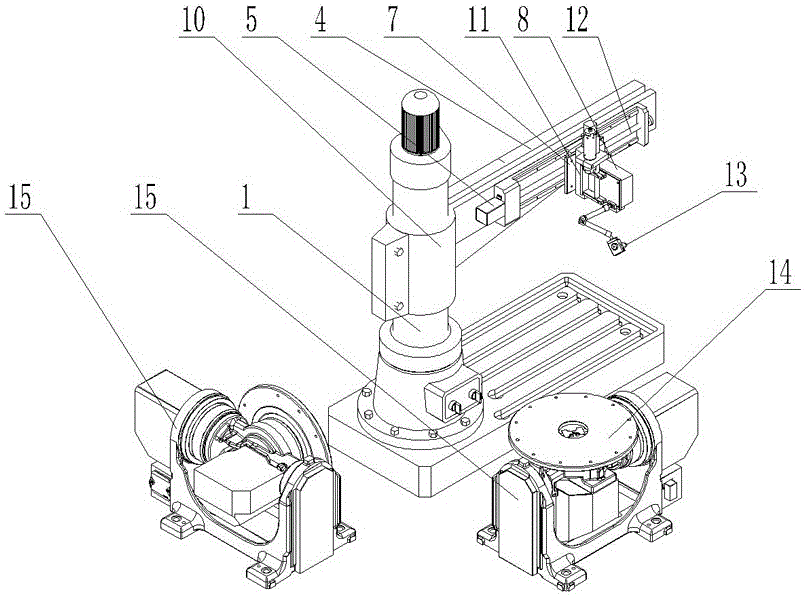

[0028] Referring to the accompanying drawings, this laser surface strengthening processing equipment for the sealing surface of flat valves includes a control cabinet 17, a powder feeding device 18 and a laser processing device 19, the control cabinet 17 is provided with a controller, and the laser processing The device 19 has a column, and the column 1 is equipped with a rocker arm 4 that can rotate in all directions through a shaft sleeve 10, wherein the rocker arm 4 can be rotated manually or electrically; A fastening bolt 9 is arranged on the sleeve 10, and when the rocking arm 4 is manually rotated to a certain position, the bolt 4 is tightened to fix the rocking arm 4. When electric rotation, be that the sleeve 10 of rocking arm 4 on described column 1 is connected with a driving device transmission transmission, this driving device can be motor, utilizes the rotating shaft transmission connection gear of motor, in the sleeve of rocking arm A ring gear with external teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com