A kind of prestressed ceramics and preparation method thereof

A prestressing and prestressing layer technology, applied in the field of architectural ceramics, can solve the problems of low strength and low impact resistance, and achieve the effects of high strength, improved prestress and uniform thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A kind of preparation method of prestressed ceramics, for above-mentioned prestressed ceramics, this preparation method comprises the following steps:

[0051] (1) Burn the frit;

[0052] (2) Mix the fired frit and other raw materials of the prestressed layer, add water and ball mill, and ball mill to obtain the prestressed glaze slurry,

[0053] (3) Apply the prestressed glaze slurry to the surface of the body to obtain the first prestressed layer, or use the prestressed glaze slurry to make a prestressed powder using a spray drying tower, and distribute the prestressed powder on the surface of the blank , press molding to obtain a green body and form a first prestressed layer on the surface of the green body;

[0054] (4) Firing the semi-finished ceramics obtained in step (3) to obtain prestressed ceramics.

[0055] Specifically, in step (2), the prestressed glaze slurry after ball milling is passed through a 100-mesh sieve, and the water content of the prepared pre...

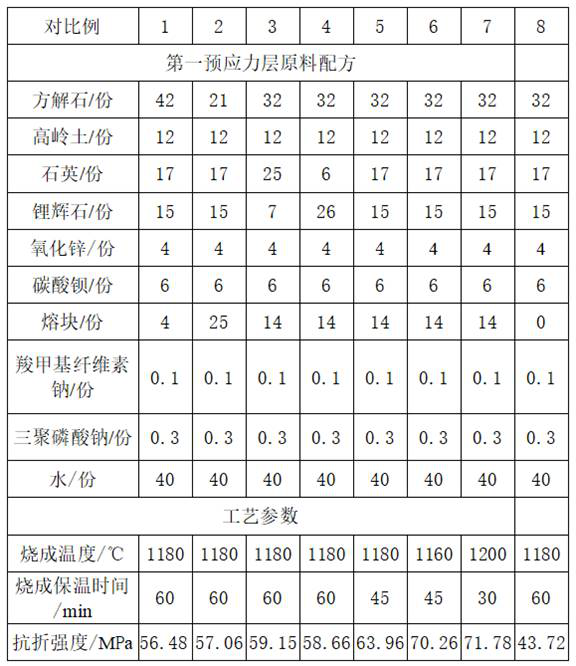

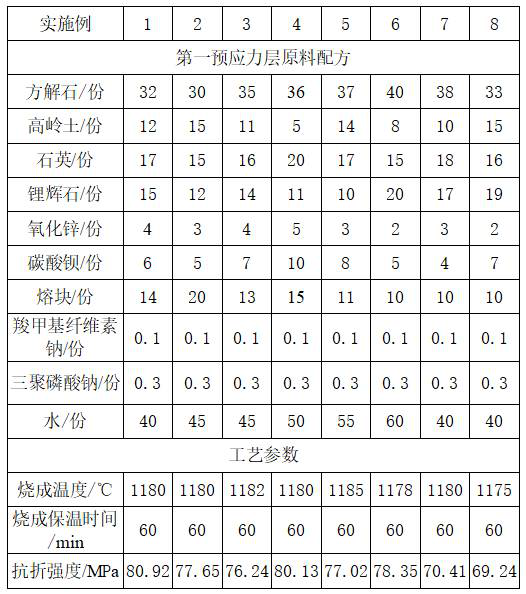

Embodiment 1-8

[0070] A kind of prestressed ceramics, the prestressed ceramics includes a green body and a first prestressed layer located on the surface of the adobe, the raw materials of the first prestressed layer include calcite, kaolin, quartz, spodumene, zinc oxide, barium carbonate and The frit, the thickness of the first prestressed layer is 270 μm. Wherein, the raw material formula ratio of the first prestressed layer is shown in Table 1 below.

[0071] In parts by weight, the raw materials of the frit are 15 parts of kaolin, 15 parts of quartz, 12 parts of talc, 17 parts of dolomite, 8 parts of aluminum oxide, 3 parts of zinc oxide, 13 parts of wollastonite and 8 parts of spodumene.

[0072] The preparation method of the prestressed ceramics comprises the following steps:

[0073] (1) Fire the frit at 1520°C and keep it warm for 30 minutes;

[0074] (2) Mix the fired frit and other raw materials of the prestressed layer, add water and ball mill, and ball mill to obtain a prestres...

Embodiment 9-10

[0082] The formula of the first prestressed layer in the present embodiment 9-10 is identical with embodiment 1-2, and difference is that the preparation method of embodiment 9-10 is different from embodiment 1-2, and the preparation method of implementation 9-10 Include the following steps:

[0083] (1) Fire the frit at 1520°C and keep it warm for 30 minutes;

[0084] (2) Mix the fired frit and other raw materials of the prestressed layer, add water and ball mill, and ball mill to obtain the prestressed glaze slurry;

[0085] (3) The prestressed glaze slurry is made into prestressed powder by spray drying tower, and the fineness of prestressed powder is 250;

[0086] (4) Applying the prestressed powder on the surface of the blank, pressing and forming it by means of cloth, to obtain the blank and form a first prestressed layer on the surface of the blank;

[0087] (5) Fire the semi-finished ceramics obtained in step (4), and heat them at 573° C. for 20 minutes and 1180° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com