Patents

Literature

43results about How to "Reduce construction safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase-change hydraulic fracturing technology

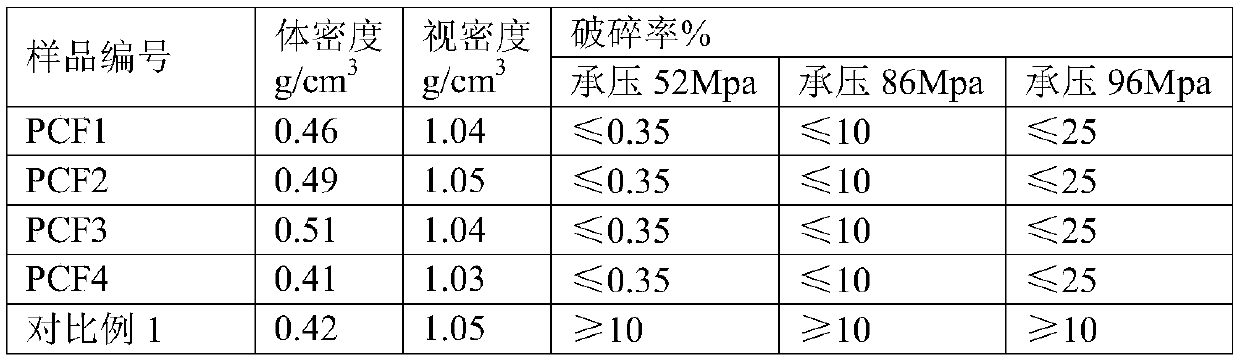

ActiveCN105971579AReduce frictionLower requirementFluid removalDrilling compositionActive agentSeawater

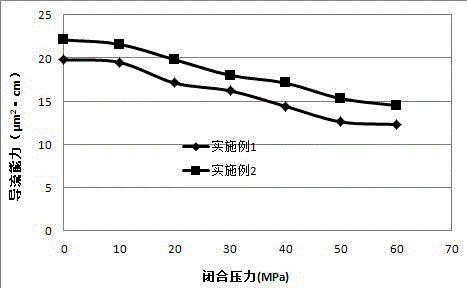

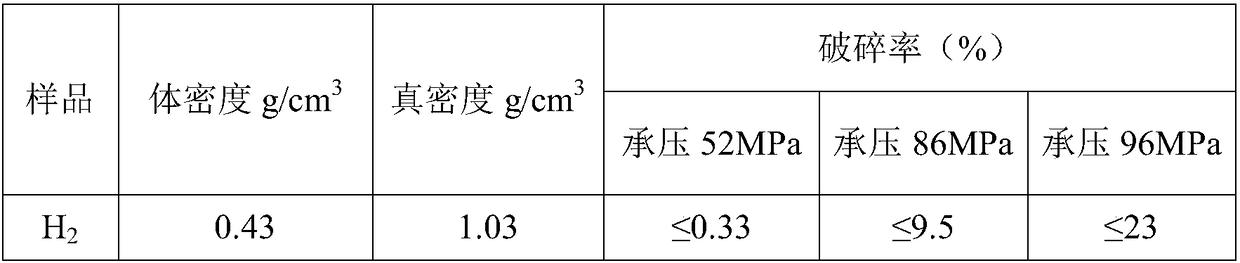

The invention discloses a phase-change hydraulic fracturing technology. The technology includes the steps that firstly, clean water or conventional fracturing fluid is injected to a stratum, so that the stratum cracks; secondly, non-phase-change liquid M and phase-change liquid N are placed in different liquid mixing tanks and injected into a shaft at the same time, wherein the injection volume ratio of the liquid M to the liquid N is (0-0.7):(0.3-1); thirdly, displacement fluid is injected into the shaft, so that the non-phase-change liquid M and the phase-change liquid N in the shaft completely enter a reservoir; fourthly, well shut-in and pressure building are conducted for 30-200 min, so that solid-phase matter generated by the phase-change liquid N is laid in cracks; fifthly, decompression is conducted, and construction is finished. The liquid M is conventional fracturing fluid, seawater, stratum water or ground fresh water, and the liquid N is composed of a super-molecular construction unit, surfactant, inorganic salt, oxidant and the like. Channels and ditches for underground oil gas seepage can be formed without solid supporting agents, flow guide capacity of hydraulic fracturing cracks is greatly improved, and the technology is simple, safe and efficient in construction operation.

Owner:PETROCHINA CO LTD +1

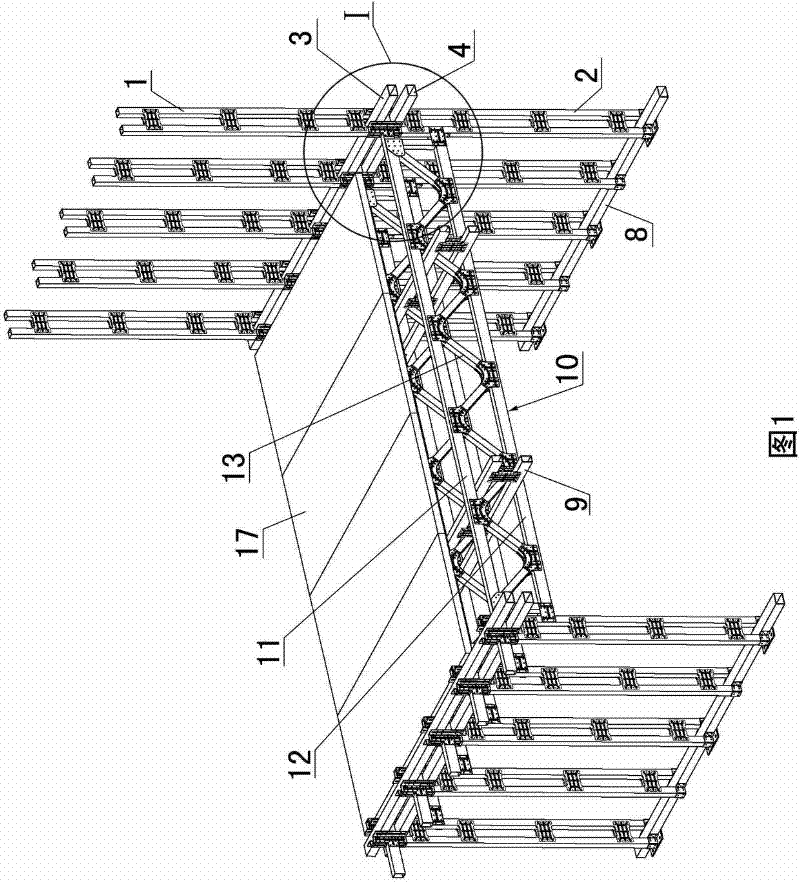

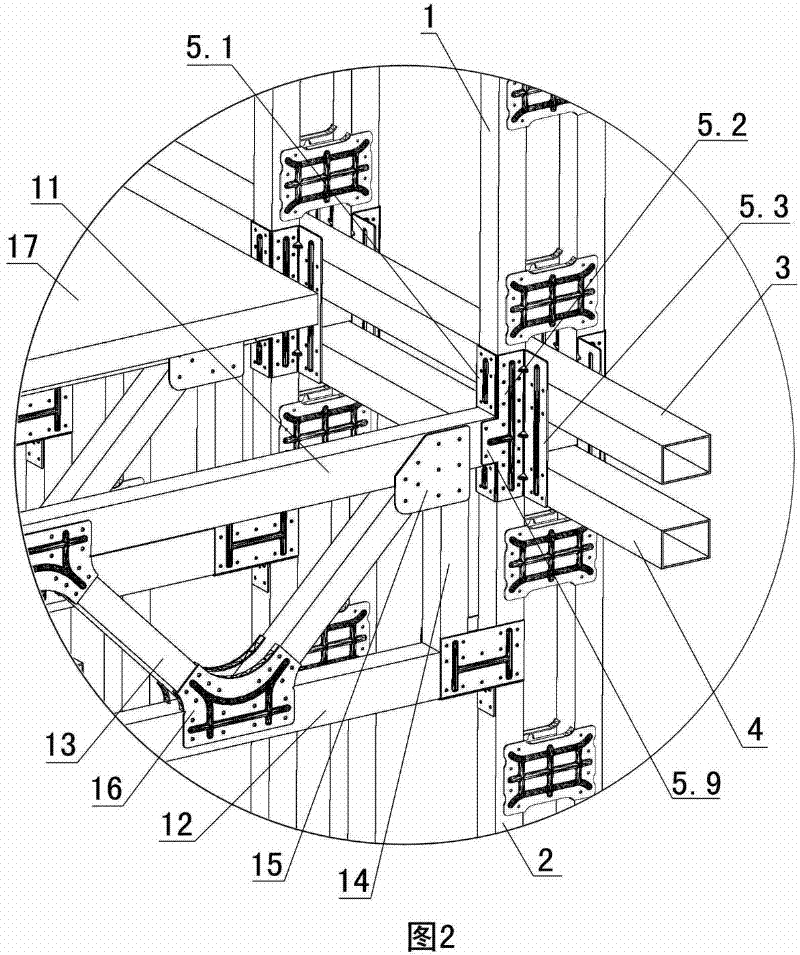

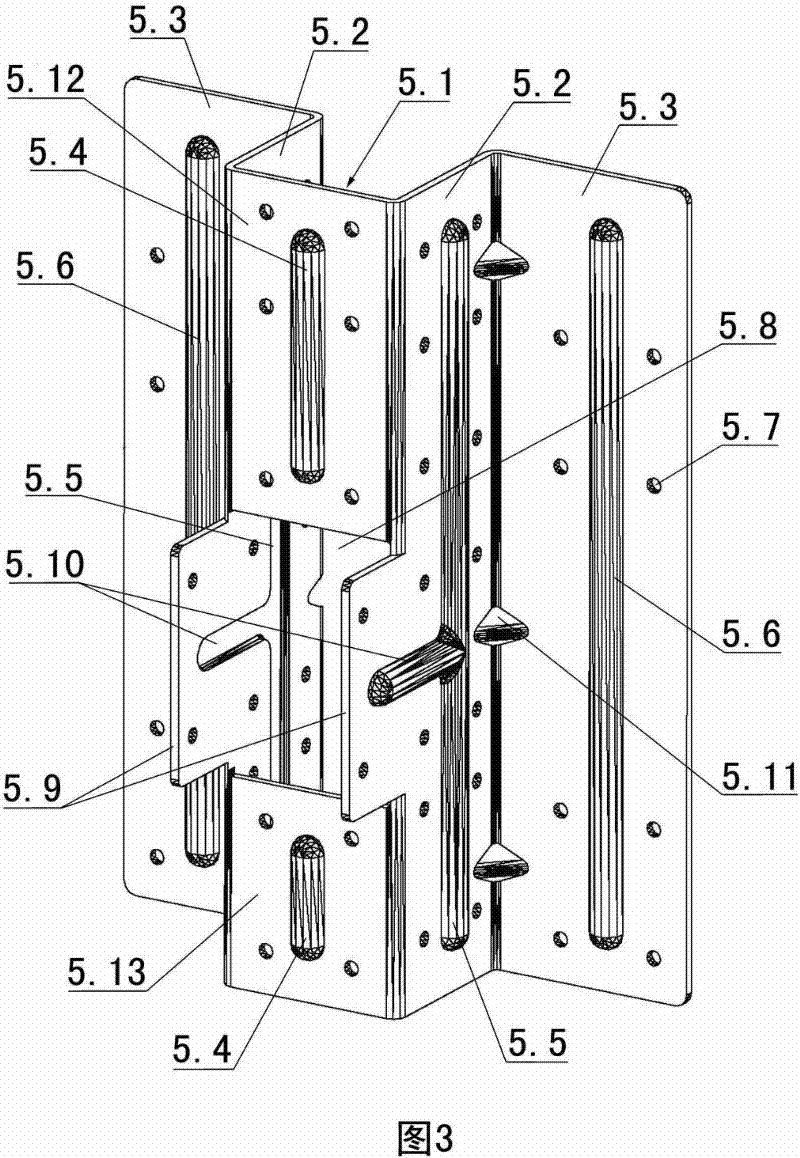

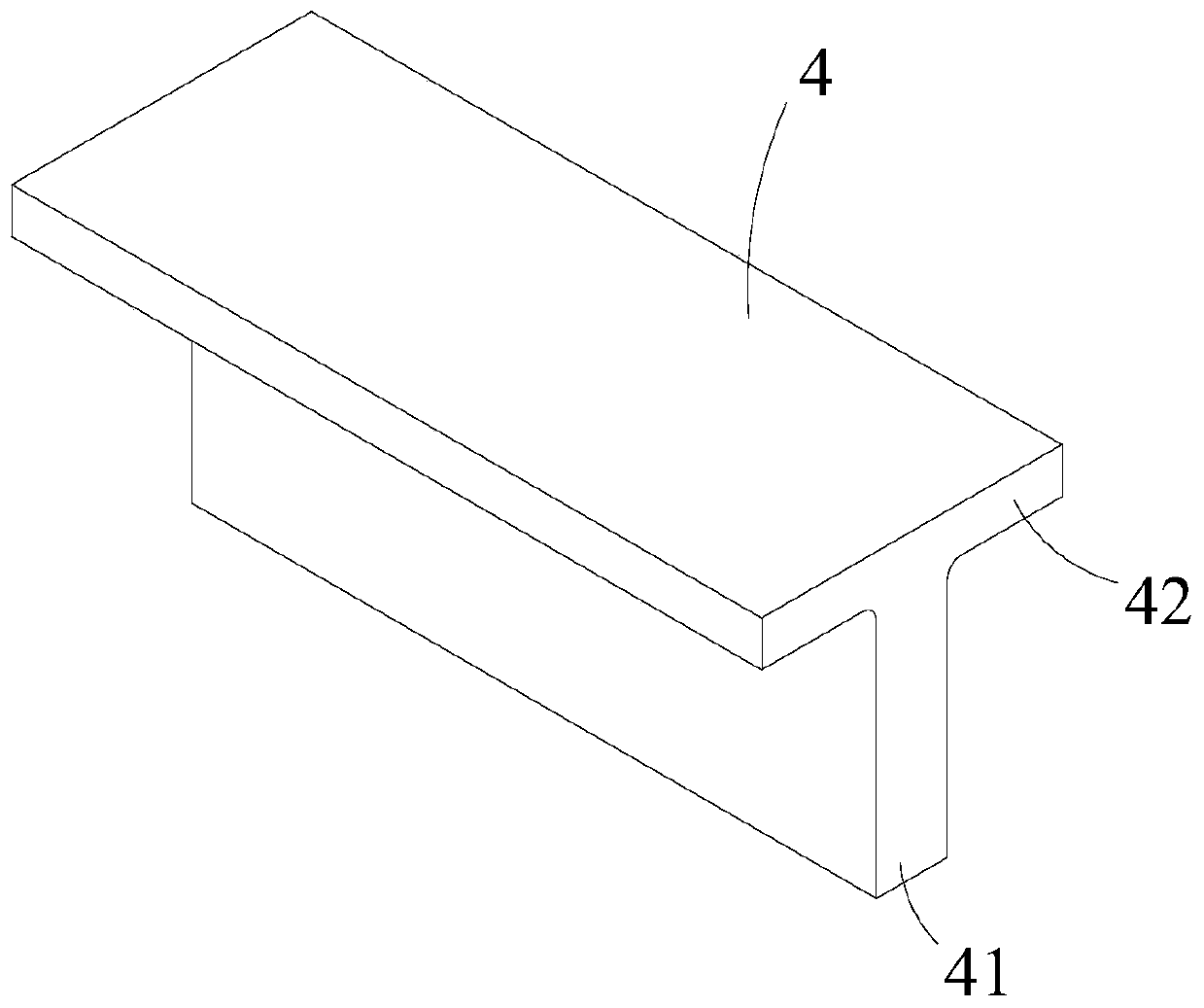

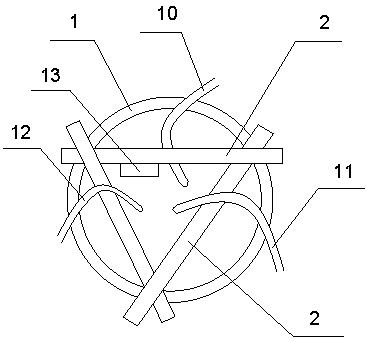

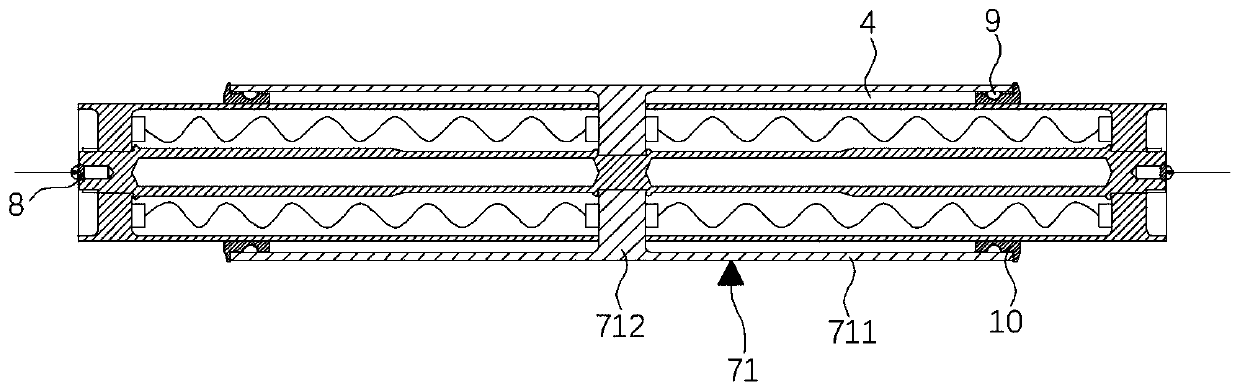

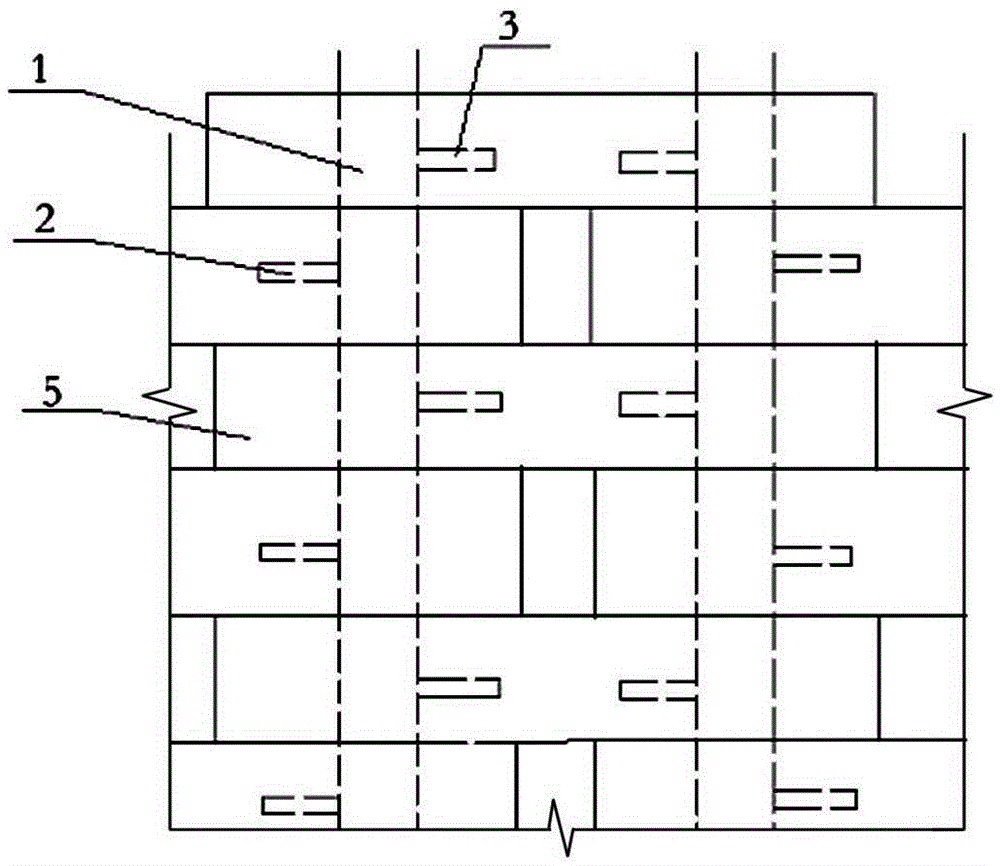

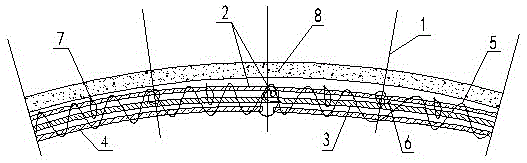

Truss combined beam and upper and layer connected light steel structure and construction method thereof

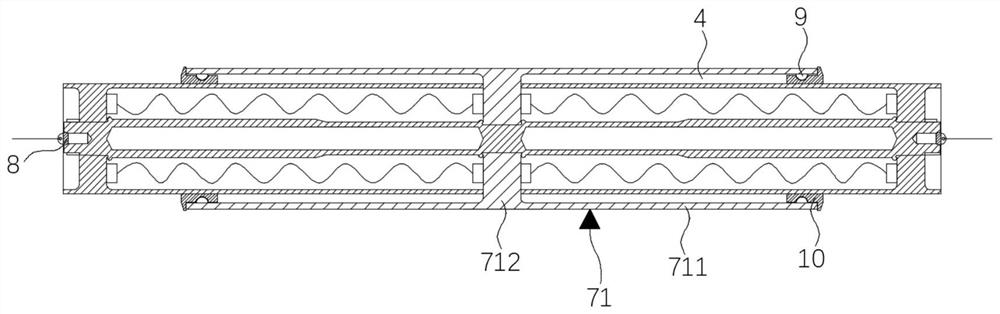

InactiveCN102359180ATroubleshoot simultaneous connectionsSolve the shortcomings that the pressure is not easy to meet the force requirementsGirdersJoistsRear quarterKeel

The invention discloses a truss combined beam and upper and layer connected light steel structure and a construction method thereof. The light steel structure comprises upper wall sheet columns distributed at intervals, lower wall sheet columns distributed at intervals, upper wall sheet column lower connecting pipes connected among the lower parts of the upper wall sheet columns, lower wall sheet column upper connecting pipes connected among the upper parts of the lower wall sheet columns, and truss combined beams connected between the upper wall sheet columns and the lower wall sheet columns through upper and lower connectors, wherein the upper and lower connectors are beam passing buckles, the web plates of the beam passing buckles consist of upper web plates and lower web plates, a square connecting port is formed between the upper web plates and the lower web plates, upper chord member connecting plates are extended from the left and right sides of the square connecting ports, and the upper chord member connecting plates and side plates of the beam passing buckles are positioned in the same plane. Through the light steel structure, the structural stability of a light steel keel house system is enhanced, and the floor surface beams, the connecting pipes and the floor panels do not easily vibrate.

Owner:筑巢(北京)科技有限公司

Phase change fracturing method

ActiveCN108561111ALow viscosityShorten the timeFluid removalDrilling compositionTime delaysFracturing fluid

The invention provides a phase change fracturing method. The method includes the following steps that a fracturing fluid is injected into a stratum to generate cracks in the stratum, and injection ofthe fracturing fluid is stopped after the to-be-generated cracks reach preset requirements; a phase change reaction liquid and a time delay heat generating agent which can be subjected to a phase change reaction at preset temperature are injected into the stratum; after injection of the phase change material liquid is substantially completed, the time delay heat generating agent exerts a heat generating action to make phase change of the phase change material liquid to complete phase change fracturing. According to the provided technical scheme, since there is no solid phase injection, not only can the friction resistance of tubular columns be effectively reduced, but also the happening time and progress of the phase change reaction can be effectively controlled due to the use of the delayheat generating agent, so that a better fracturing effect is achieved. Especially for low-temperature reservoirs, a heat generation effect of the delay heat generating agent greatly increases the rate of the phase change reaction so that the phase change material liquid can rapidly form a solid phase at a preset position, the phase change time is shortened, and the probability of successful construction is increased.

Owner:PETROCHINA CO LTD

Sieving pipe sand preventing process

ActiveCN107575186AImprove protectionNo pollution in the processFluid removalDrilling compositionSoil scienceFracturing fluid

The invention discloses a sieving pipe sand preventing process. The sieving pipe sand preventing process comprises the steps that (1), well input fluid is prepared; (2), construction programs are selected: reservoir stratum non-pressing-open sieving pipe sand prevention is selected for wells with less output sand and wells with tubular columns which cannot bear high pressure, and reservoir stratumpressing-open sand prevention is selected for wells with serious cemented loose sand output, old wells and wells with tubular columns which can bear high pressure; (3), reservoir stratum non-pressing-open sieving pipe sand prevention is carried out: a dispersion system agent B is injected into a layer on which sand prevention is about to be carried out, displacement fluid is injected into shafts,pumping stopping and well shutting are carried out, and pressure building is carried out for 20 min to 30 min, pressure release is carried out, and circular well washing is carried out; and (4), reservoir stratum pressing-open sand prevention is carried out: fracturing fluid A is injected into the layer on which sand prevention is about to be carried out at pressure higher than formation fracturepressure, and a formation generates cracks, a dispersion system agent B is injected into the cracks, displacement fluid is injected into the shafts, pumping stopping and well shutting are carried out, pressure building is carried out for 30 min to 200 min, and pressure release and circular well washing are carried out. According to the process, construction risks and potential safety hazards areeffectively reduced, tubular column raising and inputting work is not needed, and construction is convenient, easy, safe and fast.

Owner:SOUTHWEST PETROLEUM UNIV +2

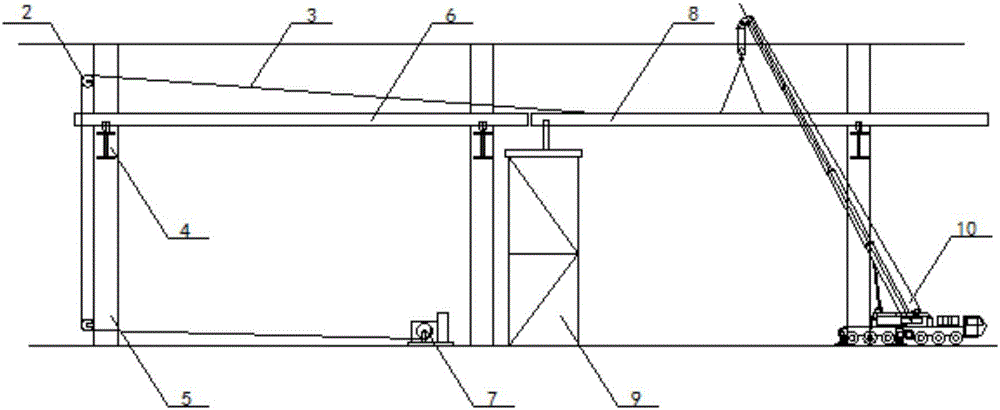

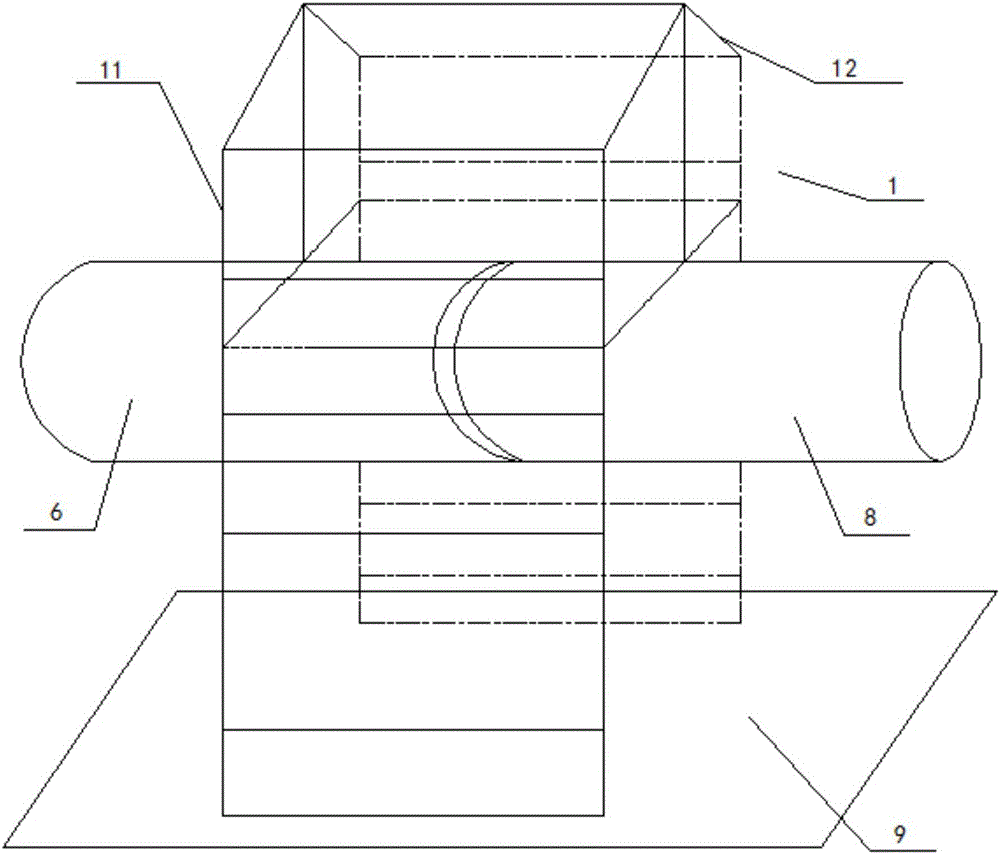

Construction method for large-span pipe corridor pipeline

ActiveCN105888262AReduce displacementImprove efficiencyBuilding material handlingSUSPENDING VEHICLERoad surface

The invention discloses a construction method for a large-span pipe corridor pipeline. The method comprises the following steps of: S1, manufacturing and installing a pipeline installation and welding protective shed; S2, installing two pulley blocks on pipe corridor truss columns, pairing pipeline segments 1 on the ground, wherein the length of the pipeline segments is greater than the distance between two adjacent pipeline support truss columns; S3, connecting a winch and a whole-pavement hydraulic crane with two sends of the pipeline segments 1 by virtue of steel wire ropes; S4, hoisting the pipeline segments 1 into proper positions on pipeline brackets by virtue of combination of the winch and the whole-pavement hydraulic crane; S5, hoisting the pipeline segments 2 to the pipeline brackets; and S6, welding so as to finish assembled welding of interfaces of the pipeline segments 1 and pipeline segments 2. The construction method for the large-span pipe corridor pipeline is capable of reducing displacement of the crane and increasing the use efficiency of the crane, not only is simple to manufacture, convenient to operate and high in applicability, but also is capable of reducing the construction cost and unsafe factors and ensuring the construction quality and safety.

Owner:CHINA MCC17 GRP

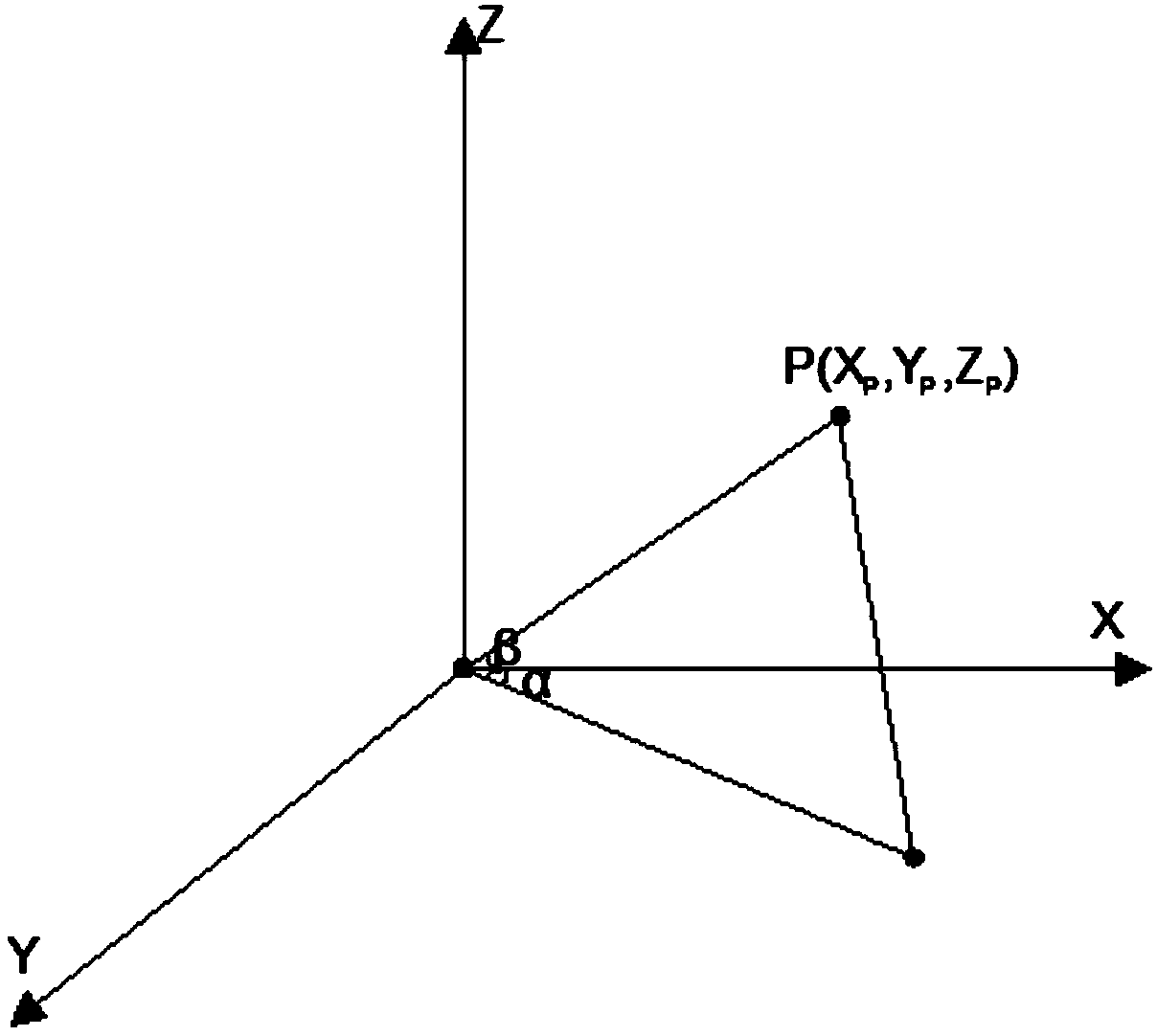

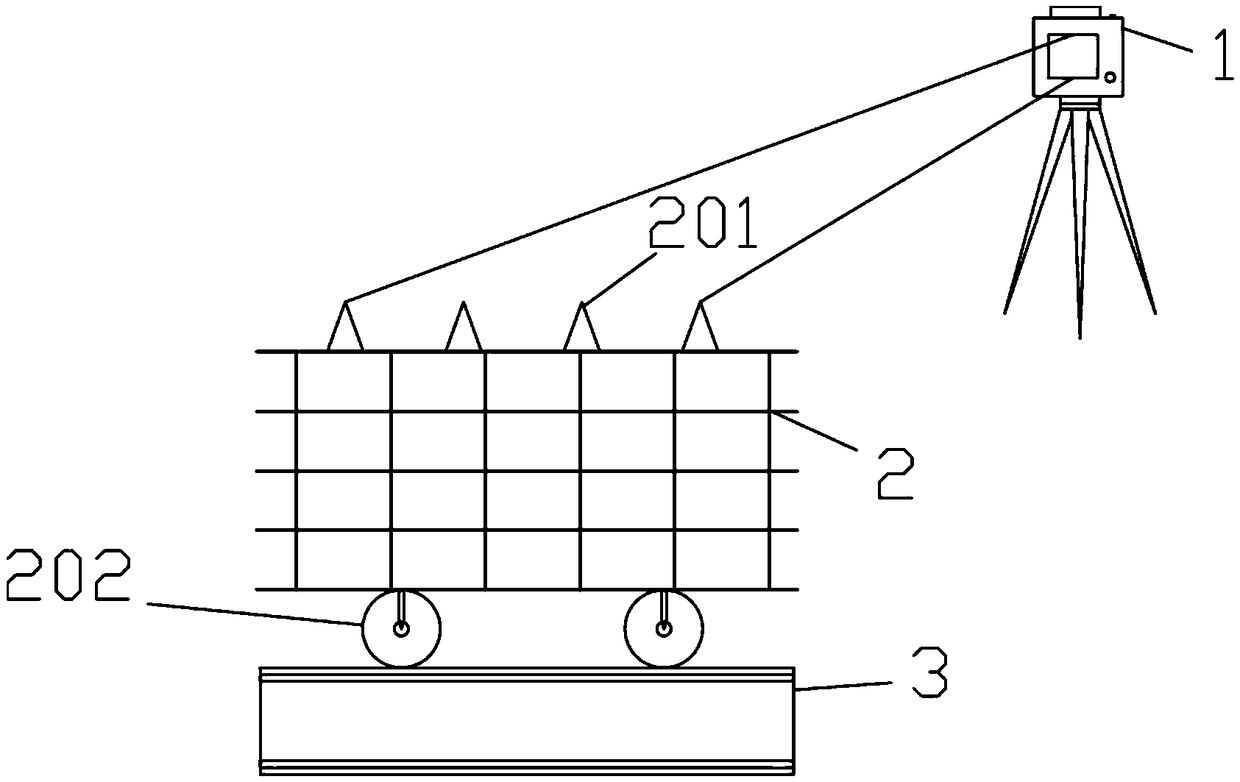

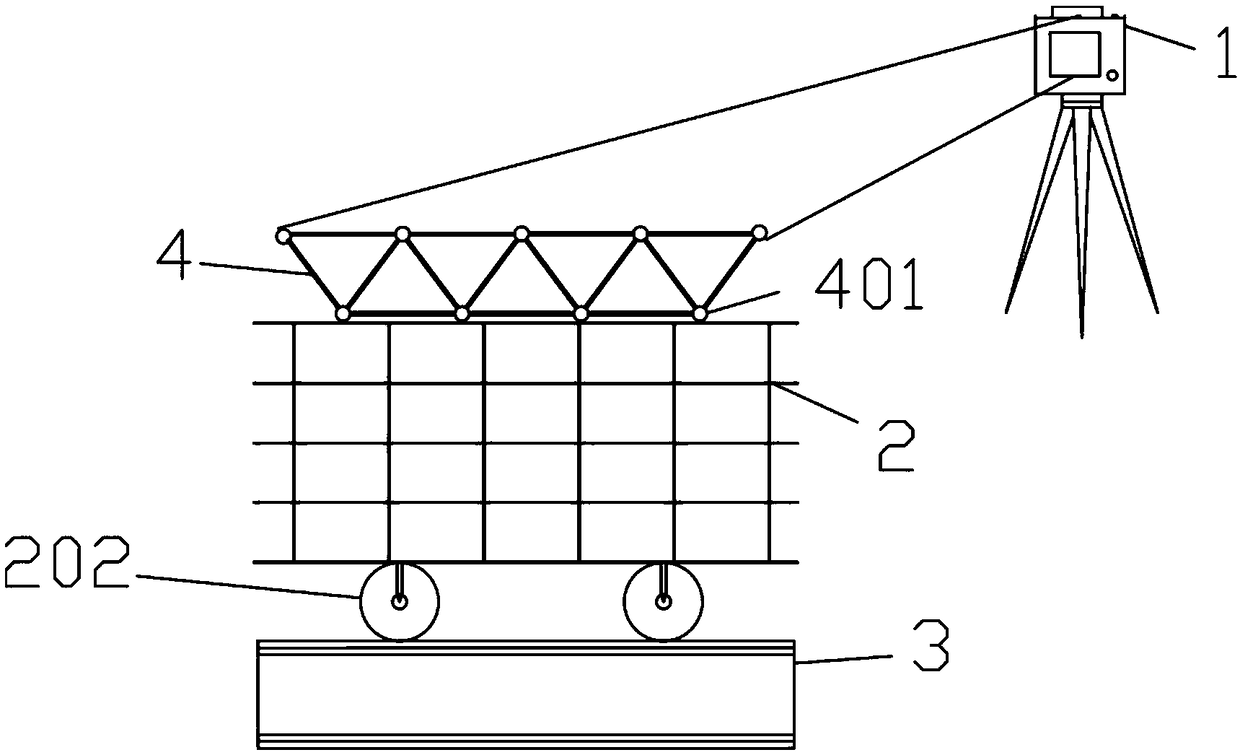

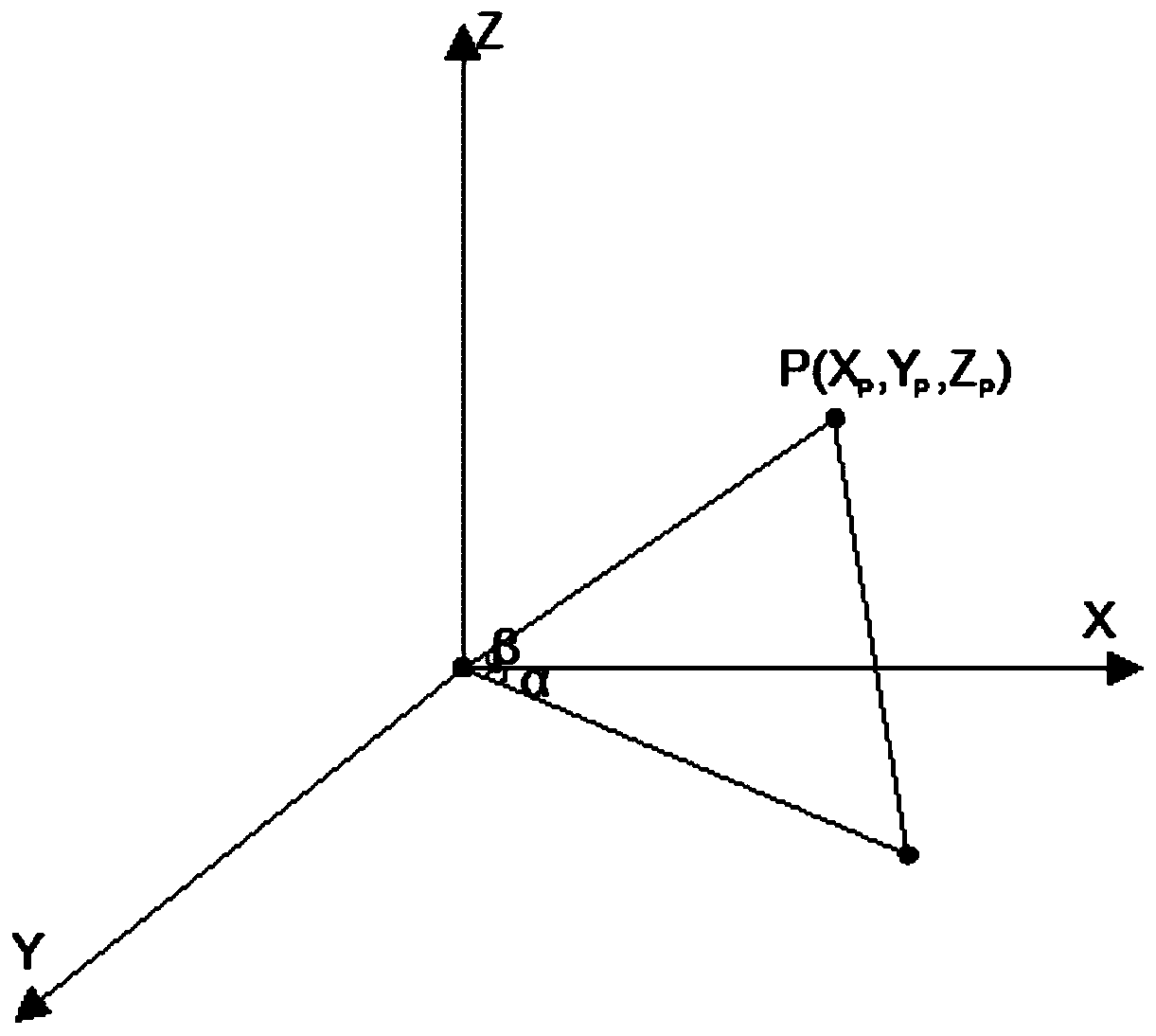

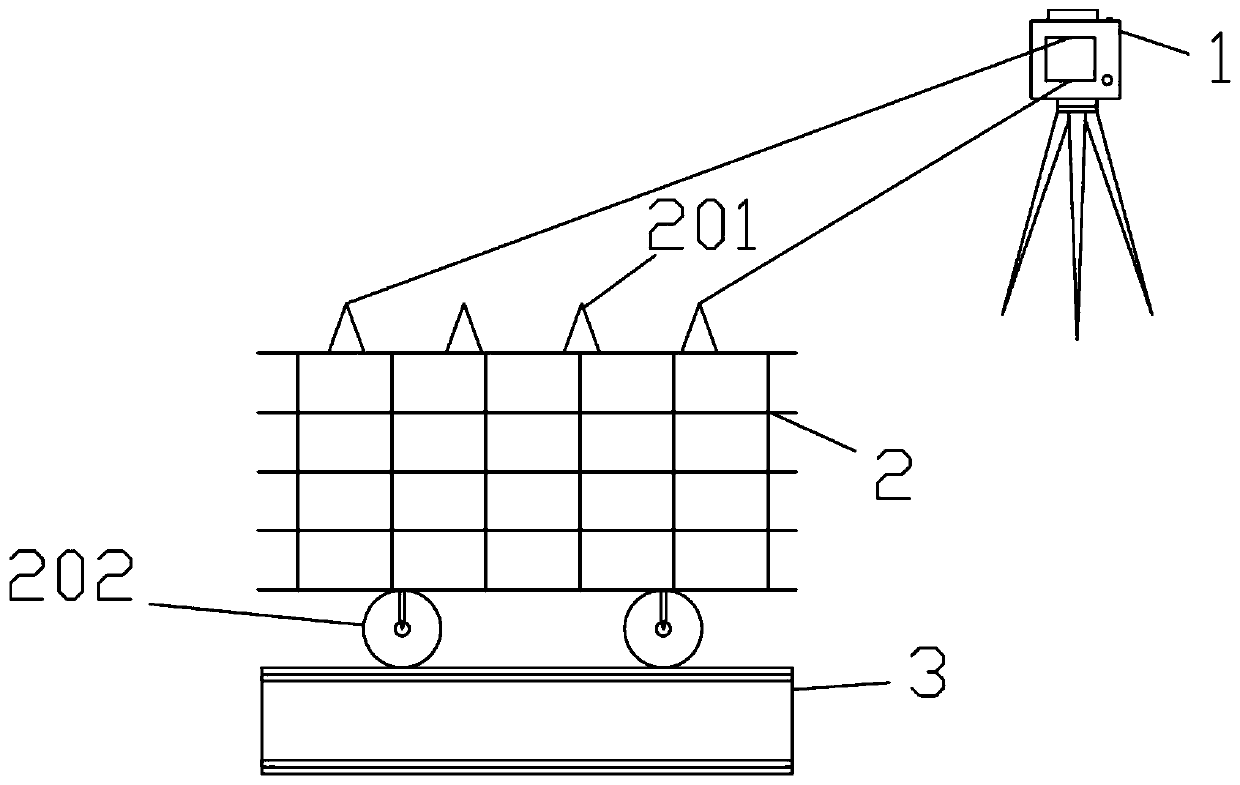

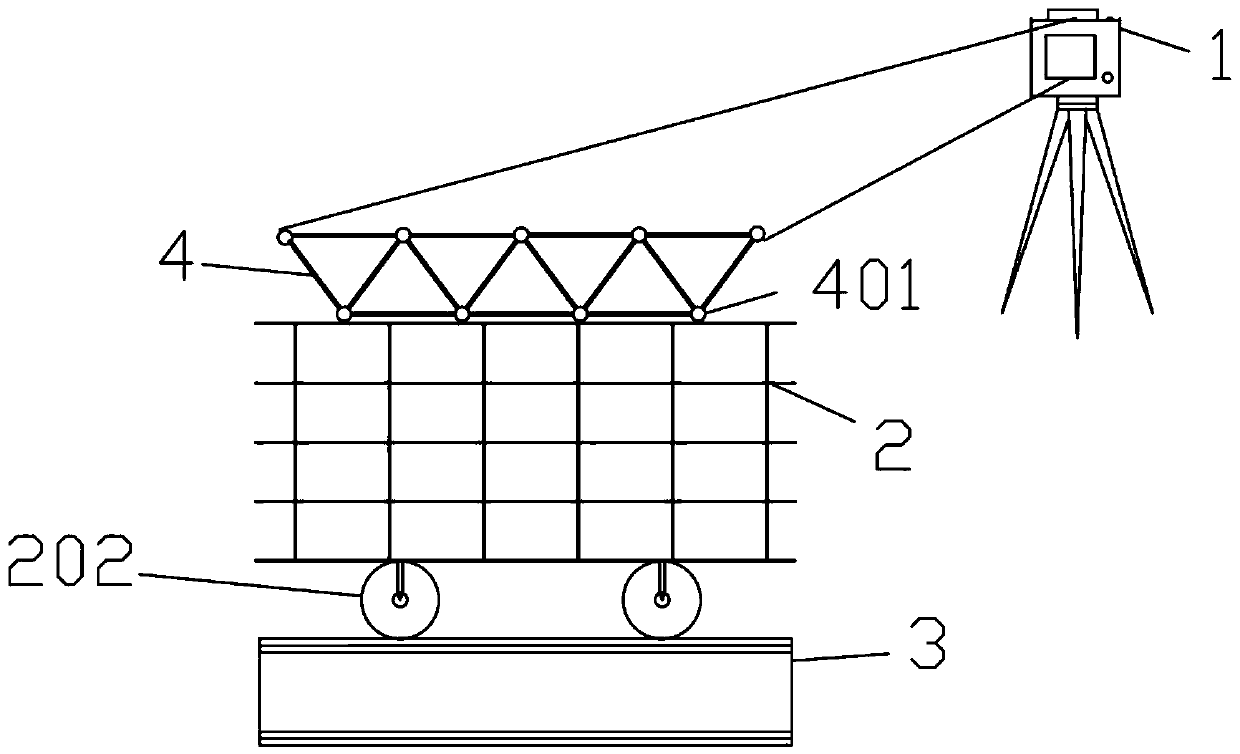

High-altitude large-span net rack sliding positioning mounting and monitoring methods

ActiveCN108824816ASolve the problem of lack of monitoring of grid deformationSolve the problem of deformation monitoringUsing optical meansBuilding material handlingTheodoliteDeformation monitoring

The invention provides a high-altitude large-span net rack sliding positioning mounting method and further provides a high-altitude large-span net rack sliding positioning mounting monitoring method.The effect that in construction through a sliding method, bolted spherical joints are quickly and accurately positioned is achieved. A high-altitude large-span net rack of a steel structure is positioned through a three-dimensional laser scanning system, the positions of all the bolted spherical joints of a whole splicing platform can be synchronously determined at a time, quickness and convenience are achieved, as for a traditional method, a total station and a theodolite are used for measuring the mounting positions of the bolted spherical joints one by one, and thus the time and labor are wasted. The problem that as for construction of a high-altitude large-span steel structure net rack through the sliding method, deformation monitoring for the net rack lacks in the process that the netrack separates from a sliding operating frame is solved, displacement deformation of key joints of the net rack is monitored through the three-dimensional laser scanning system, by comparing the deformation result of finite element calculation, the state of the net rack is judged advantageously, it is ensured that net rack deformation is within the controllable range, the construction risk is lowered, and construction safety is ensured.

Owner:ZHEJIANG UNIV +1

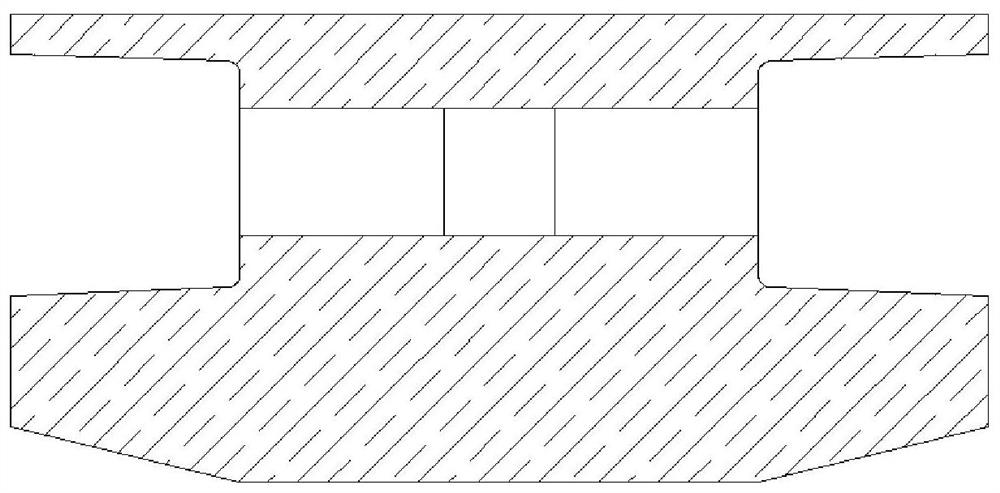

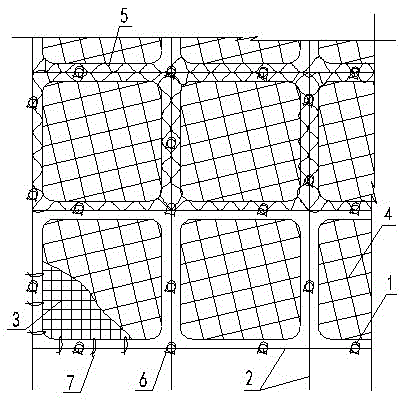

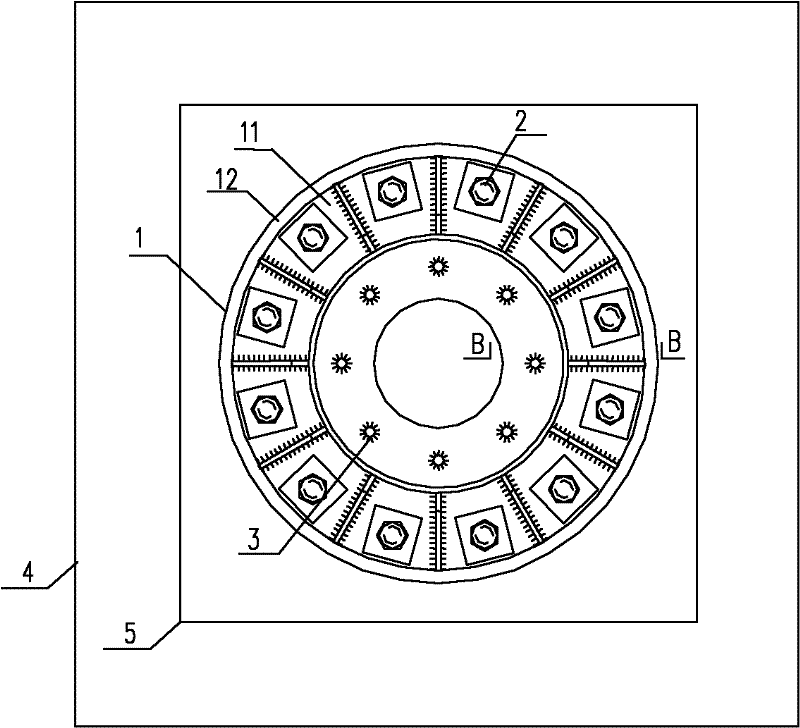

Large-span underground space deep foundation pit support system and construction method

PendingCN110878555AIncrease lateral stiffnessReduced lateral support settingsExcavationsBulkheads/pilesSupporting systemArchitectural engineering

The invention discloses a large-span underground space deep foundation pit support system. The large-span underground space deep foundation pit support system comprises a deep foundation pit, multiplesupport units are continuously arranged on the inner wall of the periphery in the deep foundation pit, an I-shaped steel plate pile is formed between two adjacent support units, each support unit comprises upper, lower, left and right prefabricated support parts which are in abut joint and spliced, the prefabricated support parts on the left and right ends are fixedly connected to the I-shaped steel plate piles through bolts, and a whole support wall is formed on the periphery inner wall of the deep foundation pit. Waterproof plain concrete is poured into gaps between the support units and afoundation on the inner wall of the excavated deep foundation pit. The four corners are each provided with one I-shaped steel plate pile. Through the prefabricated support parts, splicing combinationof the periphery of the deep foundation pit in the horizontal and vertical direction is carried out, a combined structure is formed by the deep foundation pit and the I-shaped steel plate piles, arrangement of a transverse support and an even wall of the large-span deep foundation pit can be reduced or removed, and the problem that in the prior art, the work face construction cannot be performed in a large-area manner is solved. The system has the advantages of being reasonable in structure, capable of greatly simplifying construction, low in cost, green, environment-friendly, capable of saving investment, safe, portable and the like.

Owner:中国市政工程西北设计研究院有限公司

Temperature response type phase-change fracturing fluid and using method thereof

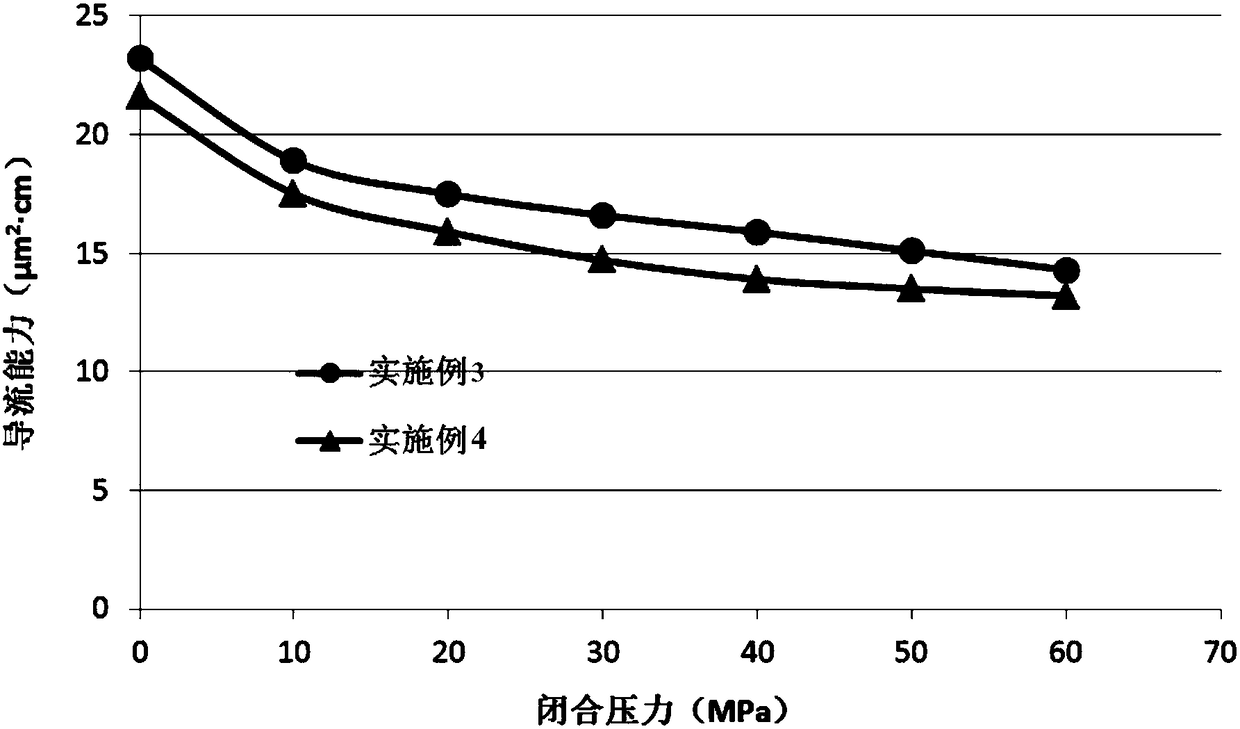

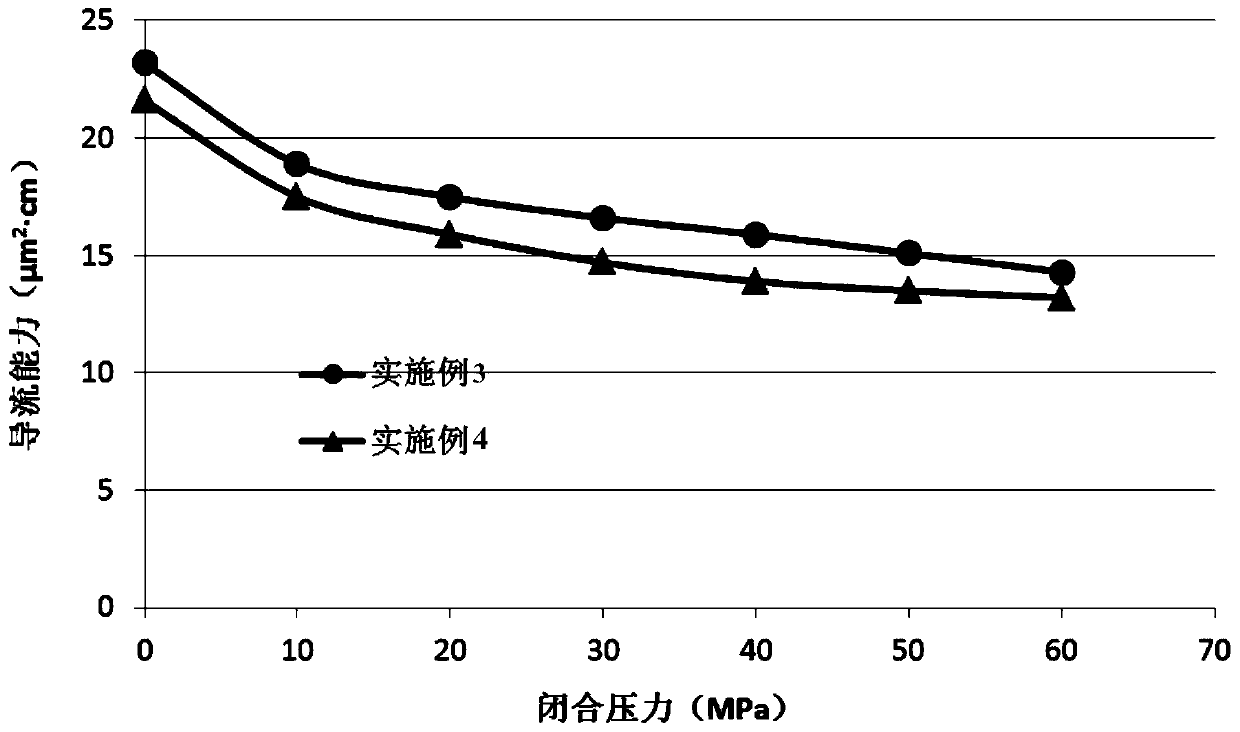

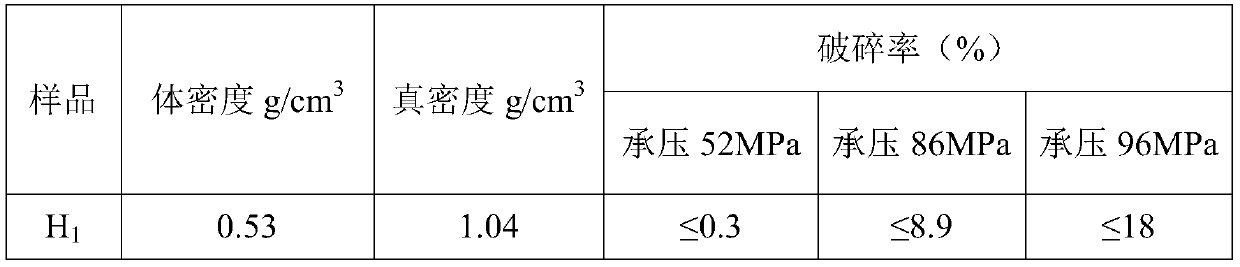

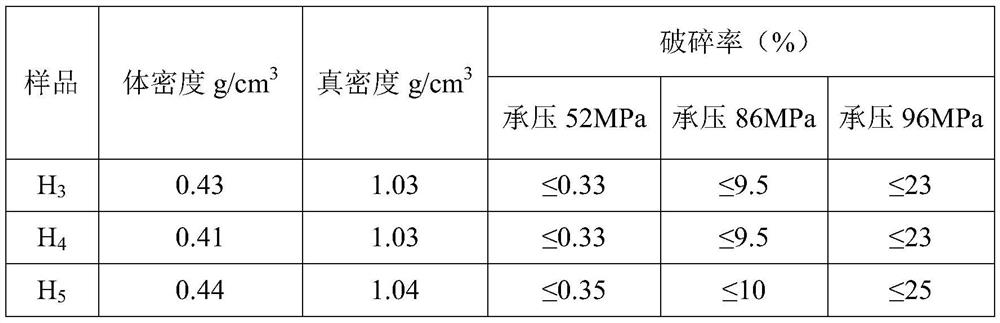

PendingCN111410948AReduce construction riskReduce construction safetyFluid removalDrilling compositionTemperature controlFracturing fluid

The invention relates to the technical field of hydraulic fracturing. A solid-phase propping agent needs to be injected into a stratum in an existing hydraulic fracturing technology, in order to solvethe problems of complex process implementation, reservoir pollution caused by fracturing fluid residues and crack blockage, the invention provides a temperature response type phase-change fracturingfluid and a use method thereof, and the temperature response type phase-change fracturing fluid is composed of the following components in percentage by mass: 20-50% of a functional oil phase and 50-80% of a functional water phase. The temperature response type phase-change fracturing fluid can realize temperature control phase change, is changed into a solid material by virtue of covalent bonds and non-covalent bonds, has specific strength and supporting property, and does not need to be added with other solid-phase proppants; by means of the temperature response type phase-change fracturingfluid, a hydraulic fracturing construction process without injecting the solid-phase propping agent can be achieved, construction risks and potential safety hazards are effectively reduced, and the temperature response type phase-change fracturing fluid is suitable for fracturing transformation production increase of oil and gas field reservoirs.

Owner:ZHEJIANG UNIV OF TECH

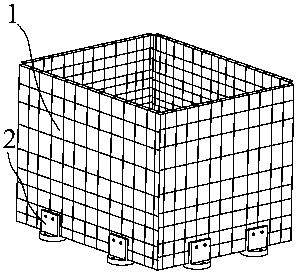

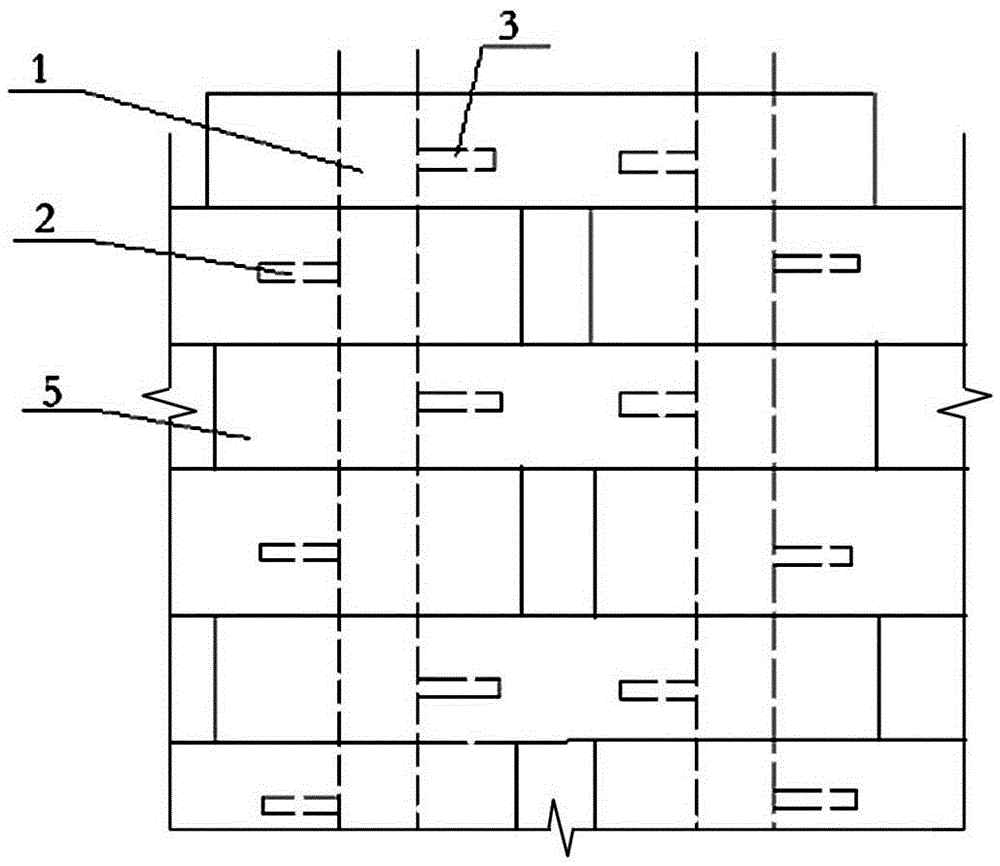

Assembly building modularized frame structure

The invention belongs to the technical field of buildings, and particularly relates to an assembly building modularized frame structure. The assembly building modularized frame structure comprises several basic panels, corner modules and base modules; the basic panels are spliced by several flat plate modules, the corner modules are located at all corners to be connected with the basic panels at different positions, and the base modules are located on the lower portions of the basic panels and used for installation and positioning of the basic panels. The base modules are installed on the ground as a fixation basis. The basic panels are spliced by the flat plate modules, the corner modules are located at all the corners to be connected with the basic panels at different positions, the basic panels are installed on the base modules, and the corner modules are connected with the adjacent basic panels to form a building basic body structure; the flat plate modules, the corner modules andthe base modules can be produced in a factory according to standards and rapidly assembled through modularization after being transported to a construction site, in the whole process, the constructionperiod is short, and multi-profession skilled personnel cooperation can be reduced during installation.

Owner:四川恒达兴铁科技有限公司

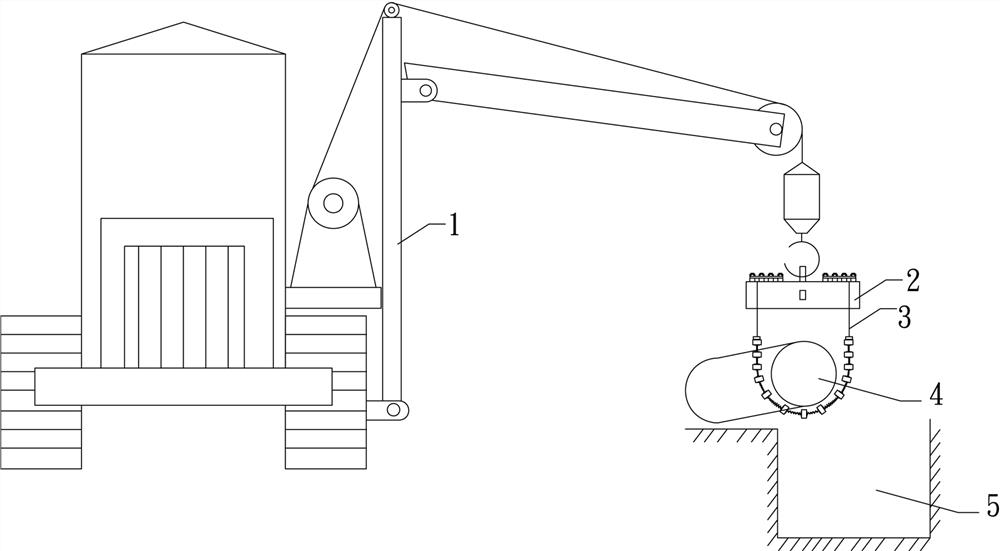

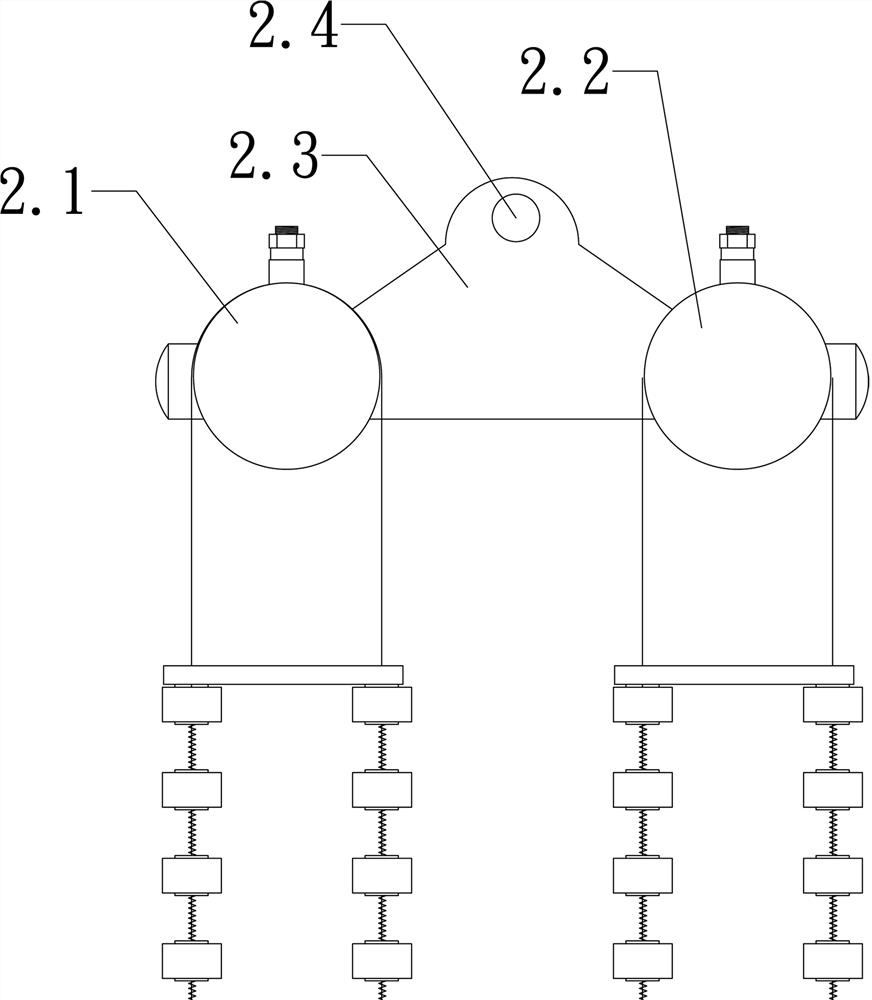

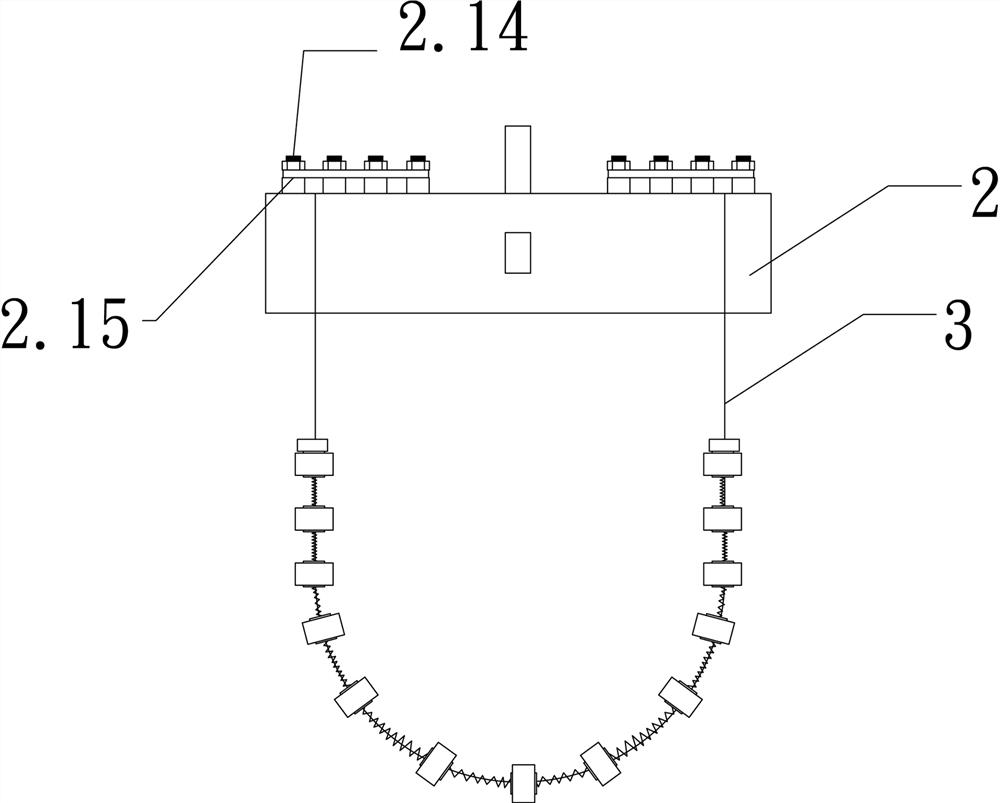

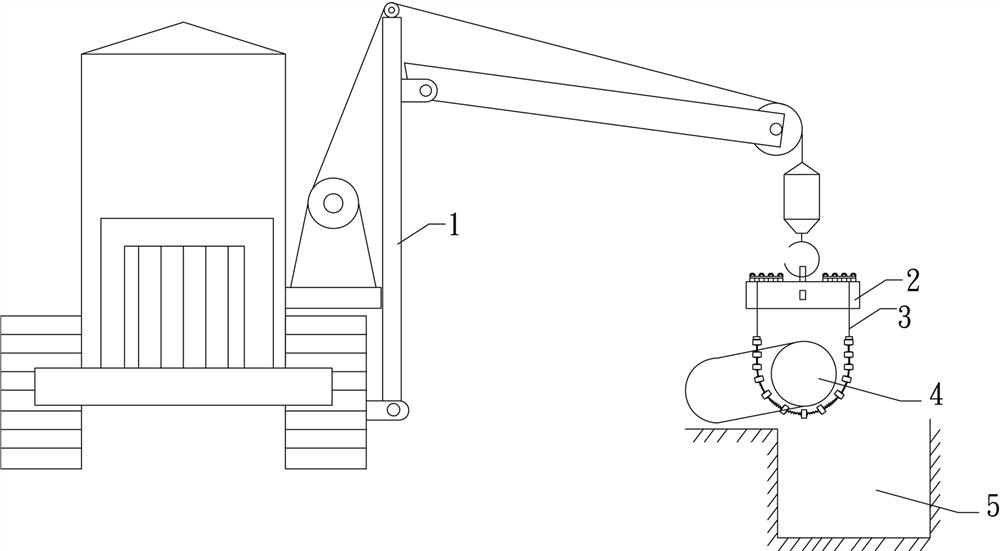

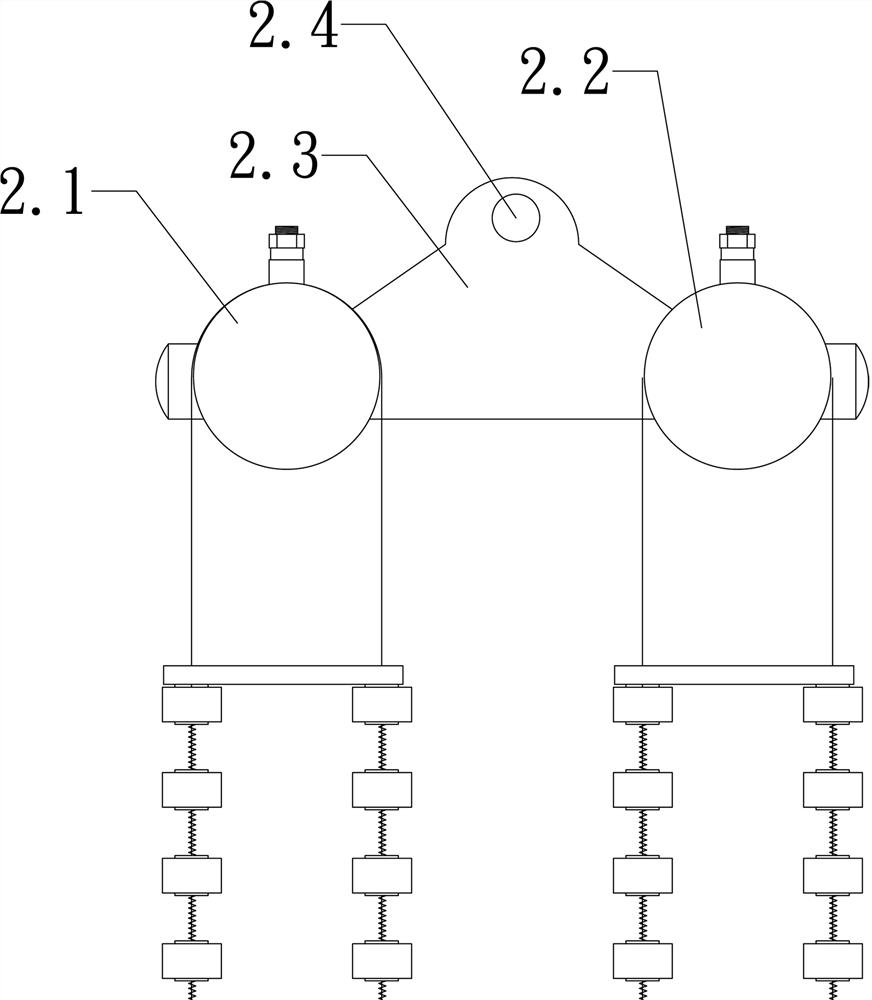

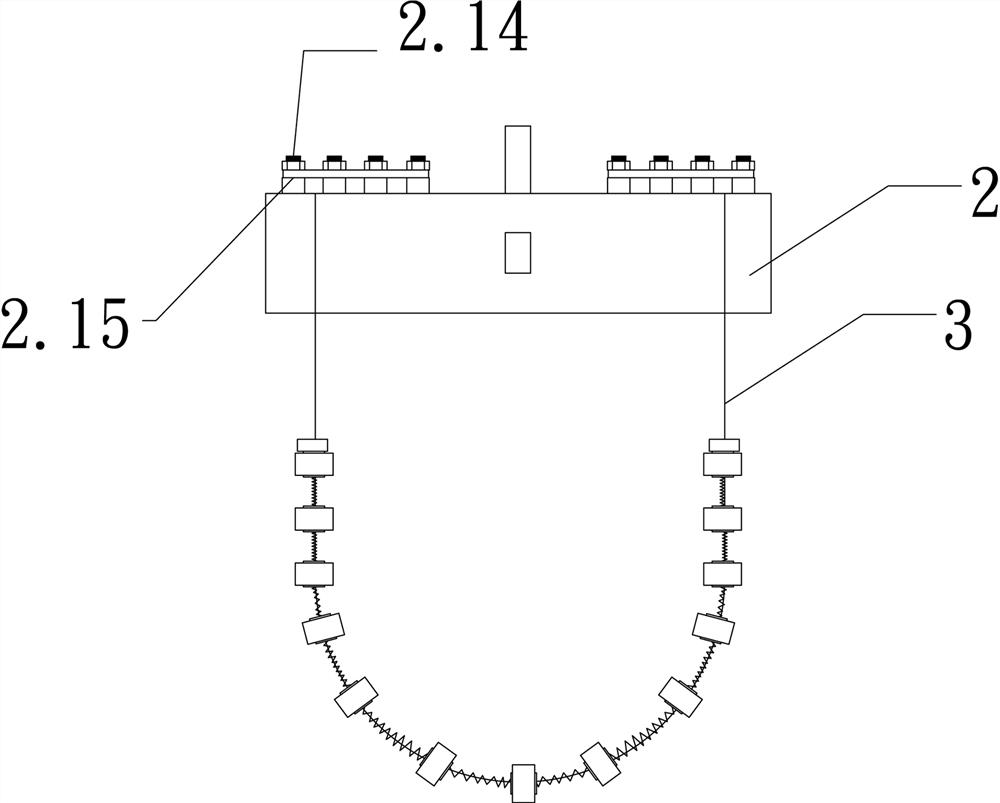

Long-distance and large-diameter cable laying construction device and method in cable trough

ActiveCN111900670AReduce wearAvoid mechanical forceCable installations in underground tubesApparatus for laying cablesArchitectural engineeringEconomic benefits

The invention relates to a long-distance and large-diameter cable laying construction device in a cable trough, which comprises a walking type lifting device, a lifting frame is arranged on the walking type lifting device in a lifting manner, and a flexible bottom supporting frame is detachably arranged on the lifting frame. The invention further discloses a long-distance and large-diameter cablelaying construction method in the cable trough. The device and the method have the following beneficial effects: firstly, a cable ground trough is formed in the ground through a ditching tool, a cableis laid beside the cable trough in the length direction of the cable trough, and the cable is laid on one side of the cable trough, so that mechanized operation is easier to realize; and according tothe long-distance and large-diameter cable laying construction device in the cable trough, the cable is transferred into the cable trough, and then the cable trough is backfilled with soil, so that the required labor force is reduced, the labor intensity is greatly reduced, the construction safety is improved, the operation method is simple, convenient and feasible, the popularization is easy, and greater economic benefits can be generated.

Owner:DIER GRP CO LTD

A construction method of continuous rigid frame bridge

ActiveCN111395167BPrevent buildupAvoid demolitionBridge erection/assemblyPre stressArchitectural engineering

The present invention relates to the technical field of continuous rigid frame construction, and discloses a construction method of a continuous rigid frame bridge, including N bridge piers arranged in sequence, and 0# blocks on the bridge piers include A0 and B0, and the construction method has the following steps: construction Pile foundation, cap and pier body; set up 0# block brackets for the middle N-2 bridge piers, and construct corresponding 0# blocks of A0 and B0 categories respectively; remove the 0# block brackets, The hanging baskets are symmetrically assembled on both sides of the 0# block of the B0 category, and the cast-in-place supports for the straight section of the side span are erected; the main beam section to the largest cantilever section of the main beam is constructed sequentially with cantilever symmetry; the construction is carried out step by step according to the principle of first side span and then middle span In the closing section, the closing of the main girder is completed; after the gaps between the adjacent side spans of the side piers and the 0# blocks of type B0 are all closed, the temporary filling device between the gaps is removed, and the side spans are temporarily tensioned and prestressed; the hanging basket is removed, Carry out bridge laying and other work. The invention avoids the construction and dismantling of a large number of temporary facilities, saves construction time and improves construction safety.

Owner:CHINA RAILWAY SIXTH GRP GUANGZHOU ENG CO LTD

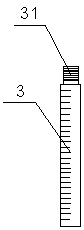

Easy to open indicating cement head

ActiveCN104295265BSmooth downCompact and reasonable structureSealing/packingEngineeringCement slurry

The invention relates to the technical field of cementing heads, in particular to an easy-opening cementing head with an indication function. The cementing head comprises a cementing head body, a gland, a substitute inlet joint, a cement slurry inlet joint, a rotary stop pin, a stop pin control valve assembly and an indication device. An injection passage is formed inside the cementing head body; the gland capable of blocking the injection passage is fixedly mounted at the upper end of the cementing head body hermetically; the substitute inlet joint communicated with the injection passage is arranged on the upper portion of the cementing head body. The cementing head which is of reasonable and compact structure is convenient to use. The rotary stop pin can be turned on and reset rapidly while falling conditions of a rubber plug can be checked through a falling reset indicating pointer; thus operation is facilitated and both time and labor are saved and precision is high. After being turned on, the rotary stop pin is disposed in a lower accommodating cavity, so that the rubber plug can fall smoothly, scratches caused by failure of turning-on are avoided, and safety and reliability are guaranteed. In addition, accidents of construction safety and cementing quality are reduced effectively so that safety and convenience are improved further.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

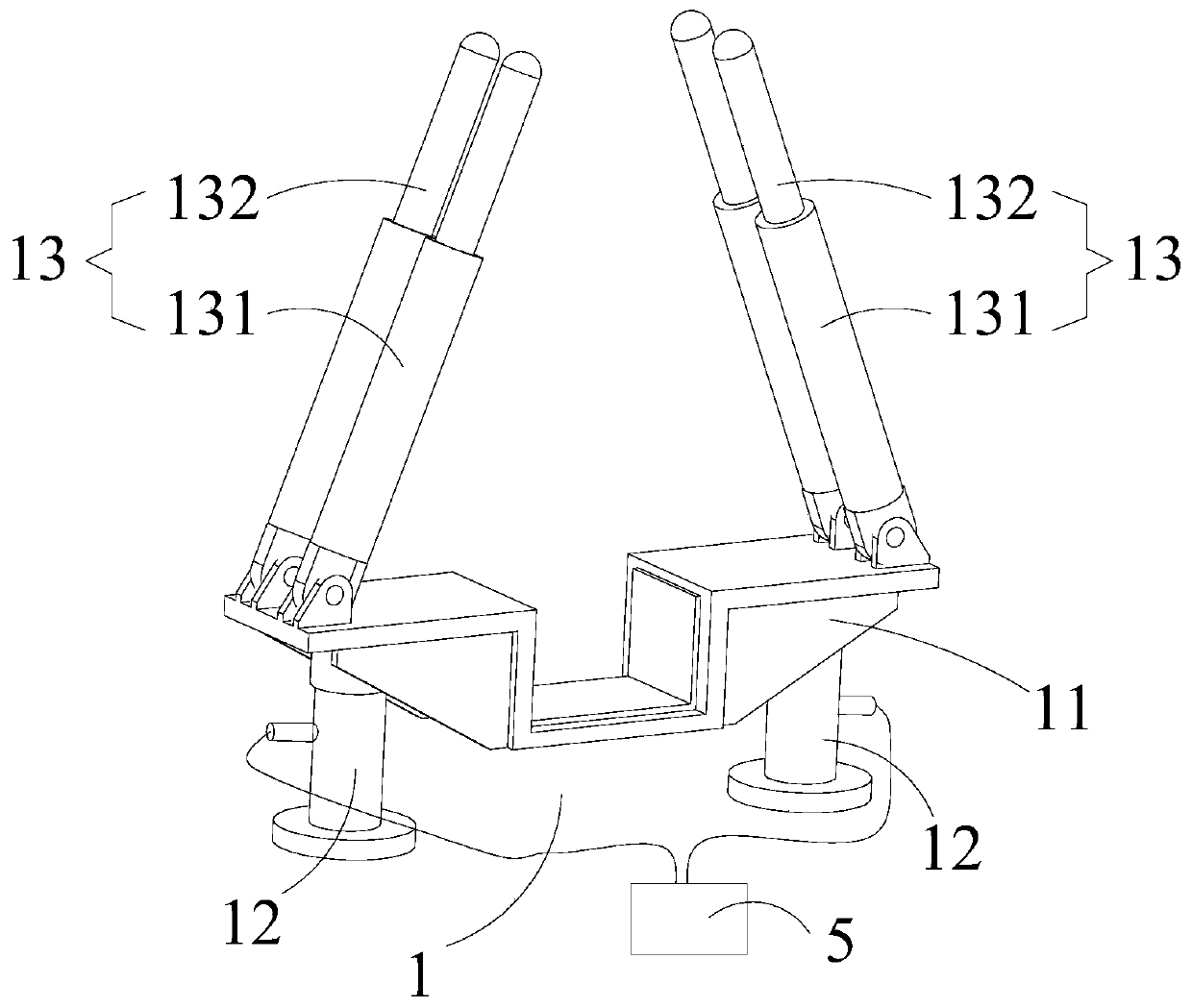

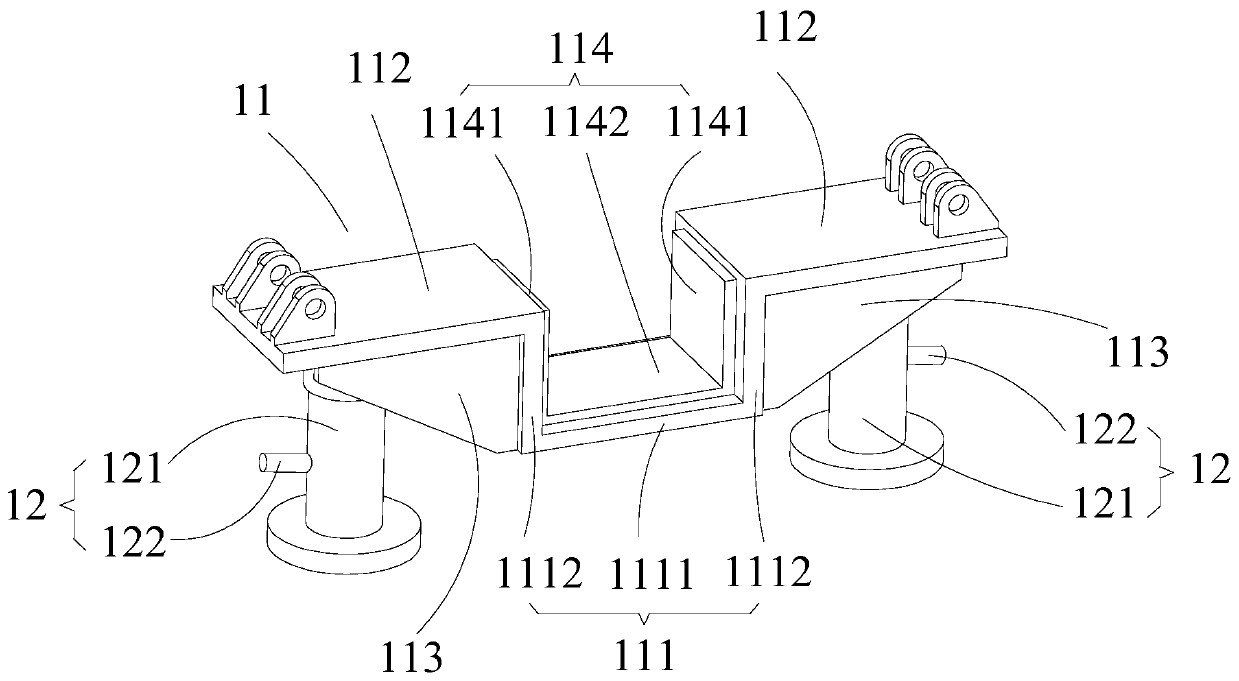

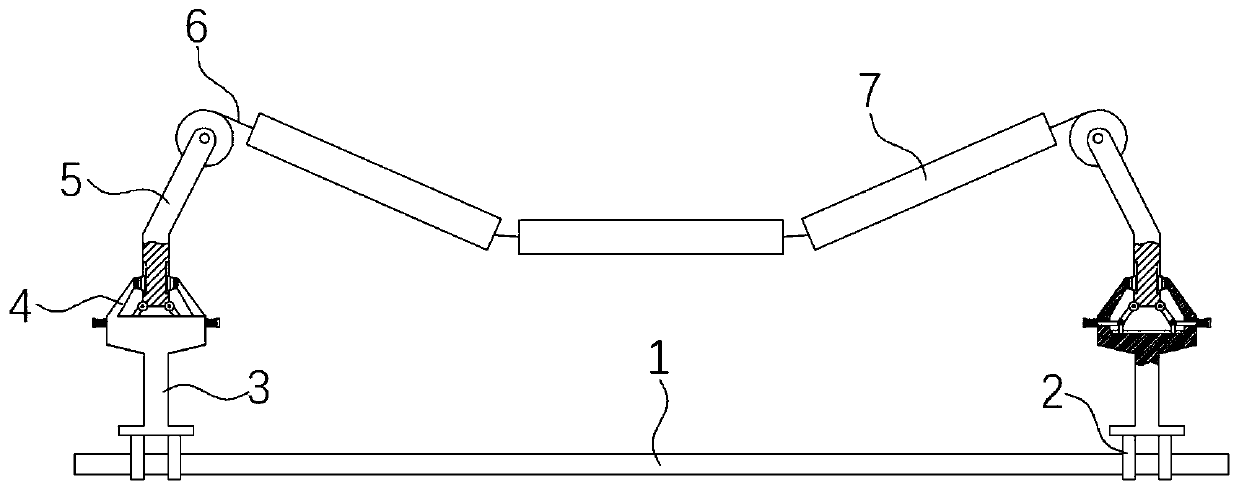

Method for erecting T-shaped beam by using small-sized machinery

The invention relates to the bridge T-shaped beam construction field, especially a method for erecting T-shaped beam by using small-sized machinery. The method comprises following steps: step 1, a jacking device and a moving device are manufactured; step 2, the jacking device is installed; step 3, the moving device is installed; step 4, the T-shaped beam is moved; step 5, the T-shaped beam is erected. By using the method provided by the invention, when a bridge girder erection machine, a T-shaped beam, or a crane cannot enter the construction site, the jacking device and a translating device can be used to erect the T-shaped beam, and can be manufactured on site, and in addition, assembly is simple, installation is convenient, and operation is easy. A special supporting device is provided,and under a precondition of guaranteeing the safety performance, the erection operation of the T-shaped beam can be completed simply and conveniently, and therefore construction difficulty, construction costs and construction safety hidden troubles are reduced.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

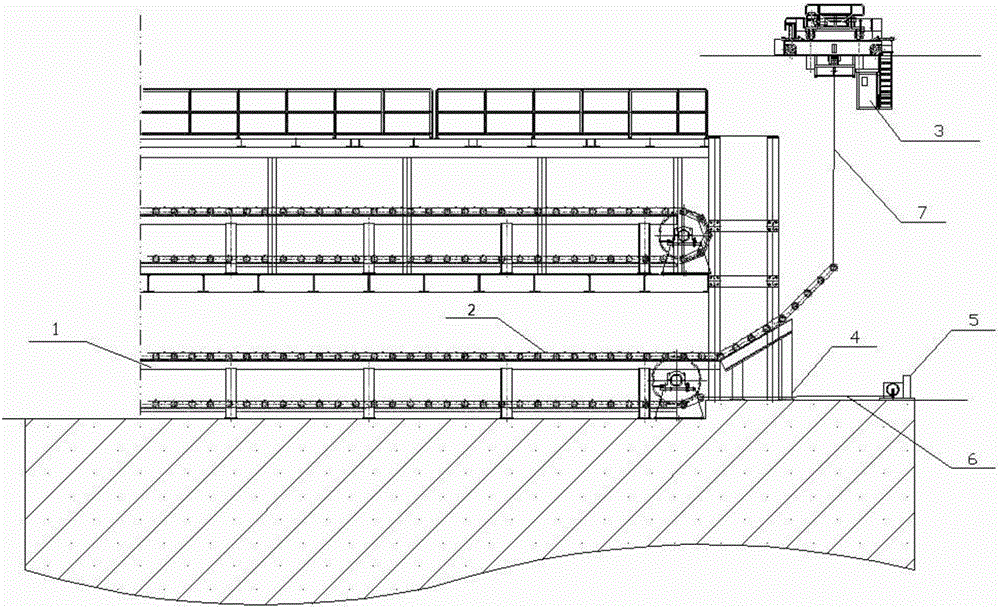

Hoisting method for large long-distance plate type conveying chain

ActiveCN106672805AOptimize human resource allocationImprove construction efficiencyConveyorsLoad-engaging elementsWinchIndustrial engineering

The invention discloses a hoisting method for a large long-distance plate type conveying chain. The hoisting method comprises the steps of arranging a winch outside a large long-distance plate type conveying chain frame; manufacturing and installing a guide frame; leading out one end of a traction steel wire rope of the winch and fixing the end of the traction steel wire rope to one end of the head part of the large long-distance plate-type conveying chain needing to be installed; assembling the head part and the rest parts of the large long-distance plate type conveying chain through hoisting by a travelling crane; vertically hoisting the assembled large long-distance plate-type conveying chain by the travelling crane through a hoisting steel wire rope; enabling the large long-distance plate type conveying chain to freely enter an installation position on the large long-distance plate type conveying chain frame under the effect of gravity through the guide frame; starting the winch to horizontally pull the large long-distance plate type conveying chain to be in place along with the travelling crane; and disassembling the hoisting steel wire rope and the traction steel wire rope to complete the hoisting. According to the hoisting method, the human resource allocation is optimized, the construction efficiency is improved, the manufacturing is simple, the operation is convenient, the adaptability is high, the construction cost and unsafe factors are reduced, and the construction quality and safety are guaranteed.

Owner:CHINA MCC17 GRP

Easily disassembled building frame structure

The invention belongs to the technical field of buildings, and particularly relates to an easily disassembled building frame structure which comprises a plurality of basic surface plates and a plurality of base modules. A plurality of flat plate modules are spliced to form the basic surface plates, the base modules are positioned on the lower portions of the basic surface plates and used for mounting and positioning the basic surface plates, the base modules serve as fixing foundations and are mounted on the ground, the flat plate modules are spliced to form the basic surface plates, the basicsurface plates are mounted on the base modules to form a building basic body structure, the flat plate modules and the base modules can be produced in a factory in a standardized manner and transported to a construction site and then can be rapidly and modularly assembled, a whole site construction period is shortened, multi-type skilled personnel matching can be decreased in the assembly process, so that whole construction safety and site management difficulties are reduced, site construction site environmental pollution can be reduced, and used material stacking site area is decreased and the like.

Owner:四川恒达兴铁科技有限公司

A method of fracturing

ActiveCN108561111BReduce frictionLower requirementFluid removalDrilling compositionThermodynamicsFracturing fluid

The invention provides a fracturing method. The method includes the following steps: injecting fracturing fluid into the formation to generate fractures in the formation, and stopping injecting the fracturing fluid after the generated fractures meet preset requirements; injecting into the formation can occur at a preset temperature The phase change material liquid and the time-delayed heat generating agent for the phase change reaction; after the phase change material liquid is basically injected, the time-delayed heat generating agent exerts a heat generating effect, so that the phase change material liquid undergoes a phase change, and the pressing process is completed. crack. The technical solution provided by the present invention can not only effectively reduce the friction of the pipe string because of no solid phase injection; moreover, the use of the delayed heat generating agent can effectively control the time and progress of the phase change reaction, so as to obtain better fracturing Effect. Especially for low-temperature reservoirs, the heat generation effect of the delayed heat generating agent greatly improves the rate of the phase change reaction, so that the deformable material liquid can quickly form a solid phase at the preset position, shorten the phase change time, and increase the probability of successful construction .

Owner:PETROCHINA CO LTD

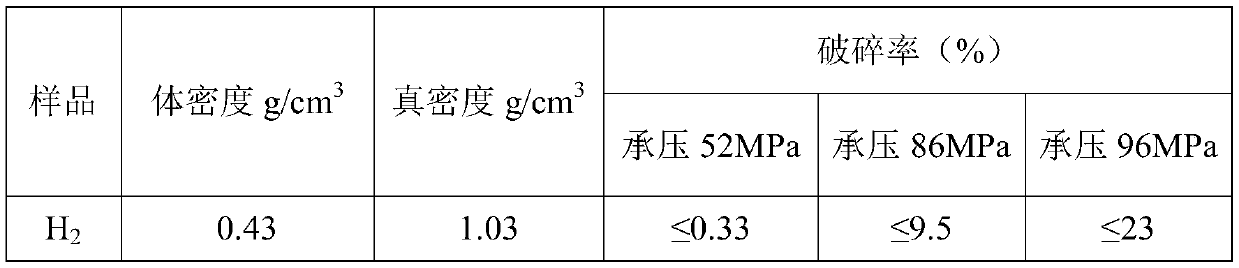

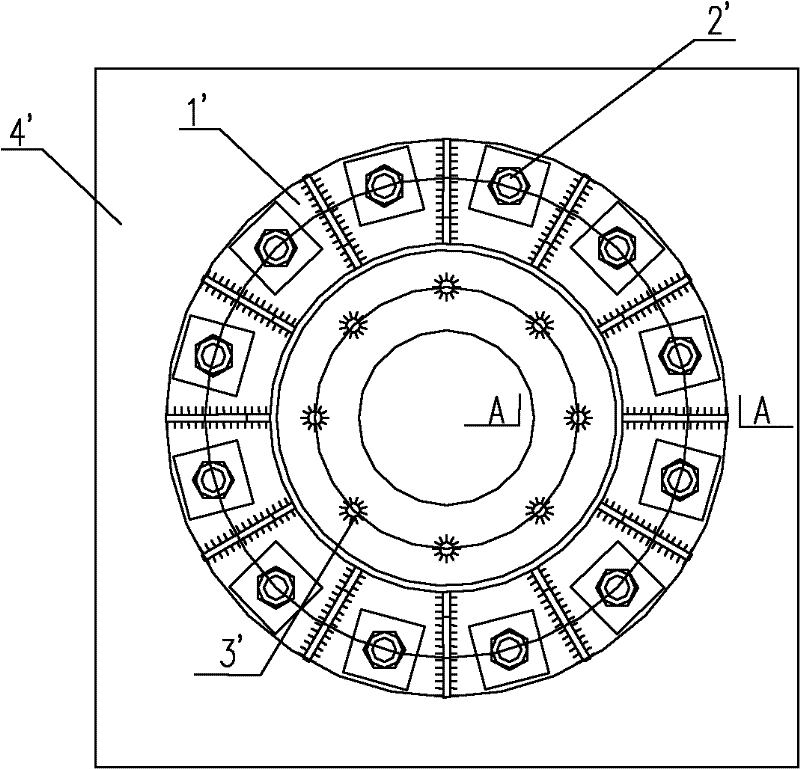

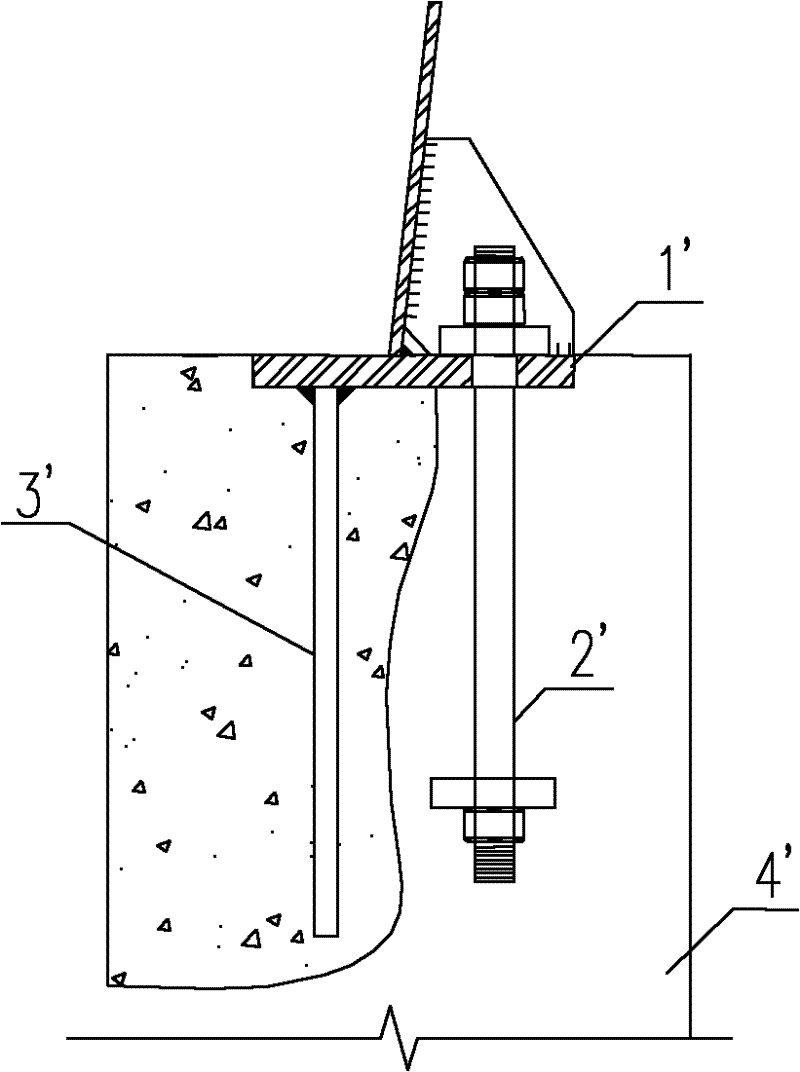

Deep well anti-burial device and using method of deep well anti-burial device for construction

PendingCN108825152AReduce construction safetyImprove removal efficiencyFlushingCross connectionStructure of the Earth

The invention provides a deep well anti-burial device and a using method of the deep well anti-burial device for construction. The deep well anti-burial device comprises a vertical pipe, and a water pump arranged in the vertical pipe in a hung mode; a set of connecting frames is arranged at a pipe opening of the vertical pipe, and the set of connecting frames is mutually connected in an end-to-endcross mode so as to constitute a closed structure to be erected on the pipe opening of the vertical pipe; three or more steel pipes are arranged in the vertical pipe in the vertical direction, a high-pressure spraying head is arranged on one of the three steel pipes, one ends of the steel pipes are fixed to the connecting frames, and the other ends of the steel pipes extend into the vertical pipe; the ends, in the vertical pipe, of the steel pipes are mutually arranged in an up-down staggered mode; a set of penetration holes are formed in the outer wall of the vertical pipe; and a filter netis arranged at the position, in the penetration holes, of the outer side of the vertical pipe. The deep well anti-burial device and the using method of the deep well anti-burial device for construction have the beneficial effects that the multiple steel pipes are arranged in the vertical pipe, the interior of the corresponding steel pipe is flushed with high-pressure water, water pumping is conducted, thus earthwork falling into a deep well is removed, the removing efficiency is greatly improved, and meanwhile, the construction safety of construction personnel is improved.

Owner:GESHAN CONSTR GROUP

Light machine tail buffer device for coal mine roadheader

ActiveCN110029992AReduce the difficulty of pullingEnsure construction safetySlitting machinesVibration suppression adjustmentsCoalEngineering

The invention discloses a light machine tail buffer device for a coal mine roadheader. The light machine tail buffer device comprises a base, and the two sides of the upper end of the base are fixedlyconnected with hoops correspondingly; the upper ends of the hoops are fixedly connected with I-shaped steel runways, and buffer mechanisms are mounted on the upper surfaces of the I-shaped steel runways; the input ends of the buffer mechanisms are connected with carrier roller frames, and the top ends of the carrier roller frames are fixedly connected with hanging pulleys; and steel wire ropes are wound on the hanging pulleys on the two sides correspondingly, and the common steel wire rope between the hanging pulleys on the two sides is connected with one or more carrier rollers. The haulagedifficulty is lowered, and the construction safety is guaranteed; and in a roadheader roadway, belt extending and buffer machine tail haulage are frequent, when a buffer machine tail is pulled, the roadheader and the buffer machine tail are connected through a chain or an anchor rod, the weight is large, thus the risk that the chain and the anchor rod are broken to hit and injure personnel exists,an existing light buffer machine tail can effectively improve the current situation, the construction safety is guaranteed, and the haulage difficulty is lowered.

Owner:SHANDONG HUAHENG MINING

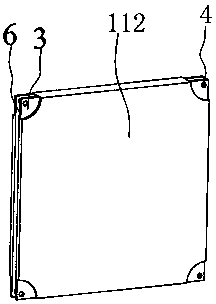

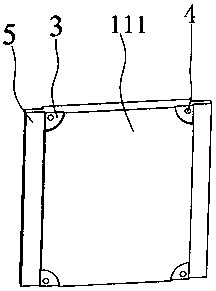

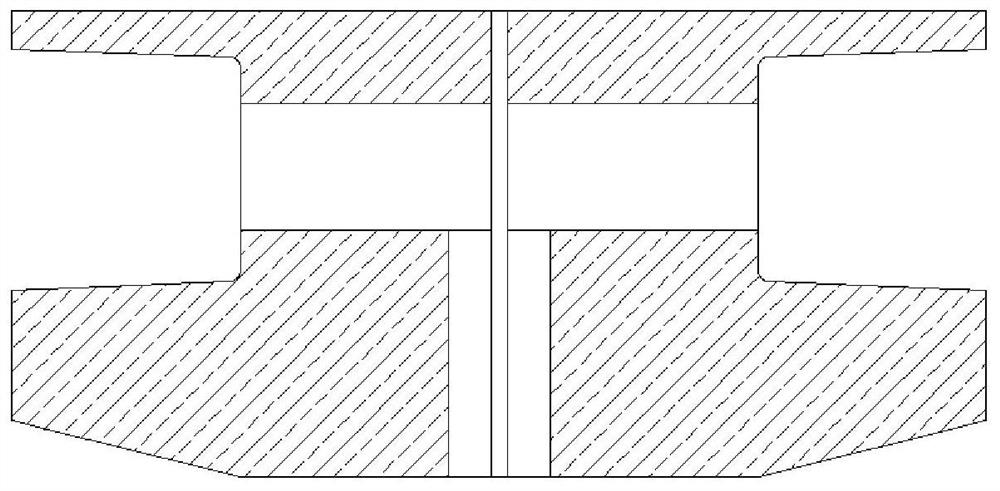

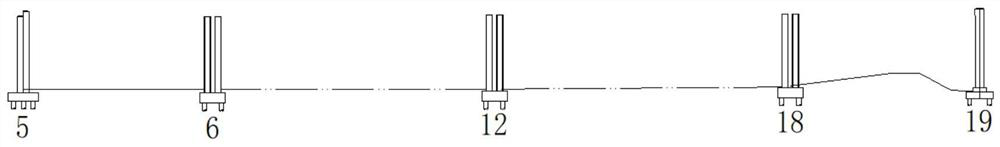

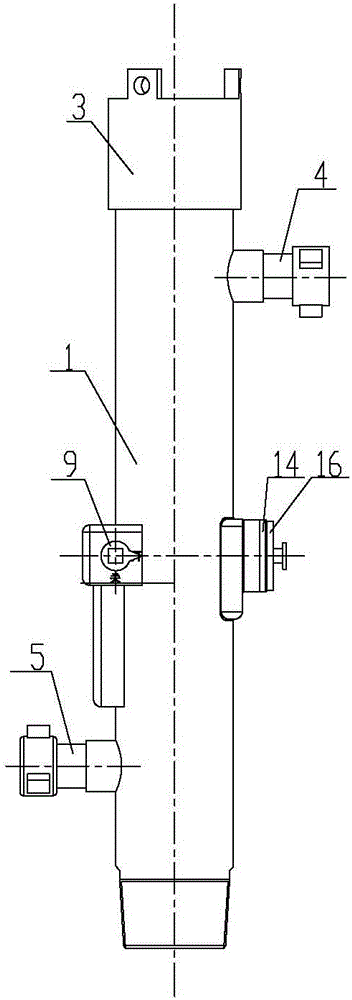

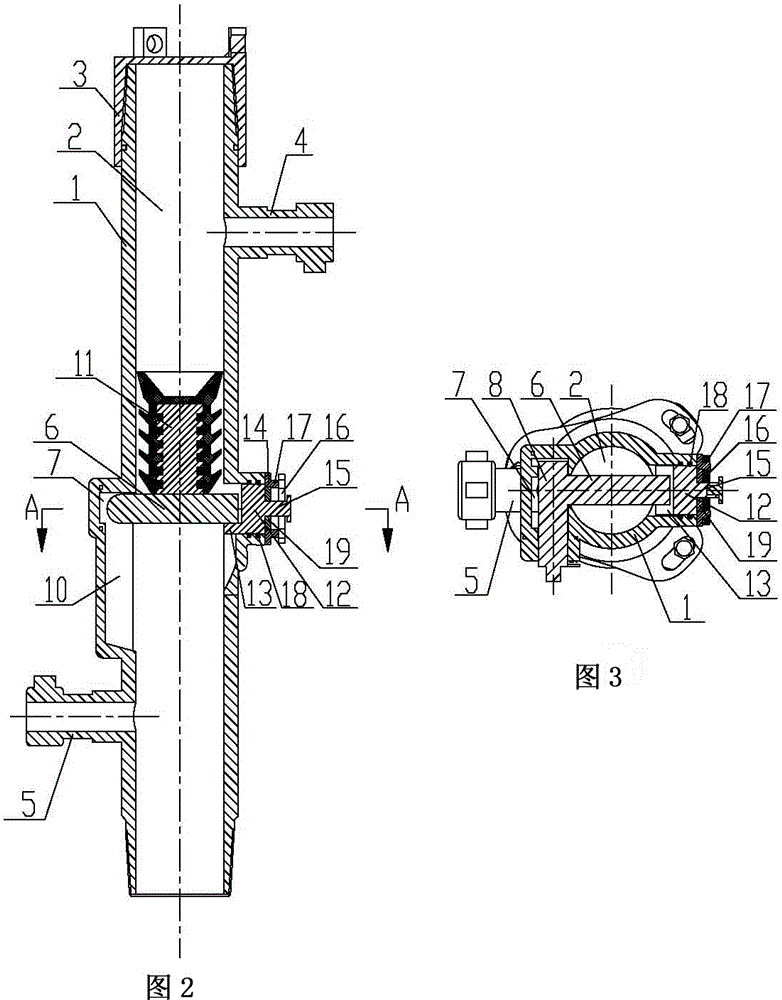

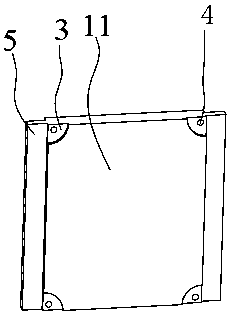

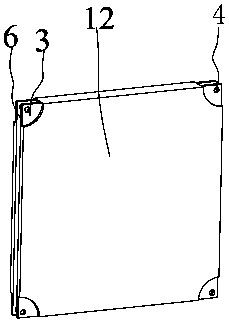

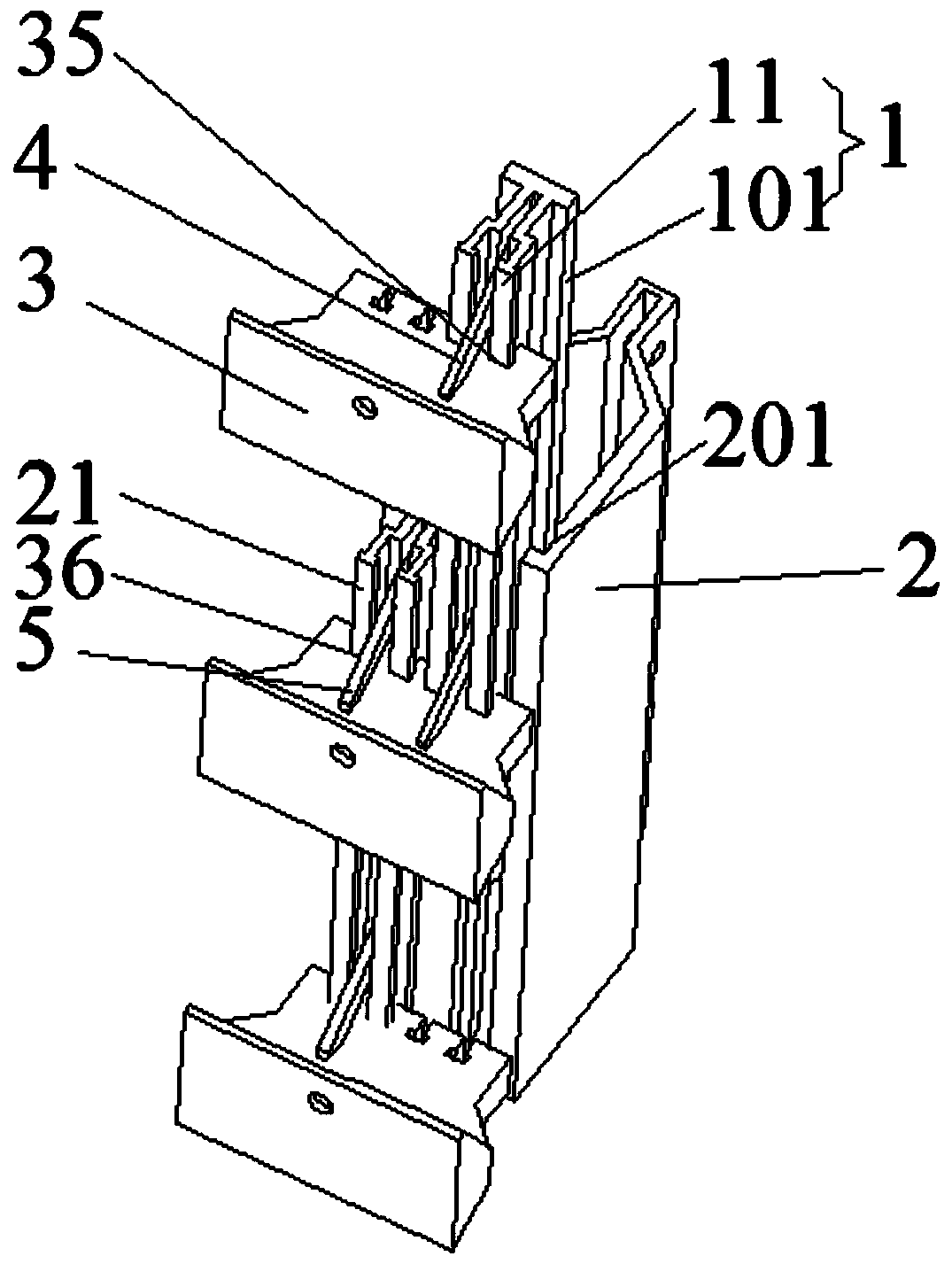

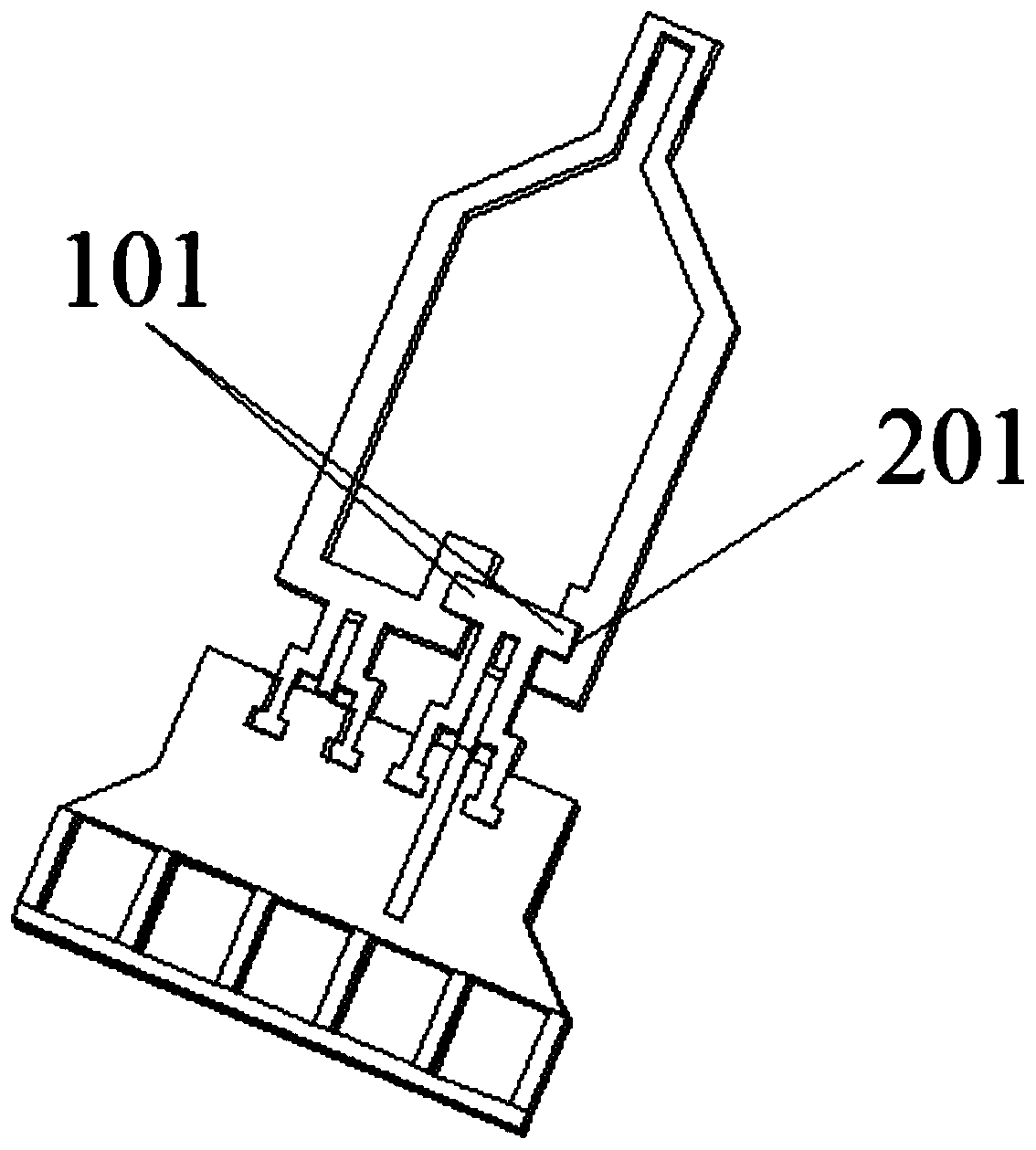

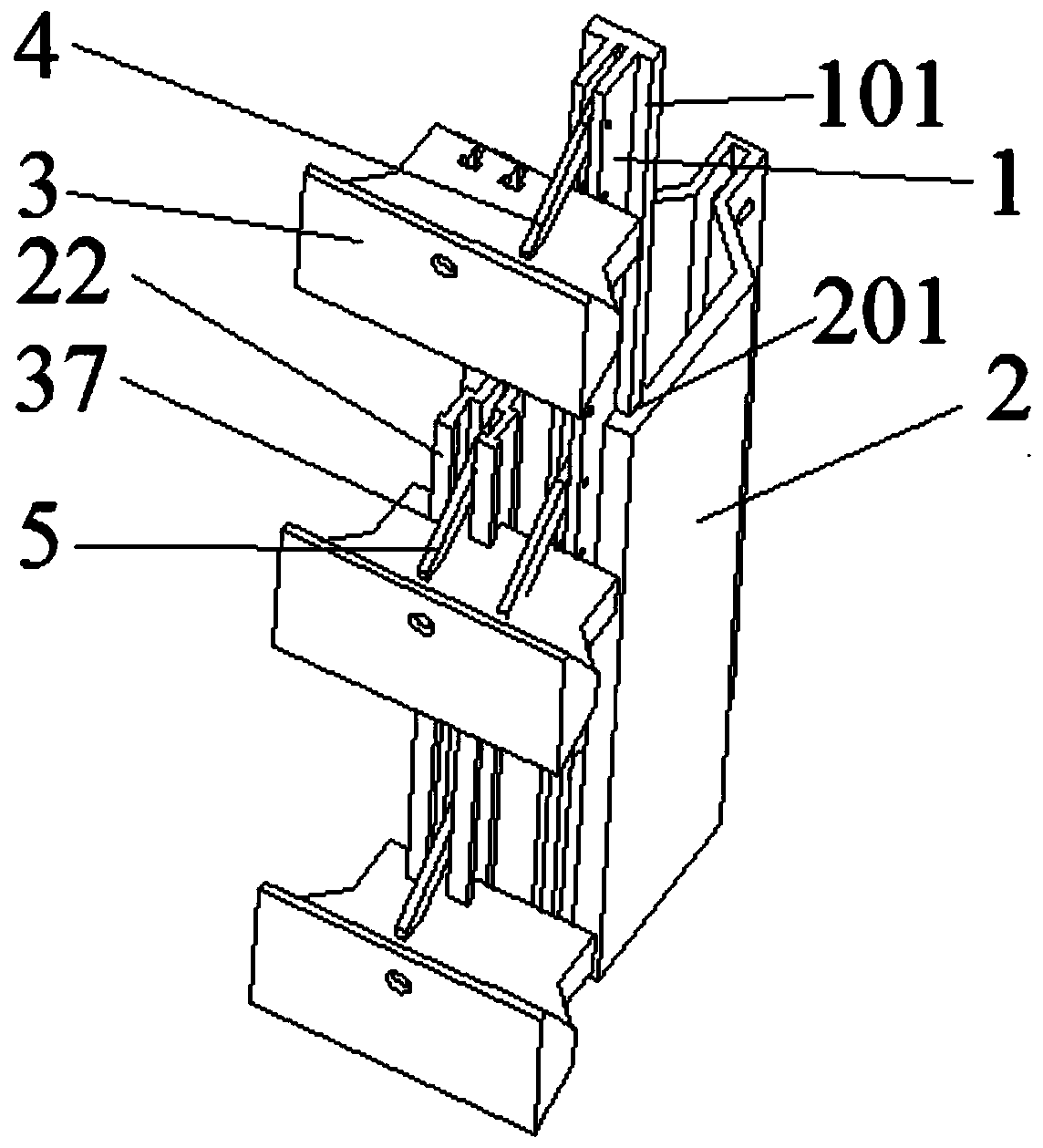

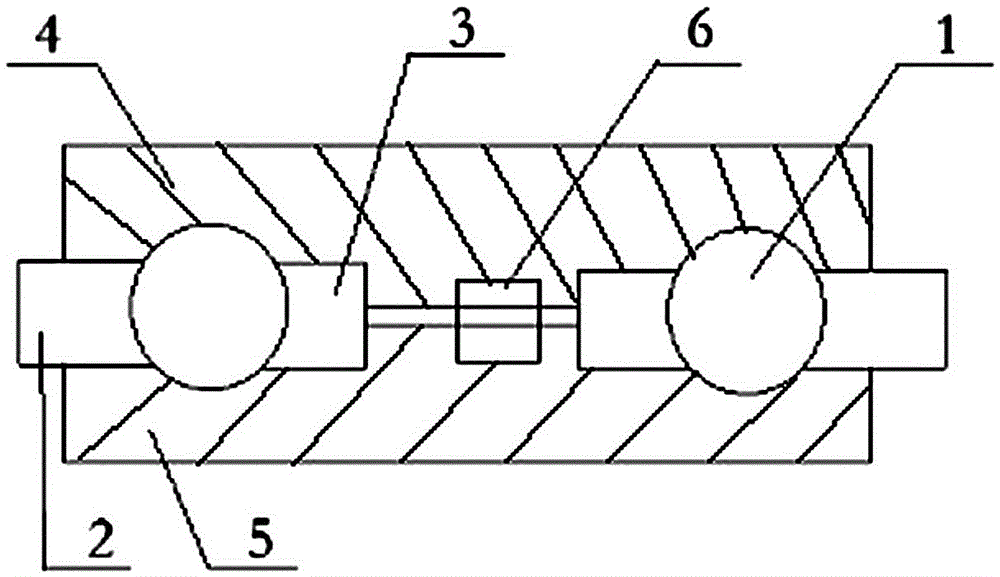

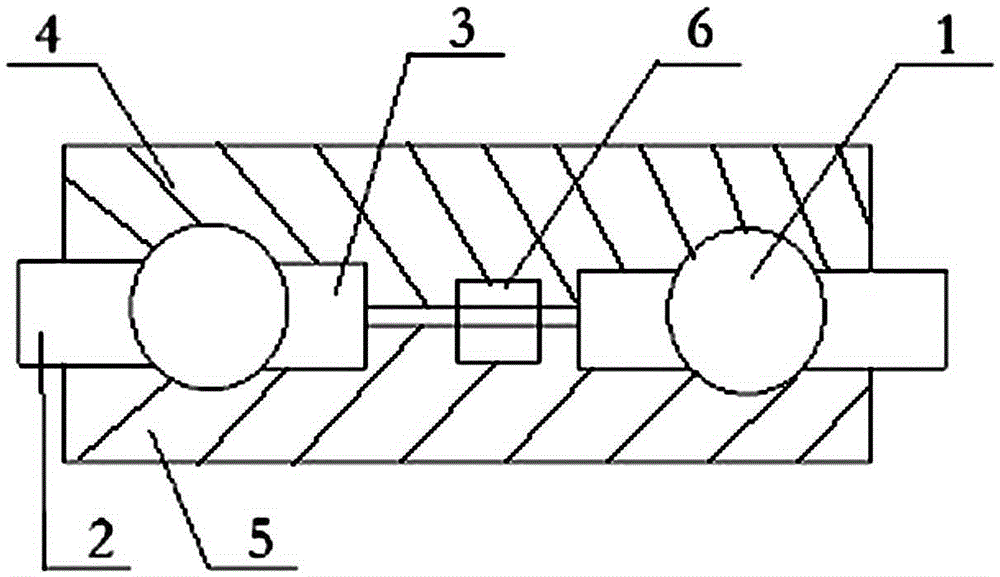

A left and right closed guide rail guide seat sliding sleeve structure

ActiveCN108049622BGuaranteed Build QualityExtended service lifeLifting devicesBuilding support scaffoldsClassical mechanicsEngineering

The invention discloses a left and right closing type guiding-rail guiding-seat sliding sleeve structure. The left and right closing type guiding-rail guiding-seat sliding sleeve structure comprises aguiding seat (3), an inner sliding rail (1) and an outer guiding rail (2), and the inner guiding rail (1) and the outer guiding rail (2) can slide relatively; the inner sliding rail (1) is provided with at least one first manipulator (4); the outer guiding rail (2) is provided with at least one second manipulator (5); the first manipulators (4) and the second manipulators (5) are used for being supported on the guiding seat (3); and any one or both of the inner sliding rail (1) and the outer guiding rail (2) are matched with the guiding seat (3) in a sliding sleeving mode. According to left and right closing type guiding-rail guiding-seat sliding sleeve structure, reducing of the mounting workload of a lifting mechanism is achieved through the left and right closing type guiding-rail guiding-seat sliding sleeve structure, meanwhile, due to the fact that the left and right closing type guiding-rail guiding-seat sliding sleeve structure does not need to be mounted on a site, so that thesituation that dust on the construction site enters the interior of a machine body is avoided, breakdowns are reduced, and the construction safety is ensured to a certain extent.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

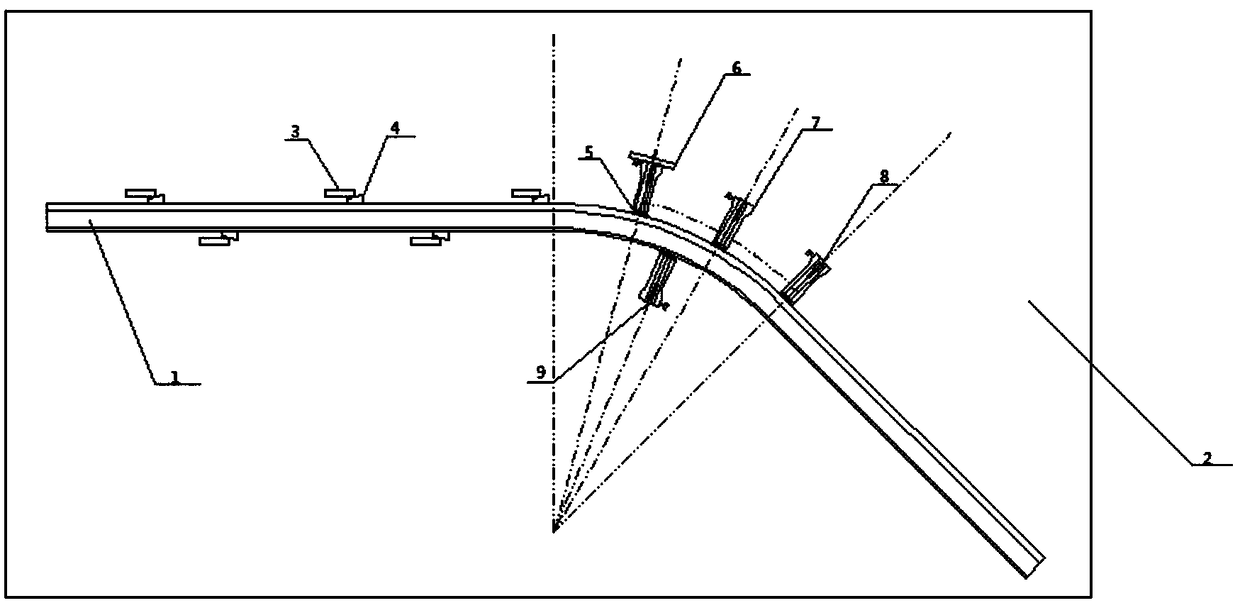

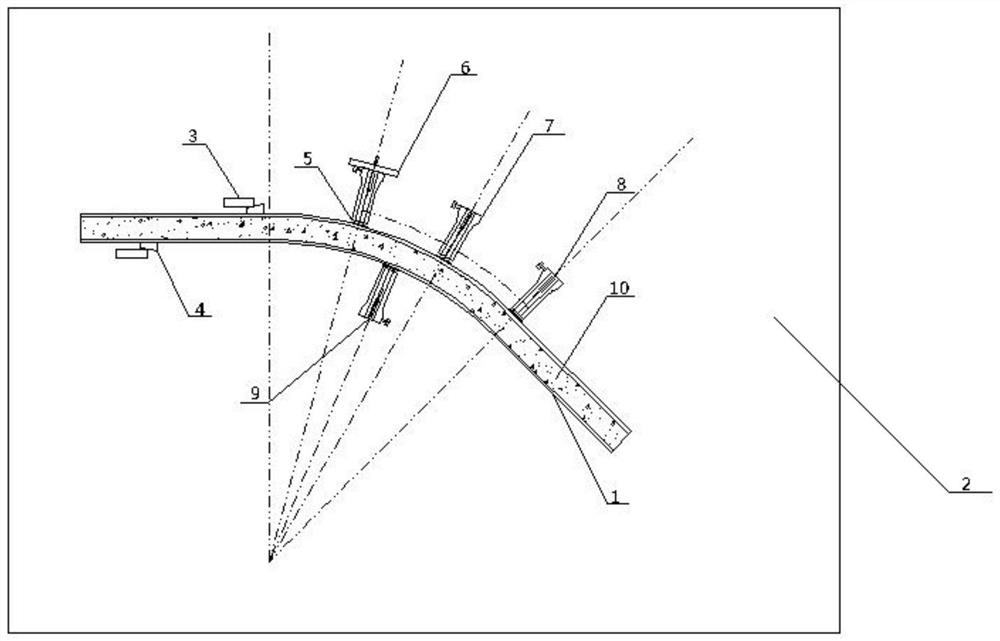

A Simple Hot Simmer Bending Method for Rails

The invention relates to a simple hot bending method for a steel rail, and belongs to a method for steel rail bending in a construction site. The simple hot bending method is characterized by adoptingjacks, a heating device and a steel rail positioning assembly device for hot bending of the steel rail. The hot bending process includes the steps that 1), a bottom plate is arranged; 2), the positioning assembly device and machines and tools for hot bending of the steel rail are prepared; 3) the steel rail is arranged; 4), hot bending is conducted on the steel rail. All groups of positioning blocks and inclined wooden wedges are uniformly and equidistantly distributed on the front and rear sides of the left straight-line section of the steel rail and installed in a staggered manner, the steel rail is fixed, a jack I, a jack II, a jack III and a jack IV are arranged corresponding to the arc segments of the steel rail, the heating device conducts continuous segmented high-temperature heating on the arc segments of the steel rail, the jack I, the jack II, the jack III and the jack IV are driven to jack up and press the steel rail in the high-temperature heating process, the steel rail is formed into shape by hot bending, the operation is convenient, the use is safe and reliable, and the construction quality and construction efficiency are improved.

Owner:CHINA MCC17 GRP

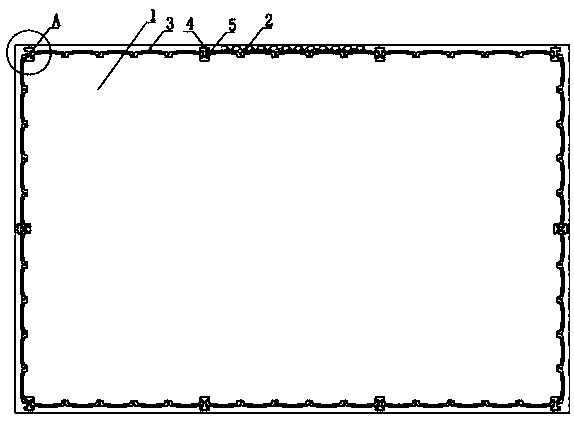

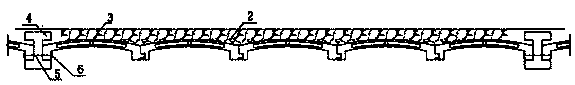

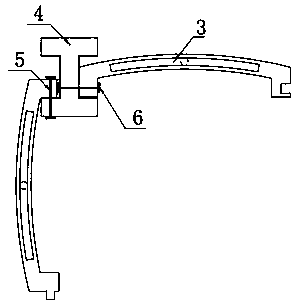

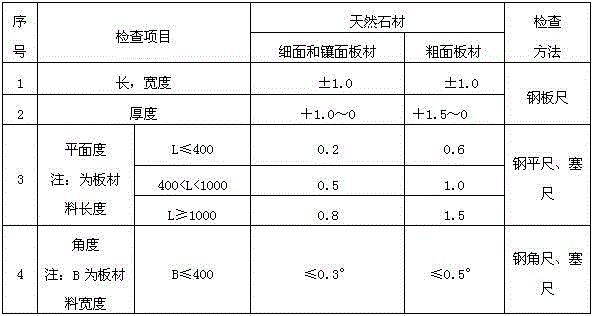

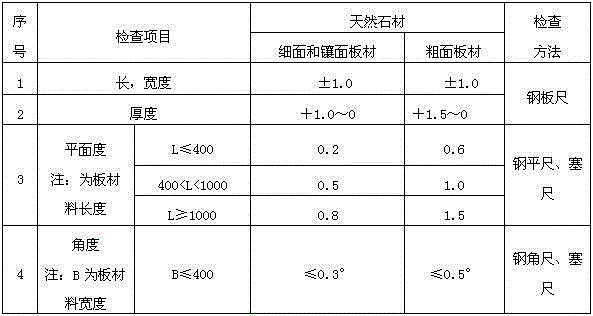

A permeable dry-hanging stone brick curtain wall

The invention relates to the field of brick curtain walls and in particular relates to an open-type dry hanging stone brick curtain wall. The open-type dry hanging stone brick curtain wall comprises a keel, more than two inside stone bricks arranged at the inner side of the keel, and more than two outside stone bricks arranged at the outer side of the keel, wherein the left wall of the keel is provided with a group of uniformly-arranged left fin plates; the right wall of the keel is provided with a group of uniformly-arranged right fin plates; the left fin plates and the right fin plates are arranged alternately, and the vertical distance between a left fin plate and a right fin plate which are adjacent vertically is a preset value; the inner side and outer side of each left fin plate are fixedly provided with an inside stone brick and an outside stone brick respectively; and the inner side and outer side of each right fin plate are fixedly provided with an inside stone brick and an outside stone brick respectively. The scheme effectively avoids the machining error, ensures the smooth installation of the stone bricks, effectively guarantees the construction quality and safety, and meanwhile reduces the construction difficulty and engineering cost input.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

Open-type dry hanging stone brick curtain wall

The invention relates to the field of brick curtain walls and in particular relates to an open-type dry hanging stone brick curtain wall. The open-type dry hanging stone brick curtain wall comprises a keel, more than two inside stone bricks arranged at the inner side of the keel, and more than two outside stone bricks arranged at the outer side of the keel, wherein the left wall of the keel is provided with a group of uniformly-arranged left fin plates; the right wall of the keel is provided with a group of uniformly-arranged right fin plates; the left fin plates and the right fin plates are arranged alternately, and the vertical distance between a left fin plate and a right fin plate which are adjacent vertically is a preset value; the inner side and outer side of each left fin plate are fixedly provided with an inside stone brick and an outside stone brick respectively; and the inner side and outer side of each right fin plate are fixedly provided with an inside stone brick and an outside stone brick respectively. The scheme effectively avoids the machining error, ensures the smooth installation of the stone bricks, effectively guarantees the construction quality and safety, and meanwhile reduces the construction difficulty and engineering cost input.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

Simple cold bending method for thin-wall steel pipe

InactiveCN113070374AEasy to operateEasy to useMetal-working feeding devicesPositioning devicesPipeMachine tool

The invention discloses a simple cold bending method for a thin-wall steel pipe, and belongs to the technical field of building construction. The method comprises the steps of: 1) arranging a bottom plate; 2) filling a thin-wall steel pipe with fine sand; 3) preparing a positioning combination device and a machine tool for cold bending of the thin-wall steel pipe; 4), arranging the thin-wall steel pipe; and 5) carrying out cold bending on the thin-wall steel pipe. According to the method, a jack, the fine sand and the positioning combination device for the thin-wall steel pipe are adopted for cold bending of the steel pipe, so that the method is convenient to operate, safe and reliable to use and high in applicability, the construction cost and unsafe factors are reduced, and the construction quality and the construction efficiency are improved.

Owner:CHINA MCC17 GRP

Construction device and construction method for long-distance and large-diameter cable laying in cable trench

ActiveCN111900670BReduce wearAvoid mechanical forceCable installations in underground tubesApparatus for laying cablesArchitectural engineeringEconomic benefits

Owner:DIER GRP CO LTD

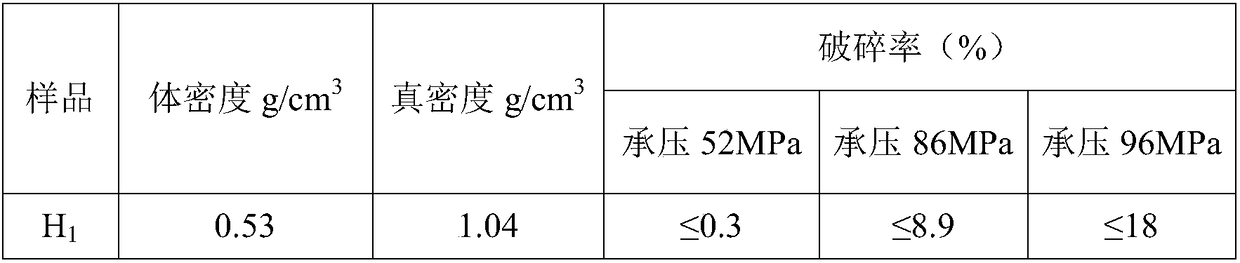

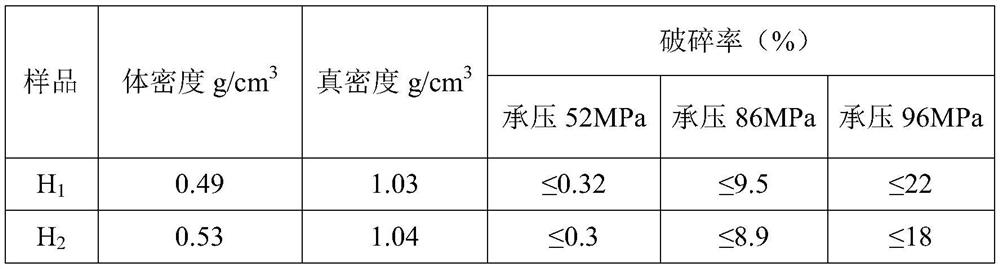

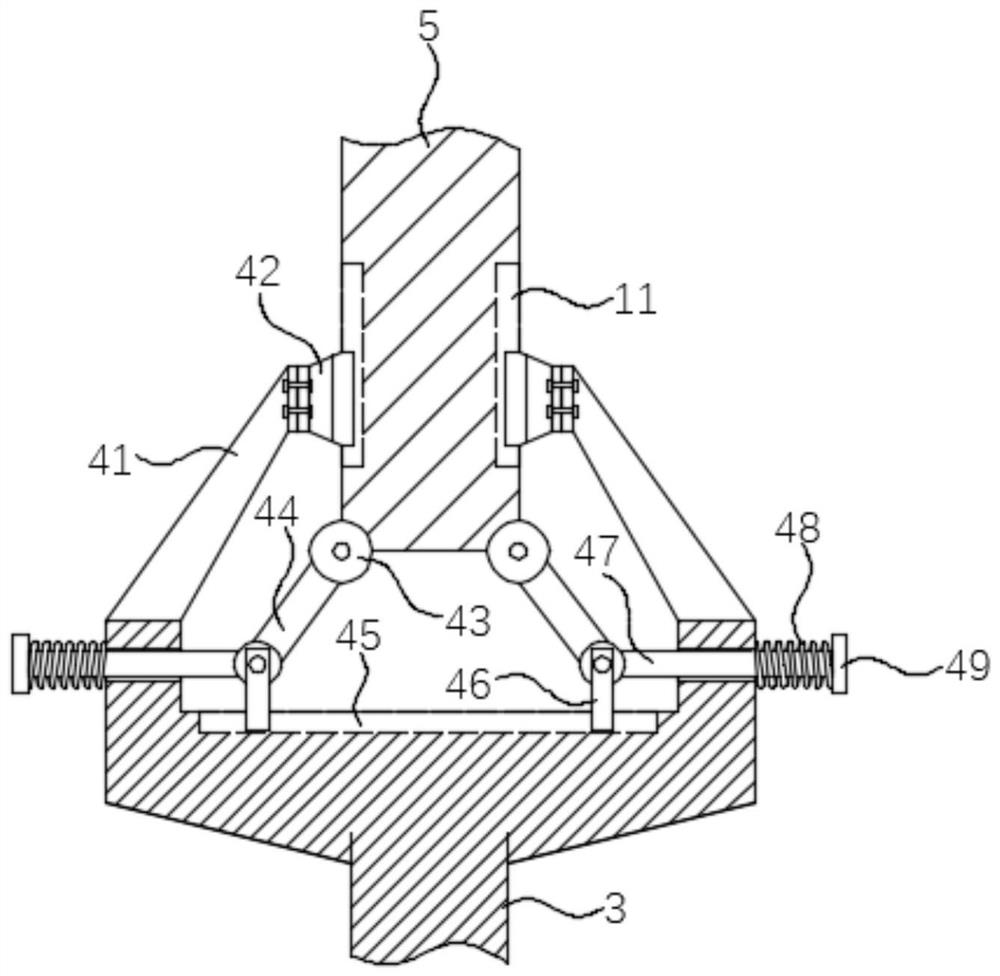

A kind of phase change material liquid and the solid phase proppant formed by it

ActiveCN108587029BReduce frictionLower requirementFluid removalDrilling compositionActive agentTriazine

The invention provides a phase change material liquid and a solid phase proppant formed therefrom. Wherein, in terms of mass percentage, the components for preparing the phase change material liquid include: supramolecular construction unit 10-60wt%, supramolecular functional unit 20-50wt%, dispersant 0.1-2wt%, inorganic structuring agent 0.1-1wt% %, initiator 0.1‑1wt%, and the rest are solvents; supramolecular building blocks include melamines and / or triazines; supramolecular functional units include dicyclopentadiene resins; dispersants include hydroxylated polysaccharides and surfactants. After the phase-change material liquid enters the reservoir, under the action of supramolecular chemistry and physics, it can form a solid-phase material to support fractures. Because there is no solid phase injection, it can effectively reduce the friction of the pipe string, reduce the requirements for construction equipment, surface pipelines, wellheads and construction pipe strings, effectively reduce construction costs, and reduce construction risks and safety hazards.

Owner:PETROCHINA CO LTD

A light-duty tail buffer device for fully mechanized mining machines in coal mines

ActiveCN110029992BReduce the difficulty of pullingReduce construction safetySlitting machinesVibration suppression adjustmentsMachineRock bolt

Owner:SHANDONG HUAHENG MINING

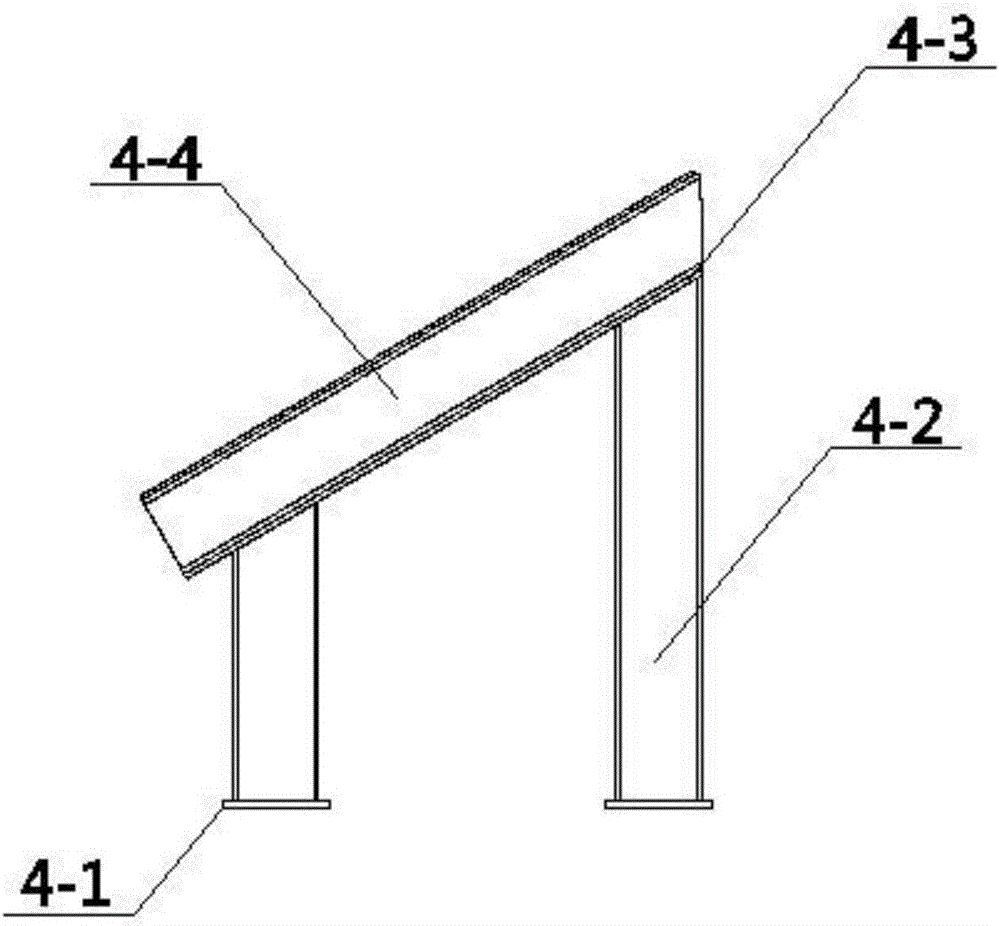

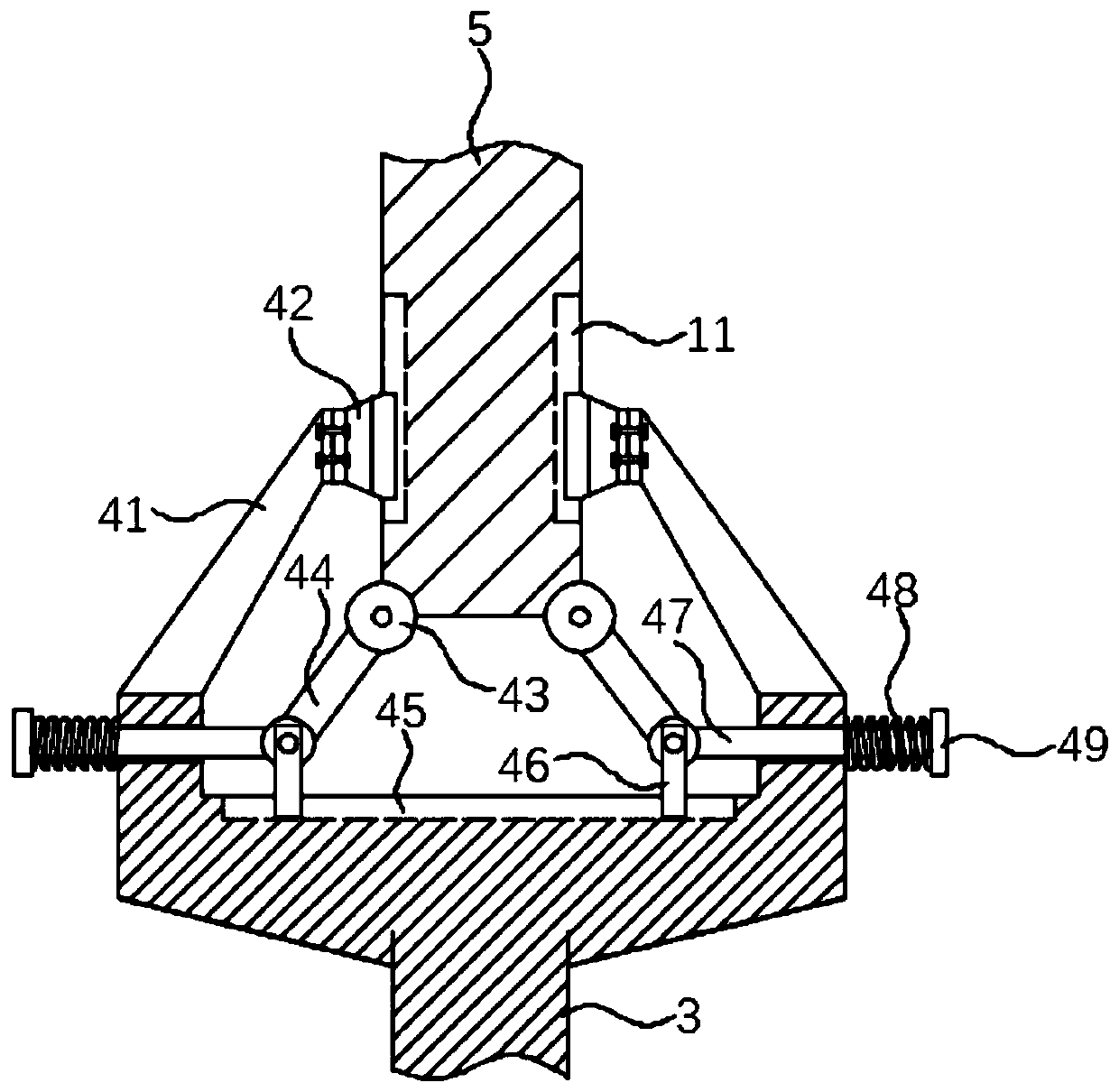

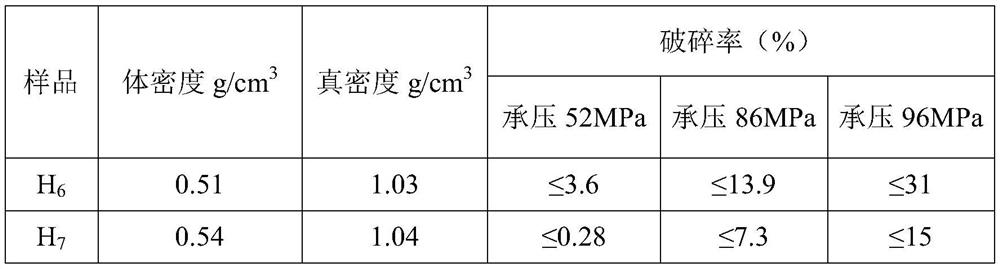

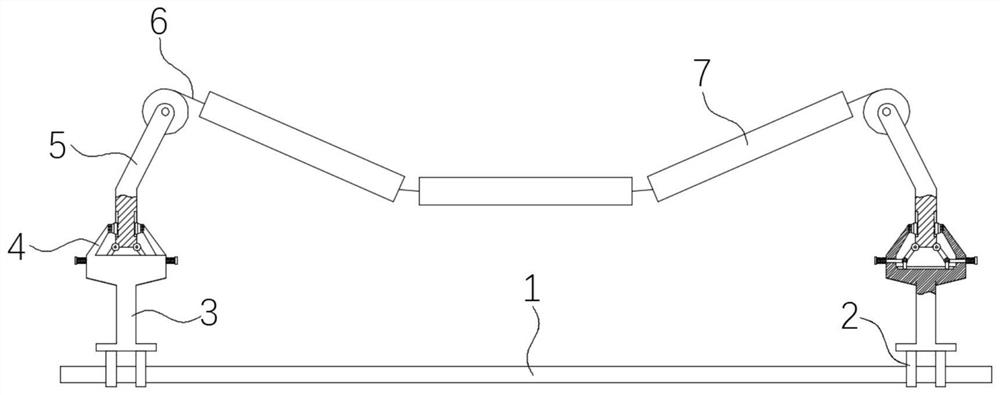

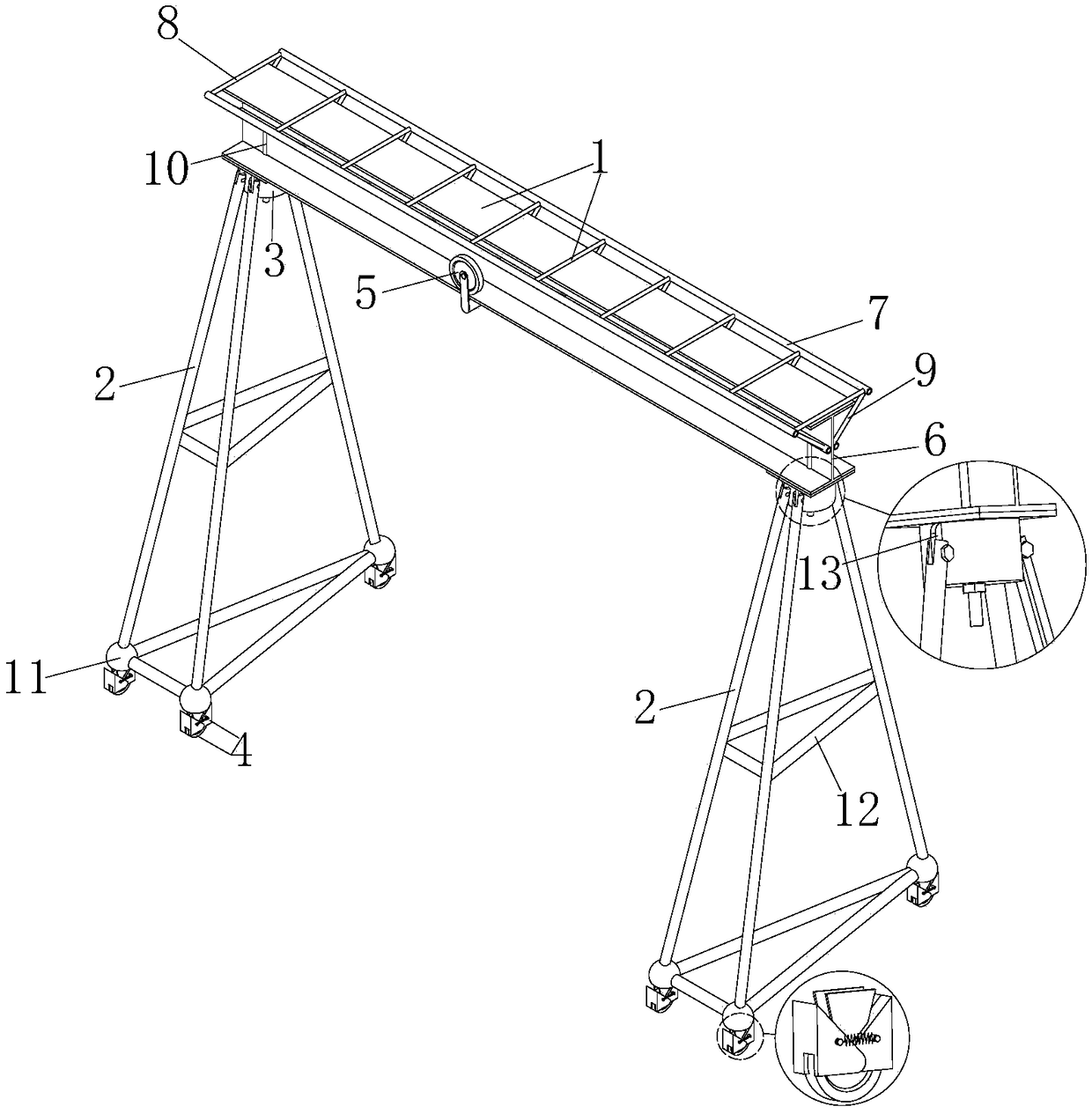

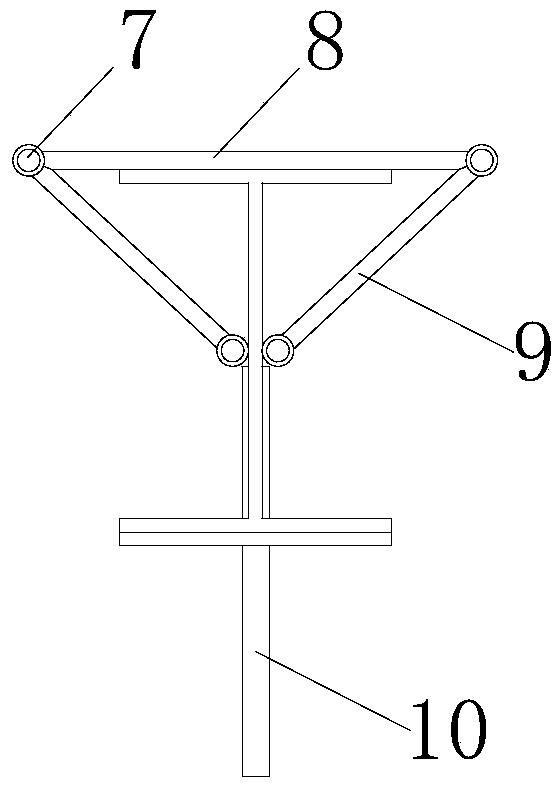

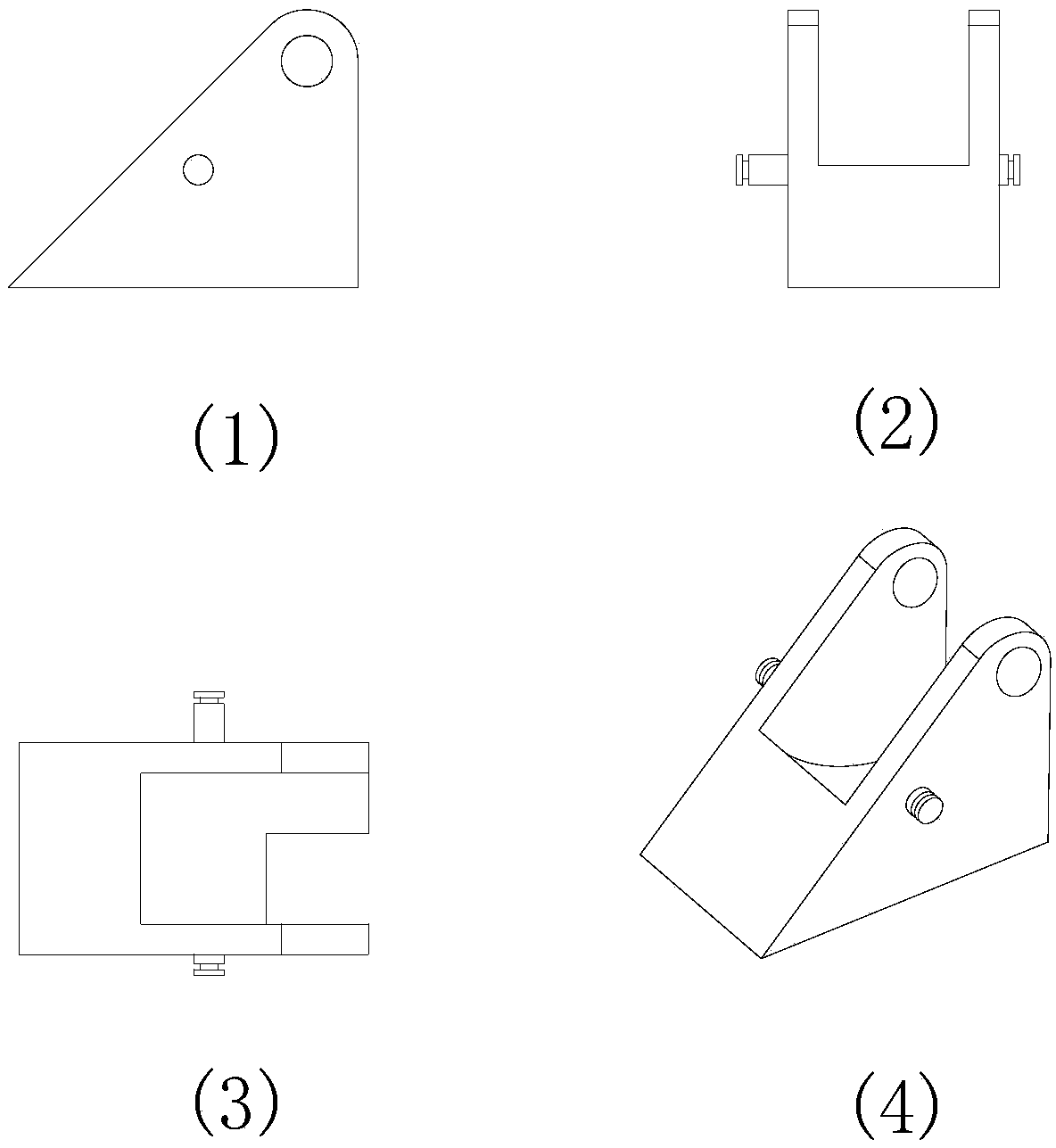

Light detachable movable portal frame device and using method thereof

PendingCN108946498AEasy to makeEasy to disassembleBase supporting structuresBraking devices for hoisting equipmentsSupport pointPortal frame

The invention provides a light detachable movable portal frame device. The portal frame device comprises a main beam, two triangular pyramid-shaped supports, connecting boxes, fixable universal wheelsand a pulley device, wherein the two triangular pyramid-shaped supports are located at the two ends of the main beam respectively, the main beam is connected with the upper ends of the two triangularpyramid-shaped supports through the connecting boxes, the fixable universal wheels are welded to supporting points of the lower parts of the triangular pyramid-shaped supports, and the movable pulleydevice is placed on the lower part of I-shaped steel of the main beam and moves in the length direction of the main beam. The invention further provides a using method of the device. By means of thedevice, articles can be moved in multiple directions on a construction site, moreover, the device can be disassembled into four parts for construction and field transfer, so that the problems of inconvenient transportation of objects, safety problems of repeated cutting and installation of a portal frame and the like on the construction site are solved.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

A method for installing a tunnel safety protection net

ActiveCN104110015BEffective protectionReduce construction safetyWater-power plantsHydro energy generationSocial benefitsGrating

The invention discloses a tunnel safety protection net and an installation method. The invention aims to provide a tunnel safety protection net with convenient assembly and disassembly, good protection performance and low cost. When the tunnel safety protection net is installed, it is fixedly connected with the anchor rod of the tunnel roof arch, which includes a supporting steel rope net fixedly connected with the anchor rod, a SO / 2.2 / 50 type steel wire grid mesh fixedly connected under the supporting steel rope net and The DO / 08 / 300 type steel wire mesh installed under the SO / 2.2 / 50 type steel wire grid; the supporting steel rope mesh is made of steel ropes with a diameter of φ16㎜, and the mesh spacing is 4500㎜×4500㎜; The DO / 08 / 300 type steel wire mesh is fixedly connected with the supporting steel rope mesh with a suture rope of φ8㎜. The installation of the tunnel protection net can greatly reduce the threat of the tunnel top arch falling block to the construction below, eliminate the safety hazard of the tunnel falling block, ensure the safety of construction personnel and equipment in the tunnel, and produce better economic and social benefits.

Owner:SINOHYDRO BUREAU 14 CO LTD

Stylobate joint of framework column

ActiveCN102071745BUnderstand the purposeLearn about featuresStrutsPillarsFillet weldArchitectural engineering

The invention discloses a stylobate joint of a framework column, which comprises an anchor bolt and a shear reinforcement, and is characterized by further comprising a flange, wherein the flange comprises an upper flange piece and a lower flange piece which are stacked and fixedly connected with each other, the lower flange piece is fixed with the top of a base, and the upper flange piece is fixed with the bottom of the framework column. During the construction of the stylobate joint disclosed by the invention, the lower flange piece which is welded with the tension anchor bolt and the shear reinforcement is cast in the top part of the base in advance, and is poured with concrete together with the base of the previous stage, after the concrete of the base reaches the requirement of the design strength, an upper framework column with the stylobate joint is hoisted in place, the anchor bolt is screwed, the periphery of the upper flange piece is welded with the upper surface of the lowerflange piece through fillet welds, so a framework can be hoisted and permanently fixed at once, the subsequent wire stretching and erection can be instantly carried out, and both the construction efficiency and safety are improved.

Owner:SHANGHAI ELECTRIC POWER DESIGN INST

A high-altitude large-span network frame sliding positioning installation and monitoring method

ActiveCN108824816BSolve the problem of lack of monitoring of grid deformationSolve the problem of deformation monitoringUsing optical meansBuilding material handlingTheodoliteLaser scanning

The invention provides a high-altitude large-span net rack sliding positioning mounting method and further provides a high-altitude large-span net rack sliding positioning mounting monitoring method.The effect that in construction through a sliding method, bolted spherical joints are quickly and accurately positioned is achieved. A high-altitude large-span net rack of a steel structure is positioned through a three-dimensional laser scanning system, the positions of all the bolted spherical joints of a whole splicing platform can be synchronously determined at a time, quickness and convenience are achieved, as for a traditional method, a total station and a theodolite are used for measuring the mounting positions of the bolted spherical joints one by one, and thus the time and labor are wasted. The problem that as for construction of a high-altitude large-span steel structure net rack through the sliding method, deformation monitoring for the net rack lacks in the process that the netrack separates from a sliding operating frame is solved, displacement deformation of key joints of the net rack is monitored through the three-dimensional laser scanning system, by comparing the deformation result of finite element calculation, the state of the net rack is judged advantageously, it is ensured that net rack deformation is within the controllable range, the construction risk is lowered, and construction safety is ensured.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com