Sieving pipe sand preventing process

A technology of sand control and craftsmanship, applied in the field of sand control technology, can solve the problems of high platform transportation costs and limited platform work space, and achieve the effects of environmental protection, reduced construction procedures, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

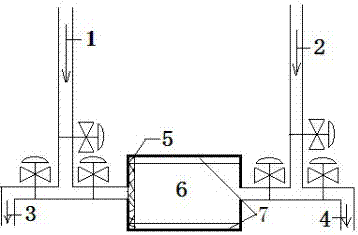

[0042] Embodiment 1 adopts the sand control experiment of not pressing open the rock slab.

[0043] The experimental temperature was 90°C.

[0044] In the first step, 3% NH is displaced from reverse drive inlet 2 4 The Cl base fluid simulates the flow from the formation to the bottom of the well during the production process, and the sand output is tested from the circulation cleaning outlet 3. Displace 3% NH from positive drive inlet 1 after reverse displacement 4 The Cl base fluid is used to clean the sand that sinks in the pipeline, and the amount of sand produced from the circulation cleaning outlet is also tested. Specifically, all the materials that flow out twice are filtered and then dried, weighed to take out the sand mass, and calculate the sand velocity. The test results are: the displacement pressure is 4MPa, and the sand output is 5.3g / h.

[0045] In the second step, agent B is displaced from the positive drive inlet under a displacement pressure of 4 MPa, and...

Embodiment 2

[0050] Embodiment 2 adopts the sand control experiment of pressing open rock slabs.

[0051] The experimental temperature was 90°C.

[0052] The first step is to displace 3%NH from the reverse drive inlet 4 The Cl base fluid simulates the flow from the formation to the bottom of the well during the production process, and the sand output is tested from the circulation cleaning outlet. Displace 3% NH from the positive drive inlet after the reverse drive is over 4 The Cl base fluid is used to clean the sand that sinks in the pipeline, and the amount of sand produced from the circulation cleaning outlet is also tested. Specifically, all the materials that flow out twice are filtered and then dried, weighed to take out the sand mass, and calculate the sand velocity. The test results are: the displacement pressure is 4MPa, and the sand output is 7.9g / h.

[0053] In the second step, the agent A is displaced from the positive drive inlet at a displacement pressure of 6 MPa, and t...

Embodiment 3

[0060] Embodiment 3 adopts the sand control experiment of not pressing open the rock slab.

[0061] The experimental temperature was 85°C.

[0062] The first step is to displace 3%NH from the reverse drive inlet 4 The Cl base fluid simulates the flow from the formation to the bottom of the well during the production process, and the sand output is tested from the circulation cleaning outlet. Displace 3% NH from the positive drive inlet after the reverse drive is over 4 The Cl base fluid is used to clean the sand that sinks in the pipeline, and the amount of sand produced from the circulation cleaning outlet is also tested. Specifically, all the materials that flow out twice are filtered and then dried, weighed to take out the sand mass, and calculate the sand velocity. The test results are: the displacement pressure is 5MPa, and the sand output is 4.8g / h.

[0063] In the second step, agent B is displaced from the positive drive inlet under a displacement pressure of 5 MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com