Assembly building modularized frame structure

A frame structure and modular technology, applied in the direction of building structure, construction, etc., can solve the problems of high skill requirements for construction personnel, high requirements for construction site management, and serious environmental pollution, so as to reduce construction environmental pollution and reduce multiple types of work The effect of skilled personnel cooperation and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

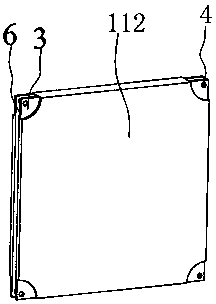

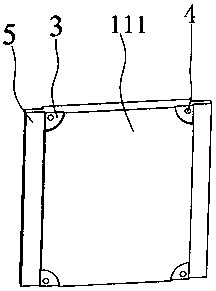

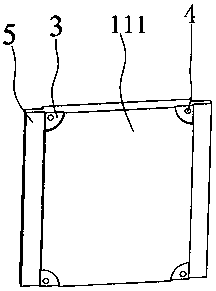

[0036] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Image 6 , attached Figure 7 , attached Figure 8 , attached Figure 9 , attached Figure 10 And attached Figure 11 As shown in this embodiment, a prefabricated building modular frame structure and its installation method include a flat panel module 1, a symmetrical flat panel module 11, a convex symmetrical flat panel module 111, a concave symmetrical flat panel module 112, an asymmetric flat panel module 12, and a corner Module 2, symmetrical corner module 21, asymmetrical corner module 22, concave table 3, threaded hole 4, protrusion 5, groove part 6, connecting block 7, the basic board surface is assembled by flat module 1, and corner module 2 Located at each corner, it is used to connect the basic panels in different positions. The corner module 2 is used to connect the adjacent basic panels to form the basic structure of the building. Both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com