Simple cold bending method for thin-wall steel pipe

A thin-walled steel pipe and cold-formed technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of thin-walled steel pipes, affecting the next process, and increasing the labor intensity of construction personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

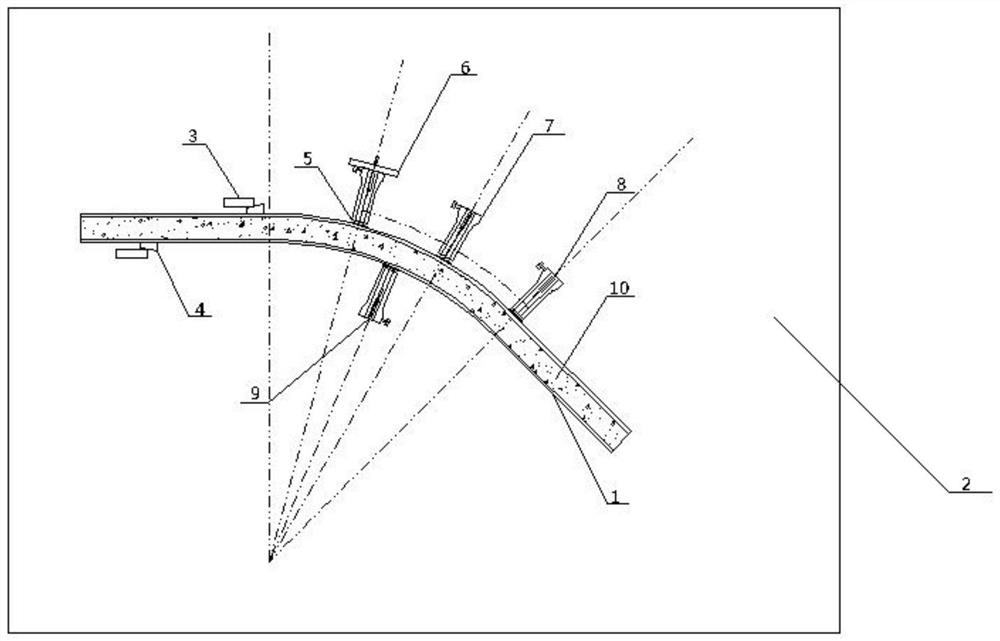

[0028] A kind of simple and easy cold-bending method of thin-walled steel pipe of the present embodiment, its steps are:

[0029] 1) Set the bottom plate:

[0030] Place a steel bottom plate 2 on the construction site, and use a level to level the bottom plate 2. The unevenness of the bottom plate 2 is: no more than 1mm per meter. Bending requirements or drawing size of thin-walled steel pipe 1: According to the bending angle of thin-walled steel pipe 1, the angle section of thin-walled steel pipe 1 is divided into three sections from left to right on the bottom plate 2 (ie, the angle section of the left section , middle section angle section, right section angle section) (referred to as left section, middle section, right section) and corresponding to the end face or interface of left section, middle section, right section angle section respectively lead out the rays of the same circle center;

[0031] 2) Thin-walled steel pipe filled with fine sand:

[0032] A considerable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com