A high-altitude large-span network frame sliding positioning installation and monitoring method

A positioning, installation, and sliding technology, which is applied to measuring devices, optical devices, and processing of building materials. To achieve the effect of reducing construction risks, reducing the amount of data processing, and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

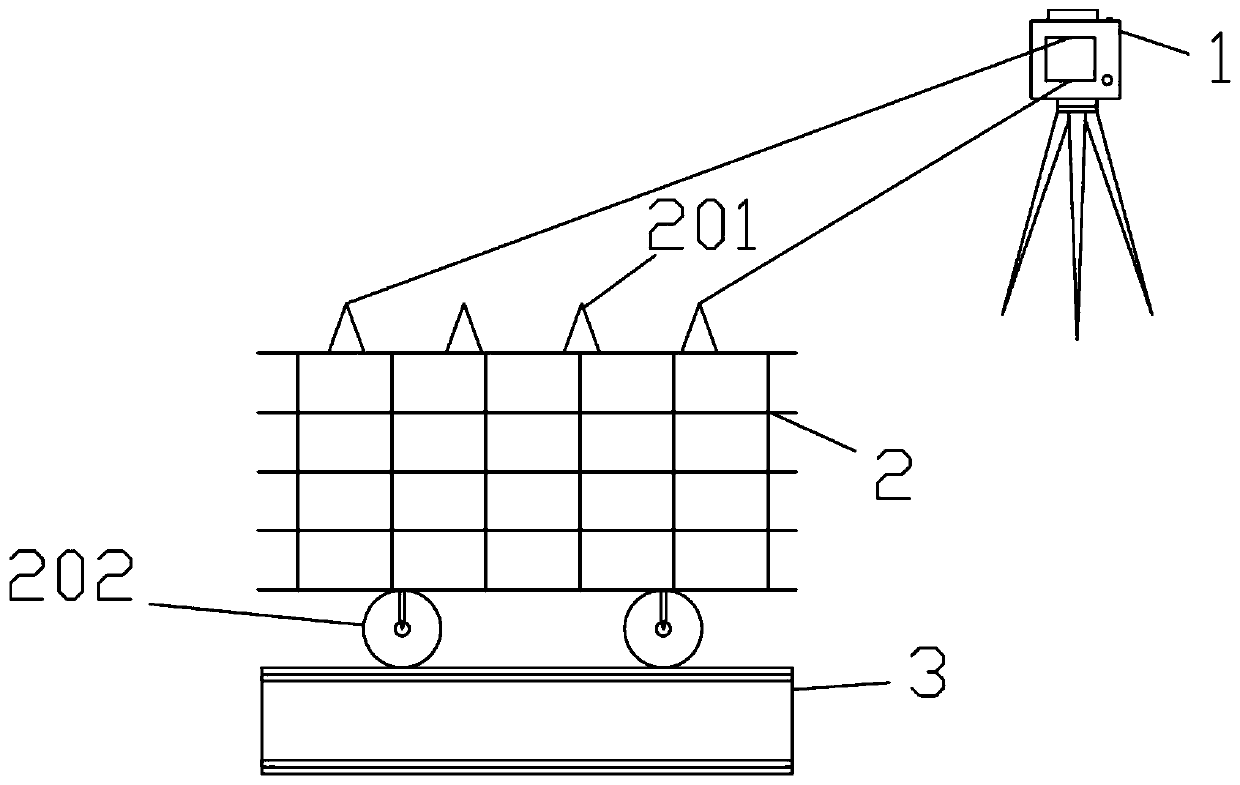

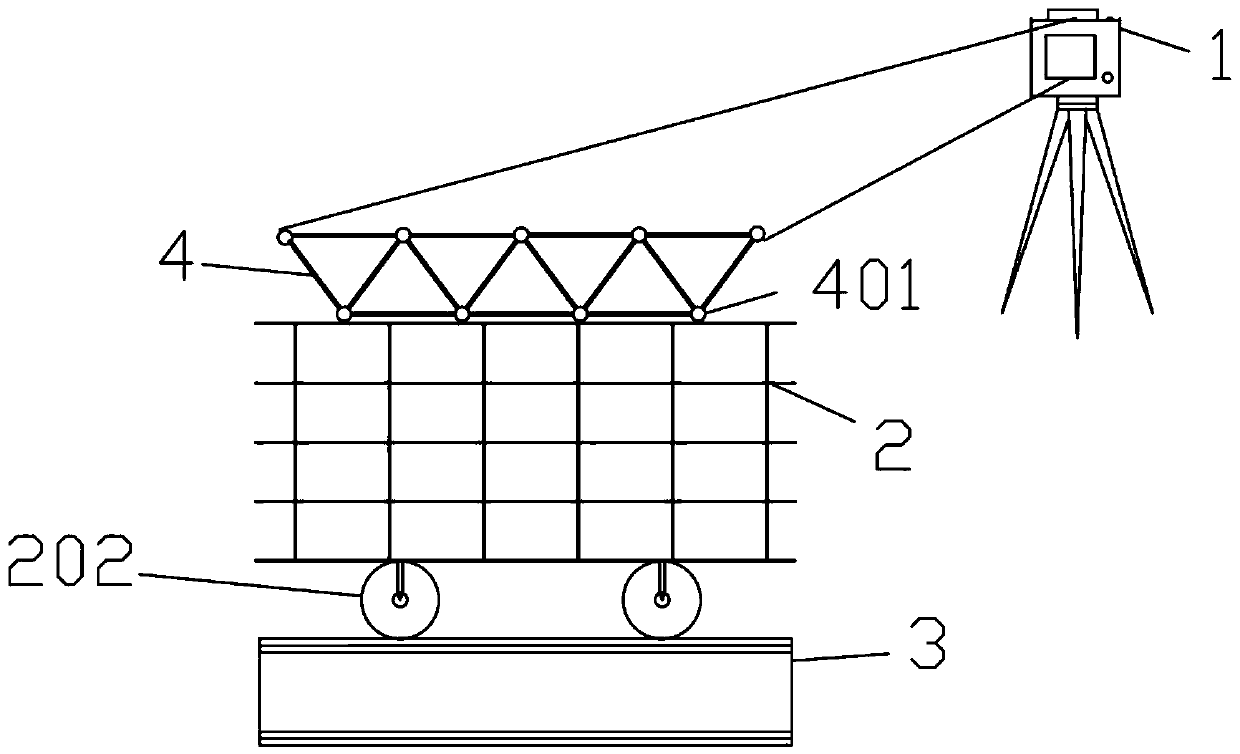

[0032] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

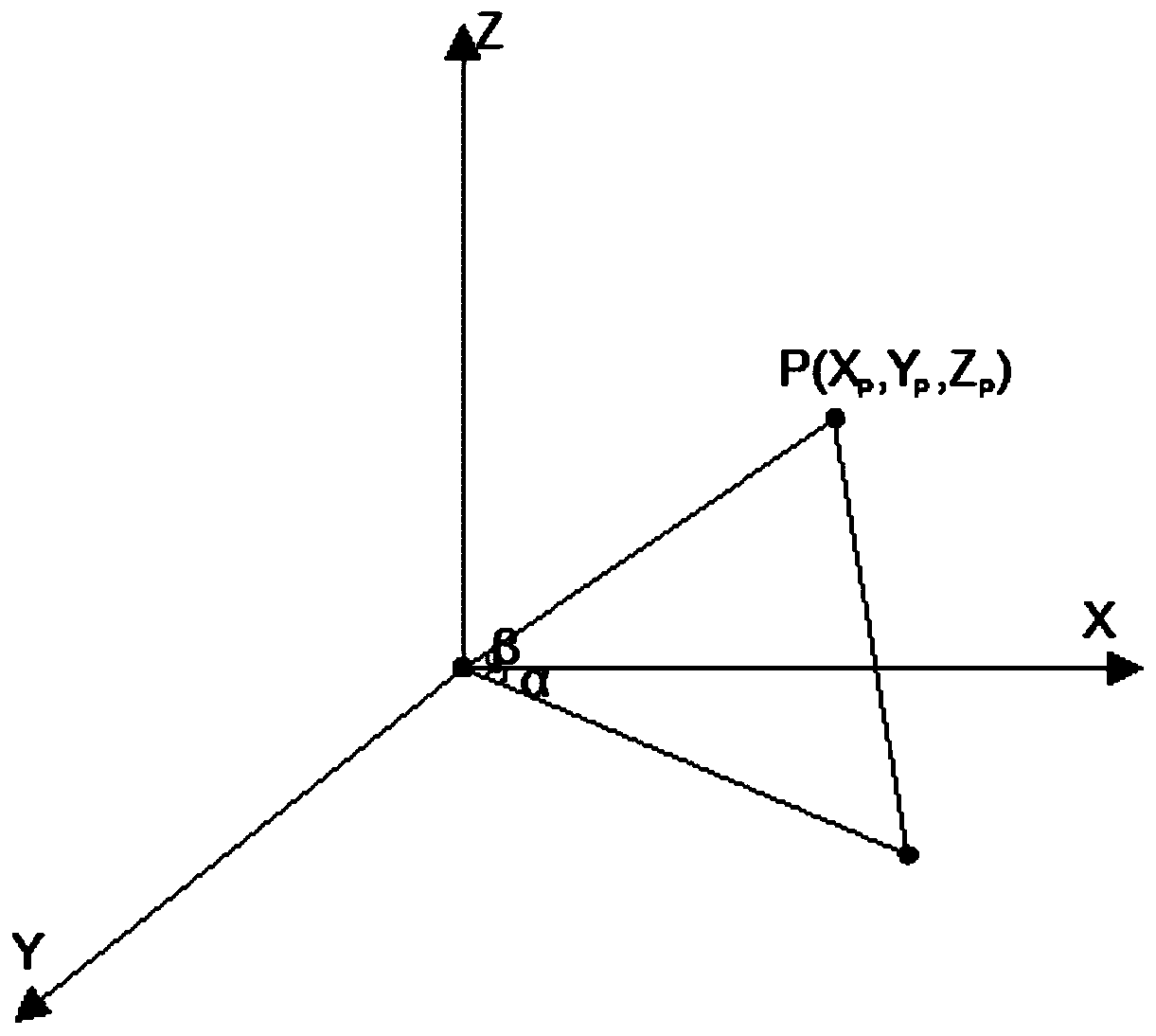

[0033] A high-altitude large-span network frame sliding positioning installation and monitoring method includes the following steps:

[0034] (1) Establish the finite element model of the high-altitude large-span grid structure and the sliding operation frame of the steel structure in the MIDAS software according to the design documents, and use the construction simulation function provided by the MIDAS software to input the high-altitude large-span grid structure. Based on unit material information, structural force information and boundary conditions, calculate the displacement of the center point of the upper chord bolt ball during the sliding construction process of the high-altitude large-span grid frame of the steel structure, and form the deformation data of the corresponding bolt ball node;

[0035] (2) Monitor the deformation data of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com