A light-duty tail buffer device for fully mechanized mining machines in coal mines

A buffer device and fully mechanized excavator technology, applied in the direction of slitting machinery, mechanical equipment, springs/shock absorbers, etc., can solve problems such as high man-hour consumption, broken ropes and injuries, and frequent belt extension of fully mechanized excavators. Reduce the difficulty of pulling and transporting, improve construction efficiency, and ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

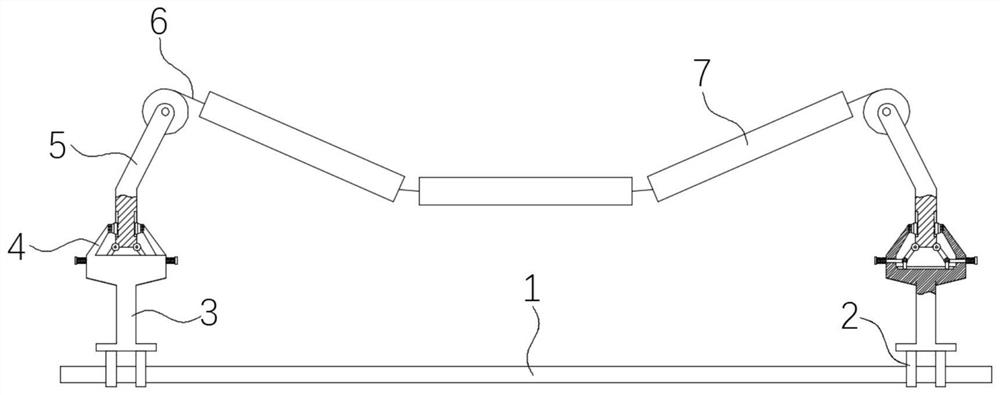

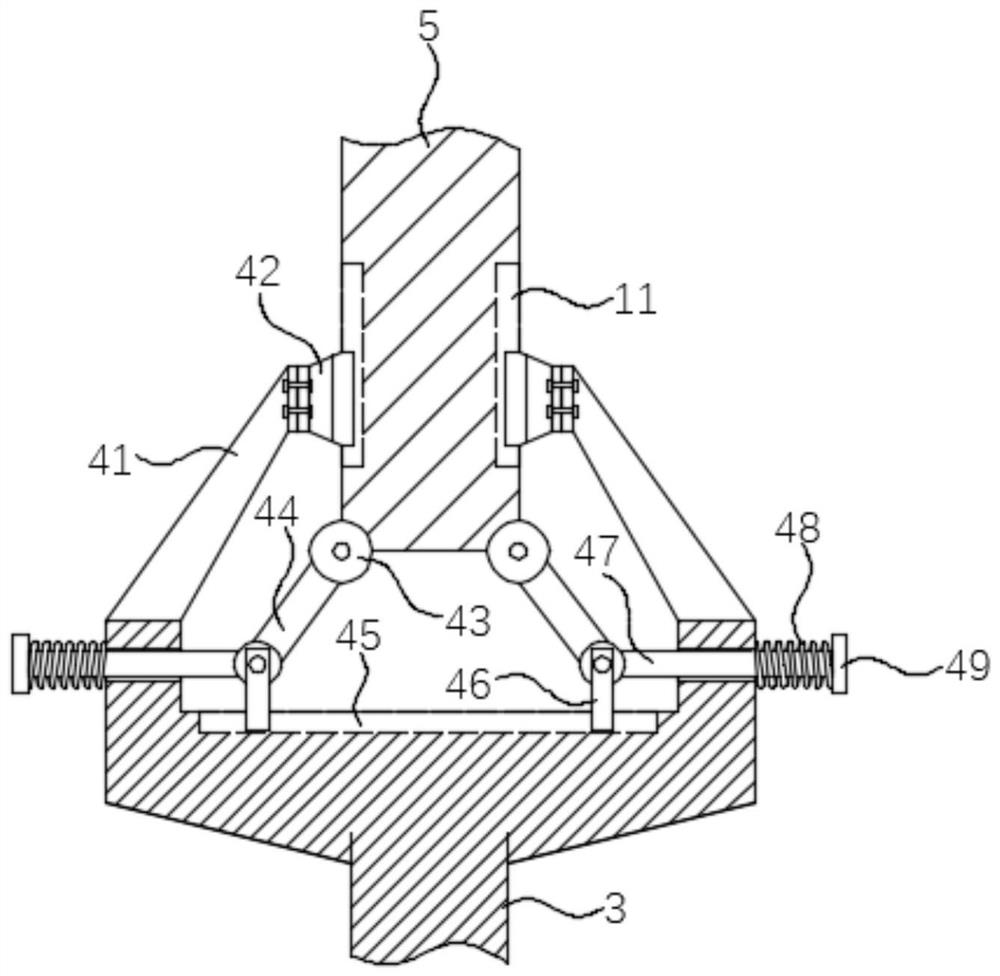

[0034] refer to Figure 1 to Figure 2 , a light-duty tail buffer device for fully mechanized mining machines in coal mines, comprising a base 1, clamps 2 are fixedly connected to both sides of the upper end of the base 1, and an I-shaped steel runway 3 is fixedly connected to the upper end of the clamp 2, and the I-shaped A buffer mechanism 4 is installed on the upper surface of the steel runway 3 .

[0035] The buffer mechanism 4 includes a support arm 41, a limit block 42, a rotary joint 43, a connecting rod 44, a chute 45, a slide block 46, a push rod 47, a return spring 48, and a block 49. The specific connection method is as follows:

[0036] Both sides of the bottom end of the idler frame 5 are connected with a connecting rod 44 through the rotating joint 43, and the end of the connecting rod 44 away from the rotating joint 43 is rotatingly connected with a slider 46 and a push rod 47. The top of the I-beam runway 3 is provided with Chute 45, slide block 46 is slidably ...

Embodiment 2

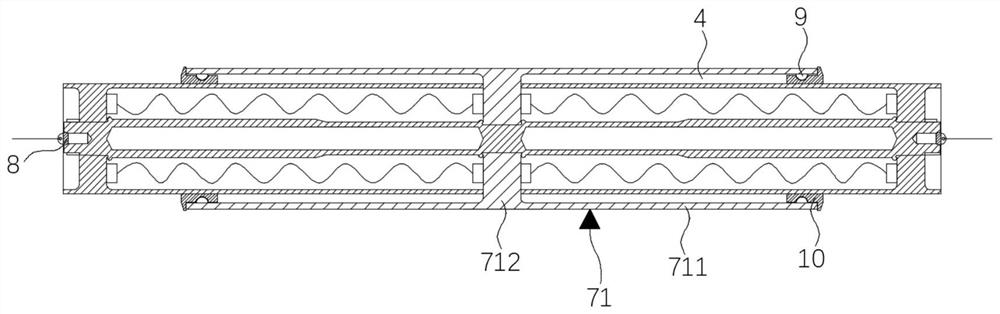

[0052] Embodiment 2 On the basis of Embodiment 1, a vibration-absorbing member 73 is further provided. The arrangement of the vibration-absorbing member 73 can greatly increase the anti-vibration performance of the roller 7 .

[0053] At least one vibration absorber 73 is arranged radially inside the cavity 725;

[0054] The vibration damping elastic metal 731 adopts a spring, and the two sides of the elastic metal 731 are fixedly connected to the outer partition 722 and the inner partition 712 through the connecting block 732 respectively.

[0055] When the idler 7 vibrates under the action of an external force, the idler 7 drives the vibration absorber 73 to perform forced vibration. When the external force gradually increases, until the vibration frequency of the idler 7 is the same as the natural frequency of the elastic metal 731, the elastic The metal 731 resonates, absorbs most of the vibration energy of the idler 7 in the resonance, and converts this energy into heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com