Stylobate joint of framework column

A technology of column foot joints and frame columns, applied in the field of column footing of steel structures, can solve problems such as affecting construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

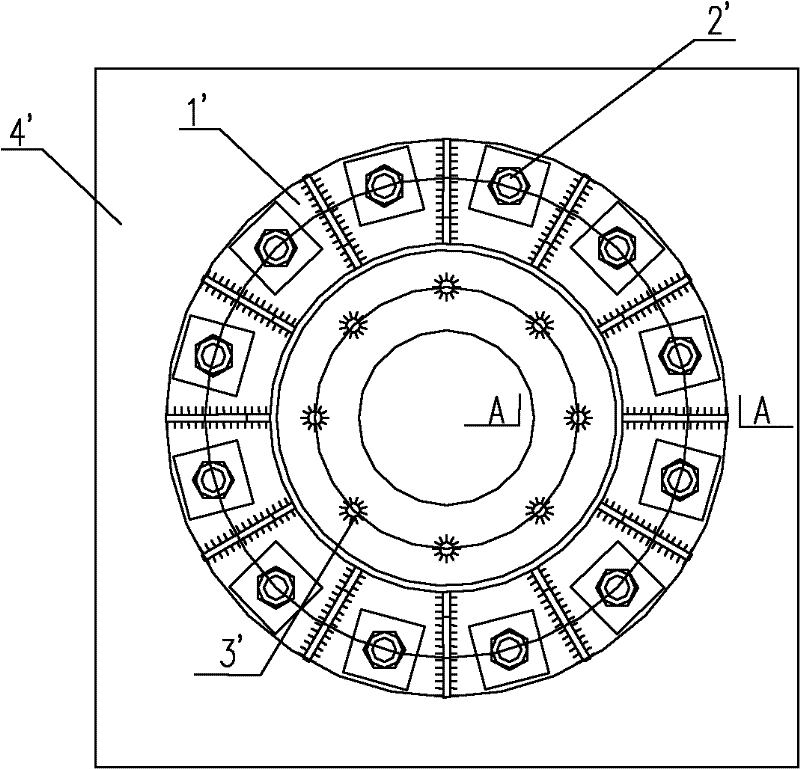

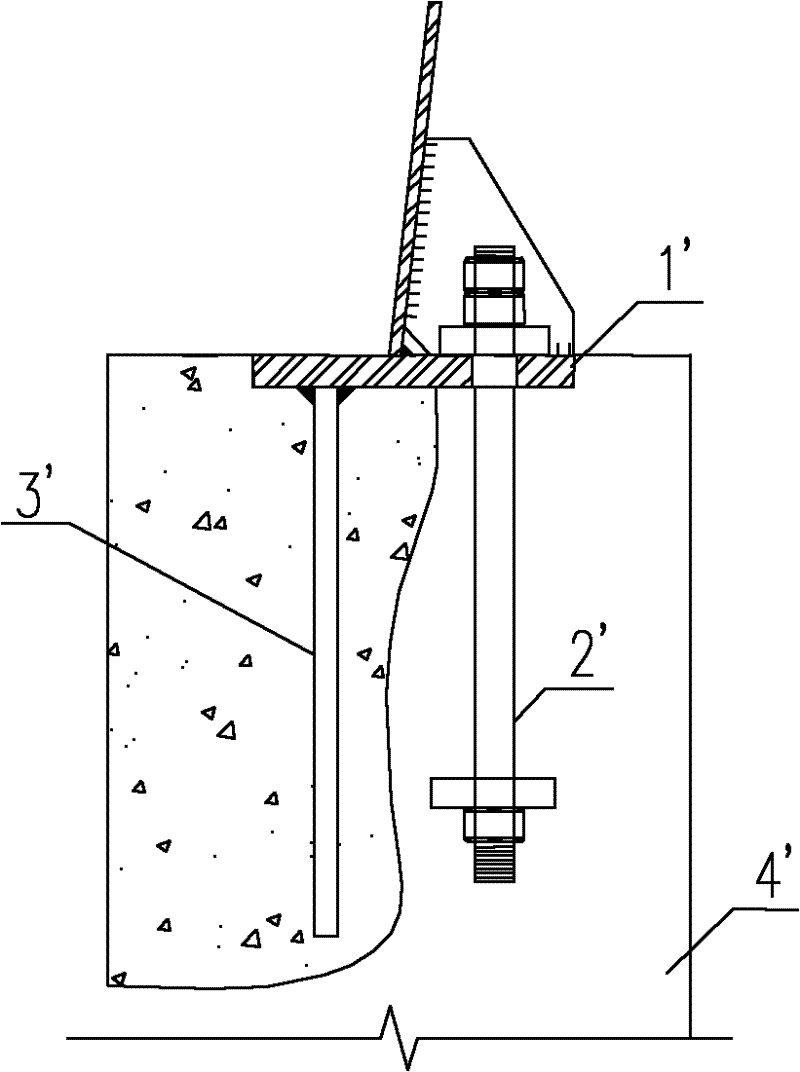

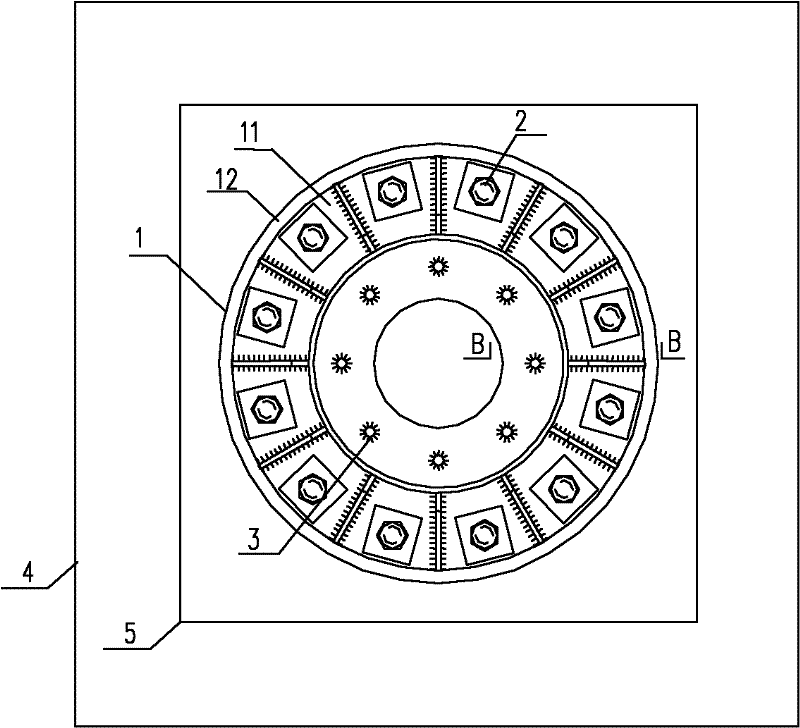

[0024] According to an embodiment of the present invention, as image 3 as well as Figure 4 As shown, the column base node of the frame column includes a bearing seat 5 set higher than the base 4, and it also includes a flange 1, and the flange 1 includes upper flange pieces 11 that are stacked and fixedly connected to each other and The lower flange piece 12 is fixed to the top of the bearing seat 5, and the upper flange piece 11 is fixed to the bottom of the frame column.

[0025] In a specific implementation process, the base 4 can be a concrete base 4, the bearing seat 5 is integrally formed with the base 4, and the bearing base 5 is higher than the top surface of the base 4 by a certain amount. In a preferred embodiment of the present invention, the area of the cross-section of the bearing seat 5 is smaller than the area of the top surface of the base 4, and the cross-section of the bearing seat 5 is a regular quadrilateral whose side length is greater than The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com