Sponge concrete brick and application thereof

A technology of concrete bricks and concrete, applied in the field of construction, to achieve the effects of easy planting of plants, good water permeability, and increased tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The spongy concrete brick of the present invention is made of concrete including garden waste, wherein the concrete used includes the following types:

[0043] (1) The spongy garden waste concrete of the present invention includes cement, sand, stones, and garden waste. The garden waste is fragmented garden waste after crushing; the concrete is made by uniformly mixing cement, sand, stones, fragmented garden waste and water, and its weight ratio is: cement: sand: The weight ratio of stone: fragmented garden waste: water is 100:90:190:5:45. Among them, the cement is 42.5 ordinary Portland cement; the sand is medium-coarse sand; the particle size of the stone is 5mm-25mm.

[0044] The preparation method comprises the following steps: step 1: drying garden wastes to obtain product 1; step 2: pulverizing the product 1 to obtain product 2 with a particle diameter of 0.1-3 cm; step 3: passing product 2 through a 10-mesh sieve Screening to obtain fragmented garden waste; Ste...

Embodiment 2

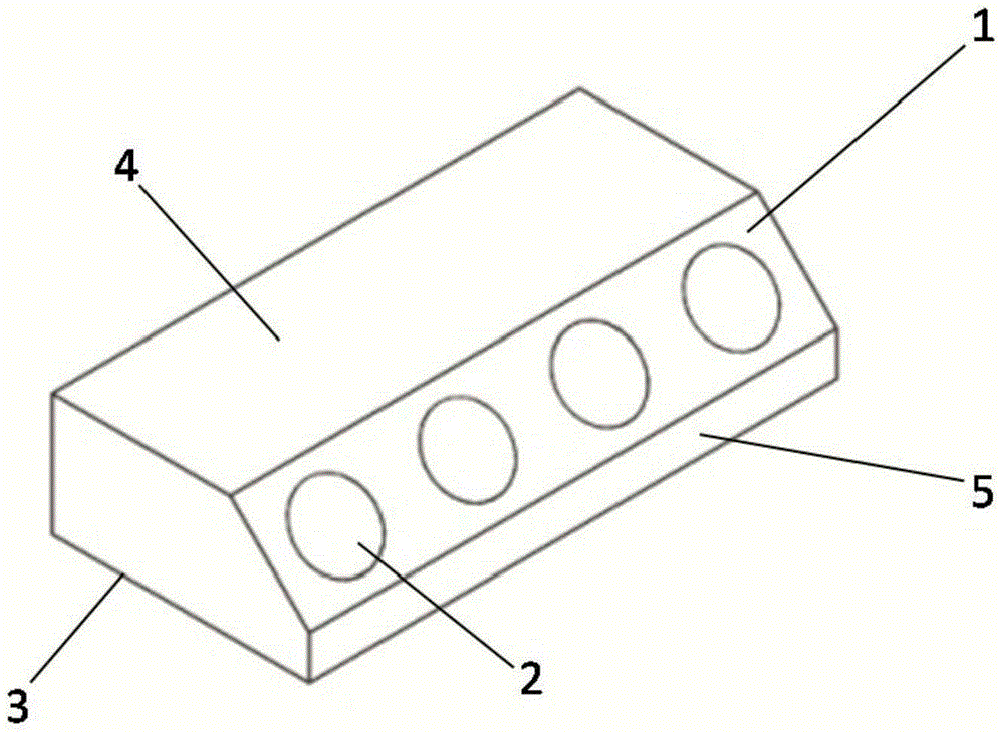

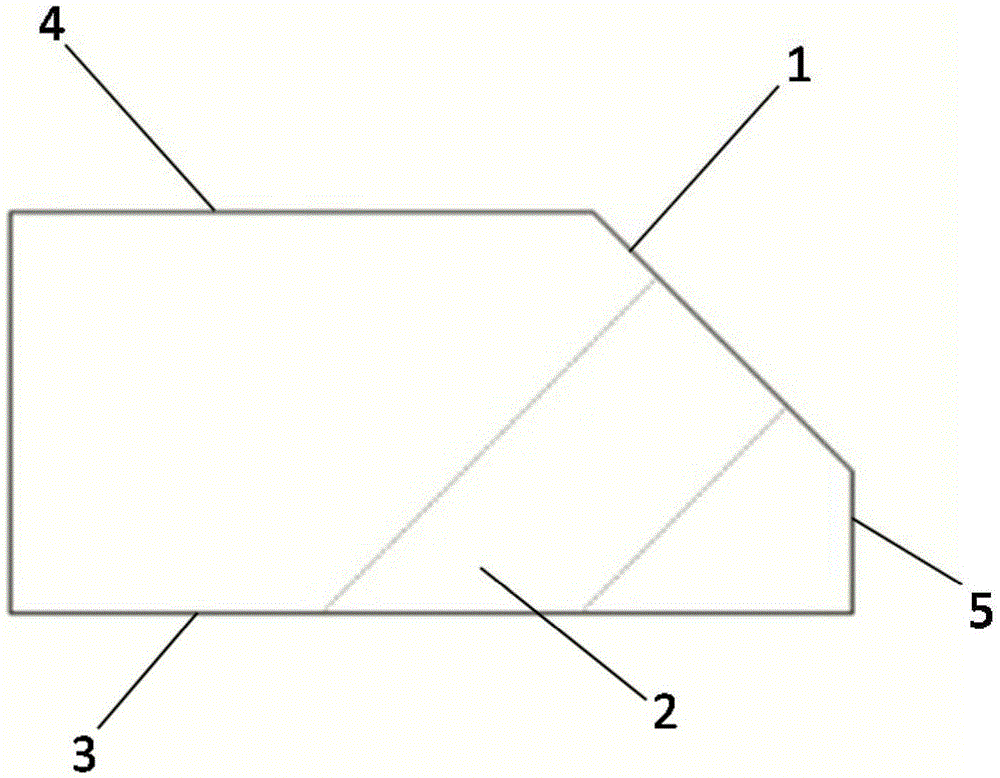

[0103] In order to further promote urban greening construction and beautify the urban landscape, the sponge concrete brick in the first embodiment can be structurally improved to be suitable for planting plants. Ordinary concrete bricks are generally elongated bricks, that is, slab bricks, and in this embodiment, such as figure 1 As shown, one side of the concrete brick is slope 1, from the section perpendicular to slope 1 (see figure 2 ), the profile of the concrete brick is trapezoidal or similar, and there are holes 2 on the slope 1. The number of holes can be 1-10, and they are evenly distributed in the length direction. In this embodiment, the holes 2 pass through the bottom surface 3. In other embodiments, the hole can pass through the opposite side of the slope 1, or pass through the side and the bottom 3 at the same time, or not pass through any other surface to form an inner cavity inside the concrete brick. The holes 2 can be circular or other shapes, which can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com