Preparation method of mesoporous silicon-dioxide-coated single-wall carbon nanotubes

A single-walled carbon nanotube and mesoporous silica technology, which is applied in the field of preparation of mesoporous silica-coated single-walled carbon nanotubes, can solve the problems of complicated operation steps, insufficient composite nanowire morphology, etc. The effect of increasing specific surface area, easy control of morphology, and adjustable shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 10 mg of single-walled carbon nanotubes, 10 mg of cetyltrimethylammonium bromide, and 50 mL of deionized water were added to a three-necked flask, and ultrasonically dispersed for 5 minutes to obtain a stable single-walled carbon nanotube dispersion.

[0032] Use 2M sodium hydroxide solution to adjust the pH value of the above dispersion to 8.0, add 0.15mL tetraethyl orthosilicate, and react at 25°C for 4 hours, so that the mesoporous silica layer is evenly coated on the single-walled carbon the surface of the nanotube.

[0033] After the reaction was finished, a black precipitate was obtained by centrifugation at 11000 rpm. Calcinate the precipitate in a muffle furnace at 300°C for 3 hours to remove the template to obtain mesoporous silica-coated single-walled carbon nanotubes

Embodiment 2

[0035] Add 10 mg of single-walled carbon nanotubes, 1000 mg of cetyltrimethylammonium bromide, and 200 mL of deionized water into a three-necked flask, and ultrasonically disperse for 720 minutes to obtain a stable single-walled carbon nanotube dispersion.

[0036] Use 2M sodium hydroxide solution to adjust the pH value of the above dispersion to 12.0, add 0.15mL tetraethyl orthosilicate, and react at 75°C for 8 hours, so that the mesoporous silica layer is evenly coated on the single-walled carbon the surface of the nanotube.

[0037]After the reaction was finished, a black precipitate was obtained by centrifugation at 11000 rpm. The precipitate was calcined in a muffle furnace at 300° C. for 3 hours to remove the template, and then the mesoporous silica-coated single-walled carbon nanotubes were obtained.

Embodiment 3

[0039] Add 10 mg of single-walled carbon nanotubes, 500 mg of cetyltrimethylammonium bromide, and 100 mL of deionized water into a three-necked flask, and ultrasonically disperse for 4 hours to obtain a stable single-walled carbon nanotube dispersion.

[0040] Use 2M sodium hydroxide solution to adjust the pH value of the above dispersion to 11.3, add 0.15mL tetraethyl orthosilicate, and react at 60°C for 12h, so that the mesoporous silica layer is evenly coated on the single-walled carbon the surface of the nanotube.

[0041] After the reaction was finished, a black precipitate was obtained by centrifugation at 11000 rpm. The precipitate was calcined in a muffle furnace at 300 °C for 3 h to remove the template.

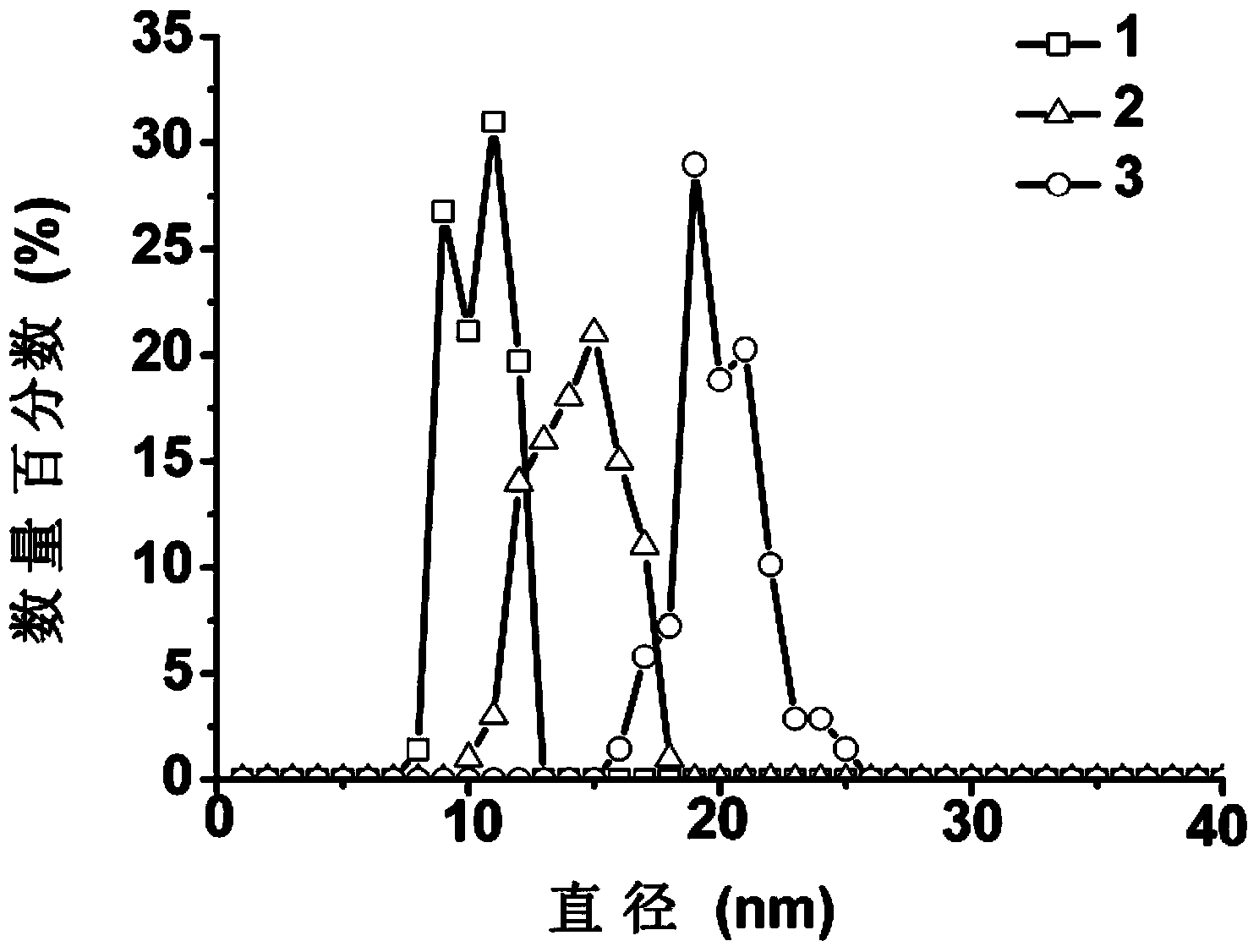

[0042] Such as figure 1 As shown by the middle curve 1, the diameter distribution of the mesoporous silica-coated single-walled carbon nanotubes obtained in this embodiment is between 7nm and 13nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com