A left and right closed guide rail guide seat sliding sleeve structure

A guide seat and closed technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of difficult installation of guide rails, high production costs, and rainwater ingress, so as to reduce failures and corrosion, Construction quality assurance, effect of reducing installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

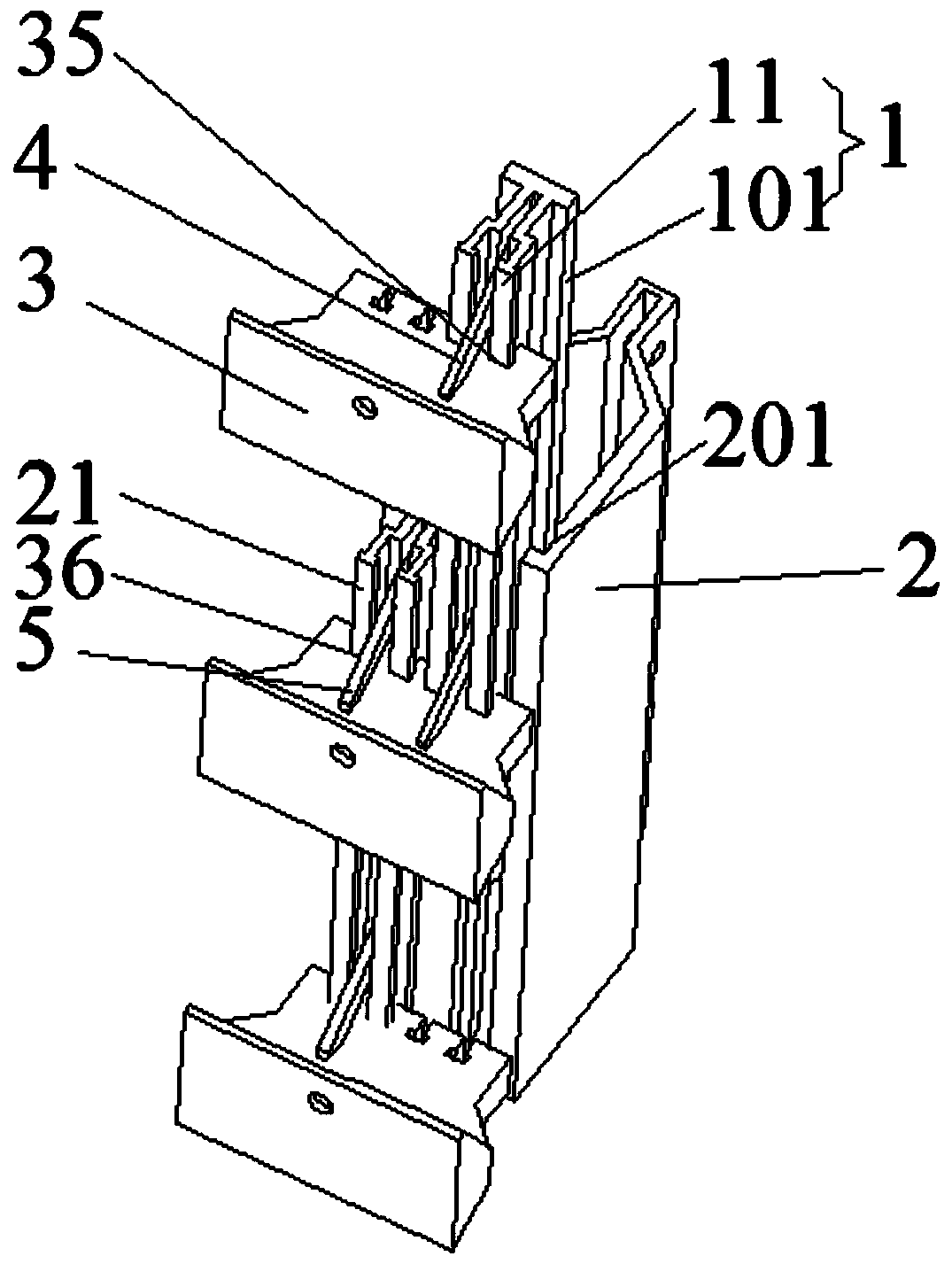

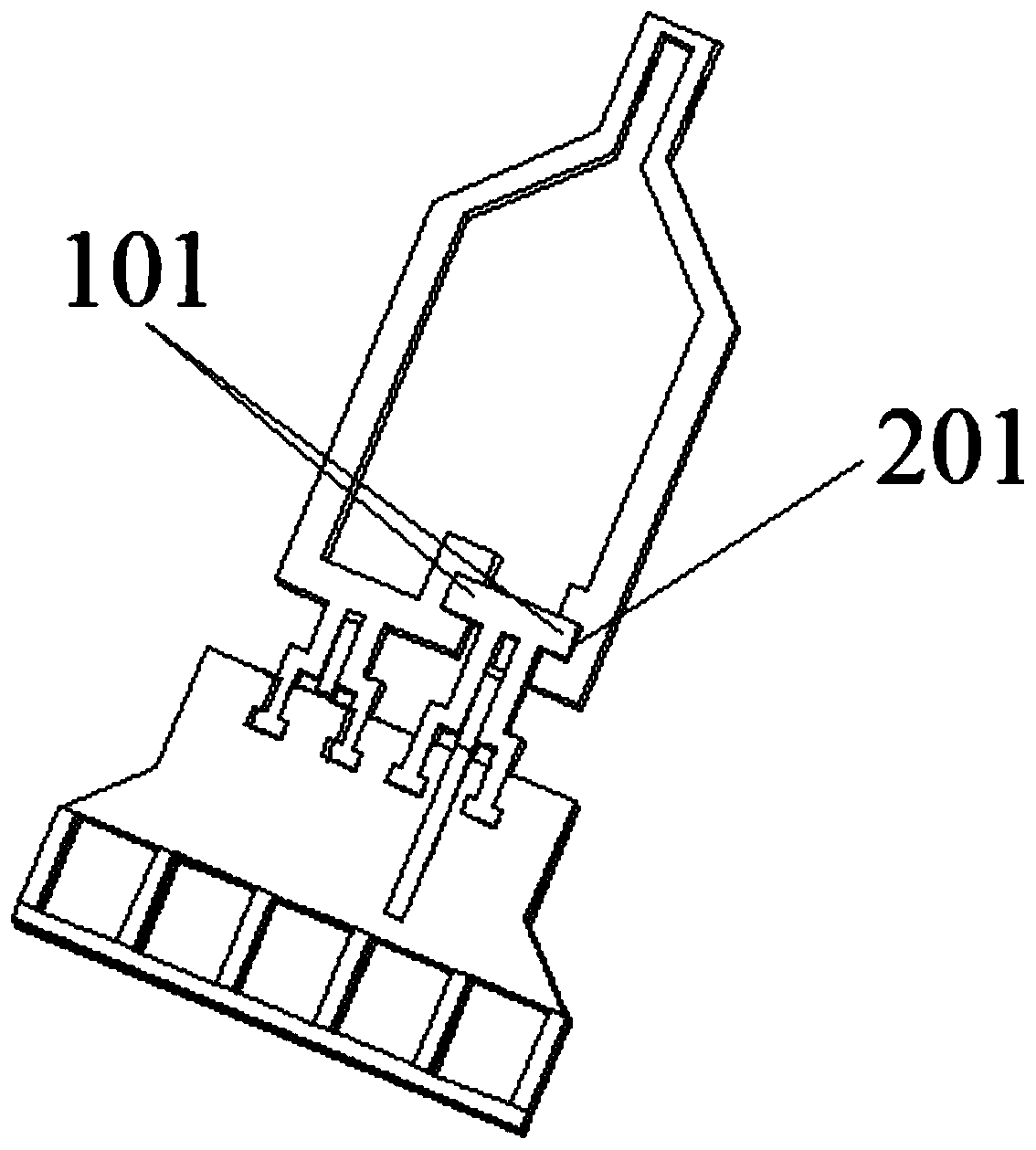

[0024] Such as Figure 1-2 as shown, figure 1 A schematic structural view showing the sliding sleeve structure of the left and right closed guide rail guide seats according to the first embodiment of the present invention; figure 2 show figure 1 The schematic diagram of the other direction of the sliding sleeve structure of the left and right closed guide rail guide seats shown. The left and right closed guide rail guide seat sliding sleeve structure includes a guide seat 3 and an inner guide rail 1 and an outer guide rail 2 that can slide relatively; the inner guide rail 1 is provided with at least one first mechanical arm 4; Two mechanical arms 5; the first mechanical arm 4 and the second mechanical arm 5 are respectively used to support on the guide seat 3; any one of the inner guide rail 1 and the outer guide rail 2 or simultaneously cooperates with the guide seat 3 sliding sleeves; when the first The mechanical arm 4 is supported on the guide seat 3, and when the seco...

no. 2 example

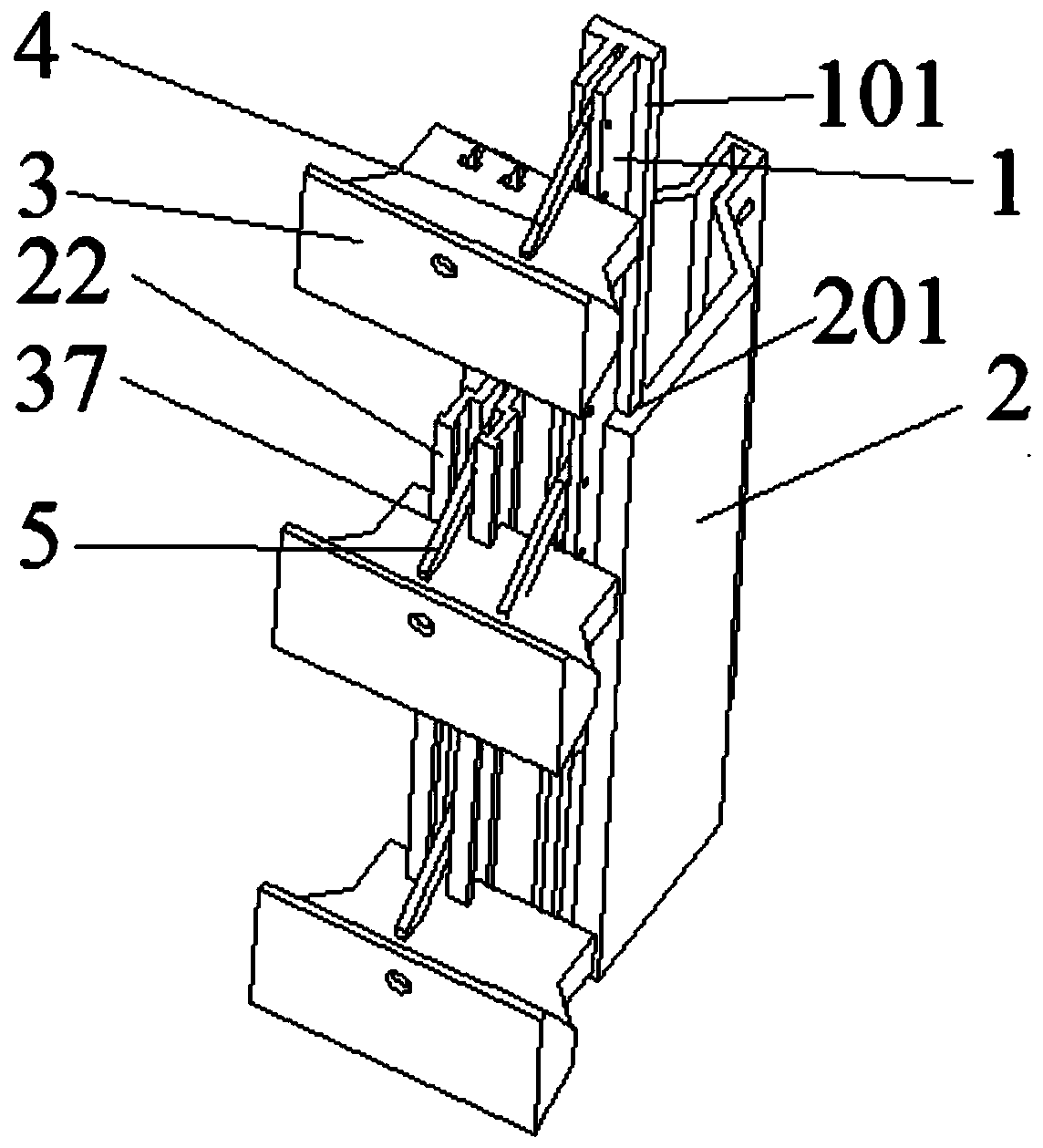

[0031] Such as image 3 as shown, image 3It shows a schematic structural view of the sliding sleeve structure of the left and right closed guide rail guide seats of the second embodiment of the present invention; the left and right closed guide rail guide seat sliding sleeve structure includes a guide seat 3 and relatively slidable inner guide rails 1 and outer guide rails 2; At least one first mechanical arm 4 is provided on the inner guide rail 1; at least one second mechanical arm 5 is provided on the outer guide rail 2; the first mechanical arm 4 and the second mechanical arm 5 are respectively used to support on the guide seat 3 ; Either one of the inner guide rail 1 and the outer guide rail 2 or at the same time cooperate with the guide seat 3; when the first mechanical arm 4 is supported on the guide seat 3 and the second mechanical arm 5 is separated from the guide seat 3, the outer guide rail 2 is used for Sliding up and down relative to the inner guide rail 1; when...

no. 3 example

[0038] like Figure 4 as shown, Figure 4 A schematic structural view of the sliding sleeve structure of the left and right closed guide rail guide seats according to the third embodiment of the present invention is shown. The left and right closed guide rail guide seat sliding sleeve structure includes a guide seat 3 and an inner guide rail 1 and an outer guide rail 2 that can slide relatively; the inner guide rail 1 is provided with at least one first mechanical arm 4; Two mechanical arms 5; the first mechanical arm 4 and the second mechanical arm 5 are respectively used to support on the guide seat 3; any one of the inner guide rail 1 and the outer guide rail 2 or simultaneously cooperates with the guide seat 3 sliding sleeves; when the first The mechanical arm 4 is supported on the guide seat 3, and when the second mechanical arm 5 is separated from the guide seat 3, the outer guide rail 2 is used to slide up and down relative to the inner guide rail 1; when the first mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com