A kind of phase change material liquid and the solid phase proppant formed by it

A phase change material, solvent technology, applied in drilling compositions, wellbore/well components, chemical instruments and methods, etc., can solve the problem of solid phase proppant (inadequate toughness of solid phase particles, affecting the conductivity of propped fractures) , the slow reaction speed of solid phase proppant, etc., to achieve the effect of shortening the reaction molding time, reducing construction risks and safety hazards, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

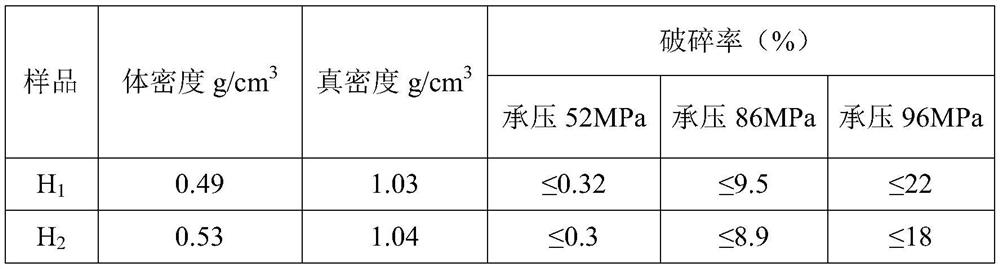

Embodiment 1

[0037] This embodiment provides a phase change material solution and a solid phase proppant with melamine substances as supramolecular building blocks.

[0038] Two kinds of phase change material liquid HPP 1 and HPP 2 The preparation process is as follows:

[0039] HPP 1 : first get xylene 50g, then add melamine 40g, dicyclopentadiene resin 30g, hydroxypropyl methylcellulose 0.5g, sodium lauryl sulfate 0.5g, phosphoric acid 0.5g, calcium chloride 0.5g, diperoxide Benzoyl 1g. All placed in a flask, stirred evenly at room temperature to complete the phase change material liquid HPP 1 preparation.

[0040] HPP 2 : First take 50g of xylene, then add 40g of 2,4-diamino-6-diallylamino-1,3,5-triazine, 30g of dicyclopentadiene resin, 0.5g of hydroxypropyl methylcellulose, ten Dialkyl sodium sulfate 0.5g, phosphoric acid 0.5g, calcium chloride 0.5g, dibenzoyl peroxide 1g. All placed in a flask, stirred evenly at room temperature to complete the phase change material liquid HPP...

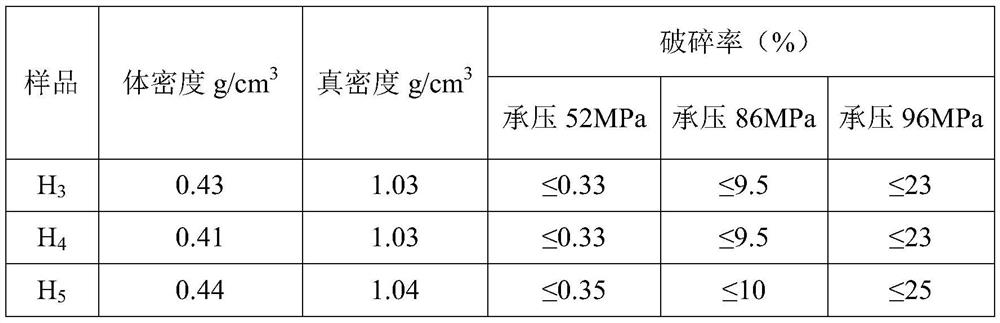

Embodiment 2

[0048] This embodiment provides a phase change material solution containing a pore-forming agent and a solid-phase proppant.

[0049] Three kinds of phase change material liquid HPP 3 、HPP 4 、HPP 5 The preparation process is as follows:

[0050] HPP 3 : first get xylene 50g, then add propenyl substituted triazine 40g, dicyclopentadiene resin 30g, polyvinyl alcohol 0.7g, sodium dodecylsulfonate 0.3g, phosphoric acid 0.5g, calcium chloride 0.5g, pass Dibenzoyl oxide 1g, ammonium bicarbonate 5g. All placed in a flask, stirred evenly at room temperature to complete the underground phase change material liquid HPP 3 preparation.

[0051] HPP 4 : First get 50g of xylene, then add 40g of acryl-substituted melamine, 30g of dicyclopentadiene resin, 0.5g of hydroxypropyl methylcellulose, 0.5g of sodium dodecylsulfonate, 1g of sodium bicarbonate, dihydrogen peroxide Tert-butyl 1g, solid paraffin 5g. All placed in a flask, stirred evenly at room temperature to complete the underg...

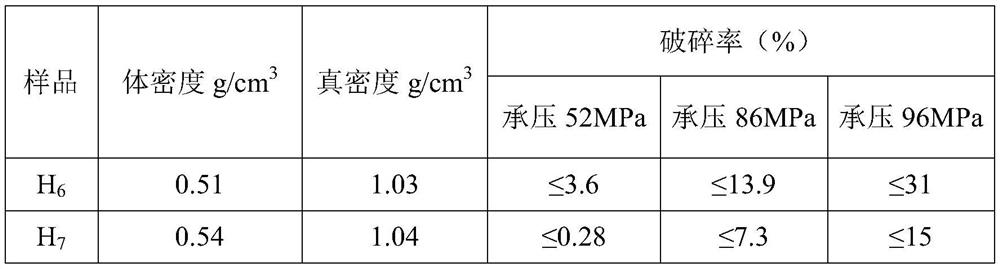

Embodiment 3

[0066] This embodiment provides a phase change material solution and a solid phase proppant with melamine substances as supramolecular building blocks.

[0067] Two kinds of phase change material liquid HPP 1 and HPP 2 The preparation process is as follows:

[0068] HPP 6 : First take 45g of xylene, then add 12g of melamine, 60g of dicyclopentadiene resin, 0.5g of hydroxypropyl methylcellulose, 0.5g of sodium lauryl sulfate, 0.5g of phosphoric acid, 0.5g of calcium chloride, di Benzoyl 1g. All placed in a flask, stirred evenly at room temperature to complete the phase change material liquid HPP 6 preparation.

[0069] HPP 7 : First take 20g of xylene, then add 60g of melamine, 20g of dicyclopentadiene resin, 0.5g of hydroxypropyl methylcellulose, 0.5g of sodium lauryl sulfate, 0.5g of phosphoric acid, 0.5g of calcium chloride, diperoxide Benzoyl 1g. All placed in a flask, stirred evenly at room temperature to complete the phase change material liquid HPP 7 preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com