Hoisting method for large long-distance plate type conveying chain

A hoisting method and long-distance technology, which are applied in the hoisting field of large-scale long-distance plate conveyor chains, can solve the problems of large manpower, material resources, long chain plate conveying distance, unfavorable personnel operation, etc., so as to increase the efficiency and applicability of construction. Strengthen, ensure the effect of construction quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

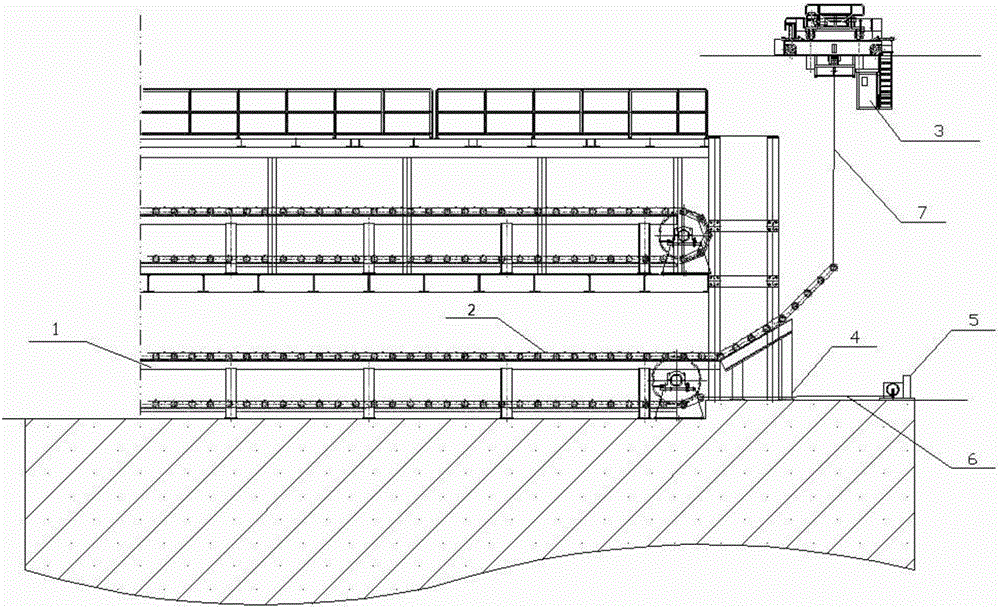

[0023] see figure 1 , the present invention provides a technical solution: a method for hoisting a large-scale long-distance plate conveyor chain, which is characterized in that it includes the following steps:

[0024] A. A winch 5 is set outside the large-scale long-distance plate conveyor chain frame 1;

[0025] B. Make and install the guide frame 4, the guide frame 4 is placed on one side of the large long-distance plate conveyor chain frame 1;

[0026] C. Lead out one end of the traction wire rope 6 of the winch 5 and fix it to one end of the large long-distance plate conveyor chain 2 to be installed;

[0027] D. Assemble the large long-distance slat conveyor chain 2 by hoisting the crane 3. After the assembly is completed, prepare to hoist the large long-distance slat conveyor chain 2 to the large long-distance slat conveyor chain frame 1;

[0028] E. The large long-distance plate conveyor chain 2 is vertically hoisted by the crane 3 through the hoisting wire rope 7; ...

Embodiment 2

[0033] see figure 1 and figure 2 , the present invention provides a technical solution: a method for hoisting a large-scale long-distance plate conveyor chain, which is characterized in that it includes the following steps:

[0034] A. A winch 5 is set outside the large-scale long-distance plate conveyor chain frame 1;

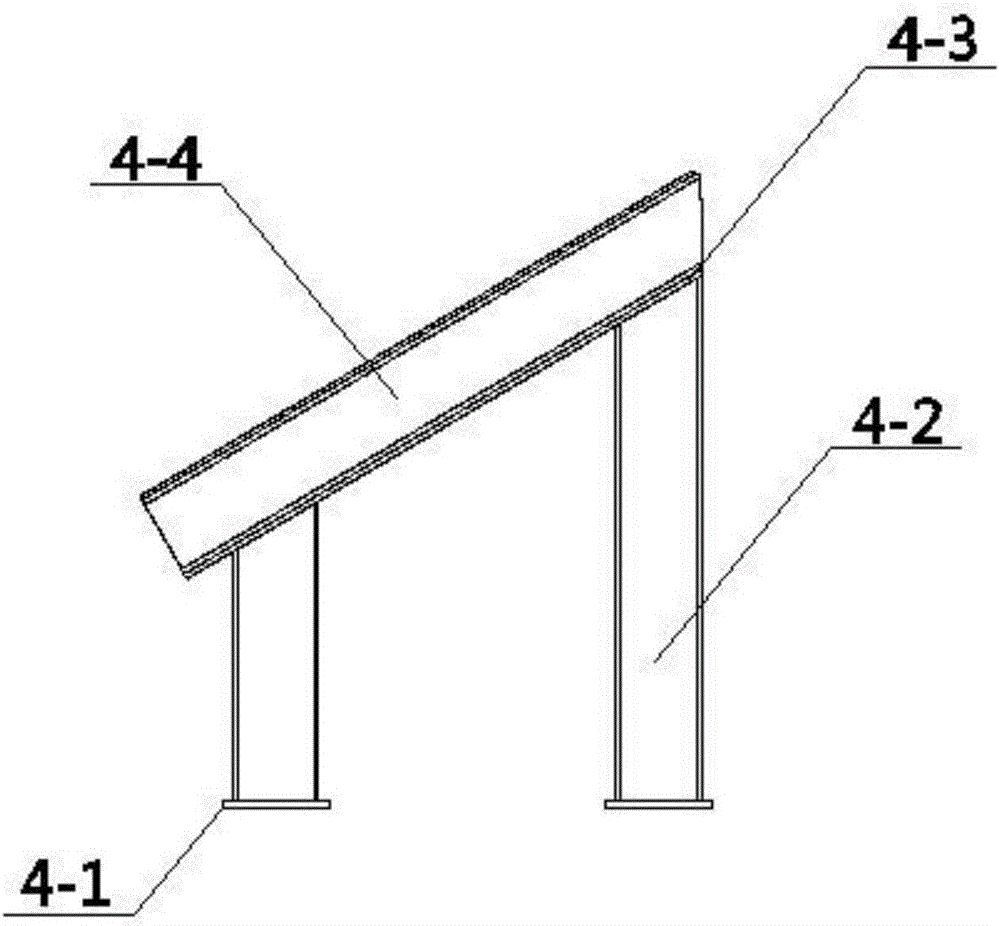

[0035] B. make and install guide frame 4, described guide frame 4 is mainly made up of backing plate 4-1, I-beam 4-2, support steel plate 4-3 and guiding H-shaped steel 4-4, and described guide frame 4 is made up of two The root I-beam 4-2 is welded with the backing plate 4-1 to form a supporting system, and a supporting steel plate 4-3 is welded above the I-beam 4-2, and the guide H-shaped steel 4-4 is set on the supporting steel plate 4-3 Above, the supporting steel plate 4-3 is welded to the top guide H-shaped steel 4-4, the angle between the guide H-shaped steel 4-4 and the bottom backing plate 4-1 is 30°, and the guide frame 4 is placed on a large One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com