Temperature response type phase-change fracturing fluid and using method thereof

A temperature-responsive, variable fracturing technology, applied in the field of hydraulic fracturing, can solve problems such as clogging of cracks, complicated process implementation, and pollution of fracturing fluid residues, and achieve high conductivity, broad market prospects, and low solid phase density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

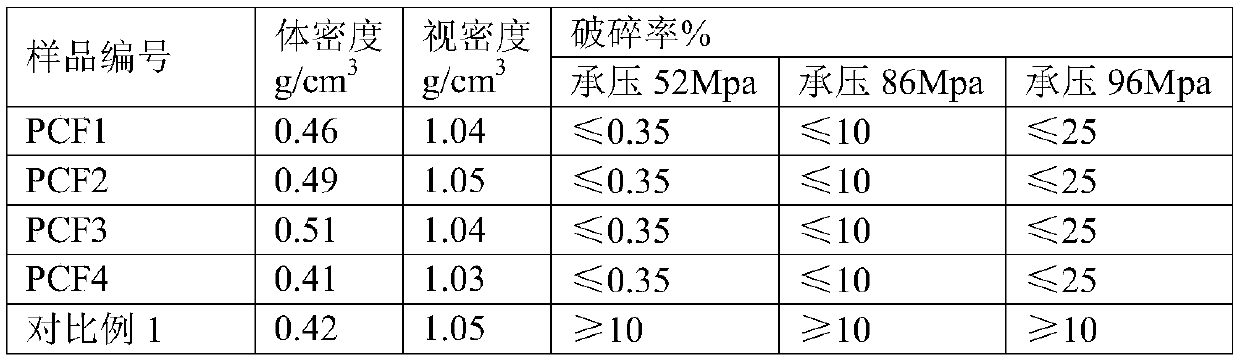

Examples

Embodiment 1

[0029] First take 10g of unsaturated polyester, then respectively add styrene (2g), glycidyl methacrylate (3g) and BPO (0.15g) to it and stir evenly to complete the preparation of functional oil phase GOP1; take 30g of To mineralize the water, polyvinyl alcohol (0.5 g) and sodium dodecylbenzene sulfonate (1 g) were added to complete the preparation of the functional water phase GWP1 with a concentration of 5 wt%.

[0030] Mix 50% GOP1 and 50% GWP1 in a beaker and stir evenly to obtain phase change fracturing fluid PCF1, place it in a constant temperature oil bath, raise the temperature to 80-90°C and react for 0.5-3 hours to stop heating, take out the beaker to observe the PCF1 sample The appearance of uniform bead-like and a little block-like solid phases shows that PCF1 can be used for phase change fracturing and can realize the transition from liquid phase to solid phase.

Embodiment 2

[0032] First take 10g of unsaturated polyester, then add styrene (2g), vinyl acetate (2g), glycidyl methacrylate (4g) and BPO (0.15g) to it and stir evenly to complete the functional oil phase The preparation of GOP2: Get 30g of mineralized water, add polyvinyl alcohol (0.5g), sodium dodecylbenzenesulfonate (1g), ammonium persulfate (0.5g), promptly complete the functional water phase that concentration is 6wt% Formulation of GWP2.

[0033] Mix and stir 20% GOP2 and 80% GWP2 in a beaker to obtain phase change fracturing fluid PCF2, place it in a constant temperature oil bath, raise the temperature to 90-100°C and react for 0.5-3 hours to stop heating, take out the beaker to observe the PCF2 sample The appearance of uniform bead-like and a little block-like solid phase has a porous structure, indicating that the phase change fracturing fluid PCF2 can be used for phase change fracturing and can realize the transition from liquid phase to solid phase.

Embodiment 3

[0035] First take 10g of unsaturated polyester, then add vinyl acetate (2g), divinylbenzene (1g), glycidyl methacrylate (4g) and BPO (0.15g) to it and stir evenly to complete the functional oil The preparation of phase GOP3: get 30g of mineralized water, add polyvinyl alcohol (0.5g), sodium dodecylbenzenesulfonate (1g), ammonium persulfate (0.5g), promptly complete the function water that concentration is 6wt% Phase GWP3 formulation.

[0036] Mix and stir 30% GOP3 and 70% GWP3 in a beaker to obtain phase change fracturing fluid PCF3, place it in a constant temperature oil bath, raise the temperature to 60-80°C and react for 0.5-3 hours to stop heating, take out the beaker to observe the PCF3 sample The appearance of uniform bead-like and a little block-like solid phases shows that PCF3 can be used for phase change fracturing and can realize the transition from liquid phase to solid phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com