Method for erecting T-shaped beam by using small-sized machinery

A mechanical and small-scale technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of difficult erection of T-beams, high construction difficulty, and high construction risk, and achieve easy operation, low construction difficulty, and simple assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

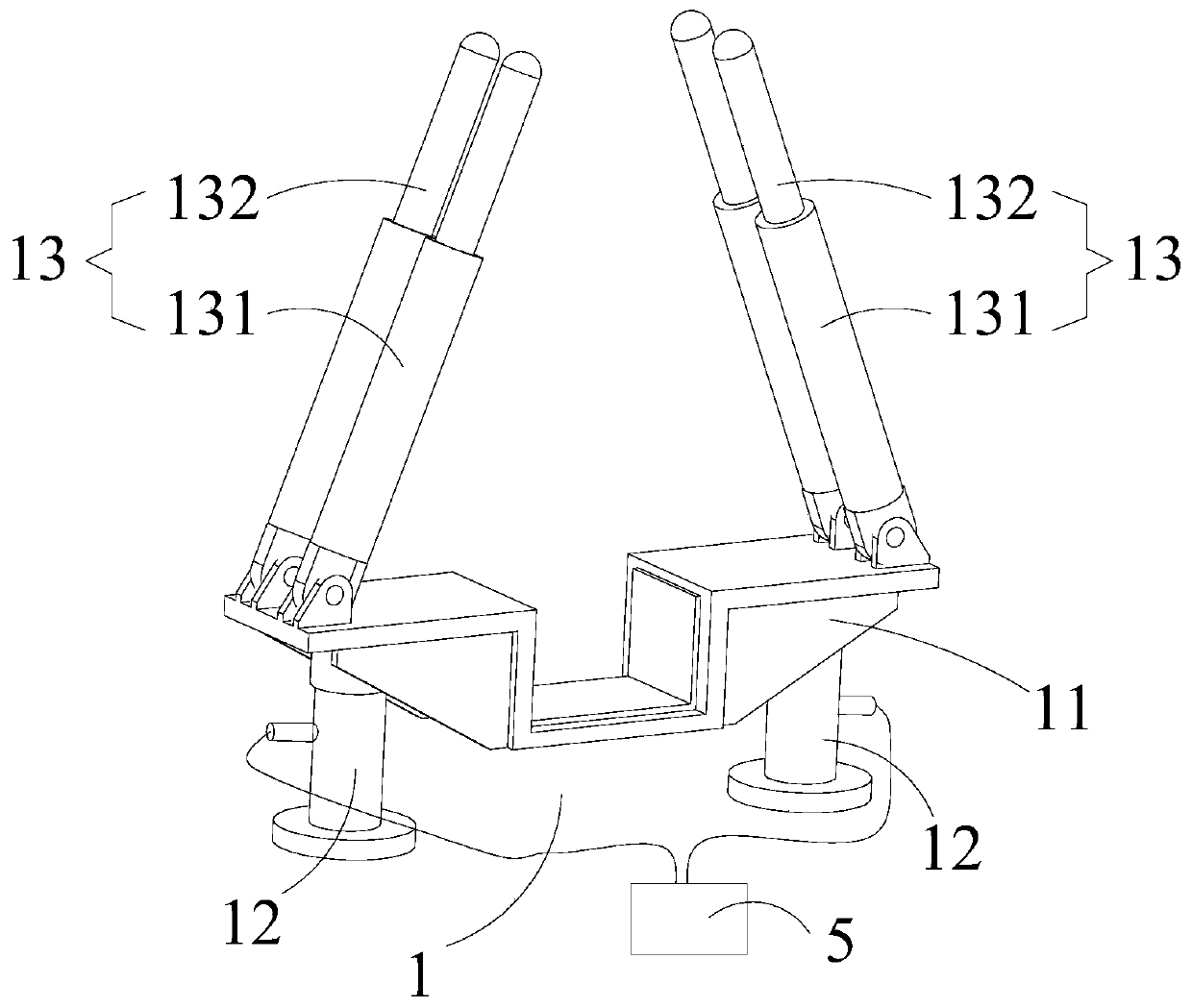

[0110] Such as figure 1 , 2 Shown in and 3, a kind of method of using small-sized mechanical erection T-beam 4 of the present invention, comprises the following steps:

[0111] Step 1, making the jacking device 1 and the moving device 2 at the construction site, wherein,

[0112] The jacking device 1 is used for jacking the T-beam 4, and the jacking device 1 includes a first bracket 11, a jacking assembly 12 and a first support rod 13, and the first bracket 11 is connected to the first bracket respectively. The bracket 11 is detachably connected to the first support rod 13, the first bracket 11 is used to vertically support the T-beam 4, and the first support rod 13 is used to laterally support the T-beam 4. The jacking assembly 12 is used to vertically push the first bracket 11;

[0113] The moving device 2 is used to move the T-beam 4, the moving device 2 includes a second support 21, a moving assembly 22 and a second support rod 23, and the second support 21 is connected...

Embodiment 2

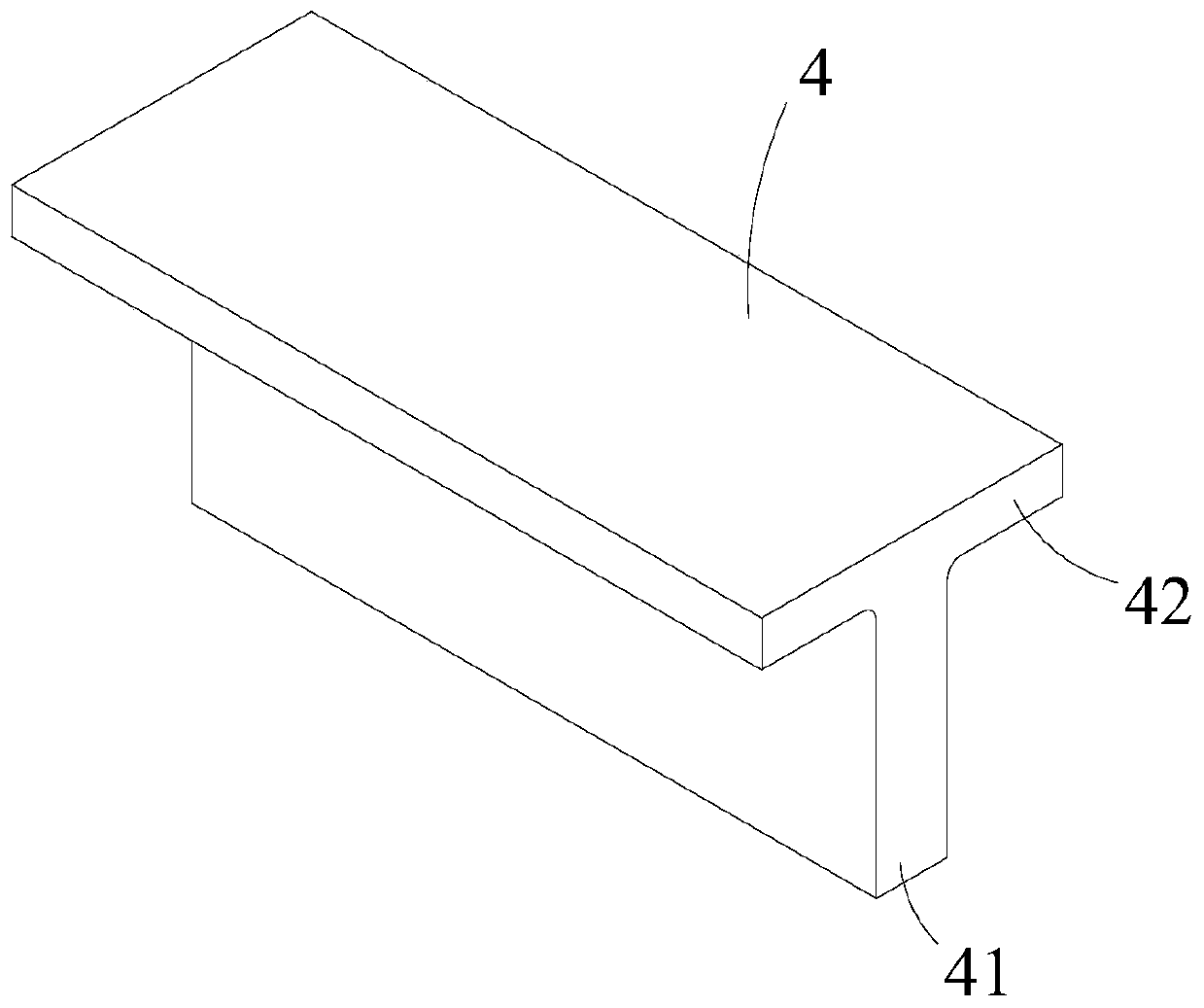

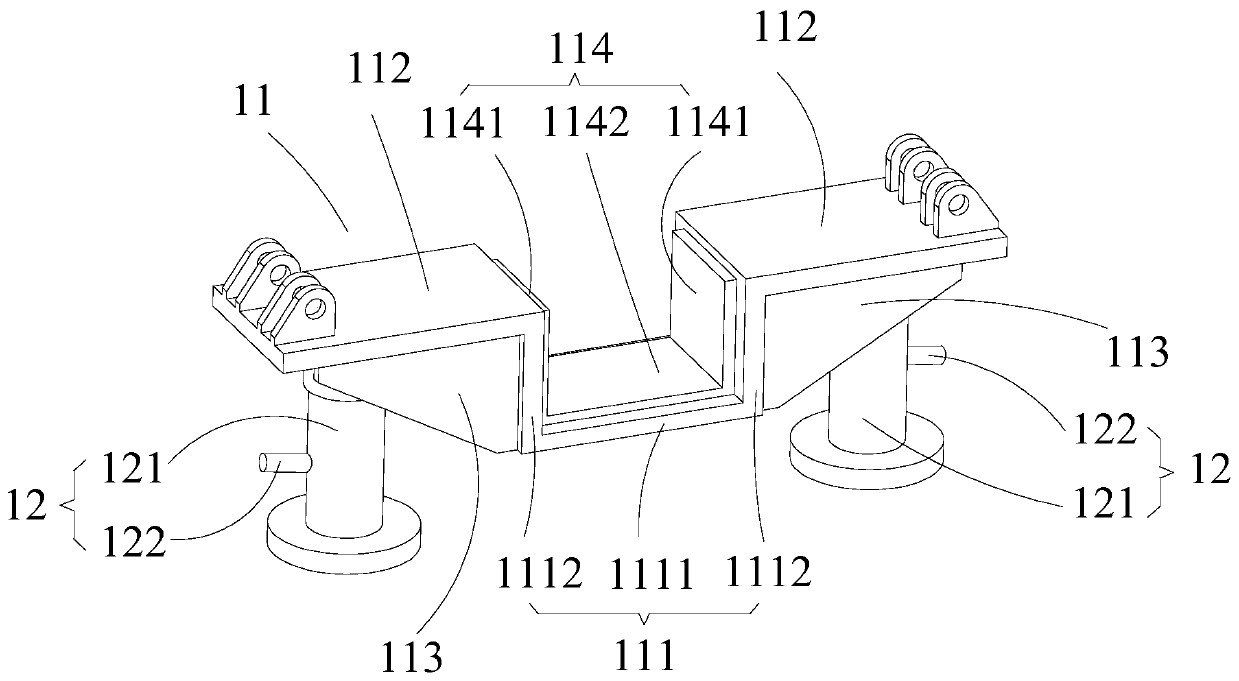

[0142] Such as figure 1 , 2 As shown in and 3, a method for erecting a T-beam 4 using a small machine as described in Embodiment 1, the first bracket 11 includes a first support portion 111 and a first support 112, and the first support portion 111 is connected with the first support 112, the first support part 111 is used to support the T-beam 4, the first support 112 is two, respectively set on the first support part 111 On both sides of each of the first supports 112, the first support rod 13 is hinged.

[0143] On the basis of the above, in a further preferred manner, the first support part 111 includes a first bottom support part 1111 and two first side support parts 1112, and the first side support parts 1112 are respectively arranged on the first bottom On both sides of the support part 1111, the first side support part 1112 is connected to the first bottom support part 1111, the first bottom support part 1111 is used to support the bottom surface of the web 41, and t...

Embodiment 3

[0156] Such as figure 1 , 2 Shown in and 3, as described in embodiment 1 or 2, a kind of method that uses small-sized machinery to erect T-beam 4,

[0157] On the basis of the above, in a further preferred manner, the second bracket 21 includes a second support part 211, and a second support part 211 connected to the second support part 211 is provided on both sides of the second support part 211. Supports 212 , the second support portion 211 is used to support the T-beam 4 , and the second support rod 23 is hinged on each second support 212 .

[0158] On the basis of the above, in a further preferred manner, the second support part 211 includes a second bottom support part 2111 and two second side support parts 2112, and the second side support parts 2112 are respectively arranged on the second bottom On both sides of the support part 2111, the second side support part 2112 is connected to the second bottom support part 2111, and the second bottom support part 2111 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com