A construction method of continuous rigid frame bridge

A construction method and rigid-frame bridge technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as construction costs, increased difficulty, high safety risks, etc., to avoid construction and demolition, improve construction safety, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

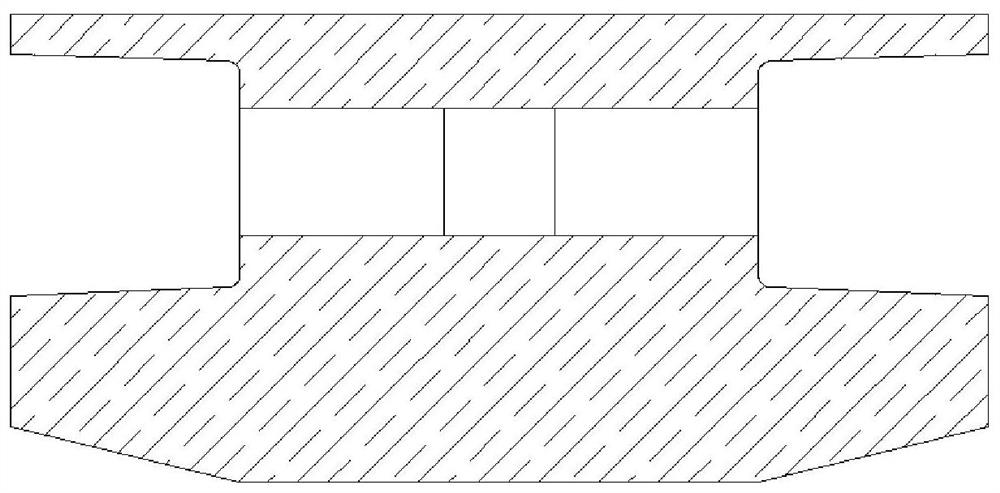

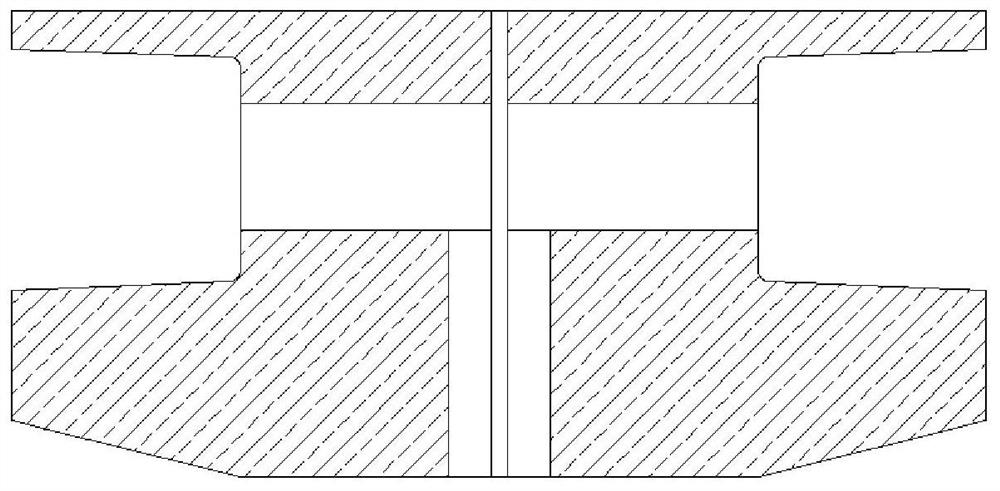

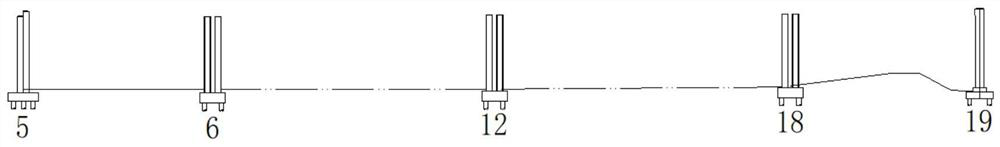

[0031] Such as Figure 1-4 As shown, the construction method of a continuous rigid frame bridge in the preferred embodiment of the embodiment of the present invention is characterized in that: it includes N bridge piers arranged in sequence, and the 0# blocks on the piers include A0 and B0. The construction method is as follows step:

[0032] Step 1, construct pile foundation, cap and pier body. Among them, during the construction of the pier body, the consolidation pier is constructed to the position below the bottom of the main beam 2m, and it is poured together during the construction of the 0# block; the construction of the non-consolidation pier is completed;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com