Construction method for large-span pipe corridor pipeline

A construction method and large-span technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of long straight-line distance for pipeline installation, limited crane working surface and space, and reduced crane use efficiency, etc., to achieve Reduce construction costs and unsafe factors, reduce displacement, and produce simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred modes of the present invention will be described in further detail below in conjunction with the embodiments.

[0020] A construction method for a large-span pipe gallery pipeline, comprising the following steps:

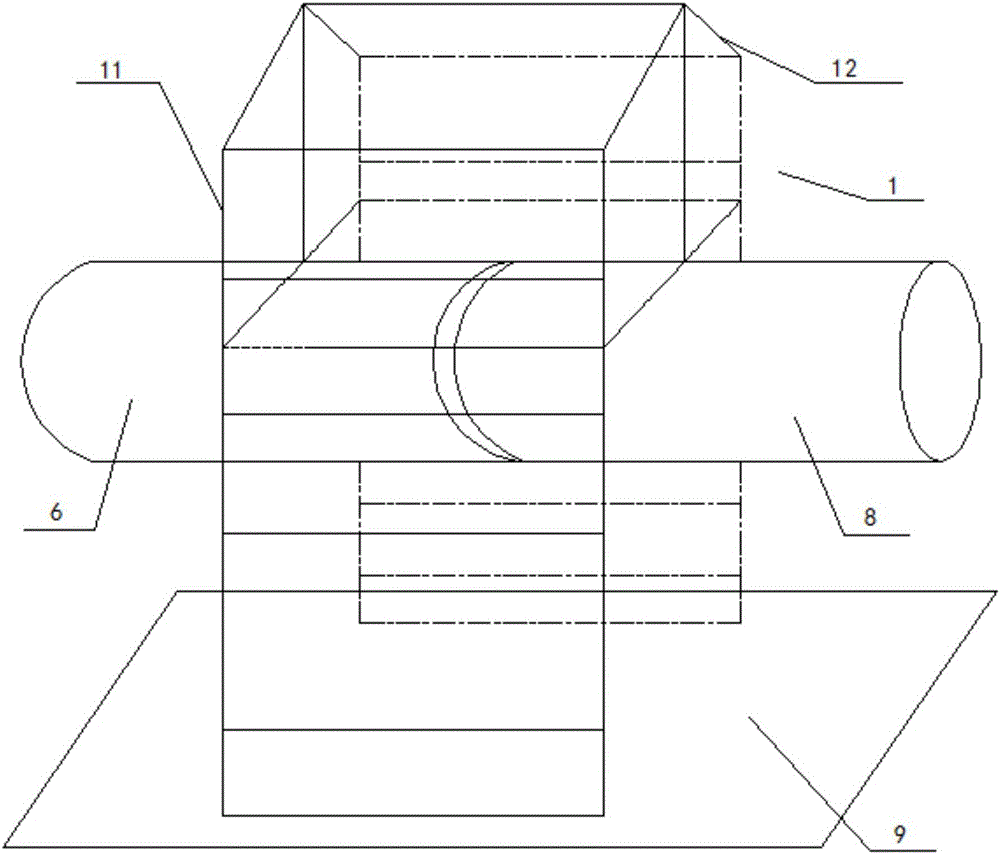

[0021] S1. Manufacture and install the pipeline welding protective shed 1, assemble and weld the frame 11 with channel steel, make the protective shed skeleton 12 with square steel on the top, and cover the outside of the skeleton 12 with a lightweight three-proof cloth to obtain the pipeline welding protection Shed 1.

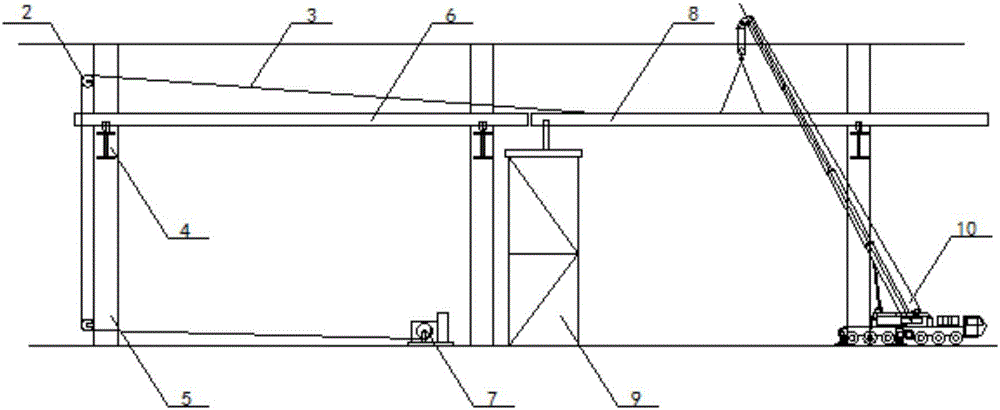

[0022] S2. Install two pulley blocks 2 on the pipe gallery truss column, one of the pulley blocks 2 is higher than the height of the pipeline section to be installed, and the two pulley blocks 2 are installed on the same pipe gallery truss column 5 and are located in the pipe gallery truss column 5 On the same side of the pipeline, the first section 6 of the pipeline is paired on the ground, and the length of the pipeline secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com