Design method of steel fiber recycled concrete beam

A technology of recycled concrete and reinforced concrete beams, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem of easy cracking stiffness of recycled concrete, to overcome easy cracking and poor stiffness, ensure structural stability, and meet performance indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structural design of steel fiber recycled concrete is carried out with a specific structural data to illustrate the design;

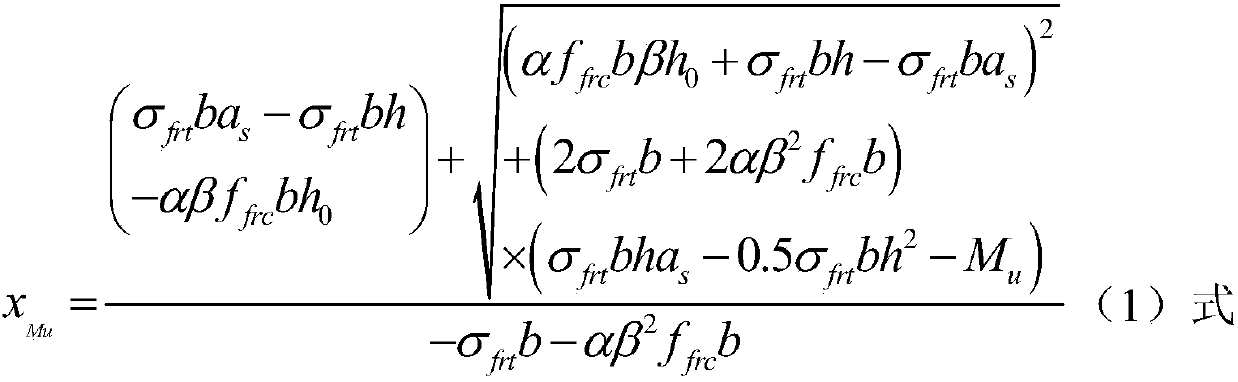

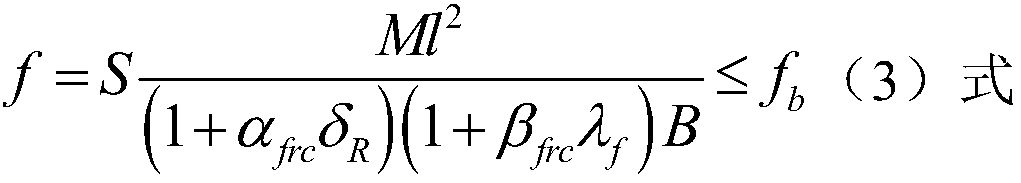

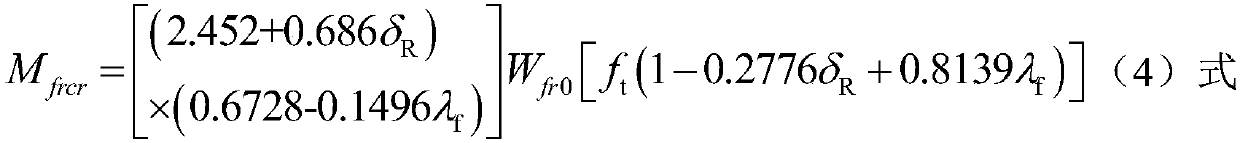

[0031] It is known that the span of a simply supported beam with reinforced steel fiber recycled concrete rectangular section is l=3m, and the width l is calculated 0 =2.7m, the design bending moment is 50kN·m. The quasi-permanent value factor ψ of the live load q =0.5, adopt C45 steel fiber recycled concrete, choose cut bow-shaped steel fiber, l f = 35mm, nominal diameter d f =0.55mm, tensile strength ≥1345N / mm 2 . The mechanical performance index of steel fiber recycled concrete is obtained by experiment, and only the replacement rate of recycled aggregate δ is given here R =50%, steel fiber volume ratio ρ f = 1.5% (at this time, The mechanical performance index of C45 steel fiber recycled concrete: the standard value of axial compressive strength of steel fiber recycled concrete f frck =46MPa, standard value of axial tensile stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com