Deformation-controllable frame filling wall and construction method thereof

A technology of infill wall and deformation control, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of frame column short column failure, strong frame column restraint, "weak layer damage", etc., to enhance the out-of-plane stability and improve the overall Sex, the effect of reducing constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

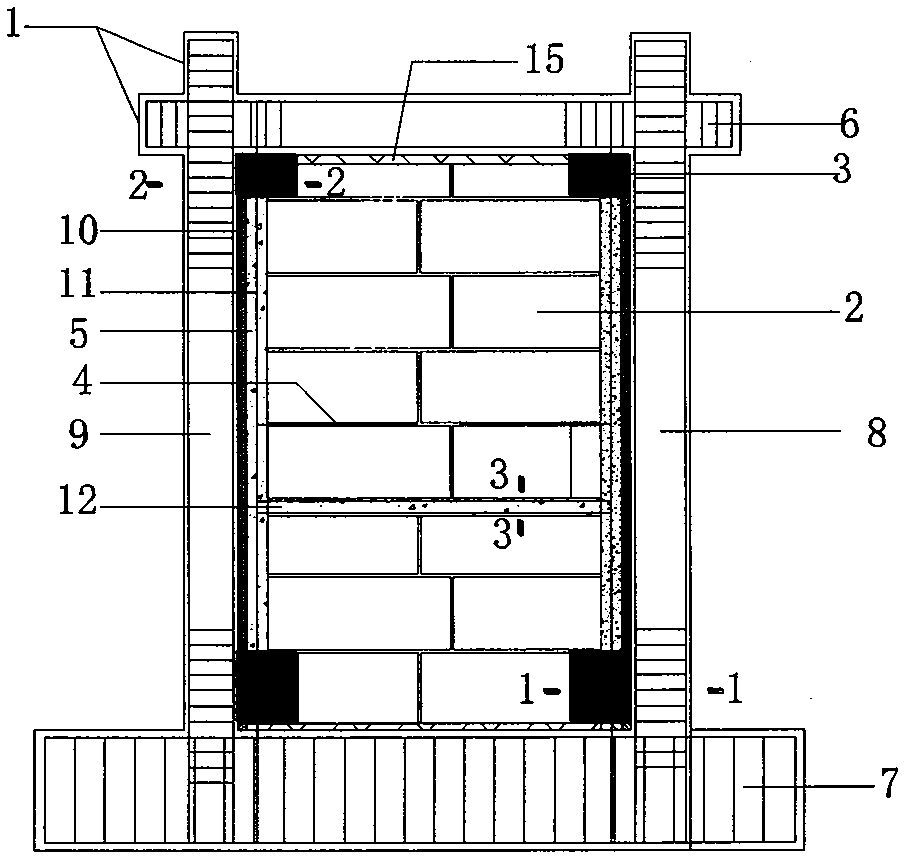

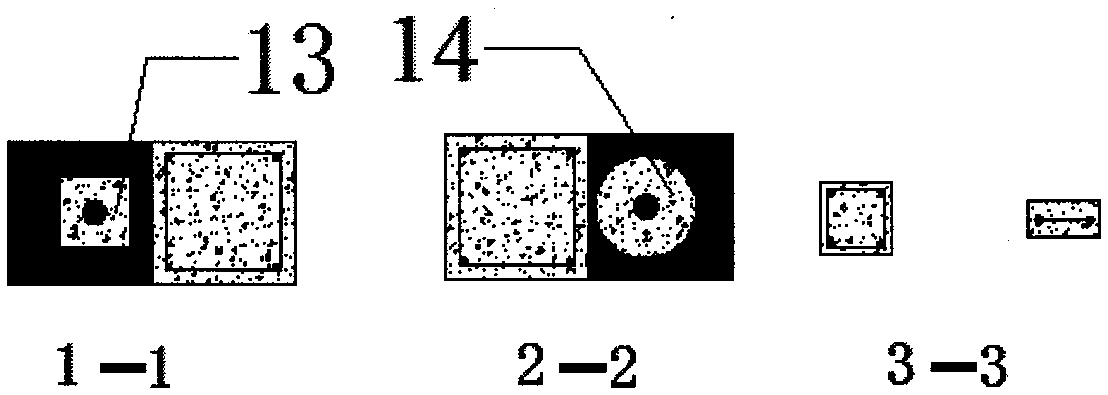

[0021] According to the technical solution of the present invention, the anti-seismic structure using the deformation controllable frame filling wall is as follows:

[0022] (1) Make the frame upper beam 6 of the frame 1, the frame lower beam 7 and the frame left column 8, the frame right column 9, and anchor the reinforcing bar of the constraint column 5 in the frame lower beam 7;

[0023] (2) The upper surface of the frame lower beam 7 is chiseled, and the elastic connecting material 15 is laid. The elastic connecting material 15 is bonded firmly with the frame lower beam 7, and the steel bar 11 passing the control part 3 through the restraining column 5 is bonded under the frame. The distance between the end of the beam 7 and the adjacent frame column is not less than 120mm;

[0024] (3) Build upper masonry on the surface of the elastic connecting material 15 and the upper surface of the deformation control part. When building a wall with a height of about 500mm, arrange ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com