Preparation method of carbon fiber reinforced resin composite material

A composite material and reinforced resin technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the production cost of PAN-based carbon fiber, the high cost of fiber preform weaving, the performance of composite materials needs to be further improved, composite materials High cost and other problems, to achieve the effect of improving fracture toughness and repairability, strong random arrangement of fibers, good strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

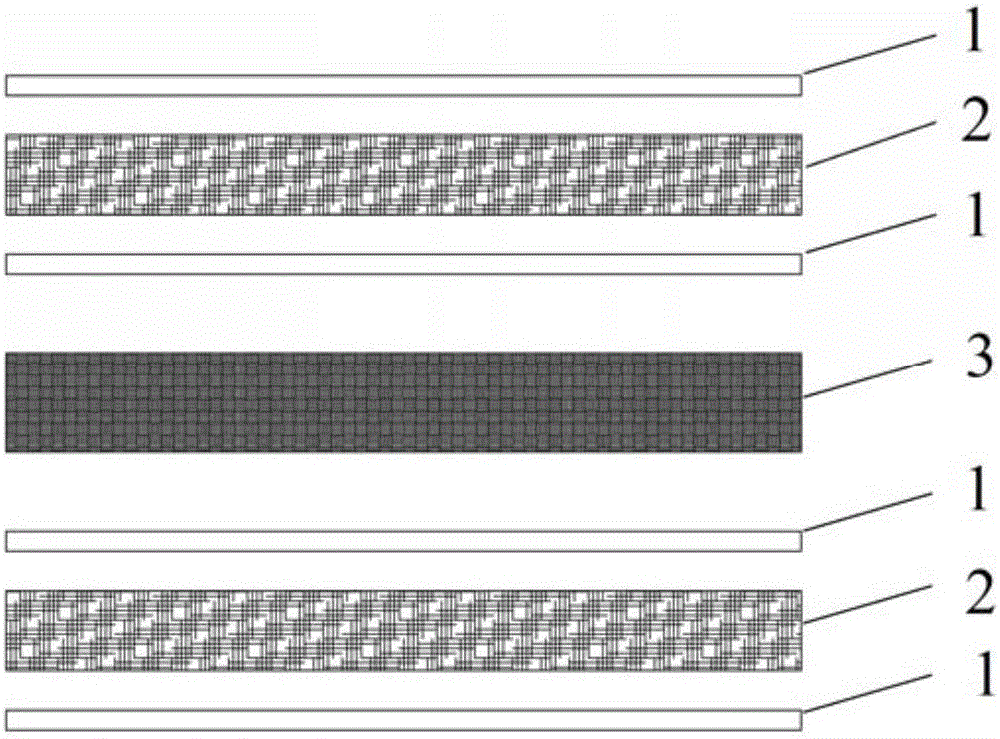

[0026] Embodiment 1: See Figure 1

[0027] A method for preparing a carbon fiber reinforced resin composite material. The low-cost pitch-based carbon fiber mat is selected as one of the reinforcements of the composite material, and the cost is low; the pitch-based carbon fibers in the preform are randomly distributed, and the degree of isotropy is smaller; the volume fraction is 30%. PAN-based carbon fiber carbon cloth-epoxy resin prepreg is selected as another reinforcement of the composite material, and the volume fraction of the fiber is 10%. A thermoplastic polypropylene film with a thickness of 0.5 mm was selected as the resin matrix of the pitch-based carbon fiber mat.

[0028] The above-mentioned pitch-based carbon fiber mat (2 places in Fig. 1), PAN-based carbon fiber carbon cloth-epoxy resin prepreg (3 places in Fig. 1), and polypropylene resin film (1 place in Fig. 1) according to 1213121 were stacked in sequence and then hot-pressed. The hot-pressing temperature w...

Embodiment 2

[0030] A method for preparing a carbon fiber reinforced resin composite material. The low-cost pitch-based carbon fiber non-woven fabric is selected as one of the reinforcements (preforms) of the composite material; the pitch-based carbon fibers in the preform are randomly distributed, and the degree of isotropy is smaller; the volume fraction is 20%. PAN-based carbon fiber carbon cloth-epoxy resin prepreg is selected as another reinforcement (prefabricated body) of the composite material, and the volume fraction of fibers is 15%. A thermoplastic polypropylene (PP) film with a thickness of 0.2 mm was selected as the resin matrix of the pitch-based carbon fiber mat.

[0031] The above-mentioned pitch-based carbon fiber non-woven fabric (2 places in Figure 1), PAN-based carbon fiber carbon cloth-epoxy resin prepreg (3 places in Figure 1), and polypropylene resin film (1 place in Figure 1) According to the order of 12121213121212121, hot pressing after overlapping placement was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com