Superspeed motorized spindle automatic tool changer and superspeed motorized spindle automatic tool changing method

A technology of automatic tool change and electric spindle, applied in the direction of positioning device, clamping, support, etc., to achieve the effect of reducing superposition links, accurate tool change, and ensuring clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

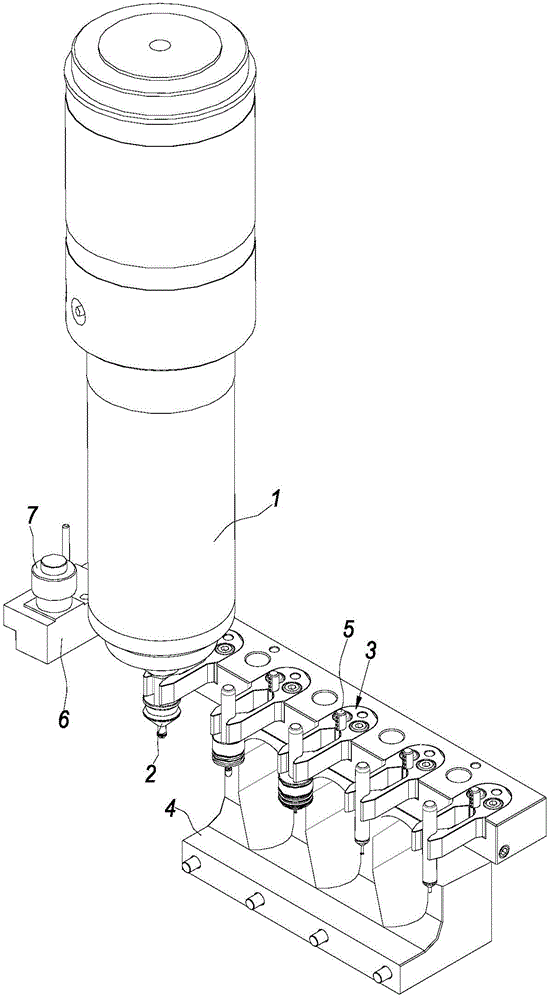

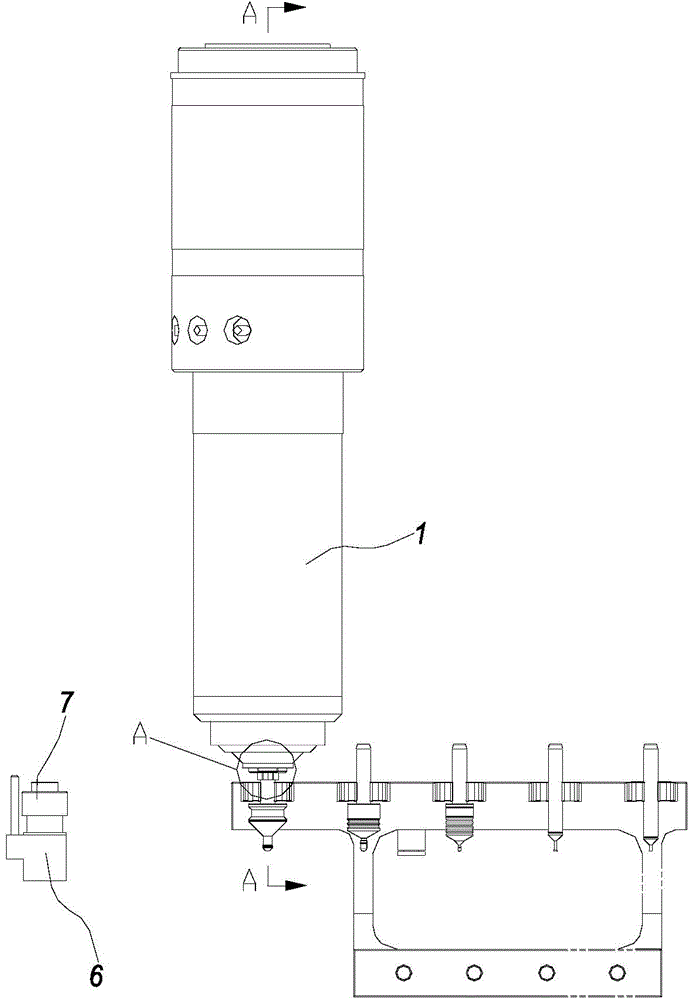

[0035] figure 1 It schematically shows an automatic tool changer for an ultra-high-speed electric spindle according to an embodiment of the present invention.

[0036] Such as figure 1 As shown, the ultra-high-speed electric spindle automatic tool change device includes an electric spindle 1, a caliper 3, a caliper mounting seat 4, an air blowing rod 5, a tool change checker 6 and a tool length measuring device 7, and the tool change checker 6 is set on the caliper One side of the mounting base 4, the tool length measuring device 7 is installed on the tool changing checker 6, there are five cutters 2, and five calipers 3.

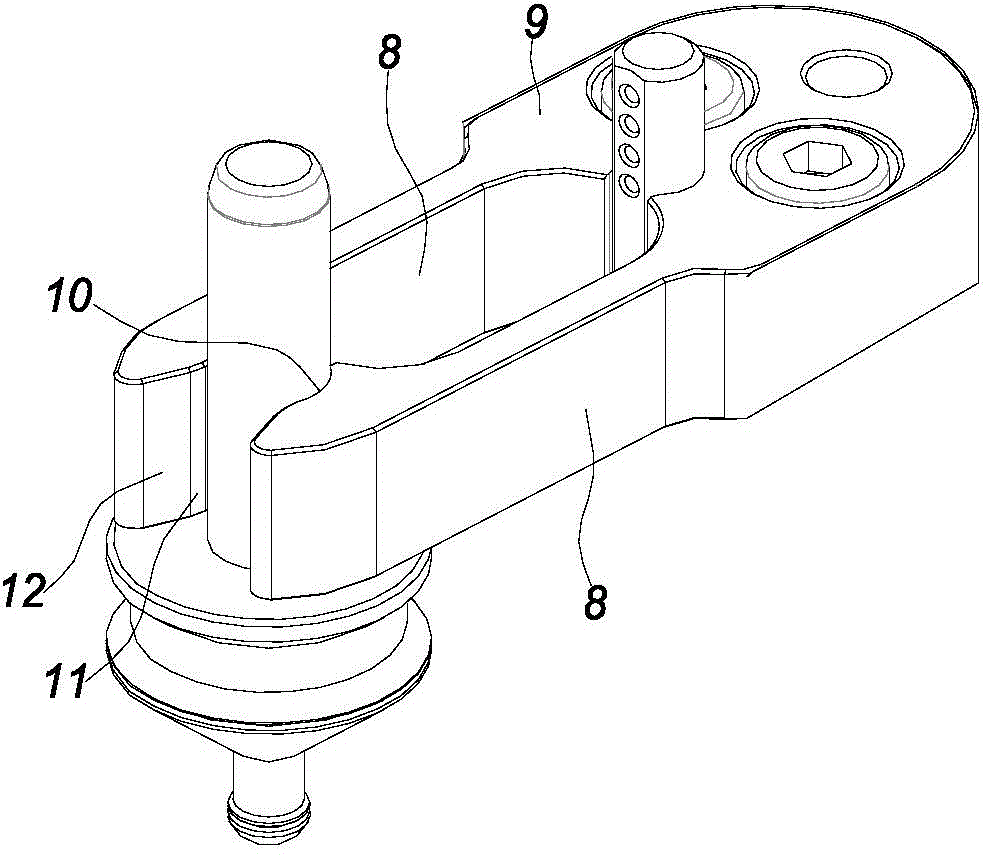

[0037] Such as figure 1 , 2 , 3, the caliper 3 is composed of two elastic jaws 8 and a positioning seat 9, the positioning seat 9 is fixed to the caliper mounting seat 4 by bolts, and the two elastic jaws 8 are symmetrically connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com