Carbon nanotube uniformly and stably loaded with iron-containing nano particles and preparation method of carbon nanotube

A carbon nanotube, stable load technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of cost and environmental protection limitations, complex process, wide distribution, etc., to save production The investment cost, the preparation method are simple and the effect of strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

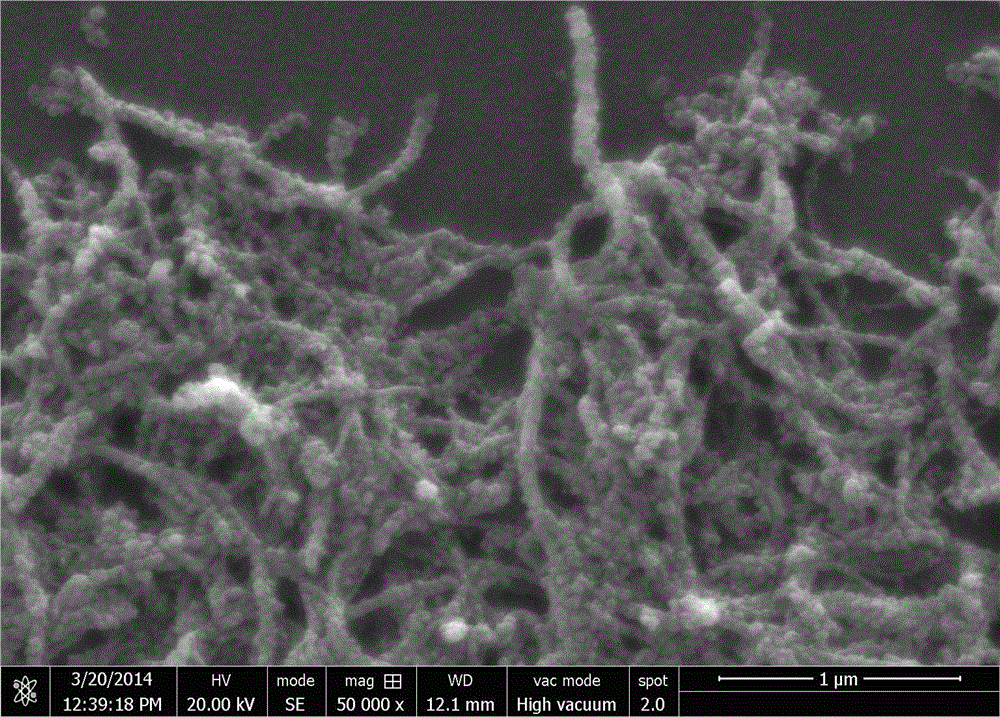

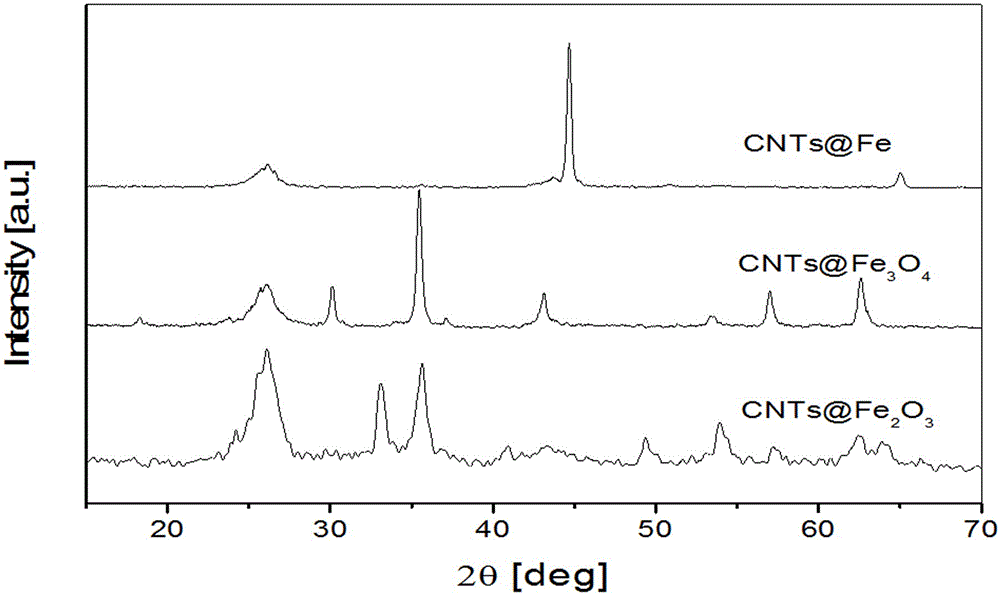

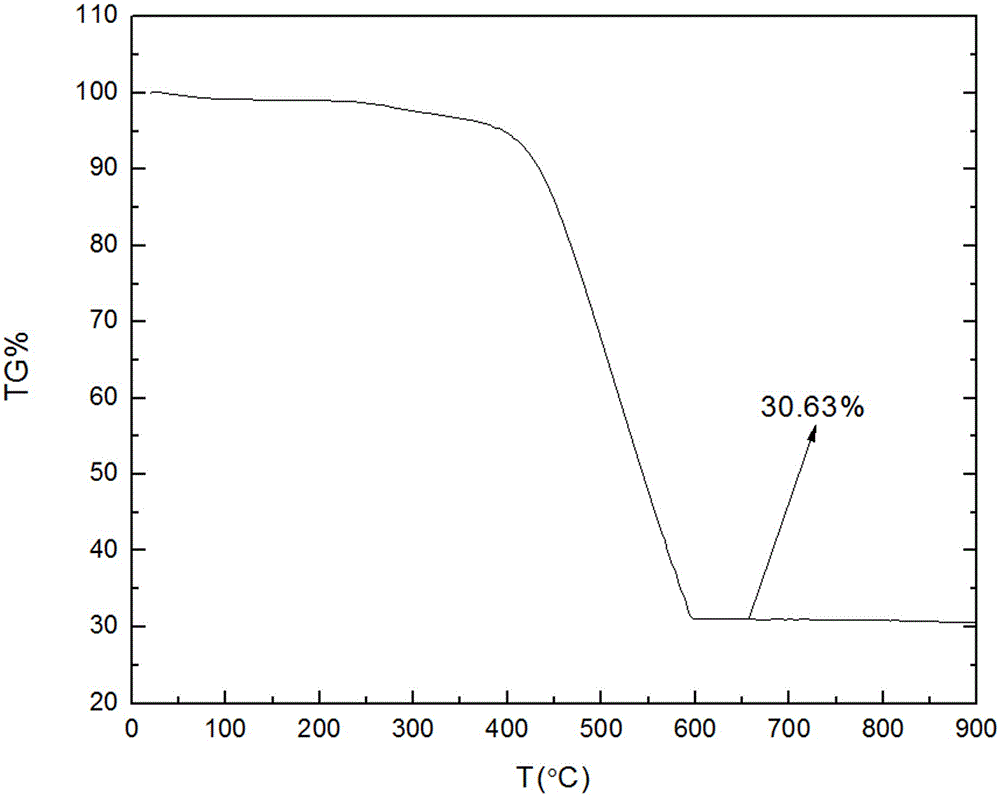

[0033] (1) Add 0.5g of carbon nanotubes, 0.05g of polyvinylpyrrolidone, and 1.0g of iron triacetylacetonate into 40ml of ethanol solvent, first stir it mechanically for 15 minutes, and then disperse it with ultrasonic waves for 1 hour to obtain a well-dispersed suspension Liquid, transfer the suspension to a 50ml high-pressure reactor, seal it and put it in an oven at 150°C, take it out after 24h and filter to obtain a carbon nanotube precursor loaded with iron-containing oxide nanoparticles.

[0034] (2) The carbon nanotube precursor loaded with iron-containing oxide nanoparticles obtained in step (1) was heated at 250°C for 2 hours under the protection of nitrogen to obtain the target product: uniform and stable carbon nanometer iron oxide particles loaded nanotube.

[0035] (3) The carbon nanotube precursor loaded with iron-containing oxide nanoparticles obtained in step (1) was heated at 420°C for 2 hours under the protection of nitrogen to obtain the target product: unifo...

Embodiment 2

[0038] (1) Add 0.5g of carbon nanotubes, 0.025g of polyvinylpyrrolidone, and 2.0g of iron triacetylacetonate into 40ml of methanol solvent, stir it mechanically for 15 minutes, and then disperse it with ultrasonic waves for 1 hour to obtain a well-dispersed suspension liquid, transfer the suspension to a 50ml high-pressure reactor, seal it and place it in an oven at 230°C, take it out after 12 hours and filter to obtain a carbon nanotube precursor loaded with iron-containing oxide nanoparticles.

[0039] (2) The carbon nanotube precursor loaded with iron-containing oxide nanoparticles obtained in step (1) was heated at 400°C for 5 minutes under the protection of argon to obtain the target product: a uniform and stable nanometer iron oxide particle carbon nanotubes.

[0040](3) The carbon nanotube precursor loaded with iron-containing oxide nanoparticles obtained in step (1) was heated at 600°C for 5 minutes under the protection of argon to obtain the target product: uniform an...

Embodiment 3

[0043] (1) Add 0.5g of carbon nanotubes, 0.025g of polyvinyl alcohol, and 1.0g of ferrocene into 40ml of methanol solvent, stir it mechanically for 15 minutes, and then disperse it with ultrasonic waves for 1 hour to obtain a well-dispersed suspension , transfer the suspension to a 50ml autoclave, seal it and place it in an oven at 180°C, take it out after 6h and filter to obtain a carbon nanotube precursor loaded with iron-containing oxide nanoparticles.

[0044] (2) The carbon nanotube precursor loaded with iron-containing oxide nanoparticles obtained in step (1) was heated at 350°C for 15 minutes under the protection of argon to obtain the target product: a uniform and stable nanometer ferric oxide particle carbon nanotubes.

[0045] (3) The carbon nanotube precursor loaded with iron-containing oxide nanoparticles obtained in step (1) was heated at 550°C for 15 minutes under the protection of argon to obtain the target product: uniform and stable nano-ferric oxide particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com