Welding method of tabs and cover plate and battery assembly

A welding method and tab technology, which is applied to battery pack parts, welding equipment, electrical components, etc., can solve the problems of occupying the internal space of the battery, affecting battery safety, and high internal resistance of the battery, so as to reduce investment and process complexity. The effect of saving production investment costs and simplifying connection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

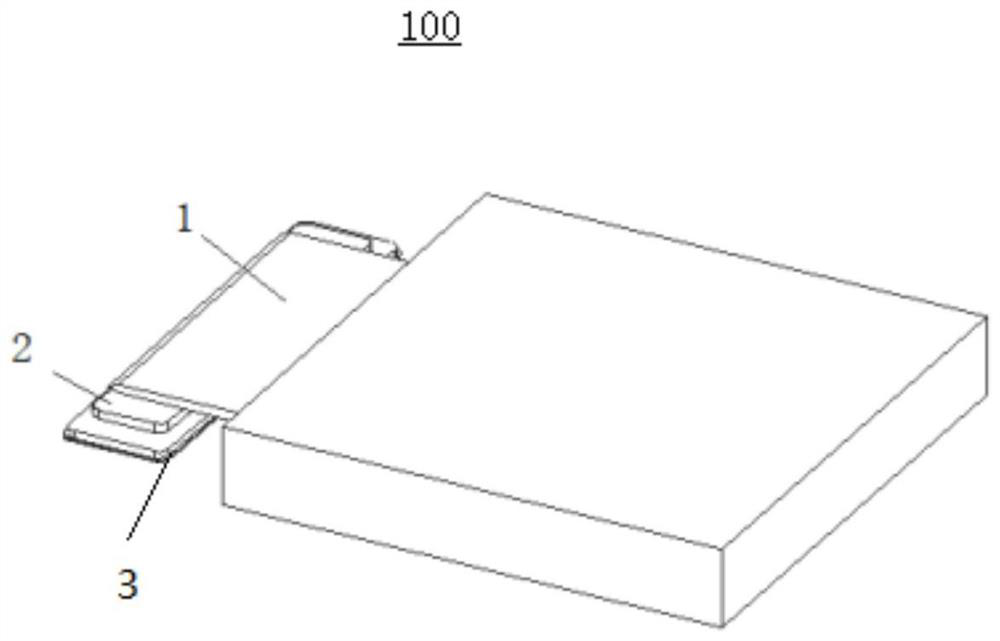

[0029] Refer below Figure 1-Figure 4 Describe the welding method of the tab 1 and the cover plate 3 according to the embodiment of the present invention. The welding method simplifies the connection mode, reduces equipment investment and process complexity, improves production efficiency, and saves production investment costs. And the battery assembly made by the welding method of this invention can also be widely used in various power batteries.

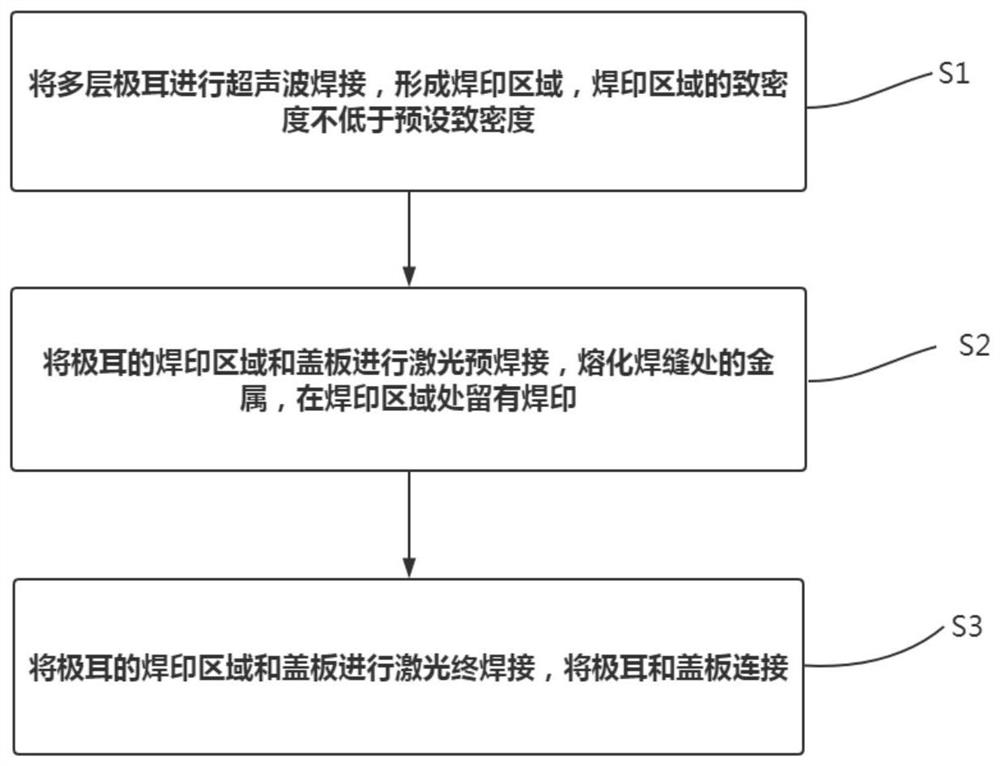

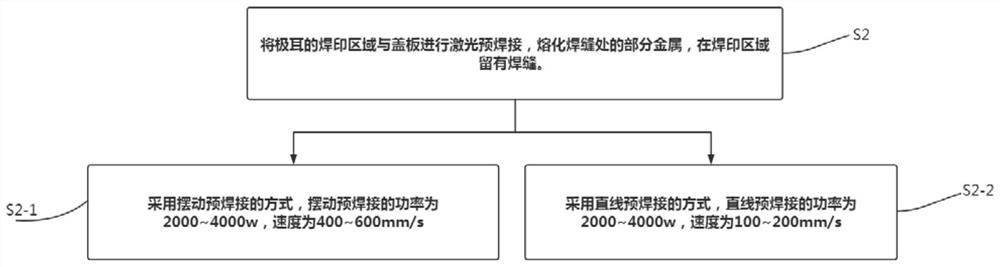

[0030] Such as figure 2 As shown, the welding method of the tab 1 and the cover plate 3 according to the embodiment of the present invention includes the following steps:

[0031] S1. Ultrasonic welding is first performed on the multi-layer tab 1 to form a welded area, and the density of the welded area is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com