Production method of vanadic oxide

A vanadium pentoxide and production method technology, applied in the field of resource recovery, can solve problems such as difficult to meet the purity requirements of vanadium products, low total recovery rate, environmental pollution, etc., achieve high grade, reduce production investment costs, processes and equipment simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

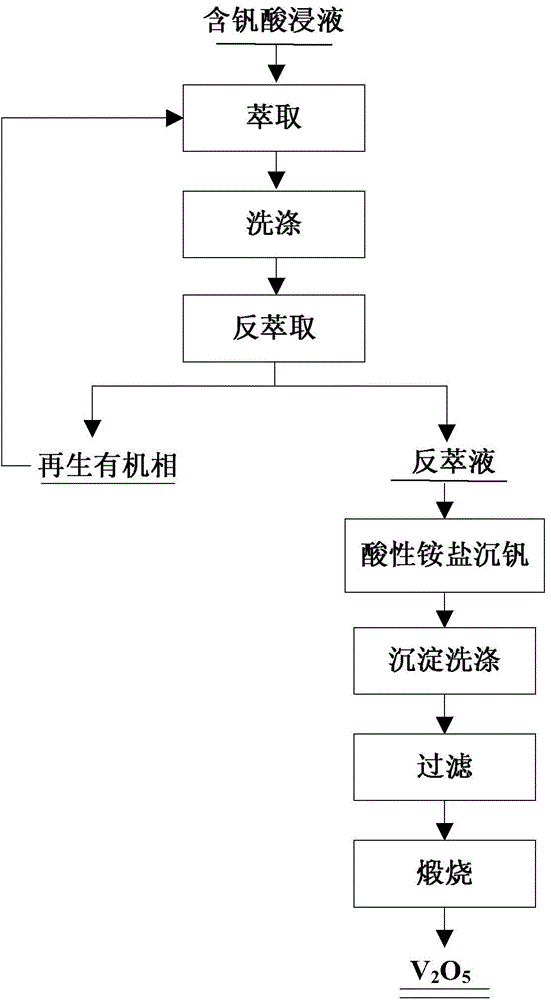

Method used

Image

Examples

Embodiment 1

[0056] a. Extraction: extract 200mL of the vanadium-containing acid immersion solution, the obtained supernatant is the loaded organic phase, and the lower supernatant is the extraction residue;

[0057] Wherein, by volume ratio in the extractant, N235: sulfonated kerosene: tributyl phosphate=5:87.5:7.5, the extraction ratio (O / A)=1:1; The company's vanadium slag is added with suitable calcium oxide and roasted, and the vanadium-containing acid immersion solution obtained by leaching with dilute sulfuric acid has a vanadium concentration of 7.46g / L and an original pH value of 2.4. Before extraction, adjust its pH to 2.0;

[0058] b. Washing: wash the loaded organic phase with 0.2mol / L sodium sulfate solution;

[0059] c, back extraction: take 0.25mol / L sodium carbonate solution as back extraction agent, carry out back extraction to the loaded organic phase after washing, back extraction ratio (O / A)=2:1, after two-phase separation, obtain The supernatant liquid is the regenera...

Embodiment 2

[0066] a. Extraction: extract 250mL of the vanadium-containing acid immersion solution, the obtained supernatant is the loaded organic phase, and the lower supernatant is the extraction residue;

[0067] Wherein, by volume ratio in the extractant, N235: sulfonated kerosene: tributyl phosphate = 10: 87.5: 2.5, extraction ratio (O / A) = 1: 1; The company's vanadium slag is added with suitable calcium oxide and roasted, and the vanadium-containing acid immersion solution obtained by leaching with dilute sulfuric acid has a vanadium concentration of 7.68g / L and an original pH value of 2.3. Before extraction, adjust its pH to 2.0;

[0068] b. Washing: wash the loaded organic phase with 0.3mol / L sodium sulfate solution;

[0069] c, back extraction: take 0.3mol / L sodium carbonate solution as back extraction agent, carry out back extraction to the loaded organic phase after washing, back extraction ratio (O / A)=2:1, after two-phase separation, obtain The supernatant liquid is the regen...

Embodiment 3

[0076] a. Extraction: extract 200mL of the vanadium-containing acid immersion solution, the obtained supernatant is the loaded organic phase, and the lower supernatant is the extraction residue;

[0077] Wherein, in the extractant, by volume ratio, N235: sulfonated kerosene: tributyl phosphate=15:75:10, the extraction ratio (O / A) is=1:1; the vanadic acid immersion solution is Chuanwei The vanadium-containing acid immersion solution obtained by leaching with dilute sulfuric acid after adding suitable calcium oxide to the vanadium slag of Iron and Steel Group Co., Ltd. has a vanadium concentration of 7.76g / L and an original pH value of 2.4. Before extraction, adjust its pH to 2.0;

[0078] b. Washing: wash the loaded organic phase with 0.5mol / L sodium sulfate solution;

[0079]c, back extraction: take 0.2mol / L sodium carbonate solution as back extraction agent, carry out back extraction to the loaded organic phase after washing, back extraction ratio (O / A)=2:1, after two-phase s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com