Method for preparing hafnium oxide from hafnium-titanium enrichment slag

A hafnium oxide enrichment technology is applied in the field of hafnium oxide preparation and hydrometallurgy preparation, which can solve the problems of waste water, waste gas difficult treatment, increased separation difficulty, poor working environment, etc., so as to save ore dressing and product purity High, production investment cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

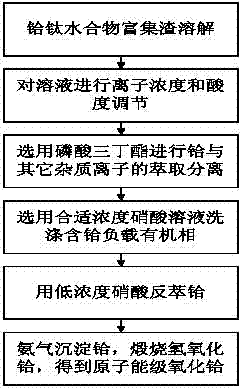

[0026] combine figure 1 In this embodiment, a method for preparing hafnium oxide from hafnium-titanium enrichment slag comprises the following steps:

[0027] Step 1. Weigh 1Kg of hafnium-titanium hydrate enriched slag, the liquid-solid ratio is 2:1, and dissolve at room temperature with 65% concentrated nitric acid, stirring and dissolving for 30 minutes, and the slag is completely dissolved to obtain a leaching solution with a hafnium concentration of 14g / L;

[0028] In step 2, the high-concentration hafnium solution gained in step 1, the acidity is adjusted to 6.5mol / L with pure water and nitric acid, and the hafnium ion concentration is 3.5g / L;

[0029] Step 3, choose 100% tributyl phosphate as the organic phase, the solution obtained in step 2 is the water phase, the ratio of O / A is 1:1, the extraction time is 3min, and three-stage countercurrent extraction is carried out, the concentration of hafnium ions in the raffinate is low at 1mg / L;

[0030] Step 4: Prepare the w...

Embodiment 2

[0034] combine figure 1 In this embodiment, a method for preparing hafnium oxide from hafnium-titanium enrichment slag comprises the following steps:

[0035] Step 1. Weigh 1Kg of hafnium-titanium hydrate enriched slag, the liquid-solid ratio is 2.5:1, and dissolve at room temperature with 65% concentrated nitric acid, stirring and dissolving for 40 minutes, and the slag is completely dissolved to obtain a leaching solution with a hafnium concentration of 16g / L;

[0036] In step 2, the high-concentration hafnium solution gained in step 1, the acidity is adjusted to 5.5mol / L with pure water and nitric acid, and the hafnium ion concentration is 5.0g / L;

[0037] Step 3, choose 100% tributyl phosphate as the organic phase, the solution obtained in step 2 is the water phase, the ratio of O / A is 1:1, the extraction time is 3min, carry out five-stage countercurrent extraction, the concentration of hafnium ions in the raffinate is low at 1mg / L;

[0038] Step 4: Prepare the washing s...

Embodiment 3

[0042] combine figure 1 In this embodiment, a method for preparing hafnium oxide from hafnium-titanium enrichment slag comprises the following steps:

[0043] Step 1. Weigh 1.5Kg of hafnium-titanium hydrate enriched slag, with a liquid-solid ratio of 2:1, stir and dissolve at room temperature with 65% concentrated nitric acid for 50 minutes, the slag is completely dissolved, and a leaching solution with a hafnium concentration of 12g / L is obtained;

[0044]In step 2, the high-concentration hafnium solution gained in step 1, the acidity is adjusted to 7.0mol / L with pure water and nitric acid, and the hafnium ion concentration is 6.0g / L;

[0045] Step 3, choose 100% tributyl phosphate as the organic phase, the solution obtained in step 2 is the water phase, the ratio of O / A is 1:1, the extraction time is 3min, and three-stage countercurrent extraction is carried out, the concentration of hafnium ions in the raffinate is low at 1mg / L;

[0046] Step 4: Prepare the washing liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com