Hot continuous rolling strip steel head width prediction method fusing rolling mechanism and deep learning

A technology of head width and deep learning, which is applied in the direction of metal rolling stand, metal rolling, metal rolling, etc., can solve the problem of the lack of single hidden layer neural network structure prediction accuracy, the prediction of width parameters is very complicated, and cannot meet the requirements of rolling. To achieve the effect of not easily falling into local extremum, saving production investment cost, and making the model easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

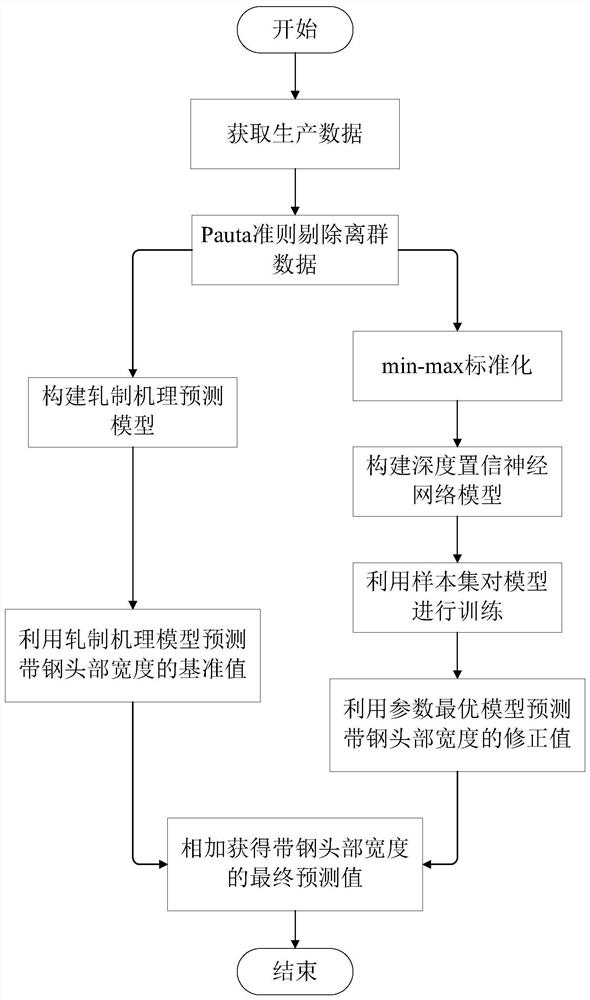

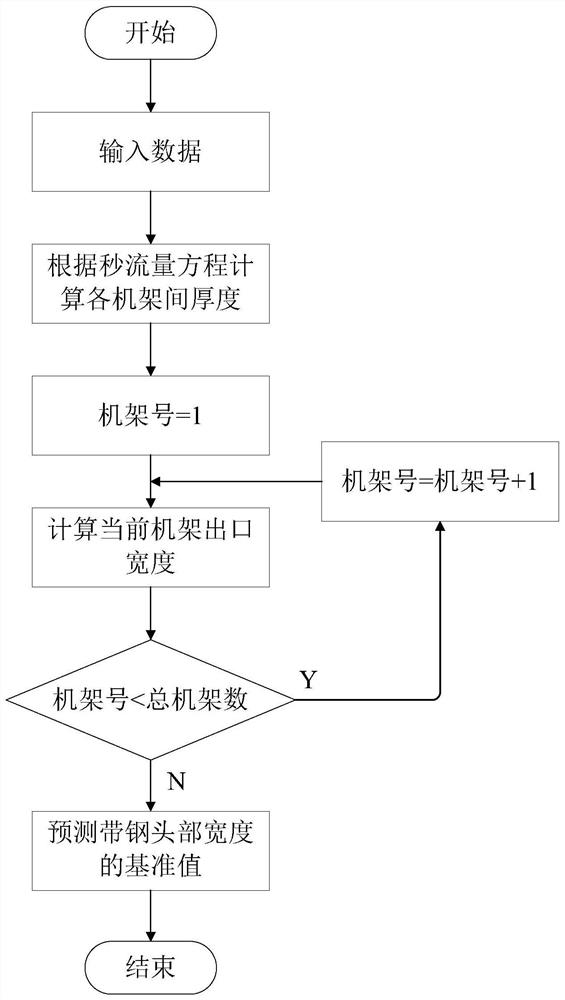

[0056] Such as figure 1 As shown, a method for predicting the head width of hot continuous strip steel that combines rolling mechanism and deep learning includes the following steps:

[0057] Step 1: Obtain the production data of the same measurement position of M different strip heads in the hot rolling site, wherein each strip head corresponds to a set of production process data, and the production data includes the production data installed on the hot rolling production line Each type of measurement data detected by each instrument, and each type of parameter data in the rolling specification data issued by the process automation level of hot continuous rolling production;

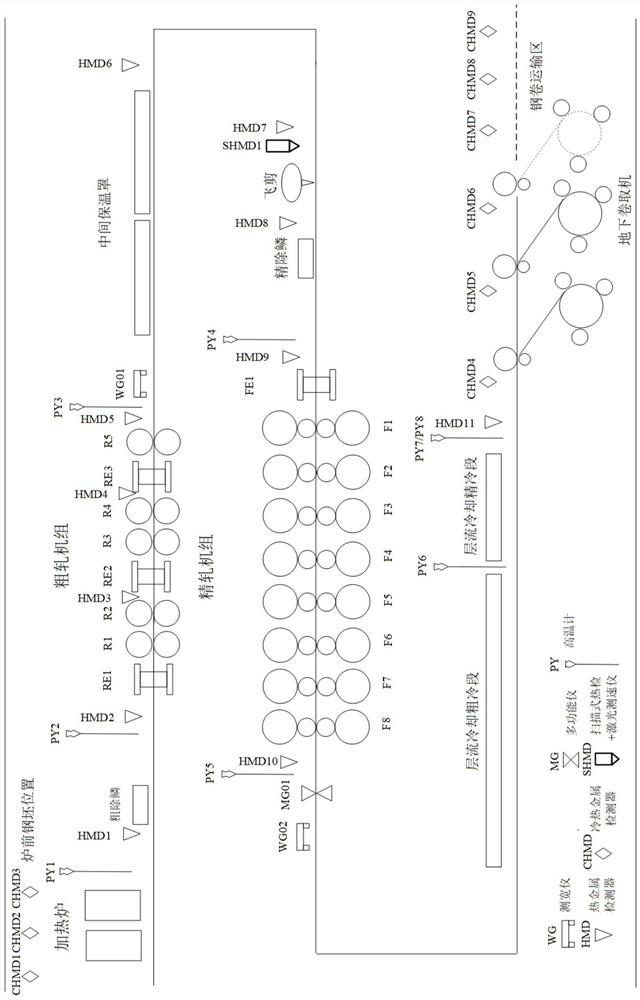

[0058] In this embodiment, a typical hot continuous rolling production line is used for the finishing unit, and the main equipment and testing instruments of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com