Glycerol subsidence coupling ester exchange continuous reaction apparatus

A technology of reaction device and transesterification, which is applied in the field of biodiesel preparation device, can solve the problem of reducing the negative impact of glycerin, achieve the effect of improving single-pass conversion rate, avoiding heat loss, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

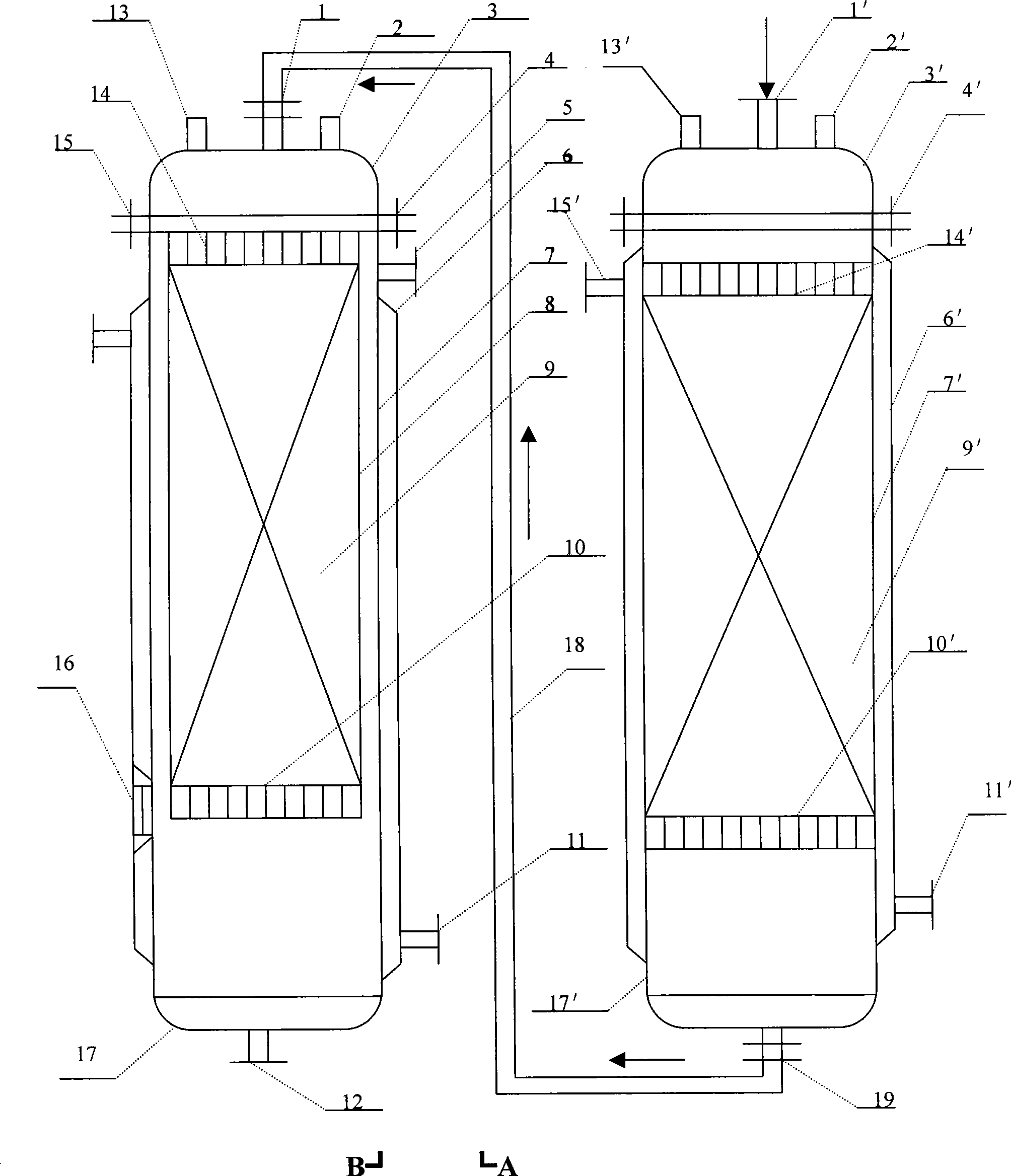

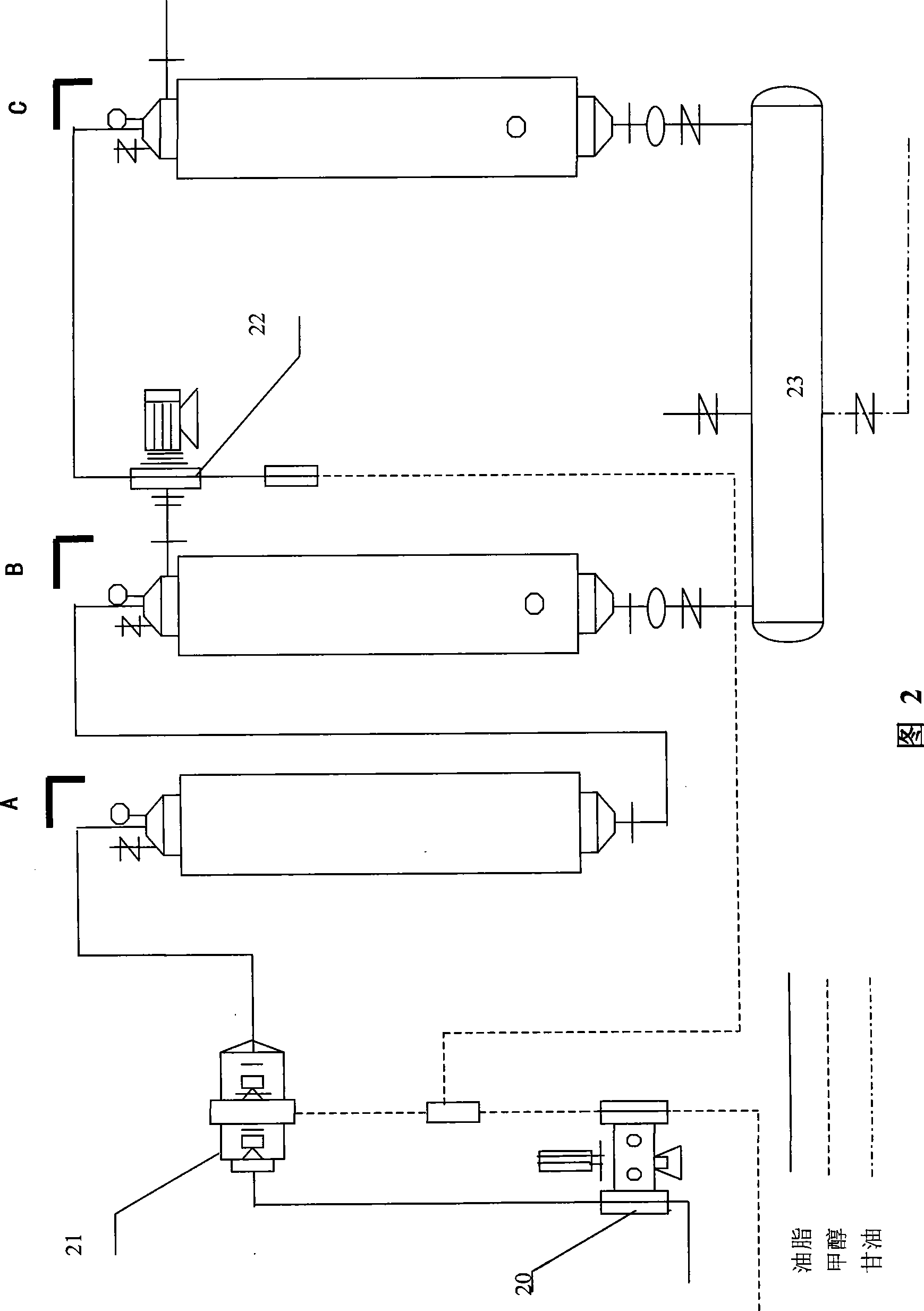

[0016] Continuous transesterification high-efficiency reaction device, the reactors in Zone A, B and C are all 1.8m high, and the height-to-diameter ratio is 10-12. Among them, the reactor in Zone B is equipped with a guide tube, and the guide tube diameter is 120mm. 1.2m high. Raw materials and catalysts are mixed by a static mixer before entering the reactor, and the flow rate of the materials is used to control the progress of the reaction. The reaction device is a high-efficiency reaction device for the transesterification reaction of animal and vegetable oils and short-carbon chain alcohols. The reaction contains volatile liquids. By adding materials from the upper part of the reactor, the vaporization of short-carbon chain alcohols during heating can be used. Further enhance the mixing effect of the reaction system in zone A, and produce obvious phase separation effect in zones B and C through the guide tube. Through the innovation of internal structure, this continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com