Sea water desalting plant implanted into wind power tower

A wind power tower and seawater technology, which is applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve the problems of easy scaling, large heat loss, high operating temperature, etc., and achieve stable pressure fluctuations, stable seawater evaporation temperature, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

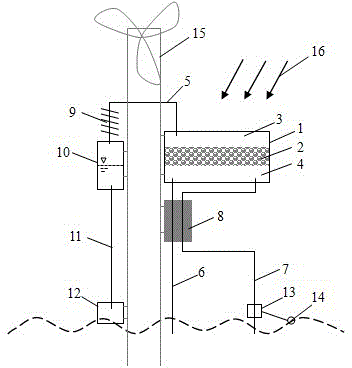

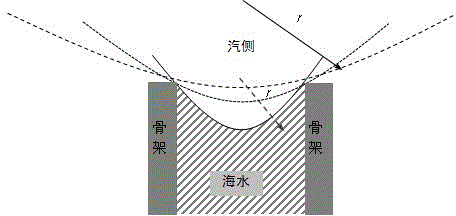

[0029] refer to figure 1, a seawater desalination device implanted in a wind power tower, including an evaporator 1, and a porous partition 2 separates the evaporator 1 into an upper steam chamber 3 and a lower seawater chamber 4, and the shell of the steam chamber 3 is made of a light-transmitting material, and the seawater The shell of chamber 4 is made of thermal insulation material, and the porous separator 2 is a hydrophilic heat-insulating porous medium, and its internal aperture is a micron hole, and the upper side of the porous separator 2 is coated with a heat-absorbing coating;

[0030] The steam chamber 3 is connected to the condenser 9, the condensation tank 10 and the fresh water tank 12 through pipelines in turn. One end of the seawater chamber 4 is connected to the seawater pipeline 6 for water intake, and the other end is connected to the brine pipeline 7 for water outlet. The seawater pipeline 6 and the brine pipeline 7 pass through The heat exchanger 8 exchan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com