Sand control and steam injection integrated device and method

A steam injection and sand control technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of ineffective distribution and utilization of steam enthalpy, unbalanced distribution of steam dryness, sand control, Problems such as complex steam injection process can improve heat sealing effect and heat utilization rate, improve sand control and steam injection effect, and avoid heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

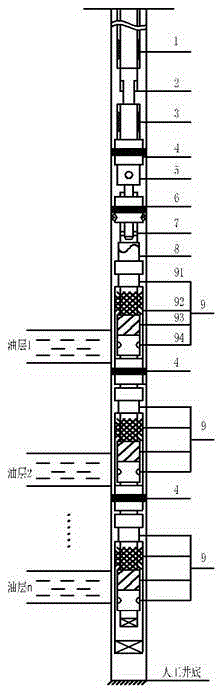

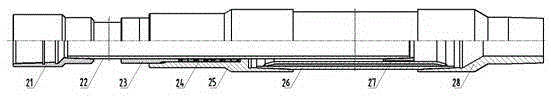

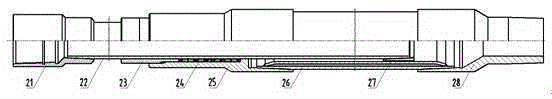

[0037] figure 1 It is a schematic diagram of the sand control and steam injection integrated device of the present invention. The sand control and steam injection integrated device consists of the first heat-insulated oil pipe 1, the heat-insulated downhole compensator 2, the second heat-insulated oil pipe 3, the long-term steam drive sealer 4, the steam injection check valve 5, and the steam drive packer 6 , the intubation sealing device 7, the safety joint 8 and the sand control steam injection unit 9 are sequentially connected. The sand control steam injection unit 9 includes a double joint 91, a screen type sand filter pipe 92 and an internal steam injection device. The internal steam injection device is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com