Method for calculating temperature of core of hot continuous rolling intermediate billet

A calculation method, hot continuous rolling technology, applied in temperature control, metal rolling, metal rolling, etc., can solve the problem that the core temperature of the intermediate billet cannot be directly measured online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

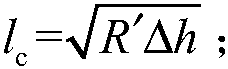

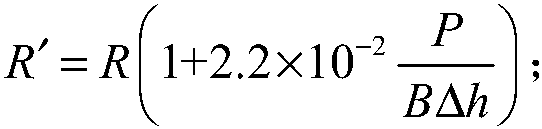

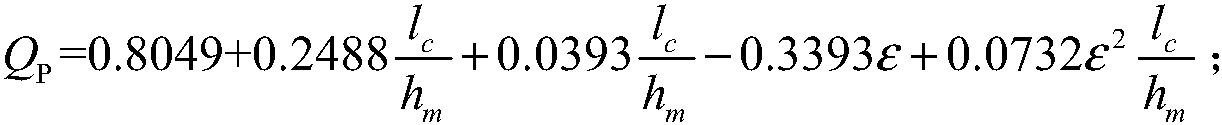

Method used

Image

Examples

Embodiment Construction

[0077] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0078] This example adopts a typical hot continuous rolling production line roughing unit, and the roughing unit adopts the arrangement form of "vertical roll + flat roll" as follows: figure 1 As shown, the vertical roll is in front and the flat roll is behind; the slab is heated in the heating furnace 1 to the furnace temperature, and the thickness gauge 2, the width gauge 3 and the temperature gauge 4 are arranged in front of the rough rolling unit 5, and the rear of the machine is arranged There are thickness gauges 8, width gauges 9 and temperature gauges 10, and speed sensors 6 and pressure sensors 7 are installed on the rolling mill in the roughing group 5; The bill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com