Hot-rolled strip steel width prediction method

A prediction method and technology for hot-rolled strip, applied in the field of rolling, can solve the problems of long adjustment time, the inability of the width adjustment amount to control the signal in time, and the large overshoot amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

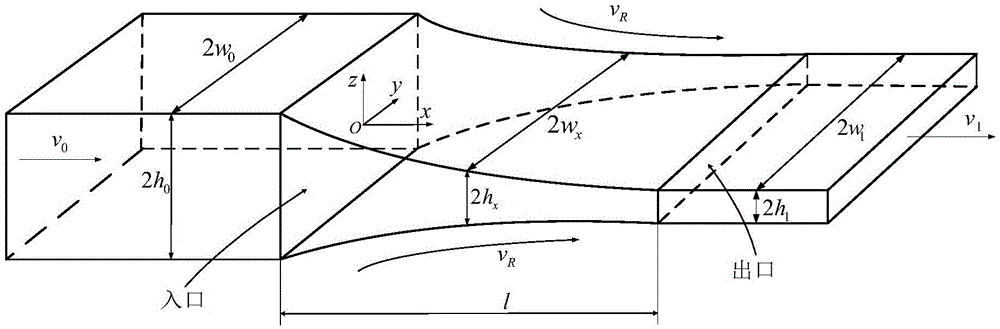

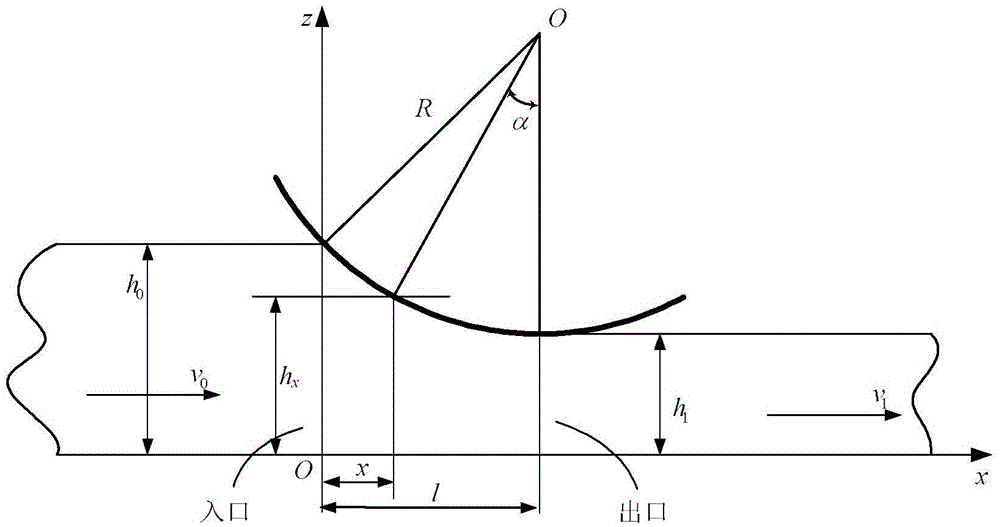

[0065] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

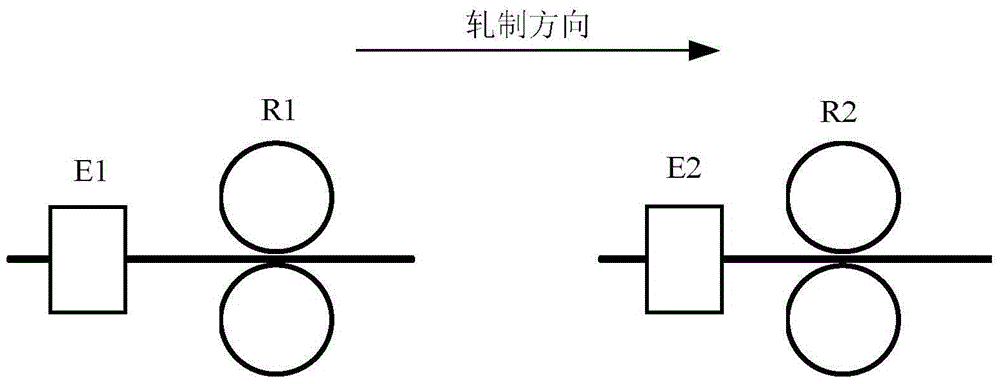

[0066] In this embodiment, take a 1450mm hot continuous rolling roughing unit in a factory as an example, the equipment layout is as follows figure 1 As shown, among them, E1, E2 are vertical roll mills, R1, R2 are flat roll mills.

[0067] A method for predicting the width of hot-rolled strip steel, such as Image 6 shown, including the following steps:

[0068] Step 1: Determine the outlet thickness of the hot-rolled slab according to the data of a certain hot-rolled pass process specification 2h 1 =0.1941m, entrance thickness of hot-rolled slab 2h 0 =0.2339m, entrance width 2w 0 =1.2712m and inlet temperature T=1162°C, slab steel type: Q235;

[0069] Step 2: Detect the inlet velocity v of the hot-rolled slab 0 = 1.444m / s and roll speed v R =1.66m / s, obtain the roll radius R=0.643m and the friction factor m=2μ=0.56 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com