Container, system and method for blending mixture

A technology for configuring systems and mixtures, applied to chemical instruments and methods, mixers, mixers with rotating containers, etc., can solve problems such as high cost, prone to errors or errors in operation, and wrong weighers, etc., to reduce production Effects of investment cost, reliability improvement, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

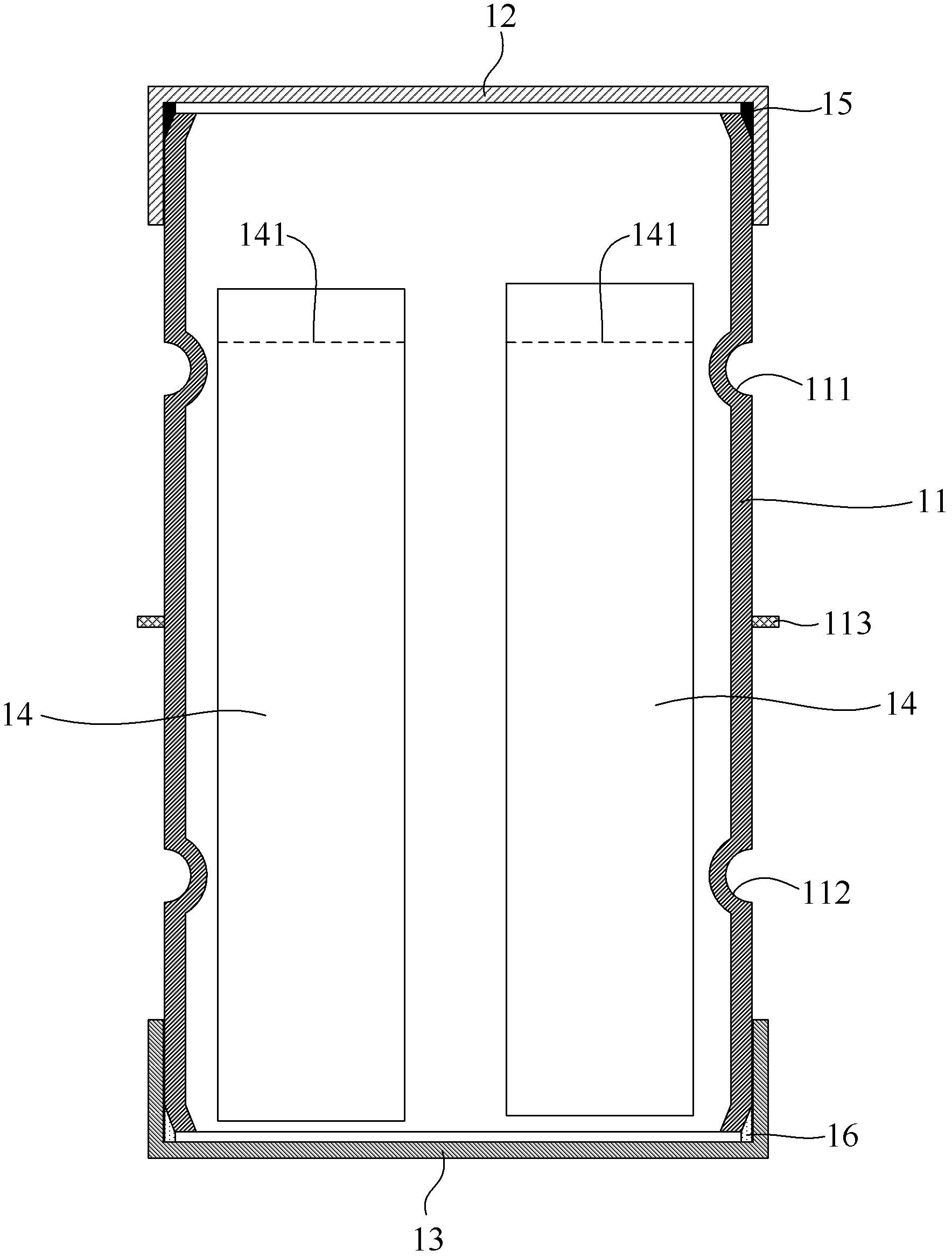

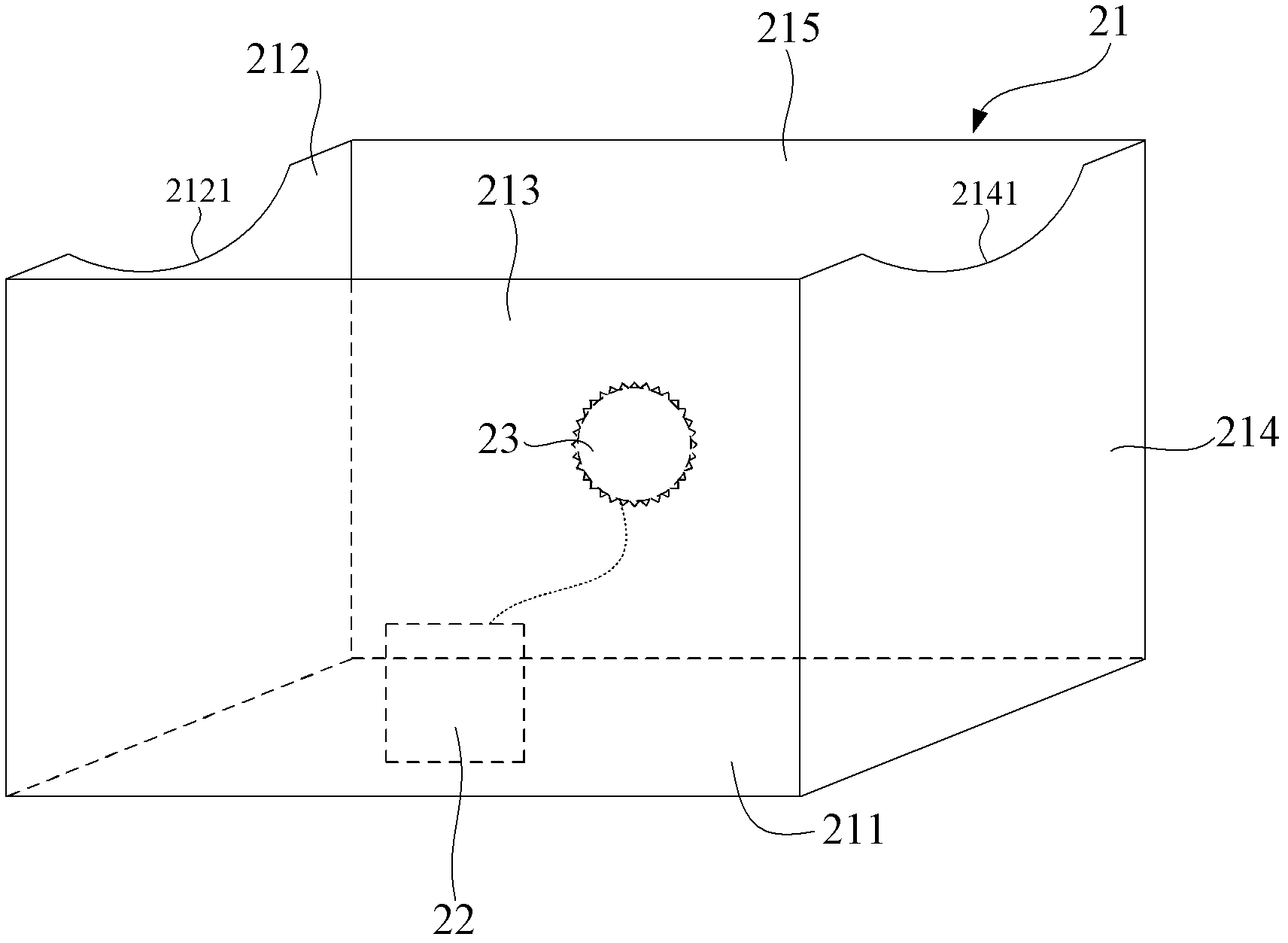

[0027] The following will combine figure 1 ~ Fig. 6 is a further detailed description of the mixture configuration container, configuration system and configuration method of the present invention.

[0028] figure 1 is a sectional view of the mixture configuration container of the present invention, figure 2 is a top view of the mixture configuration container of the present invention;

[0029] see figure 1 and figure 2 , the mixture configuration container of the embodiment of the present invention includes a container body and a container bag 14, and the container bag 14 is placed in the container body;

[0030] The container body includes a body 11, a first end cap 12 and a second end cap 13; the first end cap 12 and the second end cap 13 are respectively arranged at two ends of the body 11, and are connected to the body 11 sealed connection;

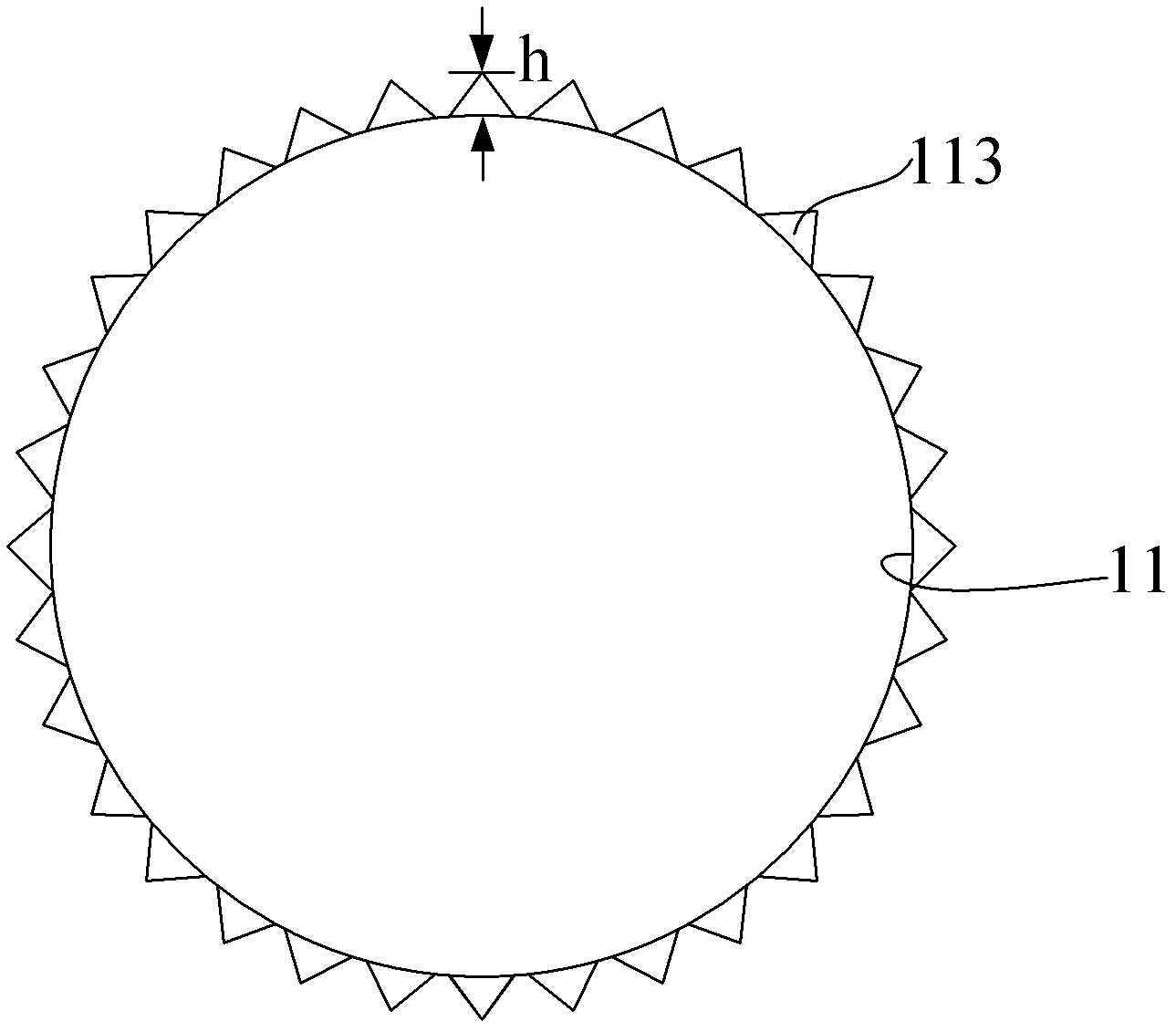

[0031] The outer wall of the body 11 is provided with a first annular groove 111, a second annular groove 112 and an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com