Method for concurrent extracting sugarcane fat and chlorophyll from dross in sugar-refiney by using solvent

A chlorophyll and solvent technology, applied in zinc organic compounds, organic chemistry, etc., can solve the problems of large solvent consumption, low product quality and output, and difficult industrial application of technology, so as to reduce production investment and operation cost and improve recovery efficiency and product quality, and the effect of avoiding decomposition and denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

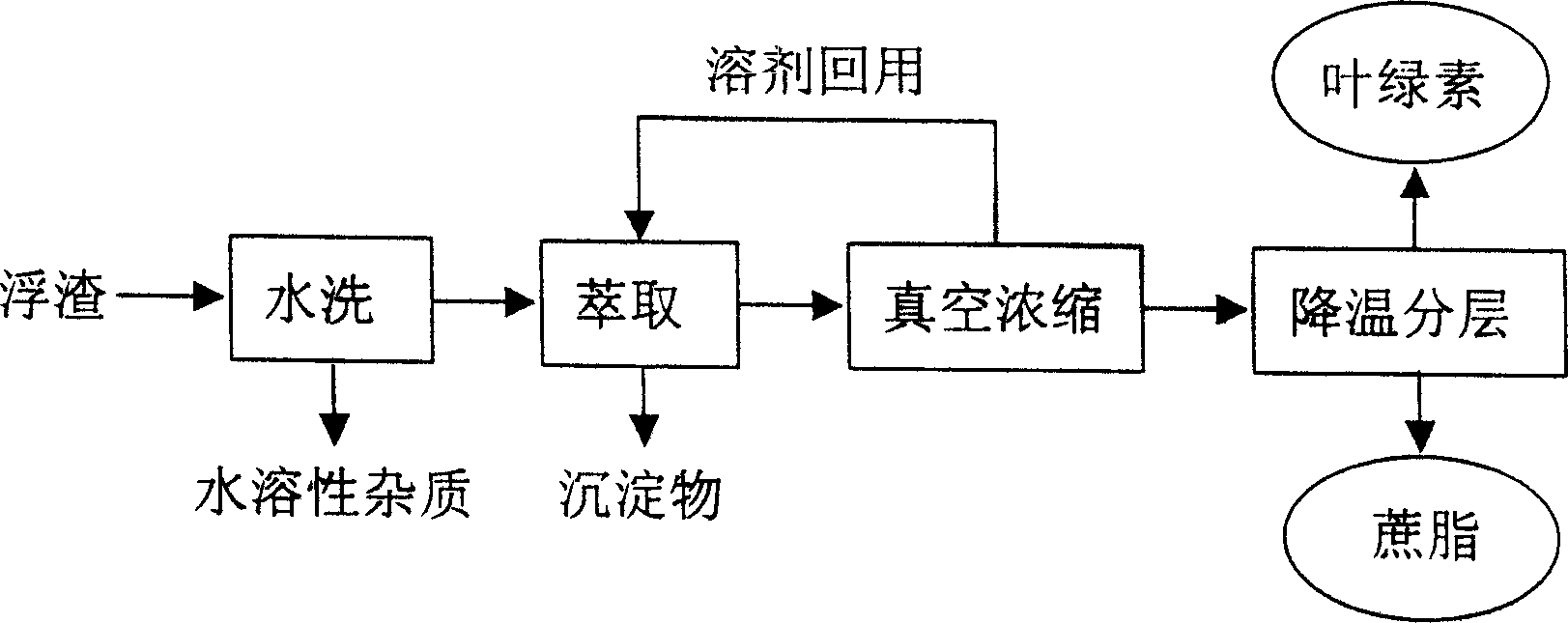

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Ethanol parallel extraction of sucrose and chlorophyll in low-temperature phosphorus float scum

[0026] Step 1 Pretreatment of scum:

[0027] Wash 300g (water content 52%) scum repeatedly with 2L, 60 ℃ hot water to reduce water-soluble impurities, take filter residue after filter cloth filtration.

[0028] The second step solvent parallel extraction of sucrose and chlorophyll:

[0029] The solvent is ethanol; the operating temperature is 60°C; the mechanical stirring speed is 50r / min; the volume ratio of solvent to scum is 2:1, the addition amount is 0.6L, and the extraction time is 80min.

[0030] Step 3 Extraction Separation and Recovery:

[0031] After the extraction, keep it at 40°C for 50 minutes, extract the supernatant, concentrate the extract with a rotary vacuum evaporator at a temperature of 50°C, recover the distilled ethanol, and concentrate the extract to 1 / 3 (200ml) of its original volume. stop.

[0032] Step 4 Separation of chlorophyll and ...

Embodiment 2

[0034] Example 2 Gasoline Parallel Extraction of Cane Fat and Chlorophyll in Carbonated Scum

[0035] Step 1 Pretreatment of scum:

[0036] Wash 500g of dry scum repeatedly with 2L, 55°C hot water to reduce water-soluble impurities, filter through filter cloth, and take the filter residue.

[0037] The second step solvent parallel extraction of sucrose and chlorophyll:

[0038] The solvent is gasoline; the operating temperature is 50°C; the mechanical stirring speed is 100r / min; the ratio of solvent to scum is 3:1, and the addition amount is 1.5L; the extraction time is 30min.

[0039] Step 3 Extraction Separation and Recovery:

[0040] After the extraction, keep the temperature at 60°C for 30 minutes, and extract the supernatant directly. Concentrate the extract with a rotary vacuum evaporator at a temperature of 50° C., recover the distilled gasoline, and stop when the extract is concentrated to 1 / 10 (150 ml) of its original volume.

[0041] Step 4 Separation of chloroph...

Embodiment 3

[0043] Example 3 Acetone Parallel Extraction of Cane Fat and Chlorophyll in Sulphite Scum

[0044] Step 1 Pretreatment of scum:

[0045] Wash 1000g of scum (water content 55%) repeatedly with 4L, 60°C hot water to reduce water-soluble impurities, and take the filter residue after filtering with filter cloth.

[0046] The second step solvent parallel extraction of sucrose and chlorophyll:

[0047] The solvent is acetone; the operating temperature is 80°C; the mechanical stirring is performed at a speed of 10 r / min; the volume ratio of solvent to scum is 1:1, and the addition amount is 1.0 L; the extraction time is 150 min.

[0048] Step 3 Extraction Separation and Recovery:

[0049] After the extraction is finished, filter the cloth directly to take the filtrate. Concentrate the extract with a rotary vacuum evaporator at a temperature of 80° C., recover the distilled acetone, concentrate the extract to 1 / 6 of the original volume, and stop.

[0050] Step 4 Separation of chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com