Process for preparing calcined kaolin for electrophoretic paint from gangue

A technology of calcining kaolin and coal gangue, which is applied in the direction of electrophoretic coating, coating, silicate, etc., can solve the problem of low kaolin index and achieve the effect of uniform product structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

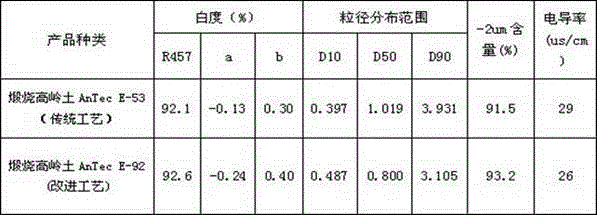

Image

Examples

Embodiment 1

[0032] Technological process: Coal gangue raw ore → primary dry iron removal → crushing → secondary dry iron removal → dry grinding → part of raw meal and part of clinker plus tap water to make slurry (solid content of slurry is 60%, and the solid part is composed of ingredients : 325 mesh coal gangue raw powder 40%, 4000 mesh calcined coal gangue clinker powder 60%, sodium polyacrylate 0.3%) → primary wet iron removal → wet grinding → secondary wet iron removal → sieve 200 mesh , 325 mesh, 500 mesh vibrating sieve → three times of wet iron removal → one drying → dispersing → calcining (around 980°C) → dispersing → product.

[0033] The process of this application is introduced as follows: the raw coal gangue is crushed by a hammer crusher to a particle size below 30mm, and the mechanical iron impurities and magnetic substances in the minerals brought in during the crushing process are removed by dry iron removal twice, and then sent to the Hurricane Mill Further pulverize to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com