Cerium, gadolinium activated yttrium aluminium garnet fluorescent powder and preparation method

A technology of yttrium aluminum garnet and fluorescent powder, which is applied in the field of rare earth aluminate fluorescent material preparation, can solve the problems of long process flow, difficult synthesis method, high synthesis temperature, etc., and achieve simple process flow, excellent luminescence performance, and particle size evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

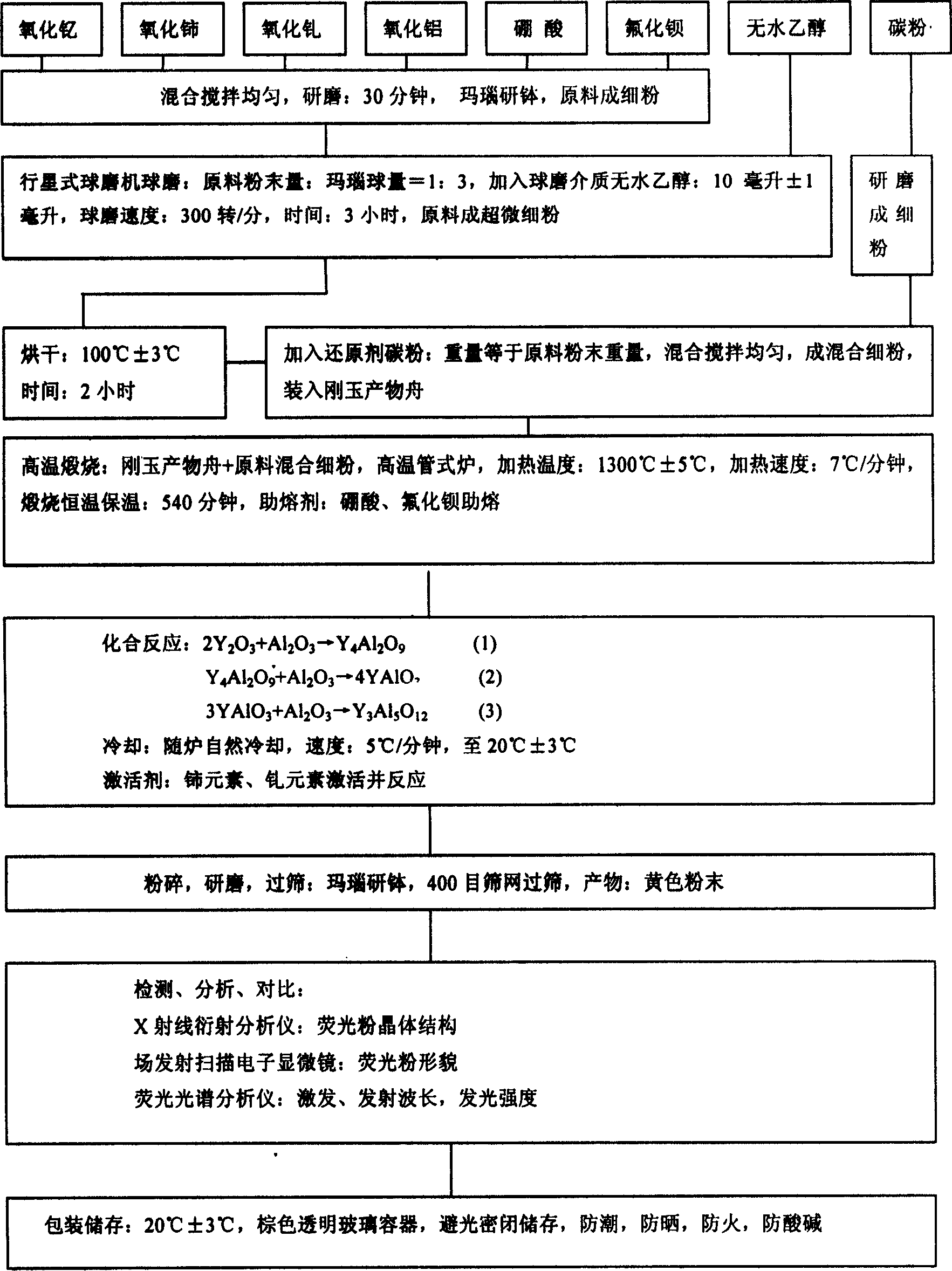

Method used

Image

Examples

Embodiment 1

[0099] All production equipment is in ready working condition;

[0100] Select according to the proportion, weigh 2.5746 grams of yttrium oxide, 0.2066 grams of cerium oxide, 5.098 grams of aluminum oxide, 6.525 grams of gadolinium oxide, 0.072 grams of boric acid, 0.072 grams of barium fluoride, 14.5482 grams of carbon powder, and 10 ml of absolute ethanol;

[0101] Put the chemical substances yttrium oxide, cerium oxide, aluminum oxide, gadolinium oxide, boric acid, and barium fluoride in a mixing container and mix them evenly;

[0102] Grind the mixed chemicals in an agate mortar for 30 minutes to form a fine powder;

[0103] Put the ground fine powder in an agate ball mill jar, add agate balls, the ratio of the raw material fine powder to agate balls is 1:3, add 10 ml of absolute ethanol as a ball milling medium, turn on the planetary ball mill for ball milling, and the ball mill rotates at 300 RPM, ball milling time 3 hours, after ball milling, the fine powder of raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com