Ceramic granule reinforced aluminium-base composite material and its preparing method

A composite material and reinforced aluminum-based technology, which is applied in the field of aluminum-based alloys, can solve problems such as deterioration and change interface bonding, and achieve the effects of less air absorption, increased wettability, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

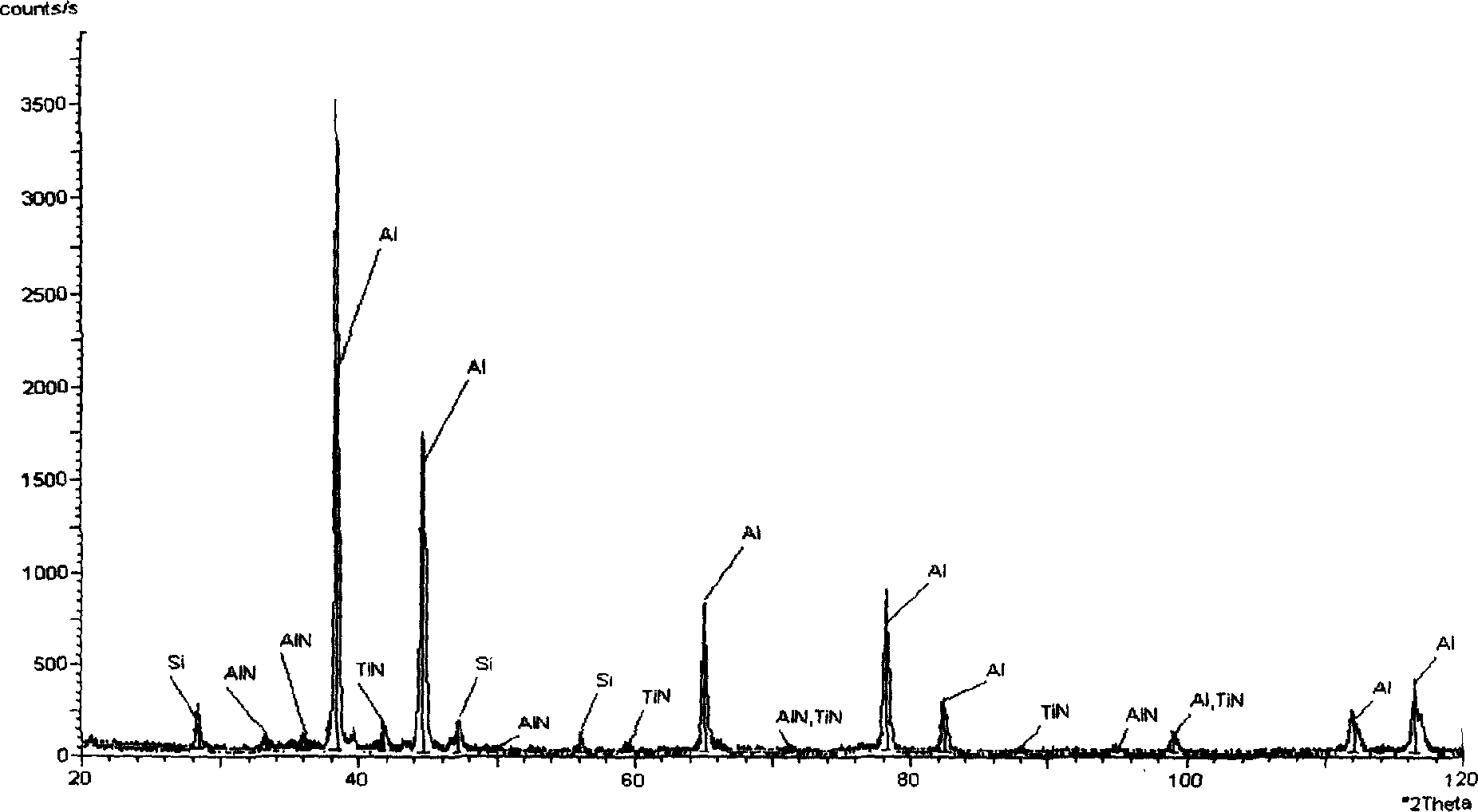

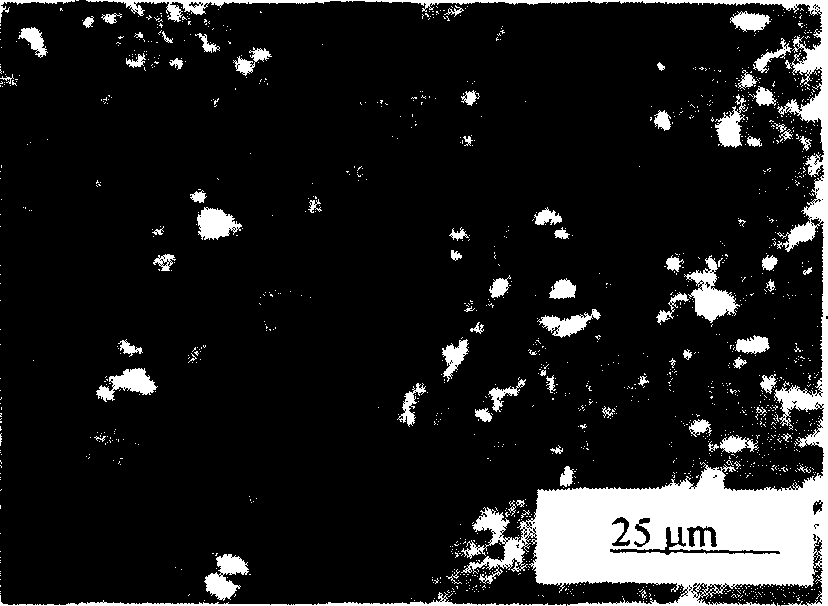

Embodiment 1

[0038] Weigh the metal with a weight percentage of 4% Si, 0.5% Cu, 0.3% Mg, and the rest of Al, and the reinforcing particles with a weight percentage of 2.5% TiN and 2.5% AlN in the range of 5-10 μm, and weigh the metal Place it separately from the reinforcing particles; put the prepared metal into the crucible, and then put the crucible into a domestic 25Kg vacuum induction heating furnace for heating, the vacuum degree is 1.3×10 -3 Pa, the temperature is at 670°C, when the metal matrix is completely melted, add the prepared reinforcement particles and the nano-Al alloy powder inoculant containing 6% Na in an amount of 1g / Kg composite material, and then mechanically stir; The melt of the composite material was poured into the piston metal mold; the model after the mold was released was water-cooled, and then aged at 170°C for 8 hours, thereby preparing the No.1 ceramic particle-reinforced aluminum matrix composite in Table 2.

Embodiment 2

[0040] Weigh the metal with a weight percentage of 5.5% Si, 0.5% Cu, 0.4% Mg, and the rest of Al, and the reinforcing particles with a particle size of 6% TiN and 6% AlN in the range of 5-10 μm by weight, and weigh the metal Placed separately from the reinforcing particles; put the prepared metal into the crucible, and then put the crucible into a vacuum induction heating furnace for heating, the vacuum degree is 1.4×10 -3 Pa, the temperature is at 700°C, when the metal matrix is completely melted, add the prepared reinforcement particles and the nano-Al alloy powder inoculant containing 5% Na in an amount of 4g / Kg composite material, and then mechanically stir; The melt of the composite material was poured into the piston metal mold; the model after the mold was released was water-cooled, and then aged at 170°C for 8 hours, thereby preparing the No.2 ceramic particle-reinforced aluminum matrix composite in Table 2.

Embodiment 3

[0042] Weigh the metal with a weight percentage of 6% Si, 2% Cu, 0.5% Mg, and the rest of Al, and the reinforcing particles with a particle size of 7.5% TiN and 7.5% AlN in the range of 5-10 μm by weight, and weigh the metal Place it separately from the reinforcing particles; put the prepared metal into the crucible, then put the crucible into the vacuum furnace for heating, the vacuum degree is 1.5×10 -3 Pa, the temperature is at 720°C, when the metal matrix is completely melted, add the prepared reinforcement particles and the nano-Al alloy powder inoculant containing 4% Na in an amount of 9g / Kg composite material, and then mechanically stir; The melt of the composite material was poured into the bar metal mold; the model after the die was water-cooled, and then aged at 170°C for 8 hours, thereby preparing the No.3 ceramic particle-reinforced aluminum matrix composite in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com