Method for producing alpha-Al2O3 by employing predecomposition technology and taking aluminium hydrogen as raw material

A pre-decomposition and aluminum hydrogen technology, which is applied in the preparation of alumina/hydroxide, etc., can solve the problems that it is difficult to ensure the stability and large-scale production of special alumina, it is not suitable for the production and use of ordinary enterprises, and it is difficult to realize the automation of production control. , to achieve the effect of shortening production time, small footprint and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

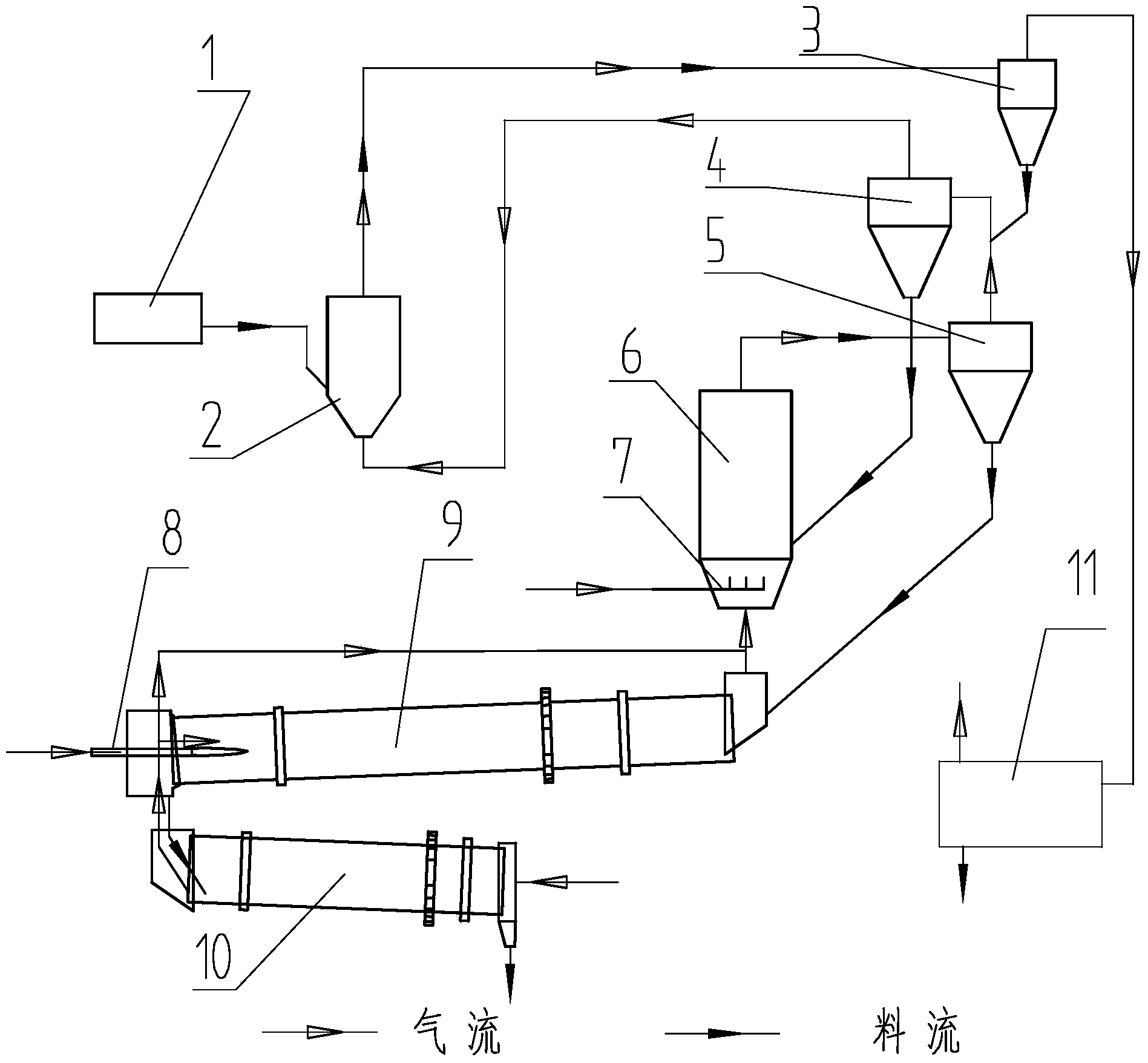

Embodiment 1

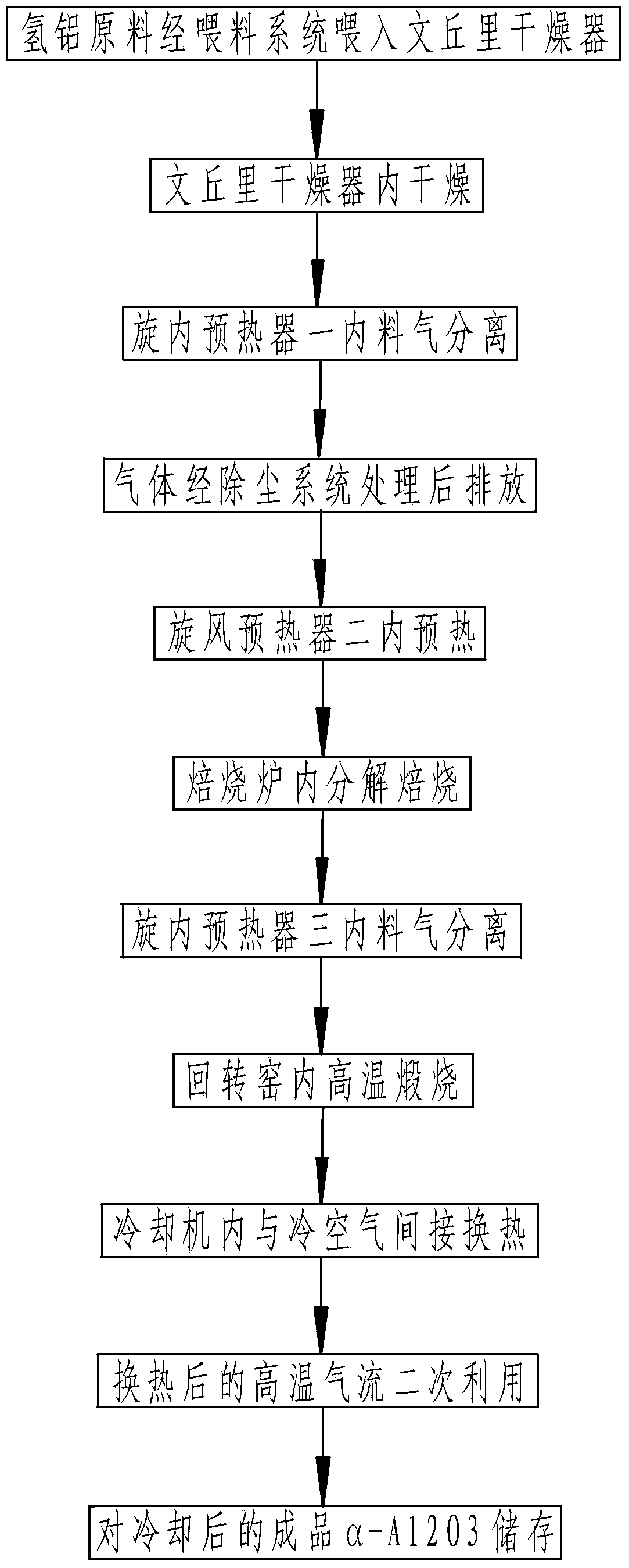

[0029] The aluminum hydrogen raw material is fed into the Venturi dryer 2 through the feeding system 1, and the aluminum hydrogen raw material is dried in the Venturi dryer 2 and then enters the cyclone preheater-3 for material gas separation, and the separated gas is treated by the dust removal system 11 Discharge, the separated hydrogen aluminum raw material is preheated in the cyclone preheater 2 4 and enters the roaster 6 for decomposition and roasting, and after the cyclone preheater 3 5 material gas is separated, it enters the rotary kiln 9 for high-temperature calcination, and in the cooler 10 Indirect heat exchange with the cold air inside, the high-temperature airflow after heat exchange is used for secondary use, and the finished product α-Al after cooling 2 o 3 store.

Embodiment 2

[0031] The aluminum hydrogen raw material enters the feeding system 1 and is metered by the metering device, and is continuously fed into the Venturi dryer 2 by the feeding device; the high-pressure air generated by the Roots blower is the primary air, and the natural gas and the primary air pass through the natural gas burner for the kiln 8 enters the rotary kiln 9, and the kiln uses a natural gas burner 8 to ignite the natural gas, and the hot gas produced enters the roasting furnace 6 from the smoke chamber at the rear of the rotary kiln 9; the natural gas enters the roasting furnace 6 from the natural gas burner 7 for combustion, and the hot gas produced After being mixed with the hot gas from the smoke chamber at the end of the rotary kiln 9, it passes through the cyclone preheater 3 5 and the cyclone preheater 2 4, and enters the Venturi dryer 2 from the gas inlet of the Venturi dryer 2, and the mixed hot gas is heated to hydrogen The aluminum raw material is dried.

Embodiment 3

[0033] The dried aluminum hydrogen flows through the pipeline with the hot gas and enters the cyclone preheater-3 from the feed gas outlet of the Venturi dryer 2 to separate the feed gas. Enter the dust removal system 11, and after being treated by the dust removal system 11, it will be discharged up to the standard, and the materials separated from the waste gas by the dust removal system 11 will be recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com