Novel crystal form multi-metal molybdate micro-nano-particles and preparing method thereof

A metal molybdate, micro-nano particle technology, applied in the chemical industry, can solve the problems of complex multi-metal molybdate micro-nano particle technology and other problems, and achieve the effects of short reaction time, simple process and simple follow-up treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

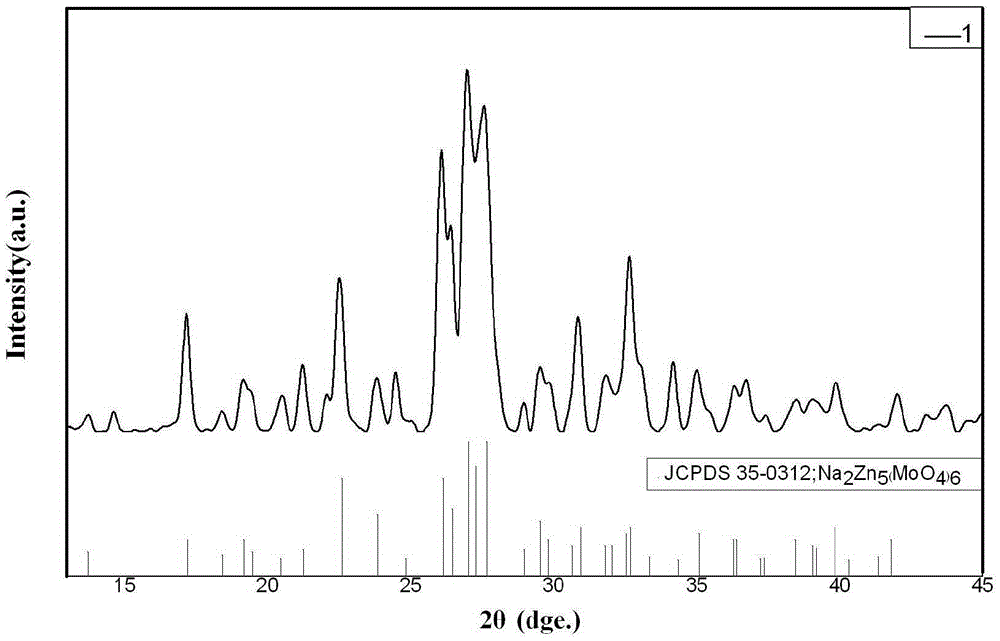

[0032] A kind of ultrasonic electrolysis using cationic membrane to prepare Na 2 Zn 5 (MoO 4 ) 6 Crystal method, the specific steps are as follows:

[0033] (1) With zinc sheet as anode, titanium mesh as cathode, 90ml of sodium molybdate aqueous solution with a concentration of 0.1mol / L as anolyte, and 90ml of hydrochloric acid with a concentration of 0.1mol / L as catholyte, in double In the chamber diaphragm electrolyzer, control current density 4A / dm 2 , temperature 55 ~ 65 ℃, electrolysis 20min under ultrasonic state.

[0034] (2) After electrolysis, take out the anolyte, wash it with deionized water and filter it to remove the remaining impurities, and dry the filtered product at 100°C for 2 hours. The heating rate of ℃ / min is increased to 450℃, and the high temperature is roasted for 1h, and then naturally cooled to room temperature after roasting, that is, pure Na 2 Zn 5 (MoO 4 ) 6 crystals.

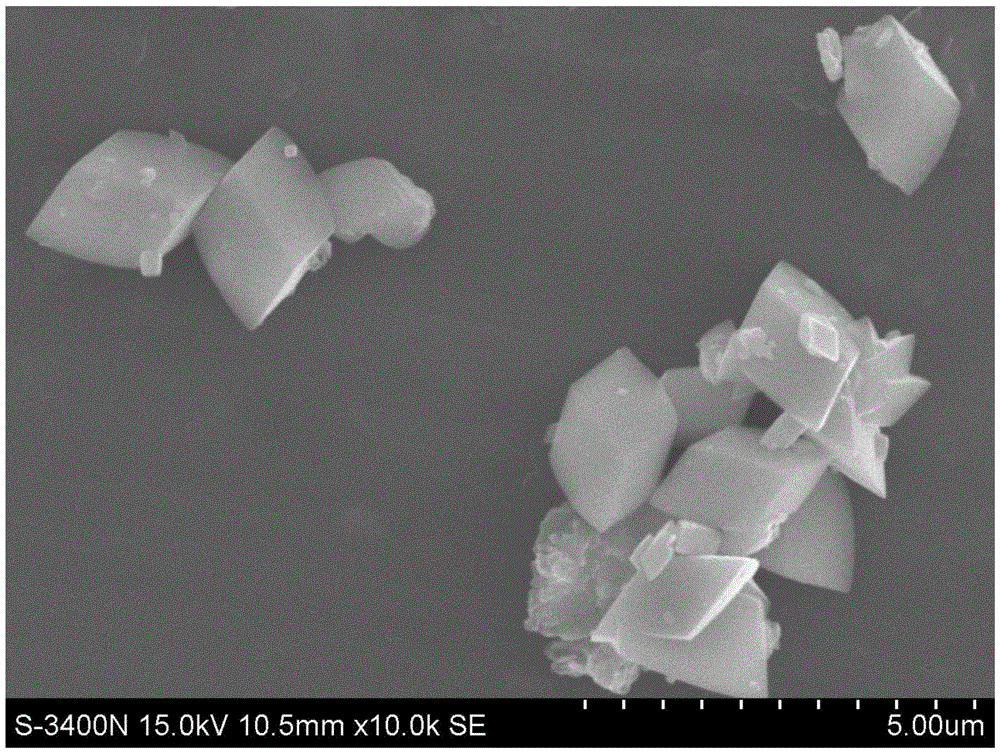

[0035] The S-3400 scanning electron microscope produced by Japan's Hi...

Embodiment 2

[0038] A kind of ultrasonic electrolysis using cationic membrane to prepare Na 2 Zn 5 (MoO 4 ) 6 Crystal method, the specific steps are as follows:

[0039] (1) Use zinc sheet as anode, titanium mesh as cathode, 90ml of sodium molybdate aqueous solution with a concentration of 0.3mol / L as anolyte, and 90ml of hydrochloric acid with a concentration of 0.1mol / L as catholyte. In the chamber diaphragm electrolyzer, control current density 4A / dm 2 , temperature 55 ~ 65 ℃, electrolysis 20min under ultrasonic state.

[0040] (2) After electrolysis, take out the anolyte, wash it with deionized water and filter it to remove the remaining impurities, and dry the filtered product at 100°C for 2 hours. The heating rate of ℃ / min is increased to 450℃, and the high temperature is roasted for 1h, and then naturally cooled to room temperature after roasting, that is, pure Na 2 Zn 5 (MoO 4 ) 6 crystals.

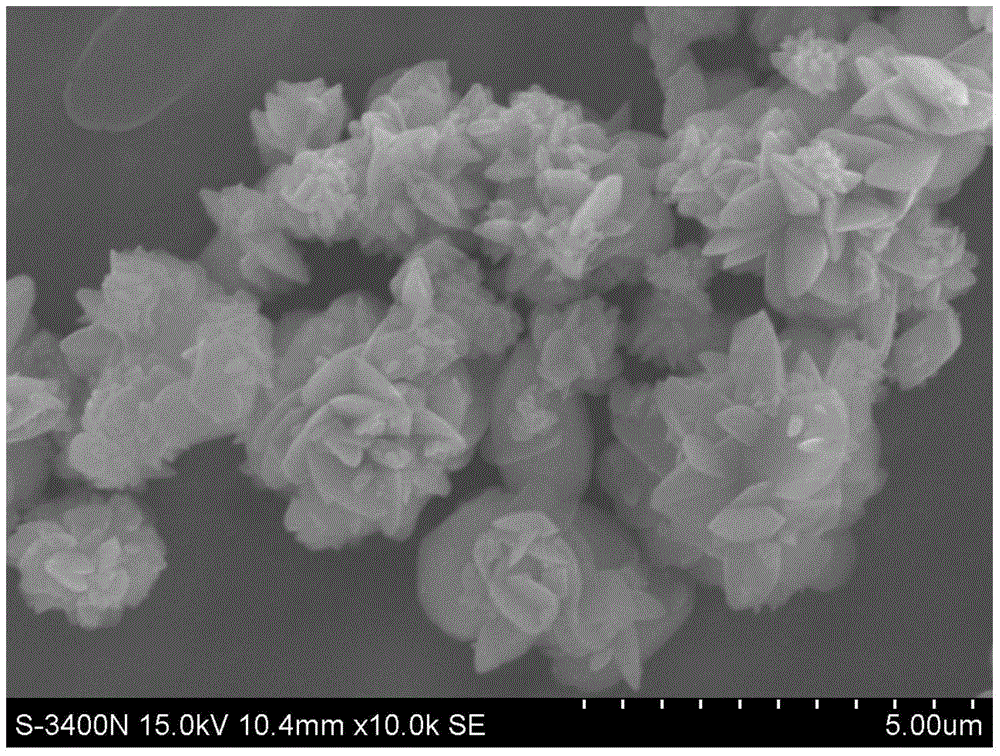

[0041] The S-3400 scanning electron microscope produced by Japan's Hitachi (Hitach...

Embodiment 3

[0044] A method for preparing Na by ultrasonic electrolysis with cationic membrane 2 Zn 5 (MoO 4 ) 6 Crystal method, the specific steps are as follows:

[0045] (1) With zinc sheet as anode, titanium mesh as cathode, 90ml of sodium molybdate aqueous solution with a concentration of 0.5mol / L as anolyte, and 90ml of hydrochloric acid with a concentration of 0.1mol / L as catholyte, in double In the chamber diaphragm electrolyzer, control current density 4A / dm 2 , temperature 55 ~ 65 ℃, electrolysis 20min under ultrasonic state.

[0046] (2) After electrolysis, take out the anolyte, wash it with deionized water and filter it to remove the remaining impurities, and dry the filtered product at 100°C for 2 hours. The heating rate of ℃ / min is increased to 450℃, and the high temperature is roasted for 1h, and then naturally cooled to room temperature after roasting, that is, pure Na 2 Zn 5 (MoO 4 ) 6 crystals.

[0047] The S-3400 scanning electron microscope produced by Japan'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com